Have you ever wondered how metal lathes work? They are amazing machines that help create parts for all sorts of projects. But what happens when your lathe needs some care?

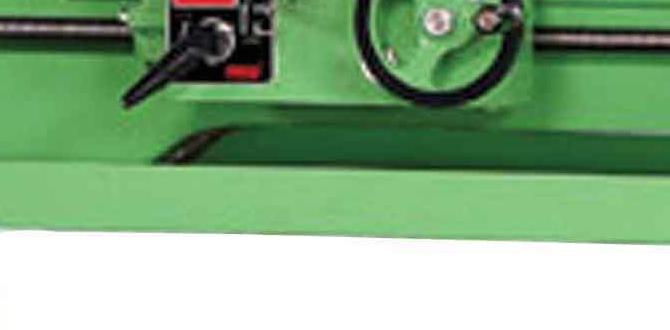

Lathe restoration is a fun way to bring old machines back to life. One popular upgrade is adding a quick change tool post. This simple tool can make your lathe easier to use. Imagine switching tools without wasting time!

Many hobbyists love restoring their metal lathes. It feels rewarding to see an old machine shine again. Did you know that some lathes can last for decades? With proper care, they can serve you for a lifetime.

In this article, we will explore how to restore your lathe and add that handy quick change tool post. Get ready for a journey that combines creativity and practicality!

Lathe Restoration: Upgrading Your Metal Lathe With Quick Change Tool Post

Lathe Restoration: Quick Change Tool Post for Metal Lathes

Restoring a metal lathe can feel like a big task. But using a quick change tool post can make it easier! This handy tool lets you swap cutting tools fast. That means less time changing tools and more time creating. A quick change tool post improves accuracy too. Did you know it can save you hours in the workshop? Learn how lathes work and how restoring them with the right tools can spark your creativity!Understanding Lathe Restoration

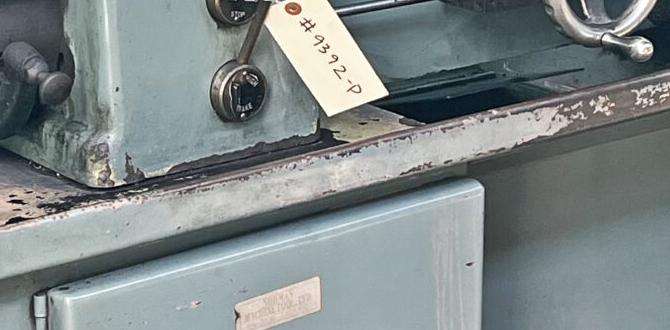

Importance of restoring metal lathes. Common issues faced in old lathes.Restoring metal lathes is like giving an old friend a makeover. It brings them back to life! Old lathes can face issues like rust, worn-out parts, and stubborn screws. These problems can make your projects slow and frustrating. But, with some TLC, you can turn a sad, rusty machine into a happy working tool. Trust me, your projects will thank you! Plus, it’s a fun challenge. You can even invite your buddies over for a ‘Lathe Restoration Party’—snacks included, of course!

| Common Issues | Solutions |

|---|---|

| Rust | Use a rust remover or sand it away. |

| Worn Parts | Replace them with new ones or upgrade. |

| Stuck Screws | Apply lubricant, then try again. |

What is a Quick Change Tool Post?

Definition and functionality of a quick change tool post. Advantages over traditional tool posts.A quick change tool post is a special device for metal lathes. It allows the user to swap tools quickly without needing many adjustments. This tool saves time and helps make work easier.

Compared to traditional tool posts, it offers many benefits:

- Faster tool changes.

- Better accuracy with less effort.

- More tools can be stored easily.

These advantages make it a favorite among machinists. Using a quick change tool post lets you focus on your project instead of wasting time on setup.

What are the benefits of a quick change tool post?

Benefits include quicker changes, improved accuracy, and easier tool management. These features help you work more efficiently and achieve better results.

Preparing for Lathe Restoration

Essential tools and materials for restoration. Safety precautions to consider.Restoring a lathe can be fun and rewarding. To start, gather essential tools and materials. You will need:

- Wrenches and screwdrivers

- Safety glasses

- Sandpaper and polish

- Grease and oil

- Paint or rust remover

Safety is very important. Always wear safety glasses. Make sure your workspace is tidy. Keep tools within reach and avoid distractions.

