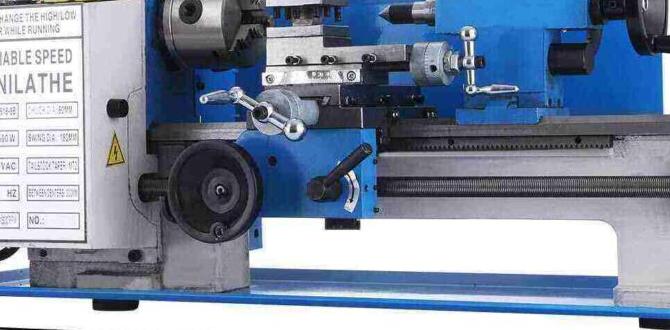

Have you ever wondered how a simple piece of metal can become a finely crafted tool? The magic often lies in the lathe. With the right metal lathe and a clever gear train, amazing surfaces can be created.

Lathes are not just machines; they are gateways to creativity. Imagine shaping a block of steel into a smooth cylinder. How do skilled workers achieve such impressive surface finishes? It all starts with understanding how a metal lathe works.

Did you know that the gear train in a lathe plays a crucial role? It can affect everything from speed to precision. The better the gear train, the finer the finish. It’s fascinating how one piece of equipment can open up endless possibilities!

In this article, we will explore the art of using a lathe. We will discuss how to achieve the best surface finish and uncover the secrets of the gear train. Get ready to dive into the exciting world of metalworking!

Lathe Surface Finish: Optimizing Metal Lathe Gear Train Performance

Lathe Surface Finish Metal Lathe Gear Train

Did you know that the quality of your metal project depends a lot on the lathe surface finish? A good finish helps reduce friction and wear. The gear train in a metal lathe plays a vital role. It controls the speed and precision of cutting. Understanding how the gear train works can improve your lathe skills. Choosing the right settings can mean the difference between a rough finish and a smooth one. With practice, anyone can master this technology!Understanding Lathe Surface Finish

Definition of surface finish in metalworking. Importance of surface finish for functional and aesthetic purposes.Surface finish is how smooth or rough a metal object feels after being shaped. It matters for two main reasons: functionality and looks. A smooth surface ensures parts fit better and work properly. Think about it: would you want a wobbly wheel on your toy car? Yikes! Plus, a nice finish makes things look shiny and new. Everyone likes a little bling! Here’s a quick table to help explain:

| Aspect | Functionality | Aesthetics |

|---|---|---|

| Definition | Fit and performance of parts | Visual appeal and shine |

| Importance | Reduces wear and tear | Attracts customers |

Key Factors Influencing Surface Finish on Metal Lathes

Material properties and their impact on surface quality. Effects of cutting tools, feeds, and speeds on finish.Many things affect how smooth the surface is on a metal lathe. First, material properties matter. Softer metals usually give a better finish. Harder metals can be tough to work with. Next are the cutting tools. Sharp tools make cleaner cuts. Dull tools can scratch the surface. Lastly, the feeds and speeds of the lathe play a role. Faster speeds can lead to a rougher finish. Balancing these factors helps achieve that shiny look!

What are the key factors affecting surface finish?

Key factors include:

- Material type: Affects smoothness.

- Tool sharpness: Sharp tools cut cleaner.

- Feed rate: Controls how fast the tool moves.

- Spindle speed: Affects surface quality.

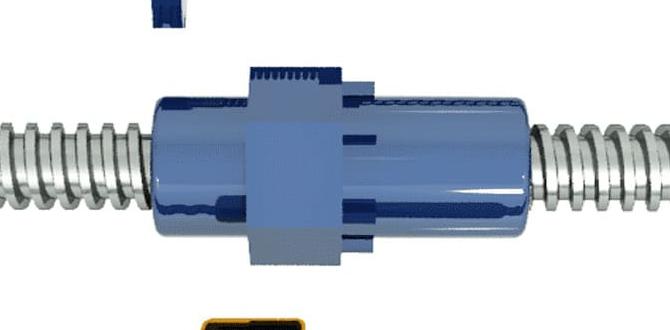

Optimizing Gear Train for Improved Surface Finish

How gear ratios affect tool movement and surface quality. Adjustments for precision and stability during machining.Gear ratios can feel like the secret sauce to cooking up the perfect metal surface. The right ratio affects how tools move, which is crucial for a smooth finish. Think of it like a dance party. If the rhythm’s off, the moves can be sloppy! Adjusting these ratios helps keep everything steady. It’s like finding your groove — precision and stability lead to quality. If only we could adjust our dance skills that easily!

| Gear Ratio | Tool Movement Impact | Surface Finish Quality |

|---|---|---|

| High Ratio | Slower Tool Movement | Better Finish |

| Low Ratio | Faster Tool Movement | Possible Roughness |

So, checking your gear train setup is essential. It will save you from the headache of bad finishes. Remember, a better surface means happier machines and users!

