The lathe is a powerful and versatile tool used in various industries to shape and cut wood, metal, and plastic. It allows for creation of precise and intricate designs, making it a valuable asset for any workshop. However, with its immense capabilities, the lathe also poses a significant risk to those who operate it.

According to recent statistics, lathe accidents account for many workplace injuries. These incidents result in physical harm and can cause financial losses for businesses. Therefore, it is crucial for individuals working with lathes to be aware of the potential hazards and follow proper safety precautions. We will discuss some essential lathe safety tips and precautions that can prevent accidents and ensure a safe working environment.

What Is A Lathe?

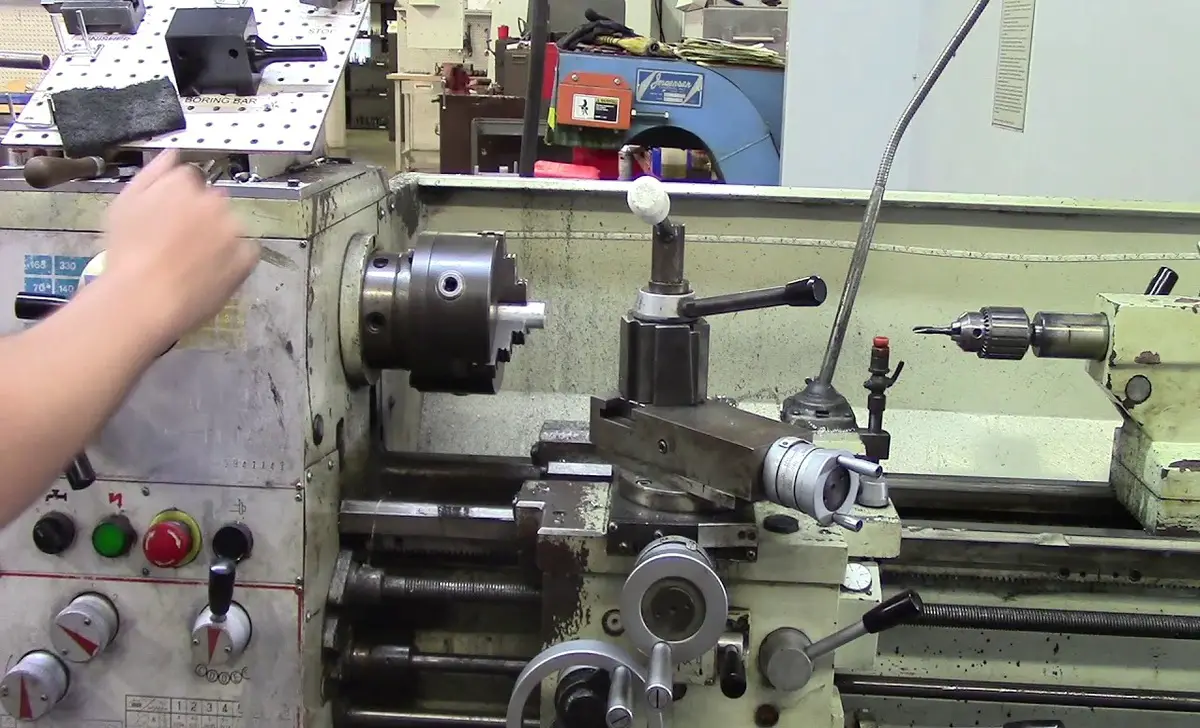

A lathe is a machine tool handy in woodworking, metalworking, and other industries. It comprises a rotating workpiece and a cutting tool that shapes the material into the desired form. The workpiece is mounted on the lathe’s spindle and rotated while the operator controls the cutting tool to remove material and create the desired shape. Lathes are essential in creating various objects with precision and accuracy.

Briefly Explain The Potential Dangers Of The Lathe

The lathe, a powerful machine used for shaping wood, metal, and other materials, poses various potential dangers if not used properly. The fast-spinning cutting tools can cause severe injuries if they come into contact with body parts. Flying debris, such as wood chips or metal fragments, can cause eye or face injuries. It is crucial to wear appropriate protective gear, follow safety procedures, and receive proper training to mitigate the risks associated with operating a lathe.

