Have you ever seen a rusty old metal lathe? You might think it’s just junk. But wait! What if I told you it could be restored to work like new? This is where the magic of lathe restoration comes in.

Many people don’t realize how important a good metal lathe controller board is. This tiny part controls the lathe’s movements. Without it, you can’t create those perfect shapes you need. Imagine wanting to make a toy car or a beautiful vase. You need that controller board to make it happen!

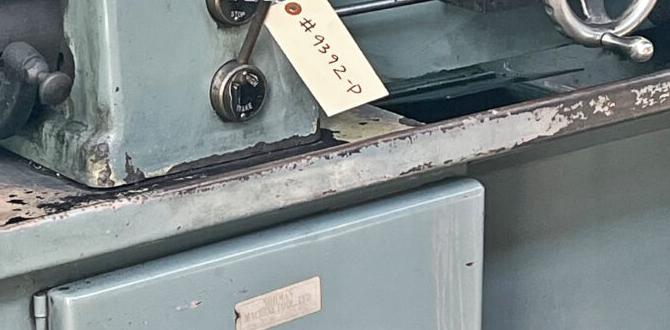

Picture this: you just bought a vintage metal lathe. It looks rough, but it has history. As you clean it, you uncover hidden treasures. Each scratch tells a story. You feel excited about bringing this treasure back to life!

In this article, we will explore the steps and tips for restoring a metal lathe. We will dive into the world of controller boards, too. Let’s discover the secrets together! You might just find your next project waiting to be restored.

Lathe Restoration: Upgrading Your Metal Lathe Controller Board

Lathe Restoration: Metal Lathe Controller Board

Restoring a metal lathe can feel like a big task, but it’s really exciting! The controller board is key for smooth operation. Have you ever wondered how these machines work? When you replace or upgrade the controller board, it can drastically improve performance. You’ll learn how to troubleshoot issues and even find modern replacements. This knowledge can help anyone seeking to bring a vintage lathe back to life, turning it into a valuable tool for projects.Assessing Your Current Controller Board

Signs that your controller board needs replacement. Tools and techniques for assessing functionality.Check your controller board for signs of trouble. Common issues to watch for include:

- Unusual noises or buzzing sounds.

- Frequent error messages on the display.

- Intermittent or no response from controls.

To assess its functionality, use simple tools like a multimeter and a screwdriver. This way, you can test connections and inspect components. Regular checks can help avoid bigger problems later!

What should I look for in a controller board?

Look for signs of wear, burnt components, or corrosion. These could mean it needs replacing!

Choosing the Right Controller Board for Your Lathe

Factors to consider when selecting a new controller board. Comparison of popular controller board options available.When picking a controller board for your lathe, consider a few key factors. First, check compatibility with your lathe model. Next, focus on features like speed control and user-friendliness. Some popular options include the VFD Controller and the CNC Controller. Each has its own perks, so choose wisely! Remember, the right board can turn your lathe into a masterpiece or leave you chasing your tail. Here’s a quick comparison:

| Controller | Features | Price |

|---|---|---|

| VFD Controller | Speed control, easy to use | $150 |

| CNC Controller | Precision control, great for complex tasks | $300 |

In the end, the right choice will keep your lathe running smoothly and save you from a headache!

Preparing for Controller Board Replacement

Necessary tools and safety precautions. Steps to safely disassemble your lathe.To replace your controller board, gather the right tools. You will need a screwdriver set, pliers, and a multimeter. Always wear safety goggles and gloves. Disconnect power from the lathe first. Follow these steps to disassemble safely:

- Unplug the lathe.

- Remove covers carefully.

- Take pictures of the wiring.

- Label wires for easier reassembly.

With careful steps, your lathe will be ready for a new controller board.

What tools do you need for lathe restoration?

You will need a screwdriver set, pliers, and a multimeter. Safety goggles and gloves are also important!

Step-by-Step Controller Board Replacement Process

Detailed instructions on removing the old board. Guide to installing and connecting the new board.Ready to dive into changing your controller board? First, unplug everything. Safety first, folks! Now, carefully remove the screws holding the old board. Keep them safe; you’ll need them later. Gently lift it out, avoiding any tangled wires. Next, grab your shiny new board.

Align it with the same screw holes and secure it in place. Don’t worry; it won’t bite! Connect the wires carefully, matching colors so they don’t play hide and seek. If you’re confused, think of it as a puzzle. You’ve got this!

| Old Board Removal | New Board Installation |

|---|---|

| Unplug all connections. | Align new board with screw holes. |

| Unscrew and remove the old board. | Secure the board with screws. |

| Disconnect wires. | Connect wires by matching colors. |

Follow these fun steps, and soon, your lathe will be ready to spin into action again. Happy restoring!

Testing the New Controller Board

How to ensure proper installation and functionality. Troubleshooting common issues after installation.To kick off your testing, start by checking connections. Ensure wires are snugly connected to the new controller board. You don’t want loose wires playing hide and seek, do you? Next, power it up and look for lights on the board. If they glow like little stars, you’re on the right path!

