Have you ever faced a tough job while using a lathe? One common issue is removing the lathe spindle center. It sounds tricky, doesn’t it? Many people feel overwhelmed when they think about this task. But, don’t worry! You’re in the right place to learn.

In this guide, we will walk you through the steps to remove a lathe spindle center safely and easily. You might think this job requires a lot of tools or special skills. However, with the right method, anyone can do it!

Did you know that the spindle is the heart of the lathe? It helps keep everything turning smoothly. Removing it can open up a world of possibilities for maintenance and upgrades.

So, are you ready to dive in? Let’s explore this helpful removal guide together and make your lathe work better than ever!

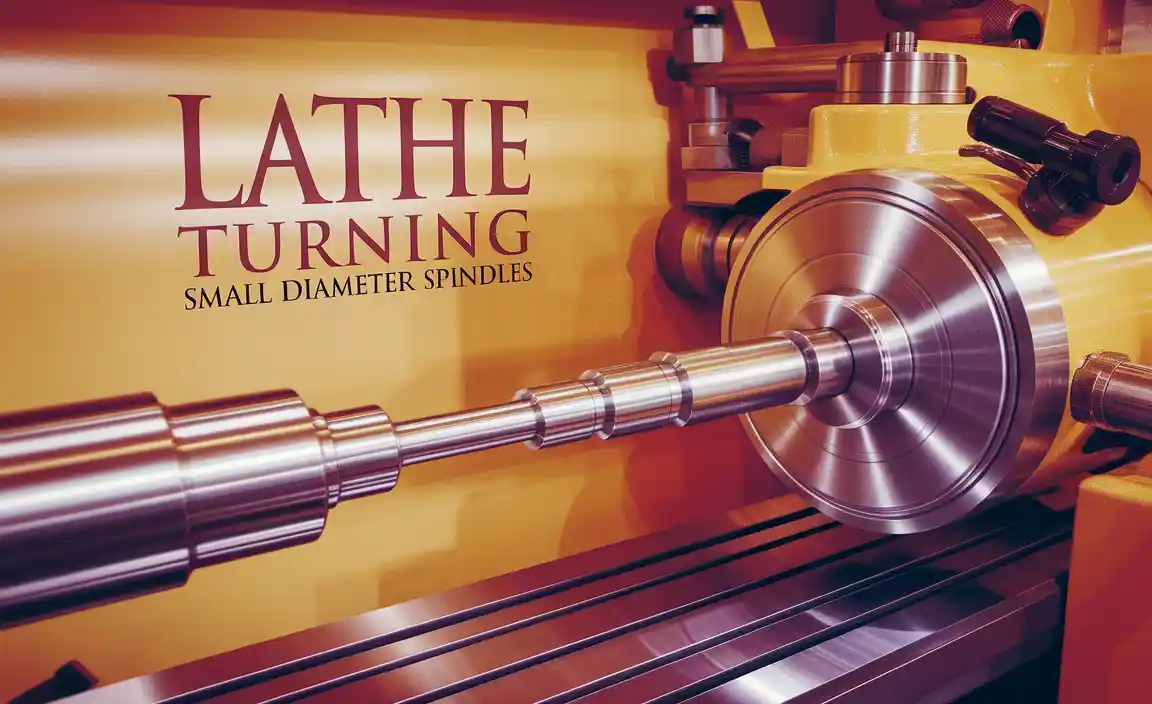

Lathe Spindle Center Removal Guide: Step-By-Step Instructions

Lathe Spindle Center Removal Guide

Removing a lathe spindle center can be tricky, but it doesn’t have to be! First, always make sure your machine is off. Use the right tools for the job, like a puller, to avoid damaging your lathe. Did you know that checking for rust can save you time? Proper maintenance is key. Clear instructions and safety tips help you navigate the process smoothly. With patience, you can easily master this skill and keep your projects running smoothly!Understanding Lathe Spindles

Definition and purpose of a lathe spindle. Importance of spindle maintenance and serviceability.A lathe spindle is a key part of a lathe machine. It holds and spins the workpiece. This spinning allows for shaping and cutting materials like wood or metal. Proper maintenance of the spindle is very important. A well-maintained spindle can lead to better results and longer machine life. Neglecting it might cause wear and bad outcomes. Keeping your spindle in good shape ensures smooth work and accurate results. Regular checks and services can save time and money.

Why is spindle maintenance important?

Maintaining your lathe spindle enhances machine performance. Regular check-ups help avoid serious problems. A routine service can prevent breakdowns and reduce repair costs. Remember, a healthy spindle means a happy lathe!

Key benefits of spindle maintenance:

- Extends the lathe’s lifespan.

- Improves cutting accuracy.

- Reduces unexpected downtime.

- Enhances overall safety during operation.

