Have you ever watched a lathe in action? It’s fascinating how this machine shapes metal! But did you know that the finish it leaves on the surface can make a big difference? A smooth surface finish can mean stronger parts. Plus, it looks amazing!

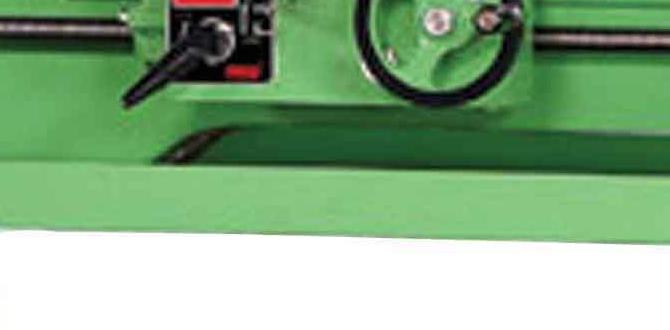

Now, think about using a metal lathe. It’s a popular tool in workshops. Many people love to create cool projects with it. But safety is just as important as creativity. That’s where the metal lathe foot brake comes in.

Imagine you’re working on your latest creation. You’re focused, and everything seems perfect. Then, suddenly, you need to stop the machine fast. Wouldn’t it be great to have a foot brake that lets you do that safely? This small feature can really change your experience.

In this article, we’ll explore all the amazing details about lathe surface finish and why the foot brake is a must-have. Let’s dive in and discover how these elements make metalworking safer and more fun!

Lathe Surface Finish: Metal Lathe Foot Brake Techniques

Lathe Surface Finish: Metal Lathe Foot Brake

Using a metal lathe can be exciting! One important feature is its foot brake. This tool helps you stop the lathe quickly, ensuring safety while you work. A smooth surface finish is also crucial. It affects how your finished item looks and feels. Did you know that different materials can change the surface finish outcome? Learning about this will help you create better projects. Proper use of the lathe and brake makes crafting enjoyable and safe.Understanding Lathe Surface Finish

Definition of surface finish in metalworking. Importance of surface finish in machining quality.In metalworking, surface finish means how smooth or rough a metal piece is after being shaped. It’s like the difference between a smooth table and a bumpy road. A good surface finish matters. It affects how well parts fit together and work. Better finishes can make machines last longer and work better. Here are some key points about surface finish:

- Better fit means less wear and tear.

- Improved appearance makes products look more professional.

- Increased durability helps in tough conditions.

Why Does Surface Finish Matter?

A smooth finish improves how a machine runs. It helps reduce friction, making processes smoother. A rough finish can cause problems, like breakage or wear. Good surface finish is important for safety and efficiency.

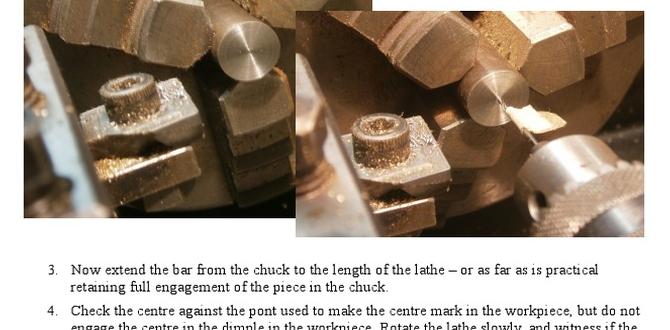

Factors Influencing Surface Finish on a Lathe

Role of cutting speed and feed rate. Impact of tool material and geometry. Effects of workpiece material characteristics.Several factors affect how smooth the finish is on a lathe. Cutting speed matters a lot. Faster speeds generally lead to a nicer finish. The feed rate also plays a role. A slower feed means less chance of rough spots. Besides this, the tool material shapes the output too. High-quality materials give better results. Lastly, the workpiece material impacts the finish. Softer metals tend to produce smoother surfaces. All these factors work together to create a perfect finish.

What is the impact of cutting speed and feed rate?

Higher cutting speeds and slower feed rates generally produce a better surface finish. These settings reduce vibrations and allow the tool to cut smoothly.

How does tool material and geometry affect results?

The quality of the tool material greatly influences the finish you get. A sharp, well-shaped tool cuts cleaner, while dull or improper shapes can cause rough surfaces.

Why are workpiece material characteristics important?

The type of material being worked on affects the final outcome. For instance, softer materials usually yield a smoother finish compared to harder ones.

