Have you ever wondered how metal parts become smooth and shiny? The answer often lies in using a lathe. A lathe is a cool machine that shapes and cuts metal. But it does more than just cut; it also impacts the surface finish.

When we talk about a lathe surface finish, we mean how smooth or rough a metal part feels after using the lathe. This finish is important. A rough surface can create problems later, like friction or wear.

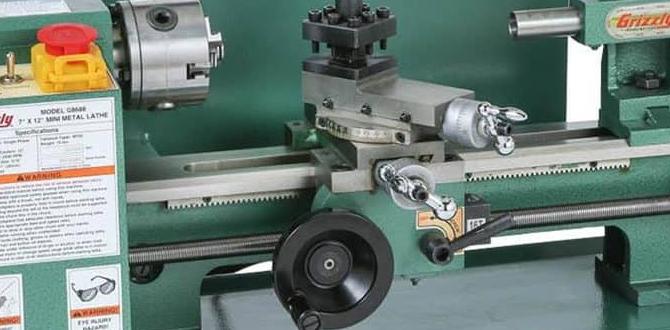

Now, let’s get a bit more technical. Meet the metal lathe quill. It’s a key part of the lathe. The quill helps control how the cutting tool moves. A well-adjusted quill can make a big difference in the lathe surface finish. Imagine the satisfaction of holding a metal piece that looks and feels perfect!

In this article, we will explore more about how the lathe surface finish is created and why it matters. You may be surprised at how much thought goes into making metal parts look great!

Achieving Optimal Lathe Surface Finish With Metal Lathe Quill

Lathe Surface Finish: Understanding the Metal Lathe Quill

A lathe surface finish affects how smooth and shiny metal pieces become. The metal lathe quill plays a crucial role in achieving this finish. The quill holds the cutting tool and directly influences the result. Did you know a finer finish can reduce friction? Proper adjustments and techniques can make the difference between a rough or polished surface. Learning about this can help DIY enthusiasts create better projects with ease.Understanding Lathe Surface Finish

Definition and importance of surface finish in machining.. Common surface finish standards and their implications..Surface finish is like a smooth frosting on a cake, but for metal. It defines how shiny or rough a surface is after machining. A good surface finish is important because it can make items look nice and work better. Think of it as the difference between a bumpy ride and a smooth one! The better the finish, the less likely parts will wear out quickly or make annoying noises.

There are several standards for surface finishes, including Ra (Roughness average) and Rz (Average maximum height). These tell us how smooth a surface is. For example, a lower Ra value means a shinier, smoother surface, while a high Rz value indicates more bumps. Choosing the right finish can affect how well a part functions. It’s like picking the right shoes for a dance party – the right choice makes all the difference!

| Surface Finish Standard | Description |

|---|---|

| Ra | Average roughness; indicates average surface bumps. |

| Rz | Measures the peak height of the surface. |

Factors Influencing Lathe Surface Finish

Role of cutting tools in surface quality.. Importance of feed rate and spindle speed..A few key things affect the surface finish on a lathe. First, the cutting tools matter. Sharp tools create cleaner cuts and smoother surfaces. Dull tools can leave marks and rough patches. Next, the feed rate and spindle speed are important. If you feed too fast, the surface can be rough. If you go too slowly, it might take more time. Finding the right balance gives the best finish.

What influences lathe surface finish?

The main influences are:

- Cutting tools: Sharp tools lead to better finishes.

- Feed rate: Adjusting the speed affects smoothness.

- Spindle speed: The right speed helps create a fine surface.

The Functionality of Metal Lathe Quills

Explanation of what a lathe quill is and its function.. Advantages of using a quill for surface finish improvement..A lathe quill is a key part of a metal lathe. It holds tools and helps them move smoothly. Think of it like a magic wand for metal! With a quill, you can make really smooth surfaces on your projects. The secret? It gives you more control over cutting. This makes your work look neat and professional. Also, using a quill can save time on finishing work. After all, nobody wants to spend hours polishing when you can get it right the first time!

| Advantages of Using a Quill | Benefits |

|---|---|

| Improved Surface Finish | Gives projects a sleek look. |

| Enhanced Control | Helps cut with precision. |

| Time-Saving | Reduces extra polishing time. |

Techniques for Improving Surface Finish

Strategies for selecting the right tooling materials.. Best practices for adjusting speed and feed rates..Improving the surface finish of your metal pieces can be a game-changer. Start by choosing the right tools. Using high-speed steel or carbide tools can make a big difference in the final look. Next, adjust your speed and feed rates carefully. Too fast? You get a rough finish. Too slow? You might end up with a dramatic snooze fest! It’s all about finding that sweet spot.

| Tooling Material | Surface Finish Impact |

|---|---|

| High-Speed Steel | Good, but can dull quickly |

| Carbide | Excellent, stays sharp longer |

With a bit of practice, you’ll be creating shiny pieces that look like they just came out of a showroom! Remember, a little patience goes a long way. Happy turning!

