Have you ever wondered how metal parts get their smooth, shiny finishes? It all happens with a machine called a lathe. Many people find that a good lathe surface finish can make all the difference in their projects. Yet, keeping a metal lathe running well is just as important as using it. Regular lathe maintenance helps keep the machine working like new.

Imagine making a beautiful piece, but it comes out rough and uneven. Disappointing, right? That’s why understanding both lathe surface finish and maintenance matters. A little care can go a long way in getting better results. Did you know that even small changes in maintenance can improve your finish? Let’s dive into the world of lathes and discover how to keep them in top shape for fantastic results!

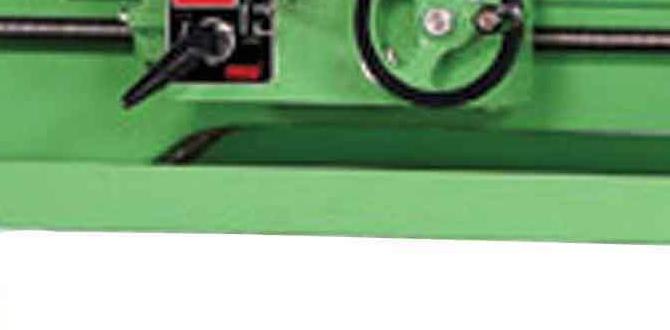

Lathe Surface Finish: Essential Metal Lathe Maintenance Tips

Lathe Surface Finish and Metal Lathe Maintenance

Creating a great surface finish on metal parts requires proper lathe maintenance. Do you know the secret behind that shiny finish? It’s all about keeping the lathe clean and well-lubricated. Regularly checking parts like bearings and belts ensures smooth operation. A well-maintained lathe prolongs its life and enhances precision. Did you know that simple rust can affect the quality? A few easy steps can help you achieve your desired results and keep your projects looking their best!Understanding Lathe Surface Finish

Definition of surface finish and its importance in machining.. Common measurement scales and techniques used to evaluate surface finish..Surface finish is how smooth or rough a machined part is. It plays a big role in how well parts fit together, reducing wear and tear. Think of it as the shiny haircut for metal! A better finish can mean less friction and longer-lasting parts. Common measurement scales include Ra and Rz. Ra measures average roughness, while Rz looks at the height of peaks and valleys. Keeping an eye on these can save you from mechanical drama!

| Measurement Scale | Description |

|---|---|

| Ra | Average roughness over a length |

| Rz | Distance from the highest peak to the lowest valley |

Factors Affecting Surface Finish on a Lathe

The impact of cutting tools and their geometry on surface quality.. Role of cutting parameters such as speed, feed rate, and depth of cut..Many things can change the smoothness of metal parts made on a lathe. One big factor is the cutting tools and their shapes. Different tools cut differently, affecting how shiny the surface will be. Another factor includes the cutting parameters. This means how fast the lathe spins, how much material we take off, and how quick we move the tool. All these parts work together to get the best finish.

What tools make a difference in surface quality?

Many tools affect the surface finish on a lathe. Sharp cutting edges can create a smoother surface. Tool geometry, like the angle of the edges, also matters.

Key cutting parameters include:

- Speed: How fast the lathe turns.

- Feed rate: How quickly the tool moves.

- Depth of cut: How much material we remove with each pass.

Types of Surface Finishes Achievable with a Lathe

Explanation of different finishes: rough, smooth, and mirror finish.. Applications and suitability of each finish type in various industries..When using a lathe, you can achieve different types of surface finishes. Each finish has its own look and feel. A rough finish is like a furry cat—soft and cozy, great for applications where grip is needed. A smooth finish is sleeker, perfect for parts in cars or machines where everything should slide perfectly. Then there’s the mirror finish, shiny enough to see your face in! This is best for decorative items or precision tools. Here’s a simple table for quick reference:

| Finish Type | Characteristics | Best Used In |

|---|---|---|

| Rough Finish | Texture is uneven | Handles, grips |

| Smooth Finish | Even and sleek | Machinery, automotive parts |

| Mirror Finish | Highly reflective | Decorative items, precision tools |

So, depending on what you need, choose your finish wisely! After all, who wants a dull-looking project? Not you!