Lathe Safety Tips And Precautions: General Safety Precautions

Understanding and implementing lathe safety measures is crucial to prevent accidents, injuries, and even fatalities. One of the primary reasons why it is important to know lathe safety tips is to protect the operator from potential harm. A lathe machine operates at high speeds and with various cutting tools, which can easily cause severe injuries if not handled properly.

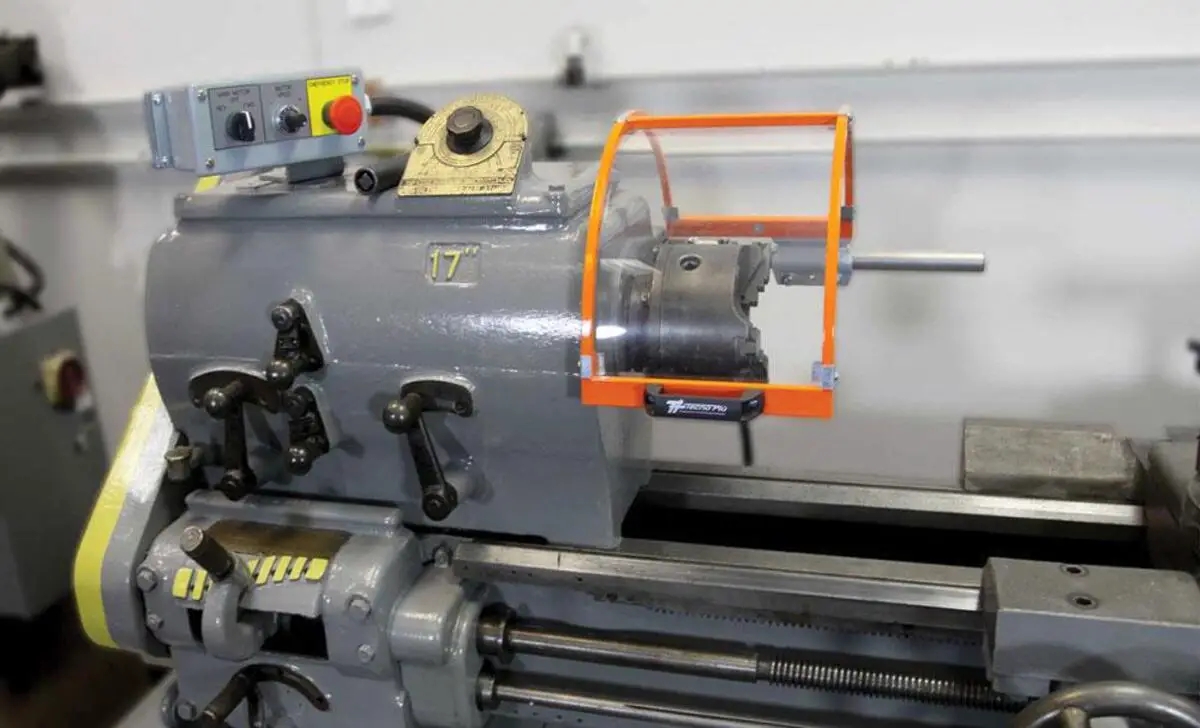

By being aware of safety precautions, such as wearing appropriate personal protective equipment like safety goggles and gloves, operators can significantly reduce the risk of workplace accidents. Here, we discuss lathe safety tips and precautions.

Use Appropriate Personal Protective Equipment (PPE)

When operating a lathe, it is important to prioritize safety using appropriate personal protective equipment (PPE). This includes wearing safety goggles, gloves, and a face shield to protect against flying debris. Additionally, ensure that loose clothing and jewelry are not worn, as they can get caught in the machine. Remember to follow all lathe safety tips and precautions to prevent accidents and maintain a safe working environment.

