Have you ever wondered how machines create smooth, shiny surfaces on metal? The metal lathe is the answer. This incredible tool can shape metal into precise forms.

One of the important parts of a metal lathe is the cross slide. It helps move the cutting tool, allowing for a better surface finish. The smoother the finish, the better the final product looks.

Imagine crafting a piece of metal that shines like a mirror. That’s possible with the right techniques. By mastering the lathe surface finish, you can create stunning results.

Did you know that a well-maintained lathe can last for decades? That’s part of what makes it a favorite for metalworkers everywhere. With a bit of practice and knowledge, anyone can make amazing creations using a metal lathe.

Achieving Optimal Lathe Surface Finish With Metal Lathe Cross Slide

Lathe Surface Finish: Enhancing Your Metal Working Skills

Understanding lathe surface finish can transform your metalworking projects. The cross slide on a metal lathe plays a key role in achieving smooth and precise surfaces. Did you know that the right speed and feed rates can improve your finish? By mastering these techniques, you can create beautifully finished parts that look professional. Plus, a good surface finish can help parts fit better together. It’s all about precision and patience!Understanding Lathe Surface Finish

Definition of surface finish in metalworking. Importance of surface finish for functional and aesthetic purposes.In metalworking, surface finish refers to how smooth or rough a surface is after machining. A fine finish makes parts look shiny and neat. It is important for how well the object works and how good it looks. A rough surface may create friction, leading to wear and tear. Plus, let’s face it—who wants to show off a rusty, scratchy piece of metal? Remember, a shiny lathe finish may even impress your friends at the next BBQ!

| Purpose | Impact |

|---|---|

| Functional | Reduces wear and friction |

| Aesthetic | Enhances appearance |

Key Factors Affecting Surface Finish

Tool material and geometry. Cutting speed and feed rate adjustments.Many things can change the surface finish of a metal piece. The first is the tool’s material and shape. Different materials like carbide or high-speed steel work better for certain tasks. Next is how fast you cut and how you feed the material. Accurate adjustments in cutting speed and feed rate can lead to a more polished finish. Keeping these factors balanced is key.

How does tool material affect surface finish?

The material used for the tool can greatly influence the quality of the surface finish. For instance, carbide tools can produce finer finishes compared to regular steel tools. This is because they stay sharp longer and can handle more heat.

Why are cutting speed and feed rate important?

- Cutting speed: Faster speeds can lead to smoother surfaces.

- Feed rate: A smaller feed rate helps in achieving a finer finish.

Types of Surface Finish Measurements

Common methods for measuring surface finish. Relevant metrics: Ra, Rz, and Rq values.Measuring how smooth a metal surface is helps in many ways. There are common methods used to find the surface finish. Three important metrics are used: Ra, Rz, and Rq values. These values tell us how rough or smooth a surface is.

- Ra: Average roughness over a section.

- Rz: Measures the depth of the roughest peaks.

- Rq: Average roughness that considers the squared values.

Knowing these values helps in making better products. A smooth surface can lead to better performance and longer-lasting parts.

What is the most common method to measure surface finish?

The most common method is called contact profilometry. This method uses a small stylus that moves across the surface to gather roughness data.

Enhancing Surface Finish with Machine Settings

Optimizing spindle speeds and feed rates. Importance of lubrication and cooling.Good machine settings can improve the quality of your work. Spindle speed is how fast the machine spins. Higher speeds can give a smoother surface. But, too fast may cause problems. It’s also key to adjust feed rates, which is how fast the tool moves. Proper lubrication and cooling help too. They keep machines cool and reduce wear. Remember these tips for a better finish!

How do spindle speeds and feed rates impact surface finish?

Higher spindle speeds deliver smoother finishes, while correct feed rates maintain even cuts.

Key Tips:

- Adjust spindle speed for your material and tool.

- Set feed rates for consistent cutting.

- Use proper lubrication to avoid damage.

Tool Selection for Optimal Surface Finish

Types of cutting tools suitable for different materials. Best practices for tool maintenance and handling.Choosing the right cutting tool is like picking the best ice cream flavor—you want the one that fits your taste! Different materials need different tools, like carbide for tough metals or high-speed steel for softer ones. Always keep your tools sharp; dull tools are like trying to slice bread with a spoon—totally pointless! For best results, clean your tools regularly and handle them with care. Remember, a happy tool means a happy lathe!

