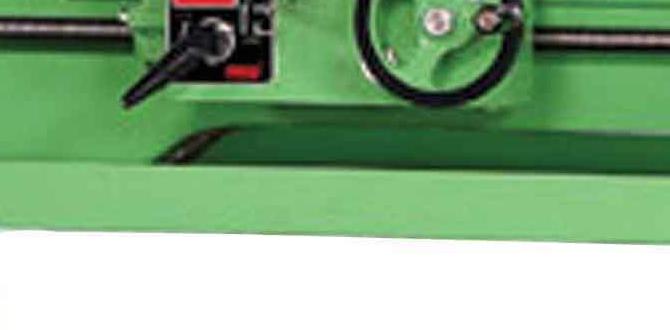

Have you ever watched a metal lathe spin? It’s truly fascinating! These machines shape metal into amazing parts. But what if your lathe doesn’t work like it used to? That’s when lathe restoration comes into play.

Imagine finding an old metal lathe in a dusty garage. The surface is rusty, and the control panel looks broken. At first glance, it might seem like a lost cause. But with some patience and care, you can bring it back to life!

Restoring a metal lathe can be a fun project. Each step reveals how these machines operate. You get to learn about the control panel and its functions. Did you know that a well-restored lathe can last for decades? It’s true!

In this article, we’ll explore the ins and outs of lathe restoration. We’ll focus on how to fix the crucial control panel too. Ready to dive into the exciting world of metal lathes? Let’s get started!

Lathe Restoration: Reviving Your Metal Lathe Control Panel

Lathe Restoration: Metal Lathe Control Panel

Restoring a metal lathe can be an exciting adventure! A crucial part is the control panel, which directs the machine’s actions. Readers will discover tips on how to clean and repair this important feature. Simple adjustments can greatly enhance its performance. Did you know that a well-functioning control panel can help create precise parts? With patience and the right tools, anyone can bring a lathe back to life and enjoy crafting unique projects.Common Issues Faced in Metal Lathe Control Panels

Identifying typical problems such as faulty wiring and malfunctioning controls. Discussion of signs indicating the need for restoration.Metal lathe control panels can face common issues. These problems often show signs that something is wrong. Faulty wiring can cause machine failures. Look for frayed wires or loose connections. Another issue is malfunctioning controls. If buttons stick or dials don’t work, it’s a warning. Pay attention if the machine won’t start or makes strange noises. Ignoring these signs can lead to bigger problems.

What are the signs that indicate a metal lathe control panel needs restoration?

Some key signs include:

- Unresponsive controls: Buttons and dials should work smoothly.

- Strange noises: Any unusual sounds could mean trouble.

- Power issues: Flickering lights or sudden shutdowns need attention.

Keeping an eye on these issues can help maintain your metal lathe effectively.

Tools and Materials Needed for Lathe Control Panel Restoration

Essential tools for dismantling and repairing control panels. Types of materials used for upgrades and replacements.Restoring a lathe control panel can feel like a puzzle! You need some nifty tools and materials to complete it. Grab your trusty screwdriver set for easy dismantling. A multimeter is like a superhero, helping you check electric connections. Don’t forget a soldering iron for those tricky repairs—it’s the glue of electronics!

| Tools | Materials |

|---|---|

| Screwdriver Set | Wires |

| Multimeter | Replacement Switches |

| Soldering Iron | Push Buttons |

For upgrades, choose high-quality replacement switches and wires. They make your lathe feel like it just got a makeover! A little care and the right gear can turn your old control panel into a shining marvel. So gear up, and let the fun—uh, I mean work—begin!

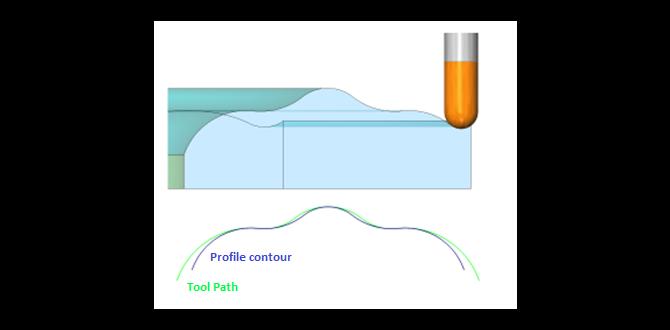

Step-by-Step Guide to Restoring a Metal Lathe Control Panel

Detailed process for safely disassembling the control panel. Instructions for inspecting and repairing faulty components.First, carefully remove the control panel from the metal lathe. Take a moment to clear the area. Make sure to take notes or pictures. This helps keep track of what goes where. Now, look at all the parts. Inspect each one for damage. If something seems broken or rusty, it might need some love. Replace faulty parts. You can use this handy table to guide your repairs:

| Component | Condition | Action |

|---|---|---|

| Wires | Frayed | Replace |

| Switches | Sticky | Clean or Replace |

| Indicators | Blinking | Check Connections |

Remember, safety comes first! Put on gloves and goggles. Fixing things might not be as fun as a day at the amusement park, but it’s definitely rewarding!