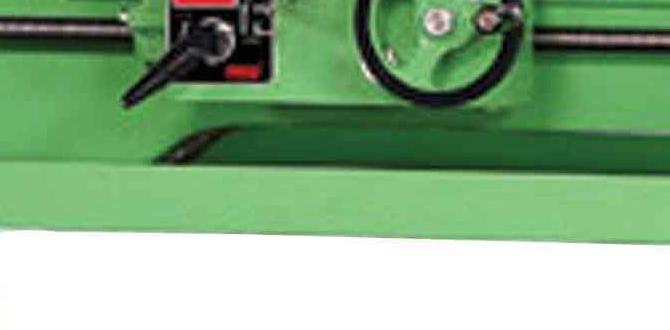

Essential Metal Lathe Maintenance Practices

Regular cleaning and lubrication procedures for optimal performance.. Importance of checking and adjusting lathe alignment and components..Keeping your metal lathe in tip-top shape is essential for great performance and a happy workshop. Regular cleaning and lubrication make machines run smoother than a buttered slide! Make sure to check for dirt and gunk and grease it up to keep everything moving. Alignment matters too; a crooked lathe is like a puzzle piece that doesn’t fit. Adjusting the alignment ensures precise cuts and better finishes.

| Maintenance Task | Frequency |

|---|---|

| Clean Lathe | After every use |

| Lubricate Parts | Weekly |

| Check Alignment | Monthly |

Remember, even your lathe enjoys a little pampering! So, keep it clean, greased, and aligned for smooth sailing.

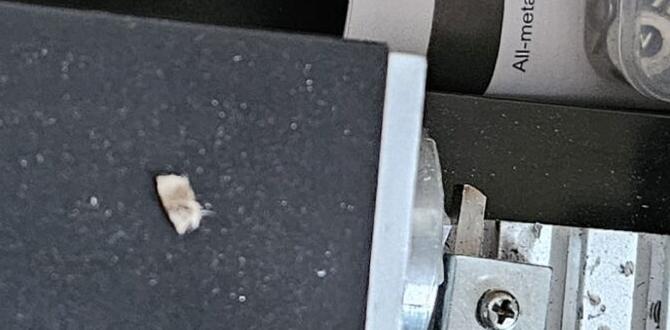

Common Lathe Problems Affecting Surface Finish

Identifying signs of wear or damage in tools and components.. Troubleshooting techniques for common issues impacting surface quality..When using a lathe, you might notice some signs that indicate problems. Look for wear or damage in tools and parts. For instance, chips, scratches, or dull tools can affect the surface finish of your work. Regular checks can help catch issues early.

- Check for dull cutting tools.

- Inspect tool holders for signs of wear.

- Look for vibration or odd noises during operation.

To troubleshoot common issues:

- Replace dull tools quickly.

- Align components correctly.

- Maintain cleanliness to reduce debris.

What are the signs of a worn lathe tool?

The main signs include dull edges, chipped parts, and rough finishes. Regular inspection will help keep your lathe functioning well.

Best Practices for Achieving Optimal Surface Finish

Techniques for tool setup and adjustment to enhance finish quality.. Tips for selecting appropriate materials and cutting conditions..To get the best surface finish on your metal lathe, proper tool setup is key. Ensure your tools are sharp and well-aligned. A dull tool is like a grumpy cat: it won’t do its job well! Think about your materials too. The right material can make cutting smoother. Also, adjust the speed and feed rate based on the type of metal. Using too fast a feed can give you a rough surface.

| Material Type | Recommended Speed (RPM) | Recommended Feed Rate (in/min) |

|---|---|---|

| Aluminum | 500-700 | 10-20 |

| Steel | 300-600 | 5-15 |

| Brass | 600-900 | 15-25 |

With these tips, you can improve your lathe’s performance. Remember, patience is a virtue, especially in metalwork. Start slow, and soon you’ll have a finish that shines brighter than a new toy!

Case Studies: Successful Lathe Surface Finish Applications

Examples of industries that benefit from precise surface finishes.. Analysis of specific projects where optimal maintenance led to improved outcomes..Many industries enjoy the smooth touch of a well-finished surface. For instance, the automotive sector benefits from great lathe work. A shiny finish on car parts means less friction and more speed, like a cheetah wearing roller skates!

In aerospace, precise finishes ensure parts fit together like a perfect puzzle. Take the example of a company that upgraded their lathe maintenance. They reported a 60% reduction in defects thanks to their careful upkeep!

| Industry | Benefits of Surface Finish |

|---|---|

| Automotive | Reduced friction, improved speed |

| Aerospace | Better fitting parts, increased safety |

These stories show how important lathe surface finishes are. With good maintenance, any project can soar high, just like a rocket!