What tools do I need for lathe restoration?

Essential tools for lathe restoration include wrenches, screwdrivers, and safety gear. Make sure to have grease and paint ready for a smooth finish!

Steps to Restore a Metal Lathe

Detailed breakdown of the restoration process. Cleaning and inspection techniques.Restoring a metal lathe can be fun and rewarding. Start by cleaning the machine. Use a soft cloth and a mild cleaner to remove dirt and grease. Inspect all the parts carefully. Look for rust, wear, or damage. Replace what is broken. Here’s a quick checklist for your restoration:

- Clean all surfaces.

- Check for rust and corrosion.

- Inspect gears and belts.

- Test all moving parts.

This process makes your lathe work better and last longer.

How do I clean and inspect my metal lathe?

To clean and inspect your metal lathe, wipe it down with a soft cloth. Check for any rust or broken parts. This helps keep it in good working shape.

Installing a Quick Change Tool Post

Stepbystep installation guide. Compatibility considerations with different lathe models.Installing a quick change tool post can feel like magic. First, gather your tools—don’t worry, it’s not a scavenger hunt! Next, remove the old tool holder from your lathe. Check the fit of the new tool post; it should snugly sit on your lathe’s saddle. Adjust it until it’s just right. Then, tighten the screws with glee! And don’t forget to check if your lathe model is compatible. Some might get cranky if you force them to fit. Here’s a quick compatibility chart:

| Lathe Model | Compatible Tool Post |

|---|---|

| Grizzly G0602 | Quick Change Tool Post A |

| Jet JWL-1442 | Quick Change Tool Post B |

| South Bend SB1002 | Quick Change Tool Post C |

Follow these steps, and you’re ready to turn metal into art! So, don’t stress; even a squirrel can do it with a little practice!

Maintaining Your Restored Lathe

Regular maintenance tips for longevity. Troubleshooting common problems.To keep your lathe in great shape, regular care is key. Check the oil levels and clean the parts often. This helps avoid rust and keeps everything running smoothly. Here are some quick tips for maintenance:

- Keep it clean from chips and dust.

- Inspect belts for wear and tear.

- Lubricate moving parts regularly.

If you notice issues, troubleshoot them right away. Listen for strange noises or look for parts that stop moving. Fixing small problems quickly can save big repairs later.

What are common issues with a lathe?

Common problems include strange noises, slippage during use, and vibrations. These issues often signal worn parts or misalignment.Frequently Asked Questions about Lathe Restoration

Common queries regarding metal lathes and tool posts. Expert answers to enhance understanding.Many people wonder about metal lathes and tool posts. Here are some common questions and simple answers to help out. For example, how often should you clean your lathe? The answer is **after every use!** Dust and chips, like mischievous gremlins, can cause big problems. Another question is about changing the tool post. The quick change tool post makes swapping tools easy: **it’s as quick as a cheetah on roller skates!** Lastly, some folks ask if lathe restoration is worth it. Absolutely! Restoring can save you money and give you a tool that runs smoothly.

| Question | Answer |

|---|---|

| How often should I clean my lathe? | After every use! |

| What’s the benefit of a quick change tool post? | It makes swapping tools easy! |

| Is lathe restoration worth it? | Yes, it saves money and improves performance! |

Conclusion

In conclusion, restoring a metal lathe with a quick change tool post can improve your projects. It allows for faster and easier tool changes. You can enhance accuracy and efficiency in your work. If you’re interested, consider researching tutorials online or visiting a local workshop. Every restoration project helps you learn and grow as a maker. Happy crafting!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Restoration, Specifically Focusing On Metal Lathes And Quick Change Tool Posts:Restoring a metal lathe means making an old machine new again. You can clean it, fix broken parts, and paint it. A quick change tool post helps you switch tools easily while working. This saves time and makes the job easier. Let’s dive in and fix up that lathe together!

Sure! Please give me the question you’d like me to answer.