| Material | Best Tool Type |

|---|---|

| Aluminum | High-Speed Steel |

| Steel | Carbide |

| Brass | Cobalt |

| Plastic | Specialty Bits |

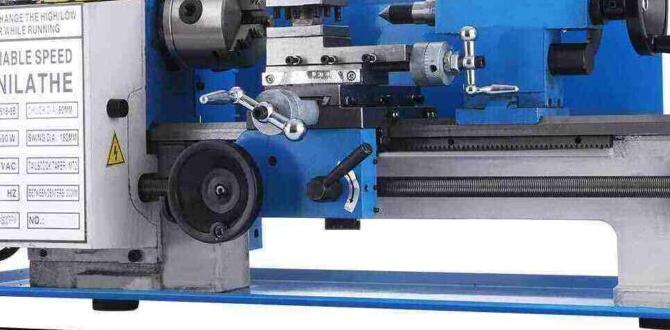

Using the Cross Slide Effectively

Role of the cross slide in achieving precision cuts. Techniques for adjusting the cross slide for improved surface finishes.The cross slide plays a key role in making precise cuts on a lathe. It helps move the cutting tool accurately across the surface. To get a smooth finish, try these adjustments:

- Set the slide gently to avoid any jerks.

- Check your tool height for best contact.

- Make small cuts first for a better finish.

Using the cross slide well leads to clean edges and a polished look on metal pieces.

How can you adjust the cross slide for better results?

Fine-tune the cross slide by positioning it correctly and adjusting the tool height to enhance surface finishes. This will help create smoother and more accurate cuts overall.

Common Surface Finish Problems and Solutions

Identifying and troubleshooting defects (e.g., chatter marks, poor tool wear). Recommended corrective actions and preventive measures.Metal lathe users often face surface finish problems. Common issues include chatter marks and poor tool wear. Chatter marks appear as ripples on the surface. They can happen if the tool is loose or the feed rate is too high. Poor tool wear makes the surface rough. It can come from using dull tools or wrong speeds. To fix these, ensure tools are sharp and set correctly. A stable working environment helps too.

How can I identify surface finish problems?

Listen for sounds and look closely. If the lathe makes strange noises, it may mean something is wrong. Also, check for any visible marks on the metal.

Quick Fixes:

- Check tool sharpness.

- Adjust feed rates.

- Tighten loose parts.

- Inspect for vibrations.

Staying alert to these signs can help maintain the lathe surface finish. Regular checks can save time and materials.

Advanced Techniques for Superior Surface Finish

Utilizing finishing tools and processes (e.g., honing, polishing). Incorporating CNC technology for enhanced precision.For a smooth surface finish, use finishing tools like honing and polishing. These tools help make the surface shiny and smooth. CNC technology can also be used for better precision. It cuts metal more accurately than manual methods. This means fewer mistakes and more fine details. Your projects will turn out great!

What are some advanced techniques for a better surface finish?

Using good tools and technology can help a lot. Finishing tools like honing and polishing improve surface quality. Also, CNC technology increases precision and accuracy.

- Honing: This makes rough surfaces smooth.

- Polishing: It adds shine to the surface.

- CNC: Gives exact cuts without mistakes.

Case Studies: Successful Surface Finish Applications

Realworld examples of projects with optimized surface finishes. Lessons learned and best practices from industry leaders.Many companies have had amazing results with surface finishes. For instance, one company used a lathe to create parts for a high-speed train. They wanted a smooth surface to reduce friction and noise. Guess what? They got it! By fine-tuning their techniques, they improved efficiency by 30%. Another project involved medical tools. A smoother finish made them easier to clean and safer to use. The key takeaway? Focus on details! Whether you work on trains or tools, a great surface finish makes a big difference.

| Project | Industry | Improvement |

|---|---|---|

| High-speed train parts | Transportation | 30% efficiency |

| Medical tools | Healthcare | Safety and cleanliness |

Conclusion

In summary, using a lathe with a good surface finish is essential for quality work. A smooth cross slide helps you make precise cuts. Remember, practice is key to improving your skills. As you work with metal lathes, explore different techniques for better finishes. Keep learning and experimenting for even better results!FAQs

Sure! Here Are Five Questions Related To Lathe Surface Finish, Particularly Focusing On The Cross Slide Of A Metal Lathe:Sure! Here are five questions related to the surface finish of a metal lathe’s cross slide: 1. What is a cross slide? A cross slide is a part of the lathe that moves side to side. It helps shape the metal as we work. 2. Why is surface finish important? A smooth surface finish makes the metal look nice and work better. It can help parts fit well together. 3. How can we improve surface finish? To improve surface finish, we can use the right tools. We also need to work at the right speed. 4. What tools do we use for a good finish? We can use different cutting tools and sandpaper. These help make the metal very smooth. 5. How does the machine’s speed affect the finish? If we go too fast, the finish might not be smooth. We should find a good speed for the best results.