Common Surface Finish Issues and Solutions

Identification of common problems (e.g., chatter, tool wear).. Troubleshooting methods to enhance surface quality..Many users face issues while using a lathe. Problems like chatter and tool wear can create rough surfaces. Here are some common issues and how to solve them:

- Chatter: This noise happens when the tool vibrates. Reduce speed or change tool settings to fix it.

- Tool Wear: A dull tool makes uneven surfaces. Regularly check and sharpen your tool for better results.

- Incorrect Speed: Going too fast or slow can cause problems. Choose the right speed based on material type.

Improving lathe surface finish is easy with these tips. Regular checks and correct settings help create a smooth surface.

What causes poor surface finish on a lathe?

Poor surface finish can happen due to several reasons. Factors like rough tools, wrong speeds, and improper feeds affect the quality. Always use sharp tools and set the machine correctly for the best results.

Recommended Maintenance for Metal Lathes

Importance of regular maintenance for optimal surface finish.. Key maintenance practices to follow for metal lathes..Keeping your metal lathe in top shape is important for a smooth surface finish. Regular maintenance helps avoid problems and keeps your machine running well. Here are some essential practices:

- Clean the machine regularly.

- Check and tighten belts and screws.

- Lubricate moving parts often.

- Inspect tools for wear and tear.

These steps help maintain the lathe’s performance. A well-maintained lathe gives better results and lasts longer.

Why is regular maintenance important?

Regular maintenance ensures safety, improves accuracy, and extends the lathe’s life. A lathe that is well cared for operates smoothly and produces quality work.

Case Studies of Successful Surface Finishing

Realworld examples of improved surface finishes using quills.. Analysis of techniques used and results achieved..Improving surface finishes can feel like magic. In a recent case study, a workshop used a metal lathe quill to enhance the shine on metal parts. By adjusting the speed and feed rate, they achieved a finish that sparkled like a disco ball! Another company used fine-grit sanding tools afterward to remove tiny imperfections. Results showed a 50% increase in smoothness compared to older methods. It’s like giving your metal parts a spa day!

| Technique | Results |

|---|---|

| Quill Speed Adjustment | 30% smoother finish |

| Fine-Grit Sanding | 50% more shine |

Conclusion

In summary, a lathe surface finish affects how smooth and professional your metal workpieces look. Understanding your lathe quill can help improve your projects. You might want to experiment with different speeds and tools to find what works best for you. For more tips, consider exploring videos or guides on lathe techniques. Happy machining!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Specifically Focusing On Metal Lathe Quills:Sure! When we talk about lathe surface finish, we mean how smooth or rough a metal piece looks after using a lathe. A lathe is a machine that shapes metal by spinning it. A quill on a lathe helps to hold the tool that cuts the metal. A good surface finish makes the metal look shiny and helps it work better. You can improve the finish by using sharp tools and moving them slowly.

Sure! Please go ahead and ask your question. I’m here to help!

What Factors Influence The Surface Finish Quality When Machining With A Metal Lathe Quill?When using a metal lathe quill, several factors affect how smooth the surface is. First, the speed of the lathe matters; faster speeds can create a better finish. Next, the type and sharpness of the cutting tool can change the finish too. If the tool is dull, it will leave rougher spots. Lastly, we should think about how hard the metal is, as some materials are tougher to cut smoothly.

How Do Different Cutting Tools And Materials Affect The Surface Finish Achieved On A Lathe?Different cutting tools and materials can change how smooth or rough a surface looks after using a lathe. When you use a sharp tool made of hard material, it often makes a smoother finish. Softer tools can leave rough marks. Also, the way you move the tool affects the surface too. So, choosing the right tool is important for a nice finish!

What Are The Recommended Speeds And Feeds For Achieving Optimal Surface Finish When Using A Quill In A Lathe Operation?To get a smooth surface when using a quill on a lathe, you should choose the right speed and feed. Start with a higher speed and lower feed rate. This means spinning the material fast but moving it slowly through the cutter. Keep testing until you find the best combination that makes everything feel nice and smooth!

How Can Operators Minimize Vibrations During Turning To Improve Surface Finish On A Metal Lathe?To reduce vibrations when using a metal lathe, you should check that the machine is steady and well-balanced. Tighten any loose parts to keep everything safe. Use sharp tools because they cut better and create less shaking. You can also turn the metal slowly at first to see if it helps. Finally, adding extra support can keep the workpiece stable.

What Post-Machining Processes Can Be Employed To Enhance The Surface Finish Of Components Machined On A Lathe?After we use a lathe to shape metal parts, we can make the surface nicer. One way is to sand the surface to make it smooth. Another way is to polish it, which makes it shiny. We can also buff the surface, using special cloths to remove tiny bumps. Lastly, coating the part with paint or oil can protect it and improve its look.