Have you ever wondered how a simple piece of metal can transform into something special? It’s all about the tools we use, like a lathe. Imagine taking an old, rusty metal lathe and bringing it back to life. That’s what lathe restoration is all about!

People love to restore old machines. It feels good to make something new again. But restoring a metal lathe can be tricky. It requires patience, skill, and a little bit of creativity. If done right, it can even lead to exciting projects like metal lathe automation.

Picture this: you start with a worn-out lathe, full of potential. With some hard work, you turn it into a state-of-the-art machine. It can make perfect cuts automatically. Doesn’t that sound amazing?

In this article, we will explore the fascinating world of lathe restoration and the wonders of metal lathe automation. We’ll share tips and stories that can inspire both beginners and seasoned experts. Get ready to discover how to breathe new life into old machines!

Lathe Restoration: Reviving Metal Lathe Automation Techniques

Lathe Restoration and Metal Lathe Automation

Lathe restoration focuses on reviving old metal lathes for better performance. Many enthusiasts love this hobby. They often find unique tools that tell a story. Automation can enhance these machines, making them easier to use and more efficient. Imagine turning a rough piece of metal into a smooth part with just a press of a button! Embracing automation is like giving your lathe a superpower. The world of lathe restoration and automation offers endless possibilities for makers and tinkerers.Understanding Lathe Restoration

Definition and importance of lathe restoration. Common reasons for restoring metal lathes.Lathe restoration means fixing and renewing old or damaged lathes. It is important because it helps keep these machines running well. Restoring a lathe can save money and keep valuable tools alive for a long time. Common reasons why people restore metal lathes include:

- Worn parts that need replacement.

- Rust or damage that has built up over time.

- Upgrading for better performance and accuracy.

Fixing a lathe can turn junk into treasure! It allows users to create and build again.

Why Restore a Lathe?

Restoring a lathe helps keep costs low, saves valuable equipment, and allows creativity. People appreciate having working tools instead of buying new ones.

Assessing Your Metal Lathe Condition

Key indicators of wear and damage in lathes. Tools required for a thorough assessment.Before you start any lathe projects, it’s smart to check your machine’s health. Look out for scratches and loose parts. If something wiggles like it’s dancing, it’s time to pay attention! Use simple tools like a caliper and a straightedge to measure and inspect the bed, tailstock, and headstock. These checks can save you from disaster—and possibly a flying wrench!

| Key Indicators | Tools Needed |

|---|---|

| Scratches on the bed | Caliper |

| Loose tailstock | Straightedge |

| Unusual sounds | Wrenches (for tightening) |

Step-by-Step Lathe Restoration Process

Disassembly: How to safely take apart your lathe. Cleaning and Surface Preparation: Techniques to restore components. Repairing and Replacing Damaged Parts: Identifying when to repair vs. replace.First, let’s take your lathe apart without making it cry. Start by labeling each part as you go. It’ll help you remember where everything belongs. Next, give those pieces a good scrub! Use soap and water to shine them up like a new penny. Clean surfaces can work magic. Now, if you spot a part that’s damaged, ask yourself, “Can I fix it or is it time to let it go?” Sometimes a little repair is all you need to bring it back to life!

| Step | Action |

|---|---|

| 1 | Disassemble carefully |

| 2 | Clean each part |

| 3 | Repair or replace as needed |

Integrating Automation into Lathe Restoration

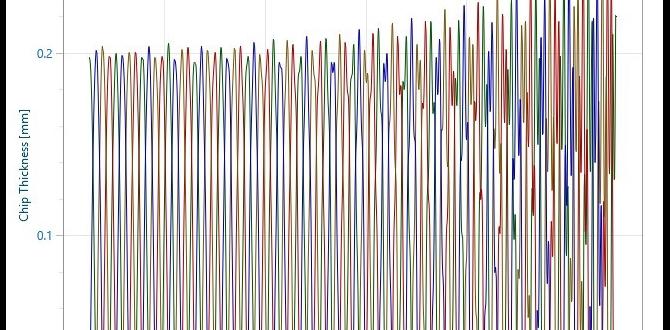

Benefits of automating lathe operations. Recommended automation tools and systems for metal lathes.Automating lathe operations makes work easier and faster. It helps to reduce mistakes and saves time. With automation, you can produce more parts with less effort. Many tools and systems can help:

- CNC Machines: These machines control the lathe automatically.

- Software Tools: Special programs can program your lathe easily.

- Sensor Systems: They monitor and adjust the lathe automatically.

This technology brings great benefits, making your lathe restoration smoother and more efficient.

What are the benefits of automating lathe operations?

Automation boosts productivity. It also improves accuracy and consistency. Stronger machines often last longer, reducing costs over time. This means better results for your work!

What automation tools are recommended for metal lathes?

Trusted tools include CNC systems, sensor kits, and smart software. They not only enhance your lathe but also make your work enjoyable.

