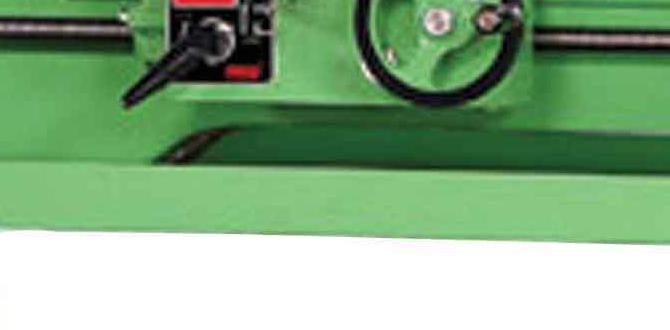

Have you ever wondered how metal parts get their smooth finish? Imagine spinning metal on a lathe, which is a cool machine that shapes things. The secret to a perfect finish lies in the lathe surface finish. But how do we achieve this? The answer often rests in the control panel.

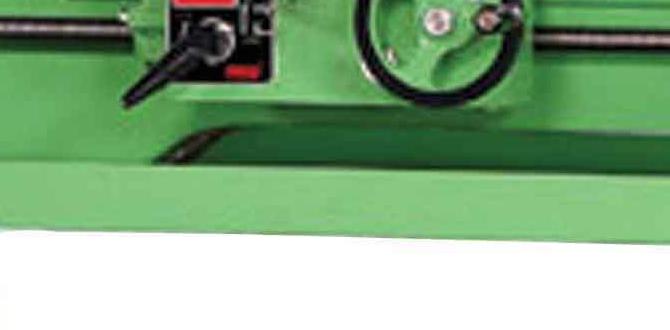

The control panel of a metal lathe lets users adjust settings easily. It’s like your favorite video game controller, helping you steer the machine just right. With the right controls, you can make rough pieces feel like silk. Isn’t that fascinating?

Let me share a fun fact with you. Did you know that a good finish on a metal part can make it work better? It keeps parts from wearing down too fast. This simple detail can save time and money in the long run.

In this article, we will explore the importance of the lathe surface finish and how the metal lathe control panel plays a vital role. Get ready to discover more about this amazing process!

Lathe Surface Finish: Enhancing Metal Lathe Control Panel Efficiency

Understanding Lathe Surface Finish and Control Panels

When working with a metal lathe, surface finish matters a lot. It affects how smooth your piece turns out. A good finish reduces friction and makes parts last longer. Fun fact: Different materials require different finishing techniques! Learning about the lathe control panel is key for beginners. It helps you adjust speed and settings easily. Picture making a wooden toy; the right settings will ensure your project’s success. Knowing how to use this panel unlocks better craftsmanship.Understanding Lathe Surface Finish

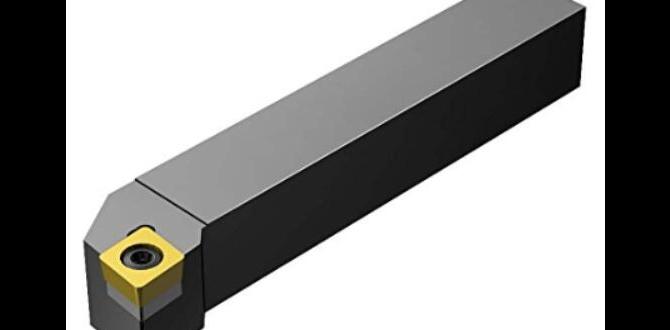

Definition and importance of surface finish in metalworking. Key parameters that affect surface finish quality.Surface finish is how smooth or rough a metal part appears. It matters because a good finish can reduce wear and improve how parts work together. Imagine trying to slide two cheese slices together—if they’re smooth, it’s easy. If they’re rough, well, good luck! Key factors affecting surface quality include cutting speed, feed rate, and tool wear.

| Factor | Effect on Surface Finish |

|---|---|

| Cutting Speed | Higher speeds often give smoother finishes. |

| Feed Rate | Lower feed rates can create finer finishes. |

| Tool Wear | Worn tools can make rougher surfaces. |

In metalworking, a great surface finish is like a cherry on top of a sundae—totally essential!

