Have you ever wondered how precise metal parts are made? One key tool in this process is the lathe. A lathe can create smooth surfaces on metal pieces that fit together perfectly.

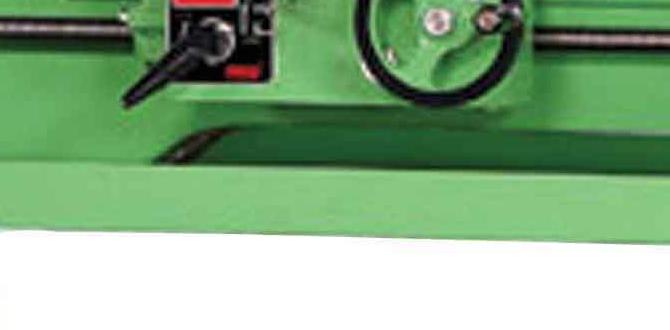

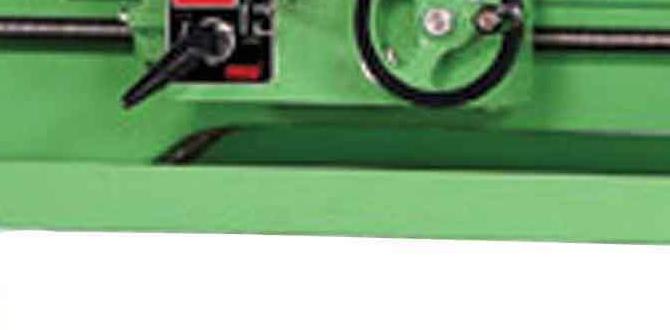

When using a lathe, the surface finish is very important. A good surface finish means less friction and better performance. If you’ve watched someone use a metal lathe, you might have noticed the handwheel. This little wheel plays a big role in getting the perfect finish. It helps control the movement of the tool, making sure every cut is just right.

Here’s a fun fact: the quality of the surface finish can be the difference between a good part and a great one. In this article, we will dive into how the lathe surface finish affects your project and why mastering the handwheel is a game changer.

Achieving Lathe Surface Finish With A Metal Lathe Handwheel

Understanding Lathe Surface Finish and the Handwheel

Lathe surface finish is crucial for making smooth metal parts. A good finish helps reduce wear and tear. Have you ever wondered how a shiny surface is created? The metal lathe handwheel plays a vital role in this process. It allows you to adjust the speed and position easily. With precision, it helps you craft detailed items. A well-finished surface not only looks great but also improves the part’s performance. Isn’t that amazing?Understanding Lathe Surface Finish

Definition and importance of surface finish in machining.. Key factors affecting surface finish quality..Surface finish refers to how smooth or rough a surface is after machining. It is important because it affects how well parts fit together and how they resist wear. A good surface finish can even improve a part’s strength! Key factors that affect surface finish include feed rate, cutting speed, and tool sharpness. Think of it like this: a smooth surface is like a polished apple—more appealing and less likely to get bruised!

| Factor | Effect on Surface Finish |

|---|---|

| Feed Rate | If too fast, it may leave rough marks. |

| Cutting Speed | Higher speeds can lead to smoother surfaces. |

| Tool Sharpness | Sharp tools create cleaner cuts! |

Components of a Metal Lathe

Description of essential parts of a metal lathe relevant to surface finish.. Role of the handwheel in achieving precision and control..A metal lathe has key parts that help it function well. The lathe bed holds everything in place. The spindle turns the workpiece. The tailstock supports the other end. Each part is important for a smooth surface finish. The handwheel allows you to make small adjustments easily. This control is vital for achieving precise cuts. With it, you can be accurate and careful as you work.

What is the importance of a handwheel in a metal lathe?

The handwheel is crucial in managing the lathe precisely. It helps control movement when you need to make small or detailed changes. This leads to a better finish on your metal piece, helping achieve the best results in your project.

How Handwheel Control Affects Surface Finish

Explanation of handwheel functionality and movement.. How handwheel adjustments can improve machining accuracy..The handwheel is like the magic wand of a lathe machine! It helps move the tool smoothly. A steady handwheel changes speed and direction just right. This ensures your metal surface looks sharp and shiny, instead of bumpy like a potato. With tiny adjustments on the handwheel, you can improve the accuracy of the cut. Smooth moves lead to a perfect finish every time! Remember, a good finish can turn a boring metal block into a shiny superstar!

| Handwheel Adjustment | Effect on Surface Finish |

|---|---|

| Small Adjustment | Improved Accuracy |

| Quick Movements | Rough Finish |

| Steady Control | Smooth Surface |

Techniques for Improving Lathe Surface Finish

Best practices for tool selection and setup.. Importance of feed rate and spindle speed..To make your lathe work smoother than a jazz saxophonist, focus on the right tools. Choosing sharp, high-quality tools is key. They can make your surface shiny and clean, like a polished apple!

The setup is equally important. Keep your tools at the right angle and ensure they’re secure. Too loose? They might dance around instead of cutting!

