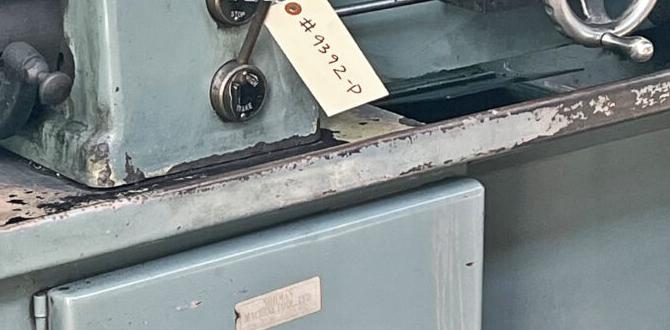

Have you ever wondered how old machines can be brought back to life? Lathe restoration can be a thrilling journey, especially when it comes to metal lathes. These powerful tools shape and cut metal, and restoring them can feel like bringing a piece of history back into action.

Imagine finding a rusty lathe in a garage. It looks broken and forgotten. But with some effort, you can make it work like new. What if I told you that adding a power feed can enhance your lathe’s skills? This upgrade lets you machine metal with ease and precision.

In our article, we will explore the exciting world of lathe restoration. We will share tips to help you rejuvenate your metal lathe. You will learn why adding a power feed can transform your projects. Get ready to discover how you can turn an old tool into a reliable companion in your workshop!

Lathe Restoration: Enhancing Metal Lathe Power Feed Efficiency Lathe Restoration Is A Critical Process For Anyone Looking To Revitalize Their Metal Lathe, Particularly When It Comes To Improving Its Power Feed Capabilities. A Well-Restored Lathe Can Dramatically Increase Productivity And Precision, Making It A Worthwhile Investment For Hobbyists And Professionals Alike. In This Article, We Will Explore The Steps Involved In Lathe Restoration, Focusing On Key Components Such As The Power Feed Mechanism. Understanding Lathe Restoration Lathe Restoration Involves A Detailed Process Of Cleaning, Repairing, And Upgrading Various Parts Of The Lathe. This Not Only Extends The Life Of The Equipment But Also Enhances Its Functionality. Key Areas To Focus On During Restoration Include The Bed, Carriage, Cross Slide, And Power Feed Components. Importance Of Power Feed In Metal Lathes The Power Feed Mechanism Allows For Automatic Movement Of The Carriage Along The Bed, Enabling More Consistent And Efficient Cutting. A Malfunctioning Power Feed Can Lead To Inaccuracies And Increased Manual Labor, Making It Essential To Ensure That This Component Operates Smoothly During Lathe Restoration. Steps For Lathe Restoration Focused On Power Feed 1. **Assessment**: Begin By Assessing The Condition Of The Lathe And Specifically The Power Feed Components. Look For Wear, Damage, Or Misalignment. 2. **Cleaning**: Thoroughly Clean All Components To Remove Oil, Dirt, And Debris. This Ensures A Better Look At Any Damages And Prepares The Parts For Repair. 3. **Repair Or Replace Parts**: Check The Gears, Belts, And Electronics Associated With The Power Feed. Repair Any Issues Or Replace Parts That Are Beyond Repair. 4. **Lubrication**: Apply Appropriate Lubricants To Moving Parts To Prevent Wear And Ensure Smooth Operation. 5. **Testing**: After Restoration, Conduct A Series Of Tests To Ensure That The Power Feed Operates Correctly At Various Speeds And Settings. Conclusion Lathe Restoration Can Transform An Old Metal Lathe Into A Reliable Machine That Enhances Productivity, Especially When The Power Feed Is In Optimal Condition. By Following These Steps And Focusing On The Necessary Components, You Can Ensure That Your Lathe Delivers Superior Performance For Years To Come.

Lathe Restoration: Metal Lathe Power Feed

Restoring a metal lathe is an exciting project. Have you ever wondered how a power feed works? It adds smooth movement for your cutting tasks. First, assess the machine’s condition and clean it thoroughly. Next, check gears and belts for wear. You might even discover some hidden rust! With a bit of patience, you can transform an old lathe into a powerful tool. Imagine the possibilities of creating precise parts for your projects! Happy restoring!Understanding Lathe Restoration

Importance of restoring a lathe for improved performance. Key components of a metal lathe that may require restoration.Restoring a lathe is important. It improves its performance, making it work better and longer. A well-restored lathe can help create more precise parts. Key parts that may need fixing include:

- Bed: This keeps the lathe stable.