Tools Required for Spindle Center Removal

List of essential tools and equipment. Safety gear recommendations.Before you begin, it’s important to gather the right tools. Here’s what you need:

- Wrenches and sockets

- Pliers

- Hammer

- Screwdrivers

- Measuring tape

Don’t forget to wear safety gear!

- Safety glasses

- Gloves

- Dust mask

Having the correct tools and safety equipment makes this job easier and safer.

What tools do you need for spindle center removal?

You will need essential tools like wrenches, hammers, and screwdrivers. Also, wear safety glasses and gloves for protection.

Prep Work Before Removal

Steps to ensure the lathe is safe and powered down. Importance of cleaning the workspace and lathe.Before starting any work, make sure the lathe is safe. First, turn off the power switch. Unplug the machine for extra safety. Next, check for any tools or debris around the area. This helps prevent accidents. Cleaning your workspace makes tasks easier and safer. A tidy lathe also performs better.

- Turn off and unplug the lathe.

- Remove any tools or debris from the workspace.

- Wipe down the lathe.

Why is it important to clean the workspace and lathe?

Cleaning helps you work safely and effectively. A clean area reduces risks and keeps the lathe in good shape. It also makes your work easier.

Step-by-Step Spindle Center Removal Process

Detailed procedures for different lathe models. Common mistakes to avoid during removal.Removing the spindle center can be tricky. It often depends on the lathe model you own. Generally, follow these steps:

- First, turn off and unplug the lathe.

- Check your lathe manual for specific instructions.

- Loosen the screws or bolts gently.

- Carefully lift the spindle off.

Avoid these common mistakes:

- Don’t rush. Take your time to avoid damaging parts.

- Don’t use the wrong tools. Always match tools to the screws.

- Don’t skip the manual. Always refer back to it!

What’s the best way to handle stubborn spindles?

Use a gentle tapping method with a soft mallet. This avoids any scratching or damage.

Troubleshooting Common Issues

Identifying problems during spindle center removal. Solutions for stuck or damaged components.Sometimes, removing the spindle center feels like trying to open a stubborn jar of pickles. You twist, you pull, but nothing happens! First, check for any stuck parts. Look for grime or rust that might be holding things back. If the component is feeling a bit too cozy, try some light tapping with a hammer. But be careful! You don’t want to turn your lathe into a drum.

| Problem | Solution |

|---|---|

| Stuck Spindle | Use penetrating oil and let it sit, then tap gently. |

| Damaged Threads | Inspect and replace as needed, or use a thread repair kit. |

If you spot damage, don’t panic! You can often fix it with some patience and the right tools. Remember, every problem has a solution, even if the solution involves just a bit of elbow grease!

Reinstallation of the Spindle Center

Best practices for reinstalling the spindle center. Tips for ensuring proper alignment and functionality.To reinstall the spindle center correctly, follow these best practices. First, clean the surfaces to remove dust and debris. This helps ensure a tight fit. Next, align the spindle perfectly. Small misalignments can cause big problems later. Use a soft hammer to gently tap it into place. Finally, securely fasten it, but avoid over-tightening. Check the alignment once more before starting the machine. Remember, careful work leads to better results!

Common Questions

What tools do I need for spindle reinstallation?You need a soft hammer, cleaning cloths, and proper wrenches for fastening. These tools help ensure your spindle aligns well and functions properly.

- Clean all contact surfaces

- Align the spindle precisely

- Use a soft hammer for adjustments

- Tighten carefully to avoid damage

- Double-check alignment

Maintenance Tips for Lathe Spindles

Routine maintenance practices to prolong spindle life. Signs of wear and when to seek professional help.Taking care of your lathe spindle is like watering a plant. Without it, things get a bit droopy! Regular cleaning can help. You should wipe it down to keep dust at bay and check the oil levels. Also, keep an eye out for any strange noises. If it sounds like a cat stuck in a blender, it’s time to get help! Remember, procrastination on maintenance can lead to bigger problems.

| Tip | Description |

|---|---|

| Routine Cleaning | Wipe the spindle regularly for a smooth operation. |

| Oil Check | Ensure oil levels are optimal to prevent wear. |

| Listen | Strange noises mean it’s time to seek help! |

By following these simple tips, you can keep your spindle in great shape! Extending its life means more productive work and fewer headaches. So, treat it well, and it will be your best buddy in the shop!

Frequently Asked Questions (FAQs)

Common queries regarding spindle removal and maintenance. Expert insights on lathe spindle care.Many people wonder about taking care of their lathe spindle. Below are common questions and helpful answers.

What are the common issues with spindle removal?

Spindle removal problems often involve stuck parts or incorrect tools. Using the right tools is important. Regular cleaning can help prevent these issues.

How can I maintain my lathe spindle?

- Clean it regularly. Dirt can harm the spindle.