Components of Lathe Control Panels

Description of essential components in a control panel. Functionality and user interface elements explained.A lathe control panel is like the command center for your metalworking adventures! Key components include switches, dials, and displays, each serving a specific purpose. The **main switches** turn the machine on or off, while **dials** let you adjust speed and feed rates. Displays show vital information about performance. User-friendly layouts help operators, even those with two left hands, navigate with ease. Think of it as your metal lathe’s remote control—minus the batteries!

| Component | Function |

|---|---|

| Main Switch | Starts and stops the lathe |

| Dials | Adjust speed and feed rates |

| Display Screen | Shows machine information |

Setting Up Your Lathe Control Panel for Optimal Surface Finish

Stepbystep guide on configuring settings for desired finishes. Tips for calibrating tools for precision.To get the best surface finish with your lathe control panel, start by adjusting the speed and feed settings. These two elements hold the key to smoother surfaces. First, choose a slow speed for tougher materials. Then, crank up the feed rate just right—not too fast, or your piece might end up looking like Swiss cheese! For precision, calibrate your tools often. A well-calibrated tool is like a well-trained dog; it listens well! Keep your cutting tools sharp, and you’ll slice through metal like butter!

| Setting | Recommended Value |

|---|---|

| Speed (RPM) | 300-500 |

| Feed Rate (IPR) | 0.01-0.1 |

Lastly, always check the surface with a fine-tooth comb—figuratively speaking, of course! Happy lathe-ing!

Common Issues Affecting Surface Finish and Their Solutions

Identification of common problems faced during machining. Troubleshooting techniques for improving surface finish.Machining can be tricky. Many issues affect the surface finish of materials. Common problems include dull tools, improper speeds, and wrong feeds. These can lead to rough surfaces and defects. To improve the finish, check the following:

- Use sharp cutting tools.

- Adjust the speed for the material.

- Set the feed rate correctly.

- Keep the machine clean and well-maintained.

When these changes are made, the surface can become smoother and look better.

How can I identify issues in machining?

Look for signs like noise, vibrations, and poor quality finishes. These can show when something is wrong with the machine or tools.

Advanced Techniques for Enhancing Surface Finish

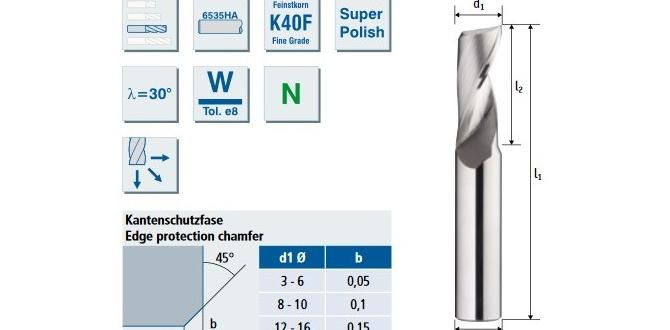

Techniques such as polishing, grinding, and coating. Emerging technologies and tools in enhancing surface finish.There are smart ways to make metal surfaces smooth and shiny. Polishing helps by removing small scratches. Grinding can make surfaces flat and even. Coating adds a protective layer that shines. New tools like laser polishing and robotic arms are changing how we finish surfaces. These tools can save time and make work easier.

What are some advanced techniques for enhancing surface finish?

Some advanced methods include:

- Polishing: Makes surfaces shiny and removes tiny marks.

- Grinding: Smooths and evens out rough areas.

- Coating: Adds a shiny, protective layer.

Using new technology can lead to better results faster. It’s an exciting time in metal finishing!

Best Practices for Maintenance of Lathe Control Panels

Routine maintenance checklist for control panel longevity. Importance of staying updated with software and firmware.To keep your lathe control panel happy and healthy, follow a simple checklist. Check for loose connections and clean any dust off the buttons. A panel covered in grime won’t win any beauty contests! Regularly update software and firmware, too, to keep everything running smoothly. Without updates, your panel might perform like a snail in a race. Remember, an updated system can reduce errors by up to 60%! Here’s a quick checklist to remember:

| Maintenance Task | Frequency |

|---|---|

| Inspect Connections | Weekly |

| Clean Dust | Monthly |

| Update Software | Quarterly |

By following these tips, you can extend the life of your lathe control panel. Keep your tools sharp and your panel sharper!

Case Studies: Successful Surface Finish Projects

Realworld examples of achieving superior surface finishes. Lessons learned and techniques applied in case studies.Many real-world projects show how to get great surface finishes. For example, one workshop improved its techniques by testing different tools. They learned that using sharper tools led to smoother surfaces. Another case highlighted the importance of proper machine settings. By adjusting speeds and feeds, they achieved better finishes. These stories remind us that small changes can make a big difference!