- Headstock: It holds the spindle and drives the machine.

- Tailstock: This helps support long pieces of metal.

- Power Feed: This controls how fast the lathe moves.

Regular maintenance keeps these parts in shape and saves money on replacements.

What does a lathe need for restoration?

Lathe restoration may need some parts. Fixing the bed and headstock is vital. These parts are key for smooth operation and accuracy.

Assessing the Condition of Your Lathe

Signs that your lathe needs restoration. Tools needed for a thorough inspection.Look for signs that show your lathe needs help. Check for rust, cracks, or strange noises. A lathe that struggles to turn may need attention. You’ll want the right tools for a closer look:

- Flashlight

- Wrench set

- Screwdriver

- Digital caliper

These tools help you see any problems clearly. Regular checks can keep your lathe in top shape.

What are the signs that my lathe needs restoration?

Some common signs include excessive wear, vibration during operations, and slow movement. Regular checks can save you time and money!

Disassembling the Lathe

Steps to safely disassemble the lathe. Documenting parts for easier reassembly.To safely disassemble the lathe, follow these steps:

- First, turn off the power and unplug the lathe.

- Remove any tools or attachments attached to the lathe.

- Carefully take off parts starting with the larger pieces.

- Place small parts in labeled containers for easy finding later.

Documenting the disassembly helps a lot. Take pictures with a phone or notepad. Write down where each part goes. You will thank yourself when it’s time to put everything back together!

Why should you document the disassembly process?

Documenting the process helps ensure that each part is reassembled correctly. This prevents mistakes and saves time.

Cleaning and Refurbishing Components

Best practices for cleaning metal lathe parts. Techniques for refurbishing worn components.Keeping your metal lathe clean ensures it works well and lasts longer. You can follow these tips for cleaning and restoring its parts:

- Use soft brushes to remove dust and chips from difficult areas.

- Soak parts in a mild cleaner for stubborn grime.

- Inspect bearings for wear and replace if needed.

- Polish surfaces to restore shine and reduce rust.

Regular cleaning and careful refurbishing can make old lathes feel like new. Remember, a clean lathe makes for better projects!

What are the best cleaning products for a metal lathe?

The best products are mild soap and degreaser. These will clean without harming your lathe.

How can worn components be refurbished?

To refurbish worn parts, you can replace them or re-machine the surface to restore fit.

Upgrading or Repairing the Power Feed

Common issues with power feed systems. How to upgrade for enhanced performance.Power feed systems can sometimes feel like they have a mind of their own. Common problems include slipping and uneven speeds. These issues can cause frustration similar to a cat refusing to cooperate during bath time! Upgrading your system can give you a smoother experience and improve performance. Consider replacing worn gears or upgrading the motor for a real boost. A happy lathe means happy projects!

| Common Issues | Solutions |

|---|---|

| Slipping feed | Check and replace worn gears |

| Uneven speeds | Upgrade the motor |

| Noise | Lubricate all moving parts |

Reassembling the Lathe

Tips for efficient reassembly. Ensuring alignment and calibration of components.Reassembling your lathe can feel like puzzle time, but without the missing pieces! To make it easier, start with a clean workspace and organize parts. Use labeled bags for screws and bits. Don’t forget to check alignment—it’s like making sure your shoes are tied before running! When tightening bolts, go in a star pattern to keep everything snug. Lastly, calibrate carefully to avoid turning your lathe into a rollercoaster ride!

| Tips | Description |

|---|---|

| Clean Workspace | Keep it tidy to avoid losing parts. |

| Labeled Bags | Sort screws and components by type. |

| Check Alignment | Ensure everything lines up before moving on. |

| Tighten in Star Pattern | Avoid uneven pressure on components. |

Follow these steps closely, and your lathe will be ready to roll—just like a well-tuned drum! Remember, patience is key; even a wizard needs time to conjure magic.

Testing Your Restored Lathe

Procedures for testing lathe operation postrestoration. Troubleshooting common issues that may arise.After restoring your lathe, it’s time to test it. Start by checking all the parts to make sure they are tight. Run the lathe at a slow speed and listen for any strange sounds. If you hear anything unusual, turn it off right away.

