Have you ever looked at a rusty old lathe and wondered if it could work again? Many people feel this way when they see a forgotten metal lathe. They dream of bringing it back to life. Restoring a lathe can be exciting and rewarding.

One important part of this process is the drive system. This system is what makes the lathe turn and cut each piece of metal. Without a good drive system, the lathe just won’t work. But how do you fix it?

Imagine finding an old lathe in a dusty garage. At first, it looks useless. But after some cleaning and repairs, you might discover a true treasure. Each turn of the restored metal lathe reveals hidden potential. You can create amazing projects with it!

In this article, we will dive into lathe restoration and the drive system. You will learn tips to help you get started on this fun journey. Are you ready to roll up your sleeves and bring that lathe back to life?

Lathe Restoration: Reviving Your Metal Lathe Drive System

Lathe Restoration Metal Lathe Drive System

Restoring a metal lathe can be a rewarding adventure. A reliable drive system is essential for smooth operation. Understanding how gears, motors, and belts interact ensures your lathe runs effectively. Have you ever wondered why some lathes produce a better finish? It often comes down to how well the drive system is maintained. With a little patience and know-how, you can breathe new life into an old machine, enhancing both performance and precision.Understanding Lathe Drive Systems

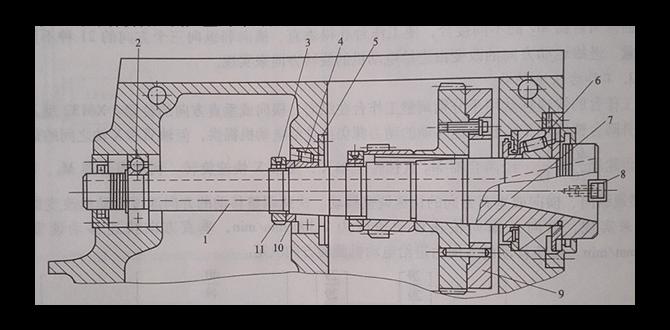

Types of metal lathe drive systems: traditional vs. modern. Key components and their functions in a drive system.Drive systems for metal lathes come in two flavors: traditional and modern. Traditional systems use belts and gears. They can be a little noisy and require more maintenance—kind of like a car from the ’80s! Modern systems often use direct drives and variable speed motors, making them quieter and easier to control. Key parts of a drive system include the motor, pulleys, and gearboxes. Each piece plays a role, ensuring smooth and precise operation. Without them, it’s like trying to bake a cake without an oven!

| Type | Key Components | Advantages |

|---|---|---|

| Traditional | Pulleys, Gears | Familiar, Easy to repair |

| Modern | Direct Motor, Controllers | Quiet, Efficient, Flexible |

In short, understanding these drive systems can lead to smoother operation and sweet success when restoring your lathe!

Assessing Your Lathe Condition

Signs that your drive system needs restoration. Tools required for inspection and evaluation.Check your lathe carefully. Look for signs that tell you it needs help. If you hear strange noises or notice rough movements, it might be time for restoration. The drive system can wear down over time. Be aware of these signs:

- Unusual sounds during operation

- Slipping gears

- Inconsistent speed

For inspection, gather some simple tools:

- Screwdriver

- Wrench

- Flashlight

These will help you evaluate its condition. A good check-up will keep your lathe running smoothly.

How do I know if my lathe needs repair?

To see if your lathe needs repair, check for odd noises and jerky movements. If you notice these signs, it’s best to look into a restoration.

Gathering Materials for Restoration

Essential tools and supplies for lathe restoration. Sourcing replacement parts for drive systems.Restoring a metal lathe requires the right tools and materials. Start by gathering essential items like:

- Wrenches and pliers

- Measuring tools

- Sandpaper and oil

- Paint for touch-ups

- Belt systems

- Bearings

- Motors

Where can I find parts for my drive system?

You can find parts at local hardware stores or online. Websites like eBay or specialized tool shops offer many options. Always compare prices to get the best deals!

Step-by-Step Drive System Restoration Process

Disassembling the lathe drive system safely. Cleaning and repairing components.Start by carefully taking apart the lathe drive system. Use a screwdriver, but avoid any superhero moves that might bend or break parts. Once fully disassembled, it’s time for a good cleaning. Dust bunnies and grease can hide everywhere! Give each component a scrub down, using gentle cleaners. Replace any worn-out parts as needed. Remember, a metal lathe is like a cake; it can’t be tasty if the ingredients are bad! Try to keep everything organized, maybe even using a table to make sure nothing gets lost along the way.

| Step | Action |

|---|---|

| 1 | Disassemble with care |

| 2 | Clean each part |

| 3 | Repair or replace broken pieces |

Upgrading vs. Restoring Drive Systems

Pros and cons of upgrading older systems. Factors to consider when choosing to upgrade.Choosing between upgrading and restoring a drive system has its ups and downs. Upgrading can bring new features and efficiency. However, it may cost more and require new parts. Restoration can keep your system original and cheaper, but it might lack modern advantages. Here are some factors to consider:

- Budget: How much can you spend?