Calibration and Maintenance After Restoration

Importance of calibration for precision. Regular maintenance tips to prolong lathe lifespan.Keeping a restored lathe in top shape requires some TLC. Calibration is key for precision. It ensures your lathe works accurately. Imagine trying to bake a cake without measuring! Regular checks can save you from troubles. For maintenance, dust and oil are your friends! Clean it after each use and oil moving parts every few weeks. This can help your lathe last longer and work better.

| Maintenance Tips | Frequency |

|---|---|

| Clean the lathe | After each use |

| Oil moving parts | Every few weeks |

| Check for wear | Monthly |

By following these steps, you’ll keep your lathe humming along like a well-tuned piano! Who knew maintenance could be so musical?

Case Studies of Successful Lathe Restoration Projects

Examples of metal lathe restorations and automation integration. Lessons learned from realworld restoration experiences.Many inspiring stories exist around metal lathe restorations. One notable example is a classic lathe from the 1960s, found collecting dust in a barn. After a thorough cleaning and a sprinkle of love, it was transformed into a high-speed machining wonder! Lessons learned include checking for parts compatibility and having a backup plan—like duct tape for those “oops” moments when things don’t fit. Here’s a quick look at other successful projects:

| Project | Description | Lessons Learned |

|---|---|---|

| 1920s Lathe | Revived with new parts and paint. | Always verify parts availability! |

| Modern Upgrade | Integrated automation for efficiency. | Don’t rush the automation process. |

| Rusty Relic | Restored to working condition! | Patience is key—rust doesn’t disappear overnight! |

These stories remind us that every lathe can shine again! Remember, restoration is a journey, not a race!

Resources for Lathe Restoration Enthusiasts

Essential books and online resources for learning more. Community forums and groups to connect with other restorers.If you’re diving into lathe restoration, there are some handy resources to make your journey smoother. Check out books like *The Metal Lathe* and *Lathework: A Simple Approach* to get the basics down. Online, websites like Instructables have plenty of guides. Don’t miss community forums, like the ones on Reddit or Facebook groups. These are perfect for asking questions and sharing tips. Remember, it’s always good to have a buddy to share your lathe disasters with!

| Type | Resources |

|---|---|

| Books | The Metal Lathe, Lathework: A Simple Approach |

| Websites | Instructables, YouTube Tutorials |

| Forums | Reddit, Facebook Groups |

Frequently Asked Questions about Lathe Restoration

Common concerns and misconceptions about restoring metal lathes. Expert answers to frequently asked questions on automation.Many people wonder about restoring metal lathes. Can anyone do it? Yes, with some tools and patience! Some think it’s too hard, but most lathes can be fixed with care. Is automation really helpful? Absolutely! It saves time and makes work easier. Here are some common questions:

What tools do I need for restoration?

You will need wrenches, screwdrivers, and cleaning supplies. A good manual is also helpful.

Can I automate my lathe?

- Yes, many upgrades are available! Check the manufacturer for options.

- Software can help run the machine better.

- Some automation can even improve safety.

Conclusion

In conclusion, restoring a metal lathe can be rewarding and fun. You can learn valuable skills and improve your projects. Automating your lathe adds efficiency and precision to your work. If you want to dive deeper, consider trying a small restoration project or reading more about automation techniques. Let’s get started on transforming old machines into useful tools!FAQs

What Are The Best Practices For Restoring An Old Metal Lathe To Ensure It Functions Efficiently For Automated Operations?To restore an old metal lathe, you should start by cleaning it well to remove rust and dirt. Next, check all the moving parts. If they are stiff, add some oil to help them move freely. Replace any broken pieces with new ones. Finally, test the machine to make sure it runs smoothly and safely.

What Automation Technologies Can Be Integrated Into A Traditional Metal Lathe To Improve Its Performance And Versatility?You can add a computer to control the metal lathe. This helps make cuts more precise. We can also use sensors to check if everything is working right. A robotic arm can help load and unload pieces quickly. These changes make the lathe faster and easier to use!

How Can You Evaluate The Condition Of A Used Metal Lathe Before Undertaking A Restoration Project?To check a used metal lathe, look for rust and dirt. Make sure all the parts move smoothly. Check if the bed is straight and not worn out. You can also test the motor to see if it works well. It’s important to see if you can get replacement parts easily.

What Common Challenges Do Hobbyists Face When Automating A Restored Metal Lathe, And How Can They Be Overcome?Hobbyists often face problems like choosing the right parts and wiring everything correctly. These tasks can be tricky and confusing. To make it easier, you can watch online videos or read guides that show each step. It helps to ask for advice from other people who have done it before. With patience and practice, you can get it to work!

What Are The Key Components To Consider When Designing A Control System For A Retrofitted Automated Metal Lathe?When designing a control system for an automated metal lathe, think about a few important parts. First, choose the right sensors. These help the machine understand what’s happening. Next, pick a good computer to manage everything. It makes decisions quickly. Finally, ensure all the parts work well together, like a team, so the lathe runs smoothly.