Imagine trying to work on a metal lathe, but the tailstock isn’t working properly. It’s frustrating, isn’t it? Tailstocks are crucial for supporting your workpiece. Without them, you can’t get clean cuts or precise results. That’s where a lathe repair kit comes in handy.

Did you know that a small problem in the tailstock can lead to expensive mistakes? Fixing it with the right kit makes all the difference. Plus, it’s often simpler than you think. You might discover your lathe can work like new again with just a few parts.

In this article, we’ll explore how a lathe repair kit can help you get your metal lathe tailstock back in shape. We will share tips, tricks, and stories from people just like you who faced similar challenges. So, are you ready to tackle that tailstock trouble and get back to crafting? Let’s dive in!

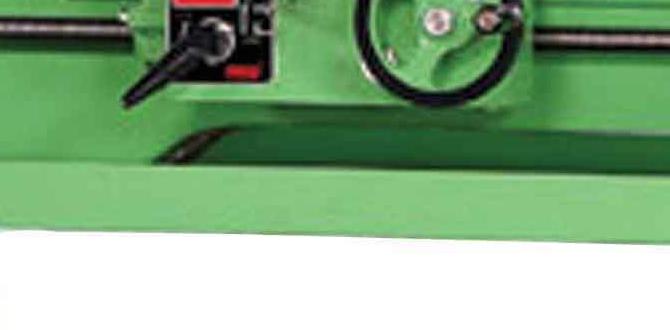

Essential Lathe Repair Kit For Metal Lathe Tailstock Maintenance

Your Guide to Lathe Repair Kit: Metal Lathe Tailstock

When your metal lathe’s tailstock fails, it can be frustrating. A lathe repair kit offers the perfect solution. This kit includes essential tools and parts to help you fix it yourself. Imagine saving time and money instead of hiring a professional! It’s easier than you think to get your lathe back in working order. Plus, learning about the repair process can boost your skills and confidence. Don’t let a malfunction slow you down; explore lathe repair kits today!Understanding Lathe Tailstocks

Definition and purpose of a lathe tailstock. Common issues encountered with tailstocks.A lathe tailstock is a part of a lathe machine. It holds the other end of the workpiece while the machine shapes it. This part can help make smooth and accurate pieces. However, tailstocks can face problems. Some common issues include:

- Difficulty in moving

- Worn-out parts

- Misalignment

- Poor locking mechanism

Understanding these problems helps users fix them quickly and keep their lathe working well.

What is the purpose of a lathe tailstock?

The purpose of a lathe tailstock is to support the workpiece and allow for precise shaping and drilling. It keeps everything in place during the process.

What are common issues with tailstocks?

- Tailstocks may not slide easily.

- Parts can become damaged over time.

- Alignment issues can affect accuracy.

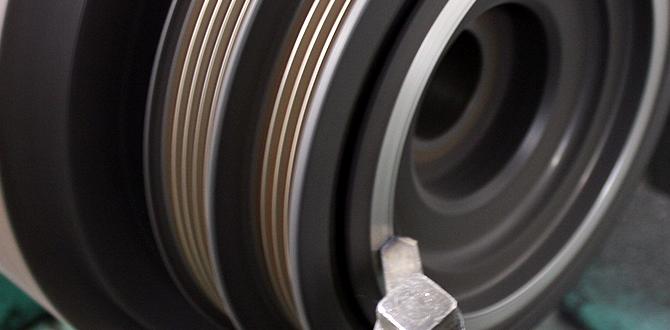

Components of a Lathe Repair Kit

Breakdown of essential tools and parts included in a typical kit. Importance of each component in a repair kit.A lathe repair kit is like a superhero’s tool belt for your metal lathe tailstock! It includes essential tools like wrenches, alignment tools, and bearings. Each piece plays a key role. Wrenches help tighten bolts, while alignment tools keep everything straight. Bearings ensure smooth movement. Without these components, your lathe could end up more confused than a chameleon in a bag of skittles! Here’s a quick breakdown of key components:

| Component | Importance |

|---|---|

| Wrenches | For tightening and loosening screws. |

| Alignment Tools | To keep parts straight and working well. |

| Bearings | Ensures smooth operation of moving parts. |

With these tools, you won’t have a lopsided lathe! Remember, every component in a repair kit is there to help you keep your lathe spinning smoothly and accurately.

Signs You Need a Repair Kit for Your Tailstock

Symptoms indicating wear and tear on tailstock components. How to assess the condition of your lathe tailstock.Detecting trouble with your tailstock is easier than finding your missing socks! Look for signs like loose handles, uneven cuts, or strange noises. If your lathe seems to be developing a personality (like squeaks or groans), it might be time for a check-up. Here’s a quick table to help you identify symptoms of wear and tear:

| Symptoms | Potential Issue |

|---|---|

| Wobbling during operation | Loose components |

| Poor alignment | Worn-out guides |

| Unusual noises | Lack of lubrication |

Inspect your tailstock regularly. If you notice one or more of these signs, consider a lathe repair kit to get it back in shape. A well-maintained tailstock will keep your projects running smoothly and may just save you from a surprise trip to the hardware store!