Upgrading Your Metal Lathe Control Panel

Benefits of modernizing your control panel features. Suggested technology and components for upgrades.Upgrading your control panel can boost your metal lathe’s performance. New features add safety, precision, and ease of use. With modern technology, you can enjoy real-time monitoring and quick adjustments. Here are some helpful upgrade ideas:

- Digital displays for clear readings

- Programmable settings for repeat tasks

- Remote operation capabilities

These upgrades can change how you work and make your projects easier.

What are the key benefits of modernizing your control panel?

Modernizing your control panel improves efficiency and safety. Features like digital displays help you see settings clearly. New components can make tasks quicker.

Safety Precautions During Lathe Restoration

Recommended safety gear and practices to ensure a secure working environment. Guidelines for handling electrical components safely.Staying safe is key during lathe restoration. Start by wearing safety gear. This gear can include:

- Safety goggles to protect your eyes.

- Ear protection to block loud noises.

- Gloves for hand safety.

- Steel-toed boots for foot protection.

What safety gear should I use during lathe restoration?

The best gear includes safety goggles, ear protection, gloves, and steel-toed boots. This prevents injuries while you work. Always prioritize your safety first!

Testing and Troubleshooting After Restoration

Methods for testing the functionality of the restored control panel. Troubleshooting common issues that may arise postrestoration.After giving your control panel a shiny makeover, it’s time to put it to work! Start by turning it on and listen for any strange noises. If it sounds like a cat in a blender, you might need to tweak some wires. Check all buttons and switches. Do they click like they’re supposed to? If not, it’s time to troubleshoot!

| Common Issues | Solutions |

|---|---|

| Poor response to inputs | Inspect wiring connections and fuses. |

| Display not working | Check the power supply and reset the system. |

| Overheating | Ensure ventilation is clear and components are clean. |

Keeping these tips in mind can save you from turning your shop into a circus. Remember, a little testing today keeps the headaches away tomorrow!

Maintaining Your Metal Lathe Control Panel

Best practices for routine maintenance to prolong lifespan. Tips for preventing future issues and ensuring optimal performance.To keep your metal lathe control panel happy and healthy, regular maintenance is key. First, wipe it down regularly to prevent dust build-up. Next, check for loose wires and fix them. Think of loose wires as little gremlins throwing a party! An annual deep clean can work wonders too. If things get noisy, that’s your lathe saying it needs help. Replace worn parts promptly. Remember, a well-maintained lathe is a happy lathe, ready to spin dreams into reality!

| Maintenance Task | Frequency | Tip |

|---|---|---|

| Wipe Down | Weekly | Dust is not your friend! |

| Check Wires | Monthly | Loose wires are party crashers! |

| Deep Clean | Annually | Like spring cleaning, but for your lathe! |

| Replace Parts | As Needed | Don’t ignore the warning signs! |

Conclusion

In summary, restoring a metal lathe’s control panel can greatly enhance its performance. We learned the importance of cleaning, rewiring, and testing components. By following these steps, you can improve your lathe’s efficiency. If you want to dive deeper, check out tutorials online or ask experienced users for tips. Happy restoring!FAQs

What Are The Common Signs Of Wear Or Damage In A Metal Lathe Control Panel That Should Be Addressed During Restoration?You should look for cracks in the panel. Peeling paint or rust can also be signs of damage. Check the buttons and knobs. If they feel loose or stick, they need fixing. Lastly, make sure the wires are not frayed or broken.

What Tools And Materials Are Typically Needed For Restoring The Control Panel Of A Metal Lathe?To restore the control panel of a metal lathe, you will need a few tools and materials. First, gather screwdrivers to remove any screws. You might also need pliers to grip and pull things apart. A soft cloth will help clean the panel, and rubbing alcohol can remove dirt and sticky stuff. Lastly, replacement buttons or knobs may be needed if any are broken.

How Do You Safely Disassemble And Reassemble A Lathe Control Panel For Inspection And Restoration?To safely take apart a lathe control panel, first turn off the machine and unplug it. Next, use a screwdriver to carefully remove the screws. Remember to keep the screws in a bowl so you don’t lose them. When you inspect or fix anything, be gentle with the parts. When putting it back, follow the steps in reverse and make sure everything is tight. Finally, plug in the machine and check if it works!

What Are The Best Practices For Cleaning And Repainting The Control Panel Components Without Damaging The Electronics?First, turn off the power to the control panel. Use a soft cloth to gently clean dust and dirt. If you need to repaint, use special paint made for electronics. Cover wires and buttons to keep them safe. Always let everything dry completely before turning the power back on.

How Can You Troubleshoot And Repair Any Electrical Or Mechanical Issues Found Within The Metal Lathe’S Control Panel During Restoration?To fix problems in the metal lathe’s control panel, first, turn off the machine. Look for any loose wires or broken parts and tighten or replace them. Test the buttons and switches to see if they work. If something is still not right, you can ask an adult for help or check the machine’s manual for clues. Always be careful when working with electricity!