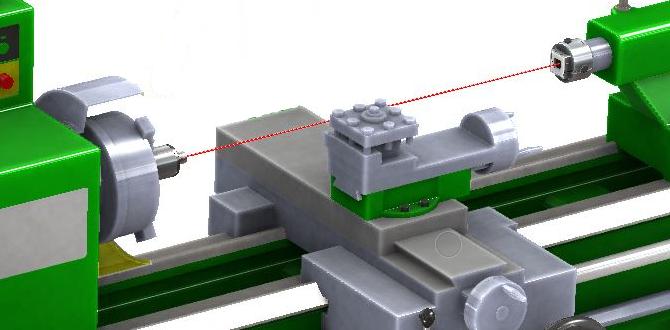

Have you ever wondered how metal parts get their shiny surfaces? One of the key players in this process is a lathe. A lathe is a machine that shapes metal by rotating it against a cutting tool.

Think about the last time you held a beautifully crafted metal item. The smooth finish makes it look perfect. This finishing touch comes from the lathe’s ability to create a fine surface on the metal. But what about the lathe surface finish itself? It plays a huge role in the quality of the final product.

Imagine a metal lathe saddle, the part that holds the tools in place as they work. If the saddle isn’t finished well, it can affect the whole machining process. Poor finishes can lead to rough surfaces and, ultimately, problems with the product.

Did you know that the right finish can also increase the lifespan of the tools used? Good surface finishes mean less wear and tear. It’s like giving your tools a cozy, protective blanket! Let’s dive into the world of lathe surface finishes and explore their importance in metalworking.

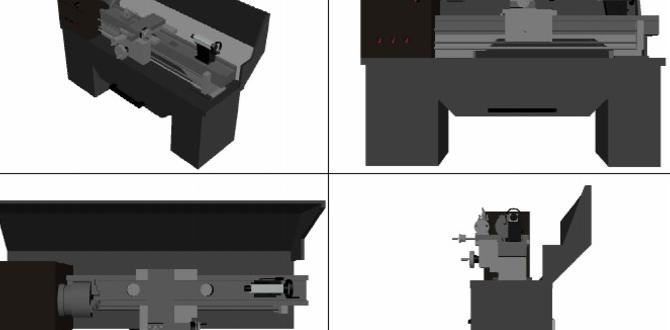

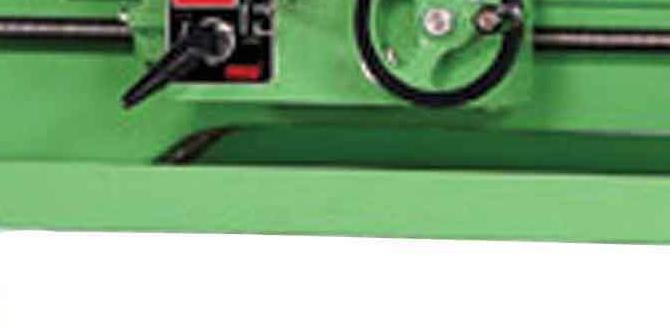

Lathe Surface Finish: Enhancing Metal Lathe Saddle Performance When It Comes To Machining, Achieving A High-Quality Lathe Surface Finish Is Crucial For The Performance And Longevity Of Components, Particularly For The Metal Lathe Saddle. The Surface Finish Can Directly Influence How Well The Saddle Operates, Impacting Both Accuracy And Durability. This Article Will Delve Into The Importance Of Lathe Surface Finish, Techniques To Achieve Optimal Results, And Factors Affecting The Quality Of The Surface Finish On Metal Lathe Saddles. Importance Of Lathe Surface Finish The Surface Finish Of The Metal Lathe Saddle Is Vital For Several Reasons: 1. **Reduced Friction**: A Smooth Surface Decreases Friction, Leading To Less Wear And Tear On Both The Saddle And The Workpiece. 2. **Accuracy**: A Finer Finish Contributes To Enhanced Precision During Machining Operations, Ensuring Tighter Tolerances. 3. **Aesthetic Appeal**: In Some Applications, The Appearance Of The Finished Product Is Important, Especially In Industries Where Aesthetics Matter. Techniques For Achieving Optimal Surface Finish To Enhance The Surface Finish Of A Metal Lathe Saddle, Various Techniques Can Be Employed: 1. **Proper Tool Selection**: Using The Right Cutting Tools, Such As Carbide Inserts Designed For Finish Cuts, Plays A Significant Role In Achieving A Desirable Surface Finish. 2. **Appropriate Cutting Speed**: Adjusting The Cutting Speed Can Impact The Finish Quality. Higher Speeds Often Result In A Better Finish. 3. **Feed Rate Considerations**: A Lower Feed Rate Generally Yields A Smoother Finish, As It Allows For Finer Cuts Over The Workpiece Surface. 4. **Coolant Usage**: Utilizing Coolant During Machining Helps To Reduce Heat And Remove Chips, Contributing To A Smoother Surface. Factors Affecting Surface Finish Quality Several Factors Can Hinder The Quality Of The Surface Finish On A Metal Lathe Saddle: 1. **Tool Wear**: Dull Or Worn Cutting Tools Can Lead To Poor Surface Finishes, Necessitating Regular Inspection And Replacement. 2. **Material Properties**: The Type Of Metal Being Machined Can Significantly Affect The Achievable Surface Finish. Some Materials Are More Challenging To Handle Than Others. 3. **Machine Condition**: A Well-Maintained Lathe Will Produce Better Finishes Compared To One That Is Poorly Serviced. Conclusion Achieving An Excellent Lathe Surface Finish On A Metal Lathe Saddle Is Critical For Machining Success. By Understanding The Importance Of Surface Finish, Employing Effective Techniques, And Recognizing Potential Pitfalls, Machinists Can Enhance The Functionality And Lifespan Of Their Lathe Saddles And Produce High-Quality Components. With Attention To These Details, The Performance Of Your Metal Lathe Will Improve Significantly, Making The Investment Worthwhile.