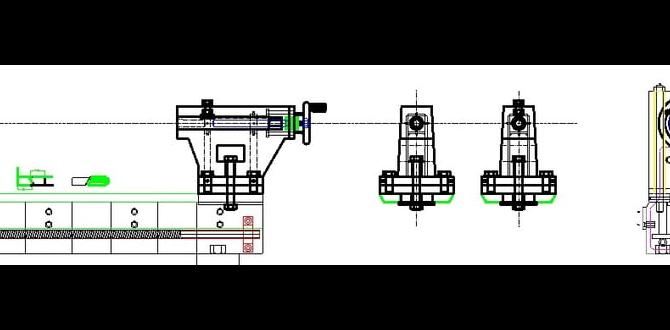

Metal Lathe Foot Brake: A Crucial Component

Description and function of the foot brake. Benefits of using a foot brake during operation.The foot brake is an important part of a metal lathe. It allows quick stopping of the machine. This feature is essential for safety during operation. The foot brake can be operated with your foot, leaving your hands free to work.

Benefits include:

- Quick Stop: You can stop the lathe immediately.

- Hands-Free: Your hands stay busy while controlling the machine.

- Improved Safety: It reduces the risk of accidents.

Using a foot brake makes working more efficient and safe. It is a simple yet effective way to gain better control over the lathe while achieving a clean surface finish.

What is the function of a foot brake on a metal lathe?

The function of a foot brake is to allow quick stopping of the lathe for safety and control while working.

Why is a foot brake important?

A foot brake is important because it helps operators stop the machine quickly, improving safety and efficiency.

How to Achieve Optimal Surface Finish with a Foot Brake

Techniques for controlling lathe speed. Maintaining consistent pressure on the foot brake.To get the best surface finish, control the lathe speed carefully. Use a lower speed for finer details. High speed works for rough cuts. Keep it steady.

Maintaining pressure on the foot brake is key. Too much pressure can cause uneven surfaces. Aim for consistent pressure while working.

- Choose the right speed for the job.

- Adjust the brake pressure slowly.

- Practice makes perfect!

What is the best lathe speed for surface finish?

A slower speed usually gives a smoother finish. Fine-tuning the speed helps create the best results.

Common Problems Affecting Surface Finish

Identifying causes of poor surface finish. Troubleshooting issues related to the foot brake.Many things can mess up the shiny surface we want on metal items. First, the lathe speed might be too fast or too slow. That can cause uneven finishes. Next, the tools used might be dull or dirty. This means they don’t cut well. Sometimes, problems with the foot brake affect our work too. If the brake isn’t tight enough, the piece can vibrate and ruin the finish. Remember, even a squeaky brake can lead to a not-so-smooth result!

| Problem | Cause | Solution |

|---|---|---|

| Uneven Surface | Incorrect Lathe Speed | Adjust Speed Appropriately |

| Dull Finish | Dirty or Dull Tools | Clean or Replace Tools |

| Vibration Issues | Loose Foot Brake | Tighten Foot Brake |

Best Practices for Maintaining Your Lathe Foot Brake

Regular maintenance and inspection tips. Recommendations for lubrication and replacement parts.To keep your foot brake in top shape, regular checks are essential. Inspect the brake every month. Look for wear and tear. Ensure all parts are secure and functioning. Lubricate moving parts with light oil to prevent rust and make them work smoothly. It’s wise to replace brake pads when needed.

- Check the brake every month.

- Use light oil for lubrication.

- Replace worn-out parts promptly.

How often should I inspect my lathe foot brake?

You should inspect your lathe foot brake at least once a month to ensure safety and good performance. Regular checks help you catch issues early.

Comparative Analysis: Manual vs. Automatic Foot Brakes

Advantages and disadvantages of each type. Situational recommendations for choosing the right system.Choosing between manual and automatic foot brakes can feel like picking your favorite ice cream flavor. Each has its perks! Manual brakes are simple and give you full control, making them great for experienced users. However, they can tire your foot faster than a toddler in a candy store. On the flip side, automatic brakes are like magic! They save effort and are easier for beginners. But, they can be pricey and sometimes just stop working like a shy cat.

| Type | Advantages | Disadvantages |

|---|---|---|

| Manual | Full control, low cost | Can cause fatigue |

| Automatic | Less effort, beginner-friendly | Higher cost, potential malfunctions |

For those new to metal lathes, automatic may be the way to go. For seasoned pros, manual might feel more natural. Consider your skill level and budget before making a choice! Happy turning!