Also, pay attention to feed rates and spindle speeds. A good rule of thumb is: faster speeds make smoother finishes. But don’t worry, if things get too fast, your workpiece won’t run away from you!

| Speed (RPM) | Feed Rate (IPR) |

|---|---|

| 1000 | 0.02 |

| 2000 | 0.01 |

Try these tips and watch your lathe surface finish improve. Your projects will look so good, even your friends might think you hired a pro!

Common Issues that Affect Surface Finish

Identifying common problems (e.g., chatter, tool wear).. Troubleshooting strategies to mitigate surface finish defects..Surface finish can be affected by common issues during machining. One big problem is chatter, which creates vibrations leading to a rough surface. Another issue is tool wear. Worn tools can’t cut well, causing uneven finishes. To fix these problems, consider these strategies:

- Keep tools sharp and properly adjusted.

- Reduce cutting speed to limit chatter.

- Ensure the workpiece is secure.

By following these tips, you can improve the surface finish on your projects.

What is Chatter in Lathe Work?

Chatter is a vibration that happens during machining. It can create wavy lines on the surface of the metal, making it look unprofessional.

Maintenance Tips for Metal Lathes

Regular maintenance practices to ensure optimal performance.. Specific care tips for handwheel components..Keeping your lathe in tip-top shape is key for smooth operation. Regular care can save you from headaches later. Clean the surfaces often to avoid dirt buildup. Check the handwheel; it loves a little oil now and then! Applying lubricant every month helps it spin like a pro. Use a soft cloth to wipe it down, and check for wear. And remember, a happy lathe can make perfect metal parts, just like how a happy chef makes the best pancakes!

| Maintenance Task | Frequency | Tip |

|---|---|---|

| Clean Surface | Weekly | Use a soft cloth. |

| Check Handwheel | Monthly | Apply lubricant generously! |

| Inspect for Wear | Every 3 months | Look closely for any issues. |

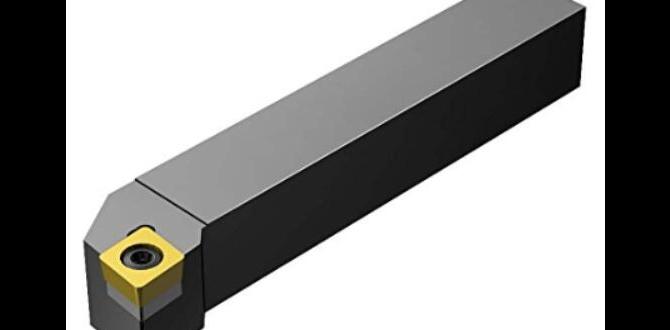

Tools and Accessories for Enhanced Surface Finish

Recommended tools for refining surface quality.. Accessories that assist in handwheel operation and finish quality..To achieve a smooth metal surface, having the right tools is key. First, a high-quality cutting tool can make a big difference. It carves through metal like a hot knife through butter. Next, consider using a fine-grit sandpaper or a polishing wheel to give it a final shine. These accessories not only help with the handwheel operation but also improve finish quality. Remember, a good finish isn’t just a treat for the eyes; it’s like giving your metal project a fancy haircut!

| Tool/Accessory | Purpose |

|---|---|

| Cutting Tool | Refines surface quality |

| Fine-Grit Sandpaper | Smooths rough edges |

| Polishing Wheel | Adds shine |

Case Studies: Success in Achieving Superior Surface Finishes

Examples of applications with excellent surface finish results.. Analysis of techniques used in successful projects..Many projects show how to get amazing surface finishes. For example, in a recent project, experts used a special technique called wet grinding. This gave a smooth finish on metal parts. Another example includes polishing surfaces to make them shine. Both methods improved functionality and aesthetics. Here are some highlights:

- Wet grinding reduced surface roughness significantly.

- Polishing enhanced the visual appeal and performance.

These examples show the success of specific techniques in achieving great results.

What are some successful techniques for achieving surface finishes?

Experts often use wet grinding and polishing to get high-quality surface finishes. These methods help make metal parts smoother and more attractive.

Future Trends in Lathe Surface Finishing Technologies

Innovations in machining that influence surface finish standards.. The evolving role of automation and smart technologies in metal lathes..In the future, lathe surface finishing will shine brighter than a freshly polished apple! Innovations in machining tools are raising the bar for surface finish standards. For example, machines now use fancy sensors to check how smooth a surface is, almost like a robot with a magnifying glass. Also, automation is taking the wheel—literally! Smart technologies help metal lathes adjust settings automatically, making them perfect for achieving that shiny finish.

| Trend | Description |

|---|---|

| Smart Sensors | These high-tech buddies analyze surface quality on the go! |

| Automation | Robots do the hard work, so you don’t have to! |

Ultimately, with these trends, getting that perfect metal finish will feel like a walk in the park—unless the park has hills!