However, if things don’t go as planned, troubleshoot common hiccups. For instance, if the motor won’t spin, check if the power supply is functioning. You can create a quick reference table for troubleshooting:

| Issue | Possible Fix |

|---|---|

| No lights on board | Check power supply and connections |

| Motor not spinning | Inspect wiring and settings |

If you do these tests and fixes, your lathe will soon be spinning like a top!

Enhancing Your Lathe with Additional Upgrades

Suggested upgrades to complement your new controller board. Benefits of integrating modern technology into your lathe.Upgrading your lathe can be fun and useful. Adding some features can enhance its performance. Here are some suggested upgrades:

- Digital readout (DRO): This helps you see exact measurements.

- Automatic tool changers: These save time by switching tools automatically.

- Better lighting: Good lights help you see details clearly.

Modern technology improves your lathe’s efficiency. It can make your work easier and more accurate. Upgrades can result in higher quality projects, giving you more satisfaction in your work.

What are the benefits of integrating modern technology into your lathe?

Modern technology helps make your lathe faster and more precise. You can produce better results with less effort. Studies show that upgraded tools can increase production speed by up to 30%!

Maintenance Tips for Longevity of Your Lathe and Controller

Routine checks and maintenance practices. Importance of keeping software and firmware updated.Taking care of your lathe and its controller keeps them running smoothly. Regular checks can catch small issues before they become big problems. Check the wires for wear and ensure the lubrication is fresh. Clean the dust off the machine often. Also, always keep your software and firmware updated. This can help avoid bugs and improve performance.

- Inspect wiring and connections

- Lubricate moving parts

- Clean the machine regularly

- Update software and firmware

Why is it important to keep software and firmware updated?

Updating software and firmware is vital for your lathe. It helps fix bugs and can add new features. Regular updates enhance security, making your machine work better and last longer. Remember, an updated lathe runs smoother and safer.

Community Resources and Support for Lathe Restoration

Forums and online resources for further guidance. Connecting with local workshops and support groups.Many people love restoring lathes. But where can you find help? Online forums are great places to ask questions. You can connect with others who share your passion. Local workshops offer hands-on support. Joining a support group can help you learn faster. Here are some ideas:

- Search for lathe restoration forums online.

- Attend local workshops for skills and tips.

- Join community groups for support and sharing experiences.

Where can I find guidance for lathe restoration?

You can find guidance through online forums and local workshops. These places allow you to ask questions and learn from others.

Conclusion

In summary, restoring a metal lathe requires careful attention to the controller board. This key component controls the machine’s functions. You can improve performance by upgrading it. If you’re interested in lathe restoration, explore tutorials online. Hands-on experience will enhance your skills. Remember, each project teaches you something new! Let’s start restoring that lathe together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Restoration And Metal Lathe Controller Boards:Sure! Here are some common questions about lathe restoration and controller boards for metal lathes. 1. **What is a lathe?** A lathe is a machine that spins metal or wood to shape it. 2. **Why restore a lathe?** You can make an old lathe work better. Restoring it can save money and let you use it for projects. 3. **How do you restore a lathe?** First, clean it. Then, fix or replace broken parts. Finally, test it to make sure it works well. 4. **What is a controller board?** A controller board is like a computer for the lathe. It helps you control how fast the lathe spins and what it does. 5. **Why upgrade the controller board?** Upgrading can make the lathe easier to use. It can also give you more control over your work.

Of course! Please provide the question you want me to answer.

What Are The Common Signs Of A Failing Controller Board In A Metal Lathe, And How Can They Be Diagnosed?If the controller board in a metal lathe is failing, you might notice some signs. The lathe may become slow or stop working altogether. The lights on the board could flicker or stay off. You can diagnose the problem by checking for loose wires or burnt parts. A simple reset may help, but if it doesn’t work, you might need a professional to look at it.

What Types Of Controller Boards Are Available For Retrofitting Older Metal Lathes, And What Factors Should Be Considered When Choosing One?You can find different types of controller boards for older metal lathes. Some popular options are Arduino, Raspberry Pi, and GeckoDrive. When choosing one, think about how easy it is to install. You should also consider how much money you want to spend. Finally, check if it works with your lathe and if you can get support if you need it.

How Can I Safely Disassemble And Inspect A Vintage Lathe’S Controller Board For Restoration Purposes?To safely take apart the controller board, first, unplug the lathe from the power source. Next, use a screwdriver to carefully remove the screws holding the cover in place. Be gentle so you don’t break anything. Once you open it, look for dust or broken parts. If you see anything wrong, take a picture before fixing. Remember to put everything back together safely!

What Are The Best Practices For Cleaning And Repairing Electronic Components On A Lathe Controller Board?To clean a lathe controller board, start by turning off the power and unplugging it. Use a soft brush to remove dust and dirt gently. For sticky spots, use a little rubbing alcohol on a cloth. Be careful not to get the alcohol on the circuits. If parts are broken, find the same ones online and replace them carefully. Always check that everything is dry before plugging it back in.

How Can I Integrate Modern Cnc Control Features Into An Older Metal Lathe While Restoring Its Original Functionality?You can add a modern CNC (Computer Numerical Control) system to your old metal lathe. First, detach the old controls and keep the parts you need. Then, buy a CNC kit that fits your lathe. Follow the instructions to connect the new controls to the machine. Finally, test it out to make sure it works well and still does what it used to.