Case Studies: Successful Applications of Lathe Surface Finishing

Highlighting industry examples of improved surface finish. Lessons learned from experienced machinists.In many industries, a great surface finish can make a huge difference. One metal shop improved their products’ smoothness by switching to lathe surface finishing. Customers noticed better quality and even started referring friends! Experienced machinists learned that a fine surface finish also reduces wear and tear, keeping tools happy. Who knew shiny metal could save money? Here’s a fun fact: a smoother surface can decrease friction by up to 30%!

| Industry | Improvement |

|---|---|

| Automotive | Enhanced durability and performance |

| Aerospace | Improved precision and reduced weight |

| Manufacturing | Increased lifespan of parts |

Conclusion

In summary, a lathe helps shape metal for smooth finishes. Foot brakes make using a lathe safer and easier. You should always check your equipment and practice proper techniques. Understanding these aspects can boost your skills. If you want to learn more, consider exploring online tutorials or joining a metalworking class. Keep practicing to improve your metal lathe abilities!FAQs

Here Are Five Related Questions On The Topic Of Lathe Surface Finish And The Use Of A Metal Lathe Foot Brake:When you use a metal lathe, it helps make smooth and nice-looking parts. A lathe foot brake is a tool you press with your foot. It stops the lathe quickly and safely. Good surface finish means fewer bumps, making parts easier to use. You want your work to be safe and nice!

Sure! Please provide the question you would like me to answer.

What Are The Key Factors That Influence Surface Finish Quality In Metal Turning Operations On A Lathe?The key factors for a smooth finish when using a lathe include cutting speed, feed rate, and tool sharpness. Cutting speed is how fast the machine spins the metal. Feed rate is how fast the tool moves along the metal piece. A sharp tool makes cleaner cuts. Keeping these factors just right helps us make better-looking parts.

How Does The Use Of A Foot Brake On A Metal Lathe Enhance Safety And Precision During Machining?Using a foot brake on a metal lathe helps stop the machine quickly. This makes it safer because you can react faster to problems. It also lets you control the machine better while working. When you stop the lathe suddenly, you can measure your work without waiting. This helps you make sure everything is just right.

What Are The Differences In Surface Finish Between Various Cutting Tools When Used On A Metal Lathe?Different cutting tools can make different surfaces on metal. Some tools, like carbide, leave a smooth finish. Others, like high-speed steel, might leave a rougher surface. The shape and sharpness of the tool also affect the finish. Using the right tool helps you make the metal look better!

How Can Operators Diagnose And Correct Issues Related To Poor Surface Finish When Using A Lathe?To fix a rough surface when using a lathe, you can check a few things. First, look at the cutting tool. Is it sharp and clean? If it’s dull or dirty, replace or clean it. Next, check the speed of the lathe. If it’s too slow or fast, adjust it. Finally, make sure the workpiece is held tightly. If it wobbles, it can cause a bad finish.

What Maintenance Practices Should Be Implemented For A Metal Lathe’S Foot Brake To Ensure Optimal Performance And Safety?To keep the foot brake of a metal lathe working well, you should check it often. First, clean the brake pedal to remove dirt and dust. Next, make sure the brake doesn’t squeak or stick. You should also check the connection wires for any wear. Finally, if something seems broken, ask an adult to help fix it!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Surface Finish And The Use Of A Metal Lathe Foot Brake:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, it helps make smooth and nice-looking parts. A lathe foot brake is a tool you press with your foot. It stops the lathe quickly and safely. Good surface finish means fewer bumps, making parts easier to use. You want your work to be safe and nice!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors That Influence Surface Finish Quality In Metal Turning Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The key factors for a smooth finish when using a lathe include cutting speed, feed rate, and tool sharpness. Cutting speed is how fast the machine spins the metal. Feed rate is how fast the tool moves along the metal piece. A sharp tool makes cleaner cuts. Keeping these factors just right helps us make better-looking parts.”}},{“@type”: “Question”,”name”: “How Does The Use Of A Foot Brake On A Metal Lathe Enhance Safety And Precision During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a foot brake on a metal lathe helps stop the machine quickly. This makes it safer because you can react faster to problems. It also lets you control the machine better while working. When you stop the lathe suddenly, you can measure your work without waiting. This helps you make sure everything is just right.”}},{“@type”: “Question”,”name”: “What Are The Differences In Surface Finish Between Various Cutting Tools When Used On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools can make different surfaces on metal. Some tools, like carbide, leave a smooth finish. Others, like high-speed steel, might leave a rougher surface. The shape and sharpness of the tool also affect the finish. Using the right tool helps you make the metal look better!”}},{“@type”: “Question”,”name”: “How Can Operators Diagnose And Correct Issues Related To Poor Surface Finish When Using A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix a rough surface when using a lathe, you can check a few things. First, look at the cutting tool. Is it sharp and clean? If it’s dull or dirty, replace or clean it. Next, check the speed of the lathe. If it’s too slow or fast, adjust it. Finally, make sure the workpiece is held tightly. If it wobbles, it can cause a bad finish.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Implemented For A Metal Lathe’S Foot Brake To Ensure Optimal Performance And Safety?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the foot brake of a metal lathe working well, you should check it often. First, clean the brake pedal to remove dirt and dust. Next, make sure the brake doesn’t squeak or stick. You should also check the connection wires for any wear. Finally, if something seems broken, ask an adult to help fix it!”}}]}