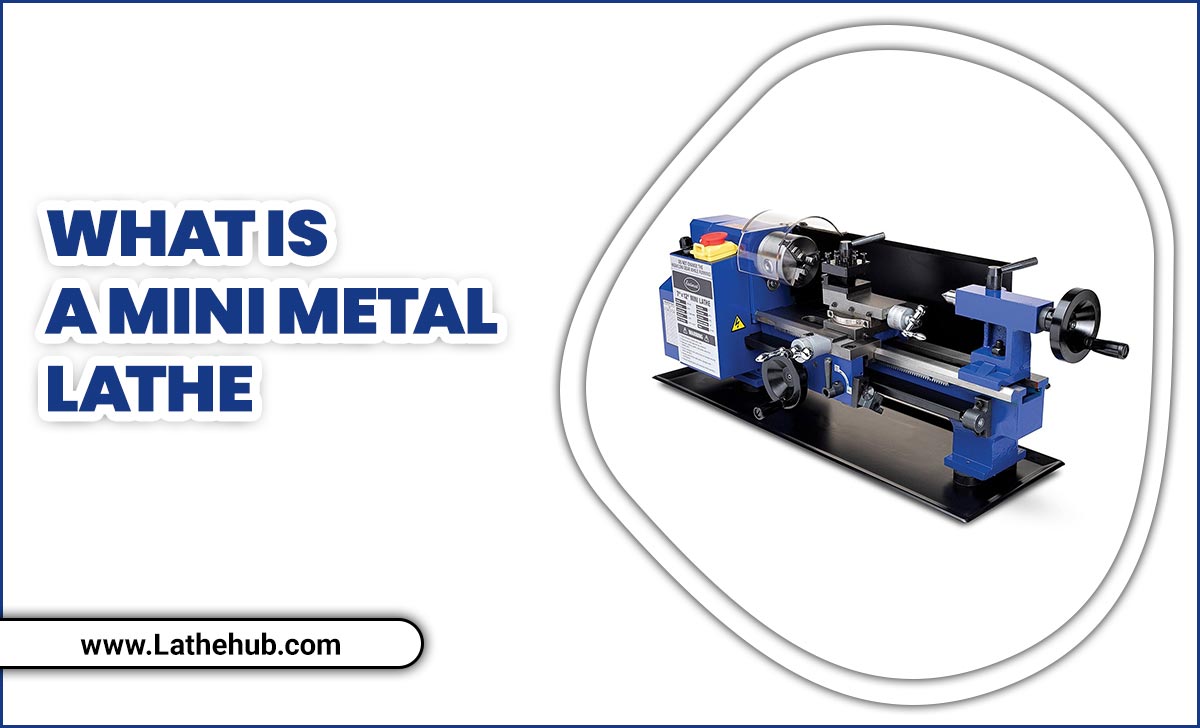

Have you ever wondered how shiny metal parts get that perfect look? The secret lies in the lathe surface finish. With a metal lathe, you can create smooth and polished surfaces. But what if your machine is old and outdated? That’s where a CNC retrofit comes into play!

CNC stands for Computer Numerical Control. This technology helps you improve your metal lathe’s performance. Imagine turning your standard lathe into a smart, efficient tool that delivers exceptional results. It sounds cool, right?

Many people don’t realize how important surface finish is. A great finish can affect the durability and appearance of your work. Plus, it makes machining easier. You might find it surprising, but even tiny bumps can ruin a piece! So, learning about lathe surface finish can really change your projects.

Get ready to dive deeper! In this article, you will discover how a CNC retrofit can transform your metal lathe and why surface finish matters so much. Let’s explore these fascinating topics together!