Next, try cutting a small piece of metal. This step helps you see how well your lathe works. If it behaves strangely or cuts poorly, check for these issues:

- Did you properly align the parts?

- Are the gears lubricated?

- Is the feed rate set correctly?

Fix these common problems to enjoy a smooth operation.

How can you identify problems in your lathe?

Watch for vibrations, unusual noises, or uneven cuts. If you notice these, troubleshooting your lathe can save time and effort. Fix the problems before they become bigger issues.

Maintaining Your Restored Lathe

Routine maintenance practices for longevity. Tips for keeping the power feed system in top condition.Keeping your lathe in great shape is important. Regularly check your machine to make it last longer. Here are a few easy tips:

- Clean it often to remove dust and grime.

- Lubricate moving parts to avoid rust and wear.

- Inspect electric connections and switches regularly.

- Tighten loose parts to keep everything secure.

Your power feed system needs care too. Keep it running smoothly by following these points:

- Check for signs of wear in gears and belts.

- Adjust feed rates carefully for better control.

- Replace worn-out parts promptly to avoid bigger problems.

How often should I maintain my lathe?

It’s best to check your lathe weekly. This helps catch issues early and keeps it working well.

Regular maintenance not only saves you money but also gives you peace of mind. Let your lathe serve you better with these simple steps!

Conclusion

In conclusion, restoring a metal lathe with a power feed can be rewarding. It improves your machining skills and increases accuracy. We learned about cleaning, repairing, and upgrading parts. If you love working with tools, consider taking on a restoration project. Check online guides for more tips and connect with other enthusiasts to share your journey.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Restoration, Specifically Focusing On Metal Lathe Power Feed:Sure! Here are five questions about metal lathe power feed and their answers: 1. **What is a power feed?** A power feed helps move the tool and material automatically. It makes cutting easier and faster. 2. **Why would you restore a power feed?** Restoring a power feed makes it work better. It can help you create smoother cuts and finish projects faster. 3. **What tools do you need for restoration?** You need some simple tools like wrenches, screwdrivers, and maybe some oil for lubrication. They help fix or clean the parts. 4. **How do you know if the power feed is broken?** If it doesn’t move or makes strange noises, it might be broken. You can check the wires or gears. 5. **Can I restore a power feed myself?** Yes, you can! With some time and care, you can follow guides and do it yourself.

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.

What Are The Most Common Issues Encountered When Restoring The Power Feed Mechanism Of A Metal Lathe?When fixing the power feed mechanism of a metal lathe, we often see a few common problems. First, there might be worn-out parts that need replacing. Second, dirt and rust can get in the way, making it hard for the machine to move. Third, the gears may not be aligned correctly. Finally, we might have loose connections that need tightening.

How Can I Determine If The Power Feed System On My Metal Lathe Needs Refurbishment Or Replacement?To check if your metal lathe’s power feed system needs fixing or replacement, look for strange noises when it runs. If it works slower than before or stops suddenly, that’s a sign too. You should also check for any broken parts or wires. If you find any issues, consider getting help or replacing parts to make it work better.

What Tools And Materials Are Necessary For Restoring The Power Feed On A Vintage Metal Lathe?To restore the power feed on a vintage metal lathe, you need a few tools and materials. First, grab a screwdriver to remove screws. You will also need pliers to grip or bend small parts. Don’t forget a wrench for tightening bolts. Finally, have some fresh electrical wires and connectors ready to fix the power parts.

How Do I Troubleshoot And Repair Electrical Components Of A Power Feed System That Is Malfunctioning?To fix a broken power feed system, you should first turn off the power to stay safe. Next, check the wires for any visible damage, like breaks or burns. Then, look for loose connections and tighten them if needed. If something looks broken, you may need to replace that part. Finally, turn the power back on carefully to see if it works again.

What Are Some Best Practices For Lubricating And Maintaining The Power Feed Components Of A Metal Lathe After Restoration?To keep your metal lathe running smoothly, you should regularly check and clean the power feed parts. Use a good quality oil to lubricate these parts, making sure you cover all moving areas. Wipe away any extra oil to prevent dirt from sticking. It’s also important to look for any signs of wear or damage. Finally, remember to follow the manufacturer’s instructions for the best care!