Keep The Lathe Area Clean And Organized

To ensure a safe and efficient working environment, it is crucial to maintain cleanliness and organization in the lathe area. We can minimize the risk of accidents and injuries by implementing lathe safety tips and precautions, such as wearing appropriate protective gear, inspecting the lathe before use, and following proper operating procedures. Regularly cleaning the lathe area, removing debris, and organizing tools and materials promote safety and improve productivity and overall work quality.

Ensure Proper Lighting And Ventilation

When working with a lathe, it is crucial to prioritize safety by ensuring proper lighting and ventilation in the workspace. Adequate lighting helps to see the workpiece and minimize the risk of accidents or mistakes. Additionally, good ventilation helps to maintain a comfortable and healthy environment by reducing the buildup of dust, fumes, and other potentially harmful particles.

Establish Clear Communication And Emergency Procedures

Establishing clear communication and emergency procedures when operating a lathe is crucial to ensure a safe working environment and minimize the risk of accidents. Effective communication among all personnel enables us to identify and address potential hazards promptly.

Additionally, implementing safety tips and precautions, such as wearing appropriate protective gear and following proper handling techniques, can enhance workplace safety. Regular training sessions and periodic equipment inspections should also be conducted to ensure everyone is well-informed and updated on lathe safety protocols.

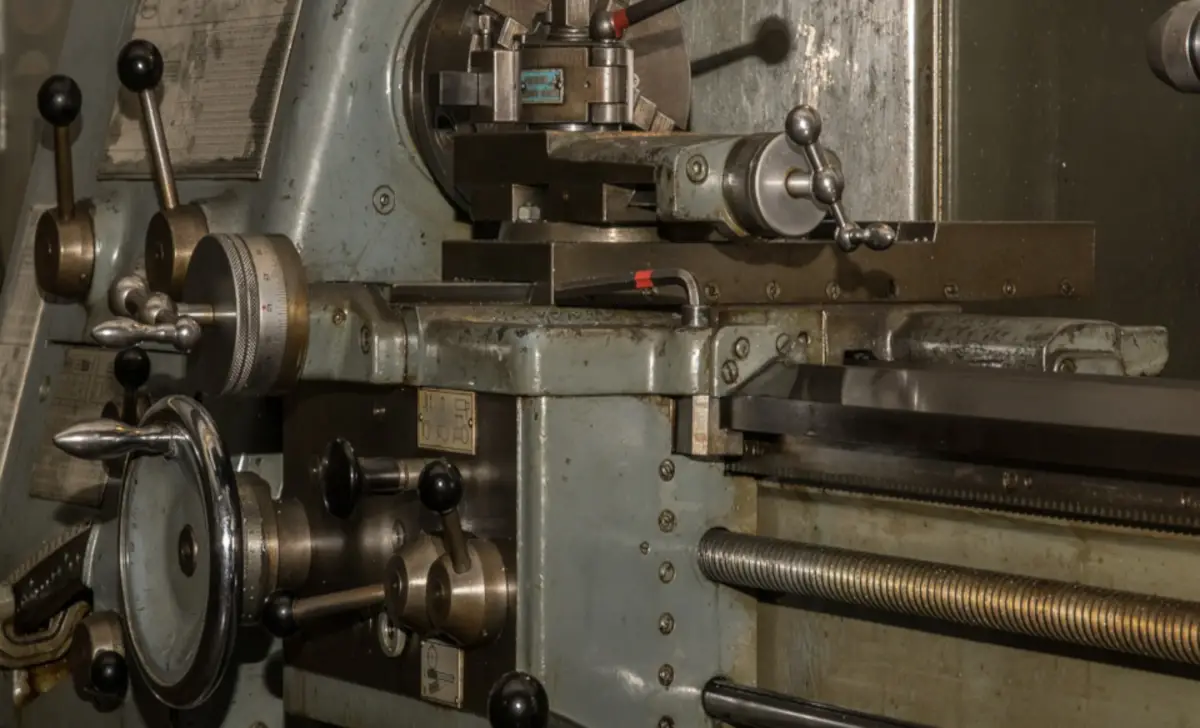

Machine Inspection And Maintenance

In the context of machine operation, prioritizing safety is crucial. Before starting any task, conduct a thorough inspection of the lathe. Look out for any signs of damage or wear. Additionally, ensure you lubricate all moving parts well and check for loose components.