Achieving Perfect Lathe Surface Finish: Metal Lathe Cnc Retrofit

Lathe Surface Finish: Metal Lathe CNC Retrofit

Are you curious about how to improve your metal lathe’s surface finish? A CNC retrofit can work wonders. It upgrades your traditional lathe into a modern era machine. This means better control and smoother surfaces. Imagine making parts that shine and fit perfectly! A well-finished product not only looks great but also performs better. With the right tools, achieving that perfect finish is easier than ever. Your lathe can be a star in your workshop like never before!Understanding Lathe Surface Finish

Definition and importance of surface finish in machining.. Key parameters that affect surface finish quality..Surface finish is how smooth or rough a piece of metal looks after machining. It’s super important because a better finish means stronger parts and less wear. Think of it as giving your metal a nice haircut—nobody wants a messy style! Key factors like tooling, speed, and feed rate can change the finish quality. If you go too fast, the result might look like a bad drawing by a toddler. Check out this table for quick reference:

| Factor | Effect on Surface Finish |

|---|---|

| Tooling | A sharp tool gives a fine finish! |

| Speed | Too high can leave a rough texture. |

| Feed Rate | Faster feeds create rougher surfaces. |

In summary, good surface finish can mean fewer problems down the road. So, treat your lathe like a good friend—it deserves care and attention!

Factors Influencing Surface Finish on Metal Lathes

Role of tooling and cutting speed in achieving desired finishes.. Impact of material selection on surface quality..Tooling and cutting speed are key factors for good surface finish. The right tools help shape the metal smoothly. Using higher cutting speeds can create a better finish by reducing friction. However, if too fast, it can lead to rough surfaces. Material selection also plays a big role. Softer metals usually give a better finish. Hard metals may require special tools. Choosing the right material is important for quality results.

What influences surface finish?

Tooling types and cutting speeds directly affect surface quality. Softer materials generally yield smoother finishes. Always consider both for the best outcomes!

- Use sharp tooling for cleaner cuts.

- Adjust cutting speed for material type.

- Choose appropriate materials for best results.

Steps to Retrofit a Metal Lathe with CNC

Essential components required for retrofit.. Detailed process of converting a manual lathe into CNC..Retrofitting a metal lathe into a CNC machine can seem daunting, but it’s a thrilling adventure! First up, gather your essential components: a CNC controller, stepper or servo motors, and a ball screw. Next, it’s time to convert your manual lathe into a high-tech CNC wonder! You’ll need to remove old parts, install the motors, and connect everything to the controller. It’s like giving your lathe a shiny new robot arm! Want to see it laid out? Here’s a simple table:

| Component | Purpose |

|---|---|

| CNC Controller | Brains of the operation |

| Stepper Motors | Moves the lathe with precision |

| Ball Screw | Drives the lathe smoothly |

Once everything is in place, run a few tests! Adjust settings, and you’ll be amazed at how your old lathe now speaks the language of CNC. Get ready for some shiny surfaces!

Best Practices for Optimizing Surface Finish Post-Retrofit

Techniques for finetuning machine settings after retrofit.. Maintenance tips for preserving surface quality over time..After retrofitting your CNC machine, fine-tuning is key to a great surface finish. Start by adjusting the speed and feed rates. These settings can greatly impact the final look of your work. Always check your tools. Worn tools can leave rough surfaces. Regular maintenance helps keep everything running smoothly. Here are some tips:

- Clean the machine often to avoid dust build-up.

- Inspect your cutting tools regularly for wear.

- Lubricate moving parts to reduce friction.

With these steps, your machine will produce quality finishes over time.

What are the techniques for optimizing machine settings?

Use correct speeds, feeds, and tool types for the material. Adjust until you find the perfect settings for a nice, smooth finish.

Tips for maintaining surface quality:

- Keep the machine clean to prevent scratches.

- Regularly check for loose parts that might affect accuracy.

- Calibrate the machine every few months.

