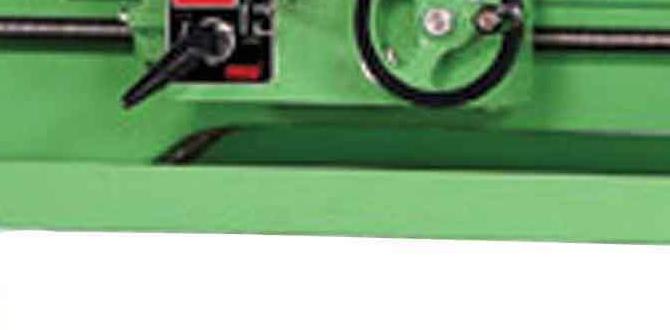

Have you ever watched a metal lathe in action? It is amazing how this machine turns raw metal into beautifully shaped parts. But what happens when a lathe gets old and rusty? That’s where lathe restoration comes in, bringing these machines back to life.

One of the key parts to focus on is the compound rest. It might sound complicated, but it is simply a tool that helps the lathe create precise shapes. A working compound rest means better projects and smoother operations. Do you know how important this little piece is?

Many people overlook the compound rest when restoring a metal lathe. They often see only the big parts. Yet, without a functional compound rest, even the best lathe can struggle. Imagine trying to carve a sculpture with a dull knife. The same idea applies here!

As we dive deeper into lathe restoration, we will explore simple steps to revive your machine. Whether you are a beginner or a seasoned pro, restoring a lathe can be both fun and rewarding. Let’s uncover the secrets to getting your metal lathe and its compound rest back in tip-top shape.

Lathe Restoration: Reviving Your Metal Lathe Compound Rest

Lathe Restoration: The Importance of the Compound Rest

Restoring a metal lathe can be an exciting challenge, especially when focusing on the compound rest. This part is vital for precise cutting and shaping. A well-maintained compound rest allows for smoother adjustments, ensuring accurate work. Restoration often involves cleaning, lubricating, and sometimes repairing wear and tear. Did you know that a small adjustment can change the entire project outcome? Learning the tips and tricks of lathe restoration can truly elevate your craftsmanship.Understanding Metal Lathe Compound Rest

Definition and purpose of the compound rest in a metal lathe. Importance of a wellfunctioning compound rest for precision machining.A compound rest is a part of a metal lathe. It helps you move the cutting tool in precise directions. The goal is to shape and cut metal accurately. A well-functioning compound rest is vital for precision machining. If it works well, your metal pieces will turn out just right. Without it, mistakes can happen. Remember, small parts need careful movements. This keeps your project smooth and professional.

What is the purpose of the compound rest?

The compound rest allows precise angle adjustments for cutting tools. This means you can create better shapes and designs in your work.

Why is a well-functioning compound rest important?

- It ensures accuracy in cuts.

- It minimizes errors.

- It saves time on corrections.

Signs Your Compound Rest Needs Restoration

Common indicators of wear and damage. Impact of a faulty compound rest on overall lathe performance.Many signs show your compound rest might be worn out. Look for scratches, bumps, or uneven movement. These can mean it’s time for restoration. A faulty compound rest can cause problems. Your lathe may not cut correctly. It can even ruin your projects. Regular checks can help keep your lathe working well.

What are the signs your compound rest is damaged?

Common signs include:- Visible scratches or dents

- Sticky or uneven movement

- Unusual noises while operating

- Loose parts that cannot secure items

Tools and Materials Needed for Restoration

Essential tools for disassembly and repair. Recommended materials for restoration (paints, lubricants, seals).Restoring a metal lathe is an exciting project. To get started, you’ll need some important tools and materials. For disassembly and repair, gather:

- Wrenches

- Screwdrivers

- Hammers

- Pliers

These tools help take apart and fix the lathe.

For restoration, you should have:

- Paints for a fresh look

- Lubricants to keep parts moving smoothly

- Seals to prevent leaks

Having the right tools and materials makes restoration easier and more enjoyable.