- Usage: Will you use it often?

- Condition: How worn is your old system?

Understanding these points can help you make the right choice!

What are the benefits of upgrading drive systems?

Benefits of upgrading include increased efficiency and advanced technology. Upgrading can enhance performance and save time on tasks.

Preventive Maintenance Tips for Longevity

Routine checks and maintenance best practices. Lubrication techniques and their importance.Regular checks keep your lathe running smoothly. Make sure to look for any worn parts or noises. Simple actions can help prevent bigger problems later. Lubrication plays a key role in your machine’s health. Greasing the right parts reduces friction and wear. This helps your lathe last longer. Here are a few tips:

- Check belts and pulleys for wear every month.

- Clean chips and dust after each use.

- Oil moving parts once a week.

Staying on top of these tasks can save time and money. Remember, a little care goes a long way!

What is the best way to lubricate a lathe?

The best way to lubricate a lathe is to use the correct oil for each part. Regularly apply oil to gears, bearings, and slides to keep everything running smoothly.

What happens if you don’t maintain a lathe?

If you neglect maintenance, your lathe can wear out faster. This might lead to costly repairs or even a complete breakdown.

Real-Life Case Studies of Successful Restorations

Examples of various lathe restoration projects. Lessons learned and common pitfalls to avoid.Many hobbyists have had great success restoring metal lathes. For example, one individual refurbished a rusted lathe and revived it to its former glory. Another person turned a worn-out machine into a reliable tool. These projects taught valuable lessons.

- Avoid rushing through disassembly.

- Keep organized notes and photos of parts.

- Test the drive system regularly during restoration.

Success rates are high among those who plan carefully. With a clear approach, anyone can enjoy a triumphant lathe restoration journey.

What are common mistakes in lathe restoration?

Common mistakes include rushing the process, neglecting documentation, and skipping maintenance checks. These pitfalls can lead to more problems down the line.

Resources and Communities for Lathe Restoration Enthusiasts

Online forums and groups for knowledge sharing. Books and guides on lathe restoration techniques.Joining a community of lathe restoration fans can make your journey much easier and a lot more fun! Online forums, like Reddit and specialized Facebook groups, are treasure troves of knowledge. Members share tips, tricks, and, yes, even some funny fails. Books and guides also offer great insights on techniques, often including illustrations that make things clearer. Remember, even wizards need a good spellbook!

| Resource | Description |

|---|---|

| Online Forums | Platforms like Reddit where you can share and learn. |

| Books & Guides | Informative texts with techniques and helpful tips. |

With the right resources, you can turn your rusty old lathe into the star of the workshop! Don’t forget, the more you learn, the less you’ll make those “oopsies.”

Conclusion

In summary, restoring a metal lathe’s drive system can be rewarding. We learned to check gears, belts, and motors for issues. You can clean, lubricate, and adjust parts for better performance. If you’re interested, consider researching more about maintenance tips and tools. With practice, you’ll enjoy using your lathe like new!FAQs

What Are The Key Components Of A Metal Lathe Drive System That Should Be Inspected During Restoration?When restoring a metal lathe, you should check a few important parts. First, look at the motor. Make sure it runs smoothly and doesn’t make strange noises. Next, inspect the belts. They should be tight and not worn out. Also, check the gears for any damage or rust. Finally, look at the bearings for smooth movement.

How Do You Determine Whether To Repair Or Replace The Drive Components In A Metal Lathe During Restoration?To decide if you should repair or replace drive parts in a metal lathe, first look closely at them. If they are worn out or broken, we check how serious the damage is. If the parts can be fixed easily and cheaply, we repair them. If they are too damaged or very old, buying new parts is better. Always think about cost and how long each option will last.

What Techniques Can Be Used To Restore Worn Gears And Belts In A Lathe Drive System?You can restore worn gears and belts in a lathe drive system with a few techniques. First, you can clean them to remove dirt. Next, you can tighten any loose belts so they work better. If gears are damaged, you can replace them with new ones. Sometimes, you can also use a special lube to help them run smoothly again.

How Does The Lubrication Of The Drive System Affect The Performance And Longevity Of A Restored Metal Lathe?Lubrication helps keep the drive system of a metal lathe running smoothly. When you add oil, it reduces friction, which means the parts won’t wear out as fast. This makes the lathe work better and last longer. If you forget to lubricate, the parts can get hot and damaged. So, always keep it oiled for the best performance!

What Modern Upgrades Can Be Integrated Into A Vintage Lathe Drive System To Improve Performance While Maintaining Its Historical Integrity?You can add a modern motor to make the lathe run more smoothly. Using a variable speed controller lets you change speeds easily. You might also switch to better bearings for less noise and wear. Finally, updating the wiring can make everything safer without changing much of its old look.