Techniques for Achieving Superior Surface Finish

Recommended machining practices and settings. Postmachining processes for optimal results.To get a shiny finish on metal, follow some key practices. First, use sharp tools and the right speed to avoid those pesky scratches. Too fast, and your metal might scream! Second, use light cuts; think of it like giving your metal a gentle hug. After machining, don’t skip post-processing steps like sanding or polishing. These make a huge difference. Remember, quality tools and care equal a happy metal piece.

| Technique | Tip |

|---|---|

| Sharp Tools | Keep them sharp for a smooth ride! |

| Correct Speed | Find the sweet spot! |

| Light Cuts | Think of it as a gentle dance. |

| Post-Processing | Sanding and polishing are best pals. |

Common Issues and Solutions in Lathe Surface Finishing

Troubleshooting common surface finish defects. Preventative measures to avoid quality issues.Many people face problems with surface finishes when using lathes. Common issues include rough surface textures and scratches. These can happen due to dull tools, incorrect speeds, or dirty work areas. To solve these problems, you can:

- Keep tools sharp and clean.

- Adjust the speed to match the material.

- Regularly clean the lathe and workspace.

Preventing issues is better than fixing them. Regular checks and proper maintenance ensure you avoid common defects. A well-maintained lathe creates a smooth and shiny finish.

What are common surface finish defects and how can I fix them?

Common defects are roughness and scratches. To fix these, make sure your tools are sharp and your lathe is clean. It helps to keep a steady speed while working.

Additional Tips to Avoid Quality Issues:

- Always check the material type.

- Use the right cutting tools.

- Monitor the work environment for dust and debris.

Case Studies: Successful Applications of Gear Train Optimization

Examples of industries benefiting from improved surface finish. Comparative analysis of before and after optimization.Industries worldwide have improved a lot due to better gear train optimization. For instance, the automotive industry has seen stunning changes. Before, car parts were rough and inconsistent. After optimization, they became sleek and shiny, almost ready for a beauty pageant! The aerospace sector also enjoyed the upgrade. It ensures safer, lighter aircraft. Below is a quick comparison:

| Industry | Before Optimization | After Optimization |

|---|---|---|

| Automotive | Rough surfaces | Shiny, smooth parts |

| Aerospace | Inconsistent quality | Lightweight, uniform components |

These examples show that gear train improvements can really make a difference. It’s like giving a superpower to machines!

Future Trends in Lathe Technology and Surface Finishing

Innovations in gear train designs. Emerging materials and their effects on surface finish quality.Exciting things are happening in lathe technology! Innovative gear train designs are popping up everywhere. These new setups make lathes more efficient and can help produce better surface finishes. For instance, gears made from stronger materials can reduce vibrations, leading to smoother results. Did you know? A shiny finish can help parts last longer and look great! Check out the table below to see some promising materials:

| Material | Effect on Surface Finish |

|---|---|

| Carbon Fiber | Superior rigidity, minimal vibration |

| Titanium | Durable, lightweight, great finish |

| Composite Plastics | Good surface quality, cost-effective |

These emerging materials are like game-changers for lathes. They help in creating parts that are not only strong but also visually appealing. The future of lathe technology is bright, and we can’t wait to see where it goes!

Conclusion

In summary, understanding lathe surface finish is key for getting smooth, quality metal parts. A gear train in a lathe helps control speed and precision. By practicing with these tools, you can improve your skills. We encourage you to explore more about lathes and experiment with different finishes. This hands-on experience will boost your confidence and expertise in metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathe, And Gear Train:A lathe is a machine that helps shape things, usually metal. It spins the metal while a tool cuts away pieces, making it smooth. The surface finish is how nice and shiny that metal looks after using the lathe. We want it to be smooth so that it feels good and works better. Gear trains are like a team of gears that helps machines move smoothly and easily.

Sure! Please provide the question you want me to answer, and I will be happy to help!

What Factors Influence The Surface Finish Of A Workpiece When Using A Metal Lathe?When using a metal lathe, several factors can affect how smooth the surface of the piece becomes. First, the speed of the lathe matters; faster speeds can make a smoother finish. The type of tool you use also plays a role; sharper tools create better surfaces. Additionally, the material of the workpiece can change the result, as some metals are easier to work with. Finally, how steady you hold the workpiece while it spins is very important for a nice finish.

How Does The Configuration Of The Gear Train In A Lathe Affect Its Cutting Performance And Surface Finish Quality?The gear train in a lathe helps control how fast the cutting tool moves. If the gears are set up well, you get smoother cuts. This means better surface quality on your workpiece. If the gears are not right, the cuts might be rough and uneven. So, good gear setup makes everything work better!

What Are The Common Techniques Used To Improve Surface Finish On Turned Parts In A Lathe Operation?To make the surface of turned parts smoother on a lathe, we can use several methods. First, we can choose the right cutting tools, which can help make a cleaner cut. Then, we can adjust the speed of the lathe to find the best setting for a nice finish. Lastly, we can use a process called sanding or polishing to smooth out any rough spots. These techniques help make our parts look and feel better!

How Do Changes In Spindle Speed And Feed Rate Impact The Surface Finish Of Machined Metal Components?When we change the spindle speed, which is how fast the tool spins, it affects the surface smoothness. If you spin it too slow, the surface might be rough. A faster spin often gives a nicer finish. The feed rate, how fast the tool moves, also matters. Moving too quickly can make the surface uneven, while a slower move helps it look better.

What Role Does Tool Material And Geometry Play In Achieving The Desired Surface Finish On A Lathe?The tool material and shape are very important for a good surface finish on a lathe. You want the tool to be strong and sharp, so it cuts smoothly. If the tool is dull or made from weak material, it can leave rough spots. Also, the shape of the tool helps control how it touches the metal, which affects how shiny and smooth the finish will be.