What tools do I need to restore a lathe?

Essential tools include wrenches, screwdrivers, hammers, and pliers. These are perfect for taking apart and fixing the lathe.

Key materials for restoration:

- Paints

- Lubricants

- Seals

Step-by-Step Restoration Process

Disassembling the compound rest: Safety tips and procedures. Cleaning and repairing components: Techniques for different materials. Reassembly: Best practices for ensuring proper fit and function.Start your restoration journey by carefully disassembling the compound rest. Always wear safety goggles to protect your eyes. Work in a clean area to avoid losing tiny parts. Next, clean and repair each component using appropriate techniques. For metal, a wire brush works well, while plastic might need gentle scrubbing. Finally, reassemble everything. Make sure parts fit snugly. Check for smooth movement. This ensures your lathe runs perfectly.

How to ensure proper safety during disassembly?

Use safety goggles and a clean workspace. Keep tools organized to prevent accidents. Take your time and follow steps carefully.

Tips for cleaning materials:

- Use a wire brush for metal.

- Gently scrub plastic with a soft cloth.

- Apply lubricants to moving parts during reassembly.

With these steps, your lathe will be restored in no time, ready for your next project!

Upgrading Your Compound Rest

Options for enhanced functionality in modern restoration. Custom modifications for improved performance and versatility.To boost your compound rest, consider new options for improved functions. Many parts can be upgraded for better work. Custom changes can enhance how you create. Think of adding features like:

- Micro-adjustment knobs for precise movements.

- Enhanced locking mechanisms for stability.

- Quick-change tools for easy swapping.

These upgrades help make your metal lathe more versatile and effective. Each change gives you better control and efficiency.

What are compound rest upgrades?

Compound rest upgrades improve the way your lathe works. They add new features and make tasks easier and more efficient.

Maintenance Tips for Longevity

Routine checks and services to prevent future issues. Proper lubrication and handling techniques to keep the compound rest in top shape.To keep your metal lathe a happy little machine, check it regularly. Look for loose bolts and signs of wear. A simple weekly glance can save you big headaches later! Proper lubrication is key. Use quality oil on the compound rest to keep things running smoothly. Remember, happy parts work better and last longer. So, avoid wrestling with dry metal—it’s a workout no one wants!

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check bolts and screws | Weekly | Loose bits lead to trouble! |

| Lubricate moving parts | Every month | A little oil goes a long way! |

| Clean the compound rest | Every use | Keep it grime-free for smooth operation. |

Resources and Communities for Lathe Enthusiasts

Online forums, groups, and workshops for support and information. Recommended books and video tutorials for further learning.Finding friends who love lathes too can be a fun adventure! Online forums and groups are great places to share tips and tricks. You can ask questions or show off your lathe work. Want to learn more? Check out books and video tutorials that make learning easy. They turn complex ideas into simple steps. Who knew metal lathes could be so entertaining? Just watch out for flying shavings!

| Resource Type | Examples |

|---|---|

| Online Forums | MetalworkingTheatre, Practical Machinist |

| Books | The Metal Lathe by Tom H. Morrow |

| Video Tutorials | YouTube channels like This Old Tony |

Conclusion

In summary, restoring a metal lathe’s compound rest can enhance your machining skills. We learned that cleaning, lubricating, and adjusting are key steps. You can achieve smoother operations and better results with some effort. Remember, practice makes perfect. If you’re interested in learning more, check out guides and videos online. Happy restoring!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Restoration, Specifically Focusing On The Compound Rest Of A Metal Lathe:Sure! Restoring the compound rest of a metal lathe is fun and rewarding. First, you should clean it carefully. You can use a soft cloth to get rid of dirt. Next, check for any broken parts. If you find any, you may need to replace them. Finally, oil the moving parts to help everything work smoothly.

Sure! Please give me the question you’d like me to answer.