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a repair kit (compatibility, quality, etc.). Recommended brands and products in the market.Picking the perfect lathe repair kit is like choosing a favorite ice cream flavor—it has to match your taste! First, check for compatibility with your metal lathe tailstock. If it doesn’t fit, you’re left with an expensive paperweight. Next, look for quality parts; flimsy kits are like trying to build a house of cards in a windstorm. Popular brands include Grizzly, Jet, and Shop Fox. They offer reliable kits that won’t leave you high and dry.

| Brand | Quality | Compatibility |

|---|---|---|

| Grizzly | High | Most models |

| Jet | Very High | Many tailstocks |

| Shop Fox | High | Compatible range |

Step-by-Step Guide to Tailstock Repair

Detailed instructions on using a repair kit for tailstock maintenance. Common repairs and their specific procedures.Fixing your tailstock is easier than you think! Start with a repair kit that has all the parts you need. Follow these steps:

- Open the tailstock and check for worn-out parts.

- Replace old screws and bearings with new ones from the kit.

- Adjust the alignment for smooth operation.

- Test it with a simple piece of wood or metal.

Common repairs include loosening or sticking parts. Always clean the area before applying new grease. A well-maintained tailstock can last for years!

What are some tips for tailstock maintenance?

Regular checks and cleaning can prevent major issues. It’s helpful to keep tools and workplace clean. Proper care leads to a longer lifespan for your lathe.

Preventive Maintenance for Lathe Tailstocks

Tips for extending the life of your lathe and tailstock. Recommended maintenance schedule and practices.Taking care of your lathe and tailstock can keep them running smoothly. Regular checks save time and money. Start by cleaning the machine weekly. Remove debris and apply a little oil to the moving parts. You should also tighten any loose screws; nobody wants a surprise from a wobbly tailstock! A good rule is to check every month, like that friend who reminds you to water your plants. If you notice anything weird, it’s time to consult your lathe repair kit. Follow this simple schedule:

| Maintenance Task | Frequency |

|---|---|

| Clean & Lubricate | Weekly |

| Tighten Screws | Monthly |

| Inspect for Damage | Every 3 Months |

With some love and care, your lathe can last longer than your favorite video game! Remember, an ounce of prevention is worth a pound of lathe repair costs!

Customer Reviews and Testimonials

Analysis of customer feedback on popular lathe repair kits. Case studies of successful repairs using specific kits.Customers have shared their experiences about lathe repair kits. Many users love how easy they are to use. They often mention improved precision and better performance after repairs. Here are some findings:

- One user fixed their tailstock and praised the kit for clear instructions.

- Another reported that using the kit saved them money on professional repairs.

- Overall, customers felt satisfied with their purchases, noting reliable quality.

When using a specific kit, success stories show how repairs can extend the life of your lathe. Always check for user feedback before buying. It can guide you to the best choices.

What are common issues with lathe tailstocks?

Common issues with lathe tailstocks include misalignment, stiffness, and wear over time. These problems affect accuracy and can make your projects difficult. Regular maintenance can help prevent these issues.

Where to Buy Lathe Repair Kits

Best platforms and retailers for purchasing repair kits. Online vs. physical store considerations.Buying a lathe repair kit can be a fun adventure! You can check out well-known online platforms like Amazon or eBay for a huge selection. These places often have user reviews, making it easier to pick the best kit without the hassle of bad surprises. If you love seeing things in person, visit a local hardware store. You can chat with staff and maybe even find some DIY tips! So, whether you click or stroll, the choice is yours!

| Platform | Pros | Cons |

|---|---|---|

| Amazon | Wide selection, customer reviews | Shipping delays possible |

| eBay | Great deals, auctions | Quality varies |

| Local Hardware Store | In-person support, instant purchase | Limited choices |

Frequently Asked Questions (FAQs)

Common queries regarding lathe repair kits and their usage. Troubleshooting tips for DIY repairs.Many people have questions about lathe repair kits and how to use them. Here are some common queries:

What is included in a lathe repair kit?

A lathe repair kit usually comes with tools, parts, and instructions. These items help fix problems with the tailstock.

How do I troubleshoot issues with the tailstock?

- Check for loose screws. Tighten any that are wobbly.

- Inspect the alignment. It should slide smoothly along the bed.

- Look for wear and tear. Replace worn-out parts from your kit.

Having a repair kit on hand can save time and hassle! Knowing how to fix problems can help keep your lathe running smoothly.