Conclusion

In conclusion, maintaining your lathe is key to achieving a smooth surface finish. Regular cleaning and oiling keep your machine running well. Check for wear and tear to prevent problems. By taking these steps, you can ensure better results in your metalwork. For more tips, explore articles on lathe care and metalworking techniques to enhance your skills!FAQs

What Are The Key Factors That Influence The Surface Finish Of Parts Machined On A Metal Lathe?The surface finish of parts made on a metal lathe depends on a few key factors. First, the type of tool we use matters; sharper tools make smoother surfaces. Second, the speed at which we turn the metal affects the finish too; faster speeds often give better results. Lastly, we need to pay attention to how we feed the material into the tool; a steady feed improves the finish. By controlling these factors, you can make a shiny and smooth surface on your metal parts.

How Do You Properly Clean And Maintain A Metal Lathe To Ensure Optimal Surface Finish Quality?To clean your metal lathe, start by turning it off and unplugging it. Use a soft cloth to wipe away dirt and oil. Check the parts for any chips or bits of metal and remove them carefully. You should also grease the moving parts to keep everything running smoothly. Regular cleaning helps the lathe make better pieces!

What Types Of Tooling And Cutting Conditions Are Best For Achieving A Superior Surface Finish On A Lathe?To get a smooth surface on a lathe, use sharp cutting tools. These tools help cut cleanly. Choose slow speeds and light pressure while cutting. This keeps the metal from getting rough. Always keep the tool and workpiece clean to help make a nice finish.

How Can One Identify And Troubleshoot Common Issues That Negatively Affect Surface Finish During Lathe Operations?To spot and fix issues that make a surface look rough, start by checking the tools. Make sure they are sharp and clean. If the tool is dull, it can create scratches. Next, look at how fast the lathe is spinning; going too fast can make the finish worse. Finally, check the way you move the tool. Moving it too fast or slow can also hurt the finish.

What Routine Maintenance Practices Should Be Implemented To Prolong The Life Of A Lathe And Improve Its Surface Finishing Capabilities?To keep a lathe in good shape, we should clean it regularly. Dust and chips can hurt the machine. We need to oil moving parts to keep them smooth. Check the belts and gears for wear and tear, and replace them if needed. Finally, always store tools properly to avoid damage.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Factors That Influence The Surface Finish Of Parts Machined On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The surface finish of parts made on a metal lathe depends on a few key factors. First, the type of tool we use matters; sharper tools make smoother surfaces. Second, the speed at which we turn the metal affects the finish too; faster speeds often give better results. Lastly, we need to pay attention to how we feed the material into the tool; a steady feed improves the finish. By controlling these factors, you can make a shiny and smooth surface on your metal parts.”}},{“@type”: “Question”,”name”: “How Do You Properly Clean And Maintain A Metal Lathe To Ensure Optimal Surface Finish Quality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean your metal lathe, start by turning it off and unplugging it. Use a soft cloth to wipe away dirt and oil. Check the parts for any chips or bits of metal and remove them carefully. You should also grease the moving parts to keep everything running smoothly. Regular cleaning helps the lathe make better pieces!”}},{“@type”: “Question”,”name”: “What Types Of Tooling And Cutting Conditions Are Best For Achieving A Superior Surface Finish On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a smooth surface on a lathe, use sharp cutting tools. These tools help cut cleanly. Choose slow speeds and light pressure while cutting. This keeps the metal from getting rough. Always keep the tool and workpiece clean to help make a nice finish.”}},{“@type”: “Question”,”name”: “How Can One Identify And Troubleshoot Common Issues That Negatively Affect Surface Finish During Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To spot and fix issues that make a surface look rough, start by checking the tools. Make sure they are sharp and clean. If the tool is dull, it can create scratches. Next, look at how fast the lathe is spinning; going too fast can make the finish worse. Finally, check the way you move the tool. Moving it too fast or slow can also hurt the finish.”}},{“@type”: “Question”,”name”: “What Routine Maintenance Practices Should Be Implemented To Prolong The Life Of A Lathe And Improve Its Surface Finishing Capabilities? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a lathe in good shape, we should clean it regularly. Dust and chips can hurt the machine. We need to oil moving parts to keep them smooth. Check the belts and gears for wear and tear, and replace them if needed. Finally, always store tools properly to avoid damage.”}}]}