What Are The Common Signs Of Wear Or Damage To The Compound Rest In A Metal Lathe That Indicate It May Need Restoration?If you notice rust or scratches on the compound rest, it might need fixing. You might see loose parts that don’t hold in place well. If the handles are hard to turn, that’s another sign. Also, look for cracks or breaks. These signs mean it’s time for some care and restoration.

What Tools And Materials Are Essential For Properly Restoring The Compound Rest Of A Metal Lathe?To restore the compound rest of a metal lathe, you need a few tools and materials. First, grab a wrench to remove parts. You will also need oil to keep everything moving smoothly. Don’t forget sandpaper to clean the surfaces. Lastly, have some grease to help protect the metal from rust.

How Can You Accurately Realign The Compound Rest After Restoration To Ensure Proper Functionality And Precision In Machining?To realign the compound rest after fixing it, you first check that it’s clean. Then, you loosen the screws that hold it in place. Next, carefully move it until it lines up straight. Tighten the screws again to keep it in the right spot. Finally, you can test it to make sure everything works well.

What Techniques Can Be Used To Remove Rust And Corrosion From The Compound Rest Without Damaging The Underlying Metal?To remove rust and corrosion from the compound rest, you can use vinegar. Pour some vinegar on the rusted area and let it sit. After a while, scrub it gently with a cloth or a soft brush. You can also use baking soda mixed with water to make a paste. Apply the paste, wait, and then scrub it off. This way, you keep the metal safe!

Are There Any Aftermarket Upgrades Or Modifications For The Compound Rest That Can Enhance The Performance Or Capabilities Of A Vintage Metal Lathe?Yes, there are upgrades for the compound rest on old metal lathes. You can add better bearings to make it move more smoothly. A DRO, or digital readout, can help you see exact measurements easier. You can also change the handle for a better grip. These changes can make your lathe work even better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Restoration, Specifically Focusing On The Compound Rest Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Restoring the compound rest of a metal lathe is fun and rewarding. First, you should clean it carefully. You can use a soft cloth to get rid of dirt. Next, check for any broken parts. If you find any, you may need to replace them. Finally, oil the moving parts to help everything work smoothly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Damage To The Compound Rest In A Metal Lathe That Indicate It May Need Restoration?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you notice rust or scratches on the compound rest, it might need fixing. You might see loose parts that don’t hold in place well. If the handles are hard to turn, that’s another sign. Also, look for cracks or breaks. These signs mean it’s time for some care and restoration.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Essential For Properly Restoring The Compound Rest Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To restore the compound rest of a metal lathe, you need a few tools and materials. First, grab a wrench to remove parts. You will also need oil to keep everything moving smoothly. Don’t forget sandpaper to clean the surfaces. Lastly, have some grease to help protect the metal from rust.”}},{“@type”: “Question”,”name”: “How Can You Accurately Realign The Compound Rest After Restoration To Ensure Proper Functionality And Precision In Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To realign the compound rest after fixing it, you first check that it’s clean. Then, you loosen the screws that hold it in place. Next, carefully move it until it lines up straight. Tighten the screws again to keep it in the right spot. Finally, you can test it to make sure everything works well.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Remove Rust And Corrosion From The Compound Rest Without Damaging The Underlying Metal?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To remove rust and corrosion from the compound rest, you can use vinegar. Pour some vinegar on the rusted area and let it sit. After a while, scrub it gently with a cloth or a soft brush. You can also use baking soda mixed with water to make a paste. Apply the paste, wait, and then scrub it off. This way, you keep the metal safe!”}},{“@type”: “Question”,”name”: “Are There Any Aftermarket Upgrades Or Modifications For The Compound Rest That Can Enhance The Performance Or Capabilities Of A Vintage Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are upgrades for the compound rest on old metal lathes. You can add better bearings to make it move more smoothly. A DRO, or digital readout, can help you see exact measurements easier. You can also change the handle for a better grip. These changes can make your lathe work even better!”}}]}