Conclusion

In conclusion, a good lathe surface finish is important for your metalworking projects. The handwheel lets you control the machine easily. Proper technique and tool choice can improve results. Remember to practice to enhance your skills. For more tips on using a lathe and achieving great finishes, check out some beginner guides online. Happy turning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And The Operation Of A Metal Lathe Handwheel:Sure! To get a smooth surface finish on a metal lathe, we need to use the right tools. We should also set the speed correctly. A slow speed can help make the surface nice and smooth. When we turn the handwheel, we can carefully adjust how fast the tool moves. This helps us create a better finish on our metal piece.

Of course! Please go ahead and ask your question, and I’ll be happy to help you.

What Factors Influence The Surface Finish Quality When Machining A Metal Workpiece On A Lathe?The surface finish quality of a metal piece on a lathe depends on a few key factors. First, the tool type matters; sharp tools make smoother surfaces. Second, the speed you turn the metal affects how clean it feels. Third, the feed rate, or how fast you move the tool, can change the finish, too. Finally, using the right cutting fluid helps keep things cool and smooth.

How Does The Handwheel On A Metal Lathe Affect The Precision Of Depth And Feed Adjustments During Machining?The handwheel on a metal lathe helps you control the tool’s movement. When you turn it, you can adjust how deep or far the tool cuts. This makes your work more accurate because you can be very precise. If the handwheel moves smoothly, your adjustments will be better. So, using the handwheel correctly helps create better, cleaner parts.

What Techniques Can Be Employed To Achieve A Smoother Surface Finish On A Lathe-Milled Metal Part?To make a metal part smoother on a lathe, you can try a few things. First, use sharp tools to cut the metal cleanly. Second, you can go slow when you machine, so it doesn’t leave rough spots. Third, use fine sandpaper or polishing pads to smooth the surface by hand. Lastly, adding some oil can help reduce friction and make it shine.

How Do Different Cutting Tools And Materials Impact The Handwheel Settings For Optimal Surface Finish On A Lathe?Different cutting tools and materials can change how smooth a surface is when we use a lathe. If we use a sharp tool, we might need to turn the handwheel less. But if the tool is dull, we should turn it more to keep things smooth. Harder materials need careful settings too, so they don’t mess up the finish. So, always check your tool and material to get the best result.

What Maintenance Practices Can Help Ensure That The Handwheel And Other Components Of A Metal Lathe Remain In Good Condition For Achieving High-Quality Surface Finishes?To keep the handwheel and other parts of a metal lathe in good shape, we need to clean them regularly. Use a soft cloth to wipe off dust and oil. Check for any loose screws and tighten them if needed. Also, remember to oil the moving parts so they work smoothly. This helps us make really nice, smooth surfaces on our projects.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And The Operation Of A Metal Lathe Handwheel:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! To get a smooth surface finish on a metal lathe, we need to use the right tools. We should also set the speed correctly. A slow speed can help make the surface nice and smooth. When we turn the handwheel, we can carefully adjust how fast the tool moves. This helps us create a better finish on our metal piece.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please go ahead and ask your question, and I’ll be happy to help you.”}},{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Quality When Machining A Metal Workpiece On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The surface finish quality of a metal piece on a lathe depends on a few key factors. First, the tool type matters; sharp tools make smoother surfaces. Second, the speed you turn the metal affects how clean it feels. Third, the feed rate, or how fast you move the tool, can change the finish, too. Finally, using the right cutting fluid helps keep things cool and smooth.”}},{“@type”: “Question”,”name”: “How Does The Handwheel On A Metal Lathe Affect The Precision Of Depth And Feed Adjustments During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The handwheel on a metal lathe helps you control the tool’s movement. When you turn it, you can adjust how deep or far the tool cuts. This makes your work more accurate because you can be very precise. If the handwheel moves smoothly, your adjustments will be better. So, using the handwheel correctly helps create better, cleaner parts.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed To Achieve A Smoother Surface Finish On A Lathe-Milled Metal Part?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal part smoother on a lathe, you can try a few things. First, use sharp tools to cut the metal cleanly. Second, you can go slow when you machine, so it doesn’t leave rough spots. Third, use fine sandpaper or polishing pads to smooth the surface by hand. Lastly, adding some oil can help reduce friction and make it shine.”}},{“@type”: “Question”,”name”: “How Do Different Cutting Tools And Materials Impact The Handwheel Settings For Optimal Surface Finish On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools and materials can change how smooth a surface is when we use a lathe. If we use a sharp tool, we might need to turn the handwheel less. But if the tool is dull, we should turn it more to keep things smooth. Harder materials need careful settings too, so they don’t mess up the finish. So, always check your tool and material to get the best result.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Help Ensure That The Handwheel And Other Components Of A Metal Lathe Remain In Good Condition For Achieving High-Quality Surface Finishes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the handwheel and other parts of a metal lathe in good shape, we need to clean them regularly. Use a soft cloth to wipe off dust and oil. Check for any loose screws and tighten them if needed. Also, remember to oil the moving parts so they work smoothly. This helps us make really nice, smooth surfaces on our projects.”}}]}