- Check for wear and tear. Look for any damage.

- Lubricate moving parts. Use proper oil to keep it smooth.

Any tips for expert spindle care?

Store your lathe in a dry place. This helps prevent rust. Always handle your spindle gently to avoid damage.

Conclusion

In conclusion, removing a lathe spindle center can seem tricky but it’s manageable with the right guide. Always follow safety steps and use the proper tools. We encourage you to practice on spare parts first. For more detailed steps and tips, check out additional resources. With patience and care, you can master this skill!FAQs

Here Are Five Related Questions On The Topic Of Lathe Spindle Center Removal:To remove the spindle center from a lathe, first, we need to unplug the machine for safety. Next, we use a special tool to loosen the center. Make sure to hold everything steady as you turn. After it’s loose, you can pull it out carefully. Always wear safety gear, like goggles, while working!

Sure! Please provide me with the question you would like me to answer.

What Tools Are Necessary For Safely Removing A Lathe Spindle Center?To safely remove a lathe spindle center, you need a few tools. First, get a good pair of gloves to protect your hands. Next, use a soft hammer to tap gently on the spindle. You might also need a wrench to loosen any screws. Finally, have a towel ready to catch any small parts that fall.

What Are The Step-By-Step Instructions For Removing A Spindle Center From A Lathe?To remove a spindle center from a lathe, first, make sure the machine is off and unplugged. Next, check for any clamps or screws holding the center in place. If you find any, use a tool like a wrench to take them off. Then, gently pull the spindle center out. Finally, store it safely until you need it again.

What Are Common Issues Or Challenges Encountered During The Spindle Center Removal Process, And How Can They Be Mitigated?During spindle center removal, you might face a few problems. The spindle can become stuck or rusty. To fix this, we can use some oil to loosen it. Sometimes, tools can break, so make sure to use the right ones and check them first. Having a friend help you can make the job easier, too!

How Can I Determine If My Lathe Spindle Center Needs Replacement Instead Of Just Removal?To see if your lathe spindle center needs replacing, check for wear and damage. Look for cracks or rough spots. If it wobbles when spinning, it might be time for a new one. You can also listen for strange noises; those may mean something is wrong. If you’re unsure, ask someone who knows more about lathes for help.

What Safety Precautions Should I Take When Performing Spindle Center Removal On A Lathe?When you remove the spindle center on a lathe, wear safety goggles to protect your eyes. Tie back long hair and remove loose clothing to avoid getting caught in the machine. Keep your hands clear of moving parts, and always turn off the power before making any changes. Make sure your workspace is clean and well-lit so you can see clearly. It’s important to follow all safety rules to stay safe!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Spindle Center Removal:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To remove the spindle center from a lathe, first, we need to unplug the machine for safety. Next, we use a special tool to loosen the center. Make sure to hold everything steady as you turn. After it’s loose, you can pull it out carefully. Always wear safety gear, like goggles, while working!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Tools Are Necessary For Safely Removing A Lathe Spindle Center?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely remove a lathe spindle center, you need a few tools. First, get a good pair of gloves to protect your hands. Next, use a soft hammer to tap gently on the spindle. You might also need a wrench to loosen any screws. Finally, have a towel ready to catch any small parts that fall.”}},{“@type”: “Question”,”name”: “What Are The Step-By-Step Instructions For Removing A Spindle Center From A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To remove a spindle center from a lathe, first, make sure the machine is off and unplugged. Next, check for any clamps or screws holding the center in place. If you find any, use a tool like a wrench to take them off. Then, gently pull the spindle center out. Finally, store it safely until you need it again.”}},{“@type”: “Question”,”name”: “What Are Common Issues Or Challenges Encountered During The Spindle Center Removal Process, And How Can They Be Mitigated?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “During spindle center removal, you might face a few problems. The spindle can become stuck or rusty. To fix this, we can use some oil to loosen it. Sometimes, tools can break, so make sure to use the right ones and check them first. Having a friend help you can make the job easier, too!”}},{“@type”: “Question”,”name”: “How Can I Determine If My Lathe Spindle Center Needs Replacement Instead Of Just Removal?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To see if your lathe spindle center needs replacing, check for wear and damage. Look for cracks or rough spots. If it wobbles when spinning, it might be time for a new one. You can also listen for strange noises; those may mean something is wrong. If you’re unsure, ask someone who knows more about lathes for help.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should I Take When Performing Spindle Center Removal On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you remove the spindle center on a lathe, wear safety goggles to protect your eyes. Tie back long hair and remove loose clothing to avoid getting caught in the machine. Keep your hands clear of moving parts, and always turn off the power before making any changes. Make sure your workspace is clean and well-lit so you can see clearly. It’s important to follow all safety rules to stay safe!”}}]}