Conclusion

In summary, a lathe repair kit for your metal lathe tailstock can save you time and money. It helps keep your tools working smoothly and efficiently. By fixing your tailstock, you improve your projects and extend your lathe’s life. Remember to research kits that suit your needs. Let’s get started and make those repairs today!FAQs

Sure! Here Are Five Questions Related To Lathe Repair Kits For Metal Lathe Tailstocks:1. What is a lathe repair kit? A lathe repair kit has tools and parts you need to fix a metal lathe’s tailstock. 2. Why do I need a tailstock? The tailstock helps hold the material steady when you cut it. It makes your work easier and safer. 3. How can I tell if my tailstock needs repair? If your tailstock is hard to move or makes strange noises, it might need repair. 4. Where can I get a lathe repair kit? You can find lathe repair kits at hardware stores or online. Check places that sell tools. 5. How do I fix the tailstock? Follow the instructions in the repair kit. Usually, you’ll take it apart, replace the old parts, and put it back together.

Sure! Please provide the question you’d like me to answer.

What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe Tailstock?A lathe repair kit for a metal lathe tailstock usually includes a few important parts. You might find screws and nuts to hold things together. There are often new bearings that help pieces move smoothly. Sometimes, the kit has a new handle or knobs for better control. You might also get a manual with instructions to help you put everything back together.

How Can I Determine If My Lathe Tailstock Needs Repairs Or A Complete Replacement?To check if your lathe tailstock needs repairs, look for loose parts or any damage. You can also see if it moves easily. If it doesn’t hold your work tight, it might need fixing. If parts are broken or worn out and cost too much to fix, you may need a new one.

What Are The Common Symptoms Of A Malfunctioning Tailstock On A Metal Lathe?If the tailstock on a metal lathe is not working right, you might notice a few things. The piece you are working on could wobble or not stay straight. You might see uneven cuts or scratches on the metal. Sometimes, the tailstock might not move smoothly, making it hard to adjust. You might also hear strange noises while using it.

Are There Specific Maintenance Tips To Prolong The Life Of A Lathe Tailstock Before It Requires A Repair Kit?To take care of a lathe tailstock, keep it clean and free of debris. Make sure to oil the moving parts regularly. Check for any loose screws and tighten them if needed. Avoid pushing too hard when using it. By doing these simple things, you can help it last longer!

Can I Use A Generic Lathe Repair Kit For My Specific Metal Lathe Model, Or Do I Need Oem Parts?You can use a generic lathe repair kit, but it’s not always the best choice. Generic parts might not fit your lathe perfectly. They can also wear out faster. It’s safer to use OEM parts, which are made just for your lathe model. They usually work better and last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Repair Kits For Metal Lathe Tailstocks:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “1. What is a lathe repair kit? A lathe repair kit has tools and parts you need to fix a metal lathe’s tailstock. 2. Why do I need a tailstock? The tailstock helps hold the material steady when you cut it. It makes your work easier and safer. 3. How can I tell if my tailstock needs repair? If your tailstock is hard to move or makes strange noises, it might need repair. 4. Where can I get a lathe repair kit? You can find lathe repair kits at hardware stores or online. Check places that sell tools. 5. How do I fix the tailstock? Follow the instructions in the repair kit. Usually, you’ll take it apart, replace the old parts, and put it back together.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe Tailstock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for a metal lathe tailstock usually includes a few important parts. You might find screws and nuts to hold things together. There are often new bearings that help pieces move smoothly. Sometimes, the kit has a new handle or knobs for better control. You might also get a manual with instructions to help you put everything back together.”}},{“@type”: “Question”,”name”: “How Can I Determine If My Lathe Tailstock Needs Repairs Or A Complete Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if your lathe tailstock needs repairs, look for loose parts or any damage. You can also see if it moves easily. If it doesn’t hold your work tight, it might need fixing. If parts are broken or worn out and cost too much to fix, you may need a new one.”}},{“@type”: “Question”,”name”: “What Are The Common Symptoms Of A Malfunctioning Tailstock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock on a metal lathe is not working right, you might notice a few things. The piece you are working on could wobble or not stay straight. You might see uneven cuts or scratches on the metal. Sometimes, the tailstock might not move smoothly, making it hard to adjust. You might also hear strange noises while using it.”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Tips To Prolong The Life Of A Lathe Tailstock Before It Requires A Repair Kit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of a lathe tailstock, keep it clean and free of debris. Make sure to oil the moving parts regularly. Check for any loose screws and tighten them if needed. Avoid pushing too hard when using it. By doing these simple things, you can help it last longer!”}},{“@type”: “Question”,”name”: “Can I Use A Generic Lathe Repair Kit For My Specific Metal Lathe Model, Or Do I Need Oem Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a generic lathe repair kit, but it’s not always the best choice. Generic parts might not fit your lathe perfectly. They can also wear out faster. It’s safer to use OEM parts, which are made just for your lathe model. They usually work better and last longer.”}}]}