Common Challenges in Achieving Surface Finish and Their Solutions

Identification of common issues faced during machining.. Practical solutions and troubleshooting tips..Machining can feel like a game of hide and seek with surface finish issues. Common problems include uneven surfaces, tool wear, and chatter. Uneven surfaces often result from poor tool setup. Tool wear can cause rough finishes, just like chewing gum on your shoe. To tackle these, keep your tools sharp, adjust cutting speed, and try cooling methods. Here’s a quick table of tips:

| Issue | Solution |

|---|---|

| Uneven Surface | Check tool alignment and adjust speed. |

| Tool Wear | Use quality tools and regular inspections. |

| Chatter | Stabilize your setup and reduce feed rate. |

Remember, a smooth finish is the goal. Keep calm and lathe on!

Future Trends in Lathe Surface Finishing and CNC Technology

Emerging technologies in lathe machining and surface finishing.. Predictions on the evolution of CNC retrofitting in the industry..New technologies are shaking up the world of lathe surface finishing. Soon, we might see machines that use 3D printing to make parts in a blink. Imagine parts so smooth they could slip from your hand like butter! Also, CNC retrofitting is evolving fast. New software will help machines learn and adapt over time. Say goodbye to the old days of manual setups. Instead, we’ll have smart lathe systems making precise cuts without a hitch.

| Emerging Technology | Prediction |

|---|---|

| 3D Printing | Faster part creation and smoother finishes. |

| Smart CNC Systems | Machines that learn and improve on their own! |

Experts believe that soon, every shop will have these smart tools. Get ready for a future where your metal lathe could practically run itself—talk about metal magic!

Conclusion

In summary, improving surface finish on a metal lathe can enhance your projects. Retrofitting a CNC system can boost precision and efficiency. You can achieve smoother finishes and better results. For practical steps, explore guides on CNC retrofitting and learn about different tools. Keep practicing, and don’t hesitate to dive deeper into this exciting field!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathe, And Cnc Retrofit:A lathe makes metal shapes smooth and shiny. This smoothness is called surface finish. You can improve it by using sharp tools or the right speed. A CNC retrofit means changing a regular lathe into a computer-controlled one. This helps us make even better shapes with less effort.

Sure! Please provide the section or question you want me to answer.

What Are The Best Practices To Achieve A Superior Surface Finish On A Metal Lathe After A Cnc Retrofit?To get a smooth finish on a metal lathe after you change it to CNC (Computer Numerical Control), here are some tips. First, use sharp tools; they cut better and leave less roughness. Next, choose the right speed for the metal you’re using. Higher speeds usually make a smoother finish. Also, keep the machine clean and well-oiled. Lastly, check your setups often to make sure everything is tight and steady. This helps avoid bumps and imperfections.

How Does The Choice Of Cutting Tools And Materials Impact The Surface Finish Quality On A Cnc Lathe?The cutting tools and materials you choose can make a big difference in how smooth a surface feels. If you use sharp tools, they cut better and create a nicer finish. Softer materials might get scratched or dented easily. We should pick the right tools and materials to get the best results. This way, our work looks great!

What Are Some Common Problems That Can Affect Surface Finish During Cnc Lathe Operations, And How Can They Be Resolved?Common problems that can affect surface finish during CNC lathe operations include dull tools and incorrect speeds. If your cutting tool is dull, it can make rough surfaces. You can solve this by sharpening or changing the tool. If the machine’s speed is too fast or slow, it may also harm the surface. Adjusting the speed to the right level can help make a smooth finish.

How Can Advanced Cnc Controls And Software Improve The Precision And Surface Finish Of Lathed Components?Advanced CNC controls and software help us make parts on lathes more accurately. They use detailed programs to tell the machine exactly what to do. This means we can create smoother surfaces and exact shapes. With better controls, we can fix small mistakes before they happen. Overall, we get better quality parts that fit together nicely.

What Techniques Can Be Employed To Measure And Evaluate The Surface Finish Of Parts Produced On A Retrofitted Cnc Lathe?To check how smooth a part is after it’s made on a CNC lathe, we can use a few simple methods. One way is to use a ruler that measures tiny bumps, called a surface roughness tester. You can also feel the surface with your fingers to see if it’s smooth. Another method is to compare it to a standard, like a known smooth surface. This helps us understand if we did a good job!