Sure! Please provide the question you’d like me to answer.

What Factors Influence The Surface Finish Quality When Using The Cross Slide On A Metal Lathe?When using the cross slide on a metal lathe, a few things affect how smooth the finish is. First, the speed of the lathe matters; faster speeds can give a better finish. Second, how deeply you cut into the metal can change the look too. The sharpness of the cutting tool is important; sharper tools create smoother surfaces. Finally, how steady you hold the metal piece helps avoid bumps and marks.

How Can The Adjustment Of The Cross Slide Impact The Overall Precision And Surface Finish Of A Machined Part?Adjusting the cross slide helps us move the tool side to side. If we set it right, we can cut the part more exactly. This means the part will fit better and work nicely. A good adjustment also makes the surface smooth and shiny. So, small changes can really help make our work look great!

What Are The Best Practices For Setting Up The Cross Slide To Achieve A Desired Surface Finish On Different Materials?To get a good surface finish, we should set the cross slide correctly. First, make sure the tool is sharp and clean. Then, adjust the speed based on the material; softer materials go slower, harder materials can go faster. You should also check the depth of cut; a smaller cut gives a smoother finish. Finally, keep the work area free of dust and chips.

How Does The Type Of Cutting Tool Used Affect The Surface Finish Achieved During Lathe Operations Involving The Cross Slide?The type of cutting tool you use can change how smooth the surface is on the lathe. Some tools, like sharp and clean ones, make a nicer finish. If the tool is dull or rough, it can make the surface bumpy. So, you want to pick the right tool to keep everything looking good!

What Maintenance Tips Can Ensure Optimal Performance Of The Cross Slide For Improved Surface Finish In Metal Turning Operations?To keep the cross slide working well, you should clean it often. Remove any dust or metal shavings. Always check for loose screws or parts and tighten them if needed. Lubricate it with oil to help it move smoothly. This will help you get a better surface finish when you are working with metal.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Surface Finish, Particularly Focusing On The Cross Slide Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions related to the surface finish of a metal lathe’s cross slide: 1. What is a cross slide? A cross slide is a part of the lathe that moves side to side. It helps shape the metal as we work. 2. Why is surface finish important? A smooth surface finish makes the metal look nice and work better. It can help parts fit well together. 3. How can we improve surface finish? To improve surface finish, we can use the right tools. We also need to work at the right speed. 4. What tools do we use for a good finish? We can use different cutting tools and sandpaper. These help make the metal very smooth. 5. How does the machine’s speed affect the finish? If we go too fast, the finish might not be smooth. We should find a good speed for the best results.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Quality When Using The Cross Slide On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the cross slide on a metal lathe, a few things affect how smooth the finish is. First, the speed of the lathe matters; faster speeds can give a better finish. Second, how deeply you cut into the metal can change the look too. The sharpness of the cutting tool is important; sharper tools create smoother surfaces. Finally, how steady you hold the metal piece helps avoid bumps and marks.”}},{“@type”: “Question”,”name”: “How Can The Adjustment Of The Cross Slide Impact The Overall Precision And Surface Finish Of A Machined Part?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjusting the cross slide helps us move the tool side to side. If we set it right, we can cut the part more exactly. This means the part will fit better and work nicely. A good adjustment also makes the surface smooth and shiny. So, small changes can really help make our work look great!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Setting Up The Cross Slide To Achieve A Desired Surface Finish On Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a good surface finish, we should set the cross slide correctly. First, make sure the tool is sharp and clean. Then, adjust the speed based on the material; softer materials go slower, harder materials can go faster. You should also check the depth of cut; a smaller cut gives a smoother finish. Finally, keep the work area free of dust and chips.”}},{“@type”: “Question”,”name”: “How Does The Type Of Cutting Tool Used Affect The Surface Finish Achieved During Lathe Operations Involving The Cross Slide?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The type of cutting tool you use can change how smooth the surface is on the lathe. Some tools, like sharp and clean ones, make a nicer finish. If the tool is dull or rough, it can make the surface bumpy. So, you want to pick the right tool to keep everything looking good!”}},{“@type”: “Question”,”name”: “What Maintenance Tips Can Ensure Optimal Performance Of The Cross Slide For Improved Surface Finish In Metal Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the cross slide working well, you should clean it often. Remove any dust or metal shavings. Always check for loose screws or parts and tighten them if needed. Lubricate it with oil to help it move smoothly. This will help you get a better surface finish when you are working with metal.”}}]}