What Are The Key Steps Involved In Restoring A Metal Lathe, And What Specific Challenges Might Arise During The Process?To restore a metal lathe, you start by cleaning it well. Next, check for broken or rusty parts and fix or replace them. You may also need to oil and grease moving parts to keep them running smoothly. Sometimes, finding the right replacement parts can be tricky or expensive. Also, putting everything back together correctly can be hard, so you must pay close attention.

How Does A Quick Change Tool Post Improve The Efficiency And Versatility Of A Metal Lathe In A Workshop Setting?A quick change tool post helps you switch tools fast on a metal lathe. This means you can work on different projects quickly. You don’t waste time changing tools. It lets you make many different shapes and sizes, so your options are endless. This makes your workshop more fun and productive!

What Types Of Materials And Components Should Be Considered When Crafting Or Purchasing A Replacement Quick Change Tool Post For A Vintage Metal Lathe?When making or buying a new quick change tool post for your old metal lathe, think about strong materials like steel or aluminum. These materials will last a long time and hold up well. You’ll also want parts like screws and clamps that fit snugly. Be sure to check if it matches the size of your lathe. This way, you can use it easily and safely!

How Can One Determine Whether A Quick Change Tool Post Is Compatible With An Existing Metal Lathe Model During The Restoration Process?To check if a quick change tool post fits your metal lathe, start by measuring the lathe’s tool post hole size. You can also look up the lathe’s model number online. Compare this information with the tool post’s measurements and specifications. When in doubt, ask a store expert for help. This way, you’ll know if the tool post will work with your lathe.

What Best Practices Should Be Followed For Maintaining And Adjusting A Quick Change Tool Post To Ensure Optimal Performance And Longevity In Metal Lathe Operations?To keep a quick change tool post working well, you should clean it often. Use a soft cloth to remove dust and chips. Check the screws and bolts to make sure they’re tight. Lubricate the moving parts with oil to help them slide easily. Adjust it carefully each time you change tools, so it stays in the right position.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Restoration, Specifically Focusing On Metal Lathes And Quick Change Tool Posts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Restoring a metal lathe means making an old machine new again. You can clean it, fix broken parts, and paint it. A quick change tool post helps you switch tools easily while working. This saves time and makes the job easier. Let’s dive in and fix up that lathe together!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Restoring A Metal Lathe, And What Specific Challenges Might Arise During The Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To restore a metal lathe, you start by cleaning it well. Next, check for broken or rusty parts and fix or replace them. You may also need to oil and grease moving parts to keep them running smoothly. Sometimes, finding the right replacement parts can be tricky or expensive. Also, putting everything back together correctly can be hard, so you must pay close attention.”}},{“@type”: “Question”,”name”: “How Does A Quick Change Tool Post Improve The Efficiency And Versatility Of A Metal Lathe In A Workshop Setting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A quick change tool post helps you switch tools fast on a metal lathe. This means you can work on different projects quickly. You don’t waste time changing tools. It lets you make many different shapes and sizes, so your options are endless. This makes your workshop more fun and productive!”}},{“@type”: “Question”,”name”: “What Types Of Materials And Components Should Be Considered When Crafting Or Purchasing A Replacement Quick Change Tool Post For A Vintage Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making or buying a new quick change tool post for your old metal lathe, think about strong materials like steel or aluminum. These materials will last a long time and hold up well. You’ll also want parts like screws and clamps that fit snugly. Be sure to check if it matches the size of your lathe. This way, you can use it easily and safely!”}},{“@type”: “Question”,”name”: “How Can One Determine Whether A Quick Change Tool Post Is Compatible With An Existing Metal Lathe Model During The Restoration Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if a quick change tool post fits your metal lathe, start by measuring the lathe’s tool post hole size. You can also look up the lathe’s model number online. Compare this information with the tool post’s measurements and specifications. When in doubt, ask a store expert for help. This way, you’ll know if the tool post will work with your lathe.”}},{“@type”: “Question”,”name”: “What Best Practices Should Be Followed For Maintaining And Adjusting A Quick Change Tool Post To Ensure Optimal Performance And Longevity In Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a quick change tool post working well, you should clean it often. Use a soft cloth to remove dust and chips. Check the screws and bolts to make sure they’re tight. Lubricate the moving parts with oil to help them slide easily. Adjust it carefully each time you change tools, so it stays in the right position.”}}]}