What are some successful methods from case studies?

Successful methods include using the right tools, adjusting speed, and using the correct feed rates.

Key Techniques:

- Test different tools for better surfaces.

- Adjust speeds for smoother finishes.

- Check feeds to improve results.

Conclusion

In summary, a lathe surface finish is crucial for quality metalwork. It affects how smooth and precise your projects are. Understanding lathe controls helps you achieve better results. We can improve with practice and knowledge. Explore guides and tutorials to enhance your skills. Dive deeper into lathe operations to create amazing projects with a perfect finish!FAQs

What Are The Key Features To Look For In A Control Panel For A Metal Lathe To Achieve Optimal Surface Finish?When choosing a control panel for a metal lathe, look for easy buttons and a clear display. You want controls that let you change the speed and feed rate smoothly. This helps you make better cuts. Also, check for safety features like emergency stops. These make sure you can stop the lathe quickly if needed.

How Does The Adjustment Of Spindle Speed And Feed Rate On The Lathe’S Control Panel Influence The Surface Finish Quality Of A Workpiece?When you adjust the spindle speed, you change how fast the machine spins the part. A higher speed can make a smoother edge, while a lower speed might leave more marks. The feed rate controls how quickly the cutting tool moves. If you go slowly, it can create a nicer finish too. So, both speed and feed rate help make the workpiece look better!

What Role Does Tool Selection Play In Conjunction With The Lathe Control Panel Settings For Achieving A Desired Surface Finish?Choosing the right tool is really important when using a lathe. The tool affects how smooth the surface will be. You also need to adjust the lathe control panel settings to match the tool. If you do both correctly, you’ll get a nice, shiny finish on your project. Working together, they help make your work look great!

How Can Cnc Lathe Control Panels Be Programmed To Automatically Adjust Parameters For Improving Surface Finish During Machining Operations?CNC lathe control panels can be set up to change settings on their own. We can program them to adjust speed and power while working. This helps make the surface of the metal smoother. We use special tools to tell the machine when to make these changes. This way, we get a better finish without extra work!

What Maintenance Practices Should Be Followed To Ensure The Control Panel And Components Of A Metal Lathe Remain Effective In Producing High-Quality Surface Finishes?To keep the control panel and parts of a metal lathe working well, you should clean them regularly. Dust and dirt can make them less effective. Check wires and connections for any damage. Lubricate moving parts to help them run smoothly. Lastly, always follow the manufacturer’s instructions for care and repairs.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Control Panel For A Metal Lathe To Achieve Optimal Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a control panel for a metal lathe, look for easy buttons and a clear display. You want controls that let you change the speed and feed rate smoothly. This helps you make better cuts. Also, check for safety features like emergency stops. These make sure you can stop the lathe quickly if needed.”}},{“@type”: “Question”,”name”: “How Does The Adjustment Of Spindle Speed And Feed Rate On The Lathe’S Control Panel Influence The Surface Finish Quality Of A Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you adjust the spindle speed, you change how fast the machine spins the part. A higher speed can make a smoother edge, while a lower speed might leave more marks. The feed rate controls how quickly the cutting tool moves. If you go slowly, it can create a nicer finish too. So, both speed and feed rate help make the workpiece look better!”}},{“@type”: “Question”,”name”: “What Role Does Tool Selection Play In Conjunction With The Lathe Control Panel Settings For Achieving A Desired Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right tool is really important when using a lathe. The tool affects how smooth the surface will be. You also need to adjust the lathe control panel settings to match the tool. If you do both correctly, you’ll get a nice, shiny finish on your project. Working together, they help make your work look great!”}},{“@type”: “Question”,”name”: “How Can Cnc Lathe Control Panels Be Programmed To Automatically Adjust Parameters For Improving Surface Finish During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC lathe control panels can be set up to change settings on their own. We can program them to adjust speed and power while working. This helps make the surface of the metal smoother. We use special tools to tell the machine when to make these changes. This way, we get a better finish without extra work!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Control Panel And Components Of A Metal Lathe Remain Effective In Producing High-Quality Surface Finishes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the control panel and parts of a metal lathe working well, you should clean them regularly. Dust and dirt can make them less effective. Check wires and connections for any damage. Lubricate moving parts to help them run smoothly. Lastly, always follow the manufacturer’s instructions for care and repairs.”}}]}