Don’t forget to verify the electrical connections and grounding for proper functioning. Lastly, test the emergency stop buttons and controls to prepare for entanglement hazards. Following these basic lathe safety guidelines and safety precautions, you can ensure a safe working environment.

Safe Operating Practices

When operating a lathe, it is crucial to follow safe operating practices. Begin by thoroughly reading and comprehending the lathe’s manual and instructions. Before starting any work, allow a proper warm-up period and familiarize yourself with the machine. Securely place the workpiece using appropriate devices, such as lathe chucks. Additionally, always use suitable cutting tools and adhere to the recommended lathe speed for proper cutting.

Avoiding Hazards

When operating a lathe, it is crucial to prioritize safety by taking certain precautions. First, ensure that you wear fitted clothing and have tied back your hair to prevent entanglement. Additionally, be cautious of flying chips and always wear approved eye protection.

Stay focused on the task and minimize any distractions that may divert your attention. Lastly, be mindful of keeping your hands and fingers away from any rotating parts to avoid potential accidents. By following these safety tips, you can effectively avoid hazards while working with a lathe.

Tips For Specific Lathe Operations

Regarding specific lathe operations, safety should always be the top priority. For turning, position and secure the tool rest while using backplates properly. When facing, ensure the workpiece is aligned correctly and use sharp tool bits for clean results. When drilling, always run the lathe at appropriate speeds and utilize the peck drilling technique for better control and accuracy. These tips and precautions will help you perform lathe operations safely and efficiently.

Emergency Procedures

Being aware of emergency procedures and safety precautions is crucial when operating a lathe. This includes knowing how to stop the lathe quickly in case of an emergency. Additionally, it is important to know how to handle any cut or injured fingers and seek immediate medical assistance.

It is also essential to report any accidents or near-miss incidents to supervisors to ensure proper measures can be taken to prevent future occurrences. Vigilance and adherence to these guidelines are key to maintaining a safe working environment.

Training And Education

When discussing lathe safety, it is crucial to emphasize receiving proper training and certification. It is crucial to receive thorough instruction on operating the lathe and understanding potential risks. Additionally, continuous learning is essential in staying updated on the latest safety guidelines and precautions. By investing in training and education, individuals can ensure their safety and the safety of others in the workplace.

Conclusion

Taking necessary precautions and following safety guidelines is crucial when operating a lathe. It is also crucial to properly maintain and lubricate the lathe. This will not only ensure smooth operation but also prolong the lifespan of the machine. You can ensure a safe and efficient work environment by implementing the tips and precautions discussed.

Always wear safety gear, keep the work area clean and well-lit, and never hesitate to ask for help or clarification. With these measures in place, you can confidently use a lathe and easily complete your projects. Always prioritize safety in your work practices and stay vigilant, as it is the key to a successful and injury-free experience with the lathe.

FAQ:

1.What Are The Safety Checks For A Lathe?

Some important safety checks for a lathe include ensuring proper installation and grounding, checking for any loose or damaged parts, inspecting the tool rest and tool rest base for stability, and examining the spindle.

2.What Is A Safety Check Sheet?

A safety check sheet is a document used to assess and ensure the safety of a particular environment, equipment, or process. It typically includes a list of specific safety criteria or requirements that must be checked or verified.

3.What Is Machinery Safety?

Machinery safety refers to the measures and precautions taken to ensure the well-being and protection of individuals operating or working around machinery.

4.What Are Lathes Used For?

Lathes are machines used in woodworking, metalworking, and other industries to shape and cut material. They rotate a workpiece on its axis while a cutting tool is applied to shape or remove material, allowing for precise and symmetrical cuts.

5.What Are The Accidents In Lathe Machines?

Accidents in lathe machines can include entanglement of clothing or hair in the rotating parts, getting fingers or hands caught in the machine, flying debris or chips causing eye injuries, and the machine itself becoming unstable and causing a fall or crushing injuries.