Understanding Lathe Surface Finish on Metal Lathe Saddle

Lathe surface finish is crucial for achieving smooth, precise metal parts. A well-finished lathe saddle helps reduce wear and tear on tools. Did you know a rough finish can lead to poor performance? Proper techniques enhance part accuracy and extend tool life. When using a lathe, selecting the right speed and feed rate is essential. These factors directly influence the surface quality. Ultimately, mastering these details can elevate any lathe project.Importance of Lathe Surface Finish

Significance of surface finish in machining processes. Effects of surface finish on part functionality and longevity.Surface finish is very important in machining. It affects how parts work and last over time. A smooth finish helps parts fit together better. This means they can move easily and will not wear out quickly. In fact, poor finishes can lead to breakage. Good surface finish can extend a part’s life, saving time and money. Every detail counts!

- Enhances performance: Smooth surfaces reduce friction.

- Increases lifespan: Quality finish prevents wear and tear.

- Improves safety: Reliable parts are safer to use.

Why is surface finish crucial in machining processes?

Surface finish plays a key role in ensuring parts function efficiently and last longer. Without it, parts may not work correctly or could break easily.

Factors Influencing Surface Finish in Metal Lathes

Tool material and geometry impact on finish quality. Effects of cutting speed, feed rate, and depth of cut.Several factors affect the surface finish in metal lathing. The type of tool material and its shape matter greatly. Harder materials can produce a smoother finish. The angle of the tool also plays a role. Other important factors include:

- Cutting speed: Faster speeds create smoother surfaces.

- Feed rate: A slower feed rate enhances quality.

- Depth of cut: Shallow cuts yield finer finishes.

Adjusting these settings carefully can lead to better results in metalworking.

What tools affect metal lathe surface finish?

The tools used are crucial. High-speed steel or carbide tools offer better finishes. Their material and shape can improve how smooth the surface ends up.

Techniques to Improve Surface Finish on Metal Lathe Saddles

Tips for optimizing tool setup and cutting conditions. Methods for postmachining treatments (e.g., polishing, coating).Improving surface finish on metal lathe saddles can be fun and rewarding! First, ensure you have the right tool setup. Using sharp tools helps make clean cuts—think of them as the “knives” of your lathe! Adjusting the speed and feed rate plays a big part too. Besides cutting, try post-machining treatments like polishing or coating. They can add a shiny touch, making your work look pro! Here’s a quick table for reference:

| Technique | Description |

|---|---|

| Sharp Tools | Use sharp tools for clean cuts. |

| Speed/Feed Adjustment | Optimize speed and feed rate for better finishes. |

| Polishing | Use polishing compounds to enhance shine. |

| Coating | Apply a protective coating for durability. |

Remember, a little humor goes a long way! So, let’s keep those machines buzzing and those saddles shining!

Common Problems and Solutions in Achieving Desired Surface Finish

Troubleshooting common issues related to surface finish. Solutions for correcting surface imperfections.Achieving the perfect surface finish can feel like hunting for a unicorn. Common problems include rough surfaces or unsightly marks. These issues usually stem from dull tools or incorrect speeds. Don’t despair! You can fix these with a few simple steps. Always use sharp tools and check your lathe settings. Want tips in a flash? Here’s a quick table:

| Issue | Solution |

|---|---|

| Rough Surface | Use a sharper tool and slower speed. |

| Scratches | Clean your lathe and check aligned parts. |

| Tool Marks | Ensure proper feed rate and depth. |

Remember, a little maintenance goes a long way. A well-cared-for lathe is like a happy pet—it works better!

Comparative Analysis: Different Types of Surface Finishes

Discussion of various surface finishing processes (e.g., grinding, milling). Pros and cons of each finishing method for metal lathe saddles.Different methods can change how metal looks and feels. Some common methods are grinding and milling. Each has strengths and weaknesses. Let’s take a look:

- Grinding: Gives a smooth finish. It’s great for precision. However, it can take longer and may wear out tools quickly.

- Milling: This method removes large amounts of material quickly. It’s fast but might leave a rougher surface than grinding.

Choosing the right method depends on what you need. Each technique has its unique advantages and challenges, making the decision important for quality.

What are the best surface finish options for lathe saddles?

Grinding and milling are top choices for lathe saddles. They help achieve the desired surface quality, durability, and overall look.

Future Trends in Lathe Surface Finishing Technology

Innovations in machining and surface finish enhancement. Impact of advanced materials and technologies on surface finish quality.New tools are shaping the way we finish surfaces on metal lathes. With innovative machines, we can achieve smoother surfaces. Advanced materials like ceramics and composites help improve quality. These materials last longer and resist wear. Future tech like robots and AI will also play a big part. They will make processes faster and more precise. This will help create better metal lathe saddles.

What are the benefits of advanced materials in surface finishing?

Advanced materials lead to better surface finishes. They help machines run smoother, reducing friction. This means parts last longer and require less maintenance.

Future innovations include:

- Robotics for precision

- AI for smarter processes

- New materials for durability

Conclusion

In summary, a lathe surface finish on a metal lathe saddle is crucial for smooth operation. A good finish reduces friction and improves durability. You can achieve this by using the right tools and techniques. If you’re interested in learning more, consider exploring videos on lathe techniques or joining a workshop. Practice will help you master this skill!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Specifically Focusing On The Metal Lathe Saddle:Sure! The lathe saddle is an important part of a metal lathe. It holds the cutting tool in place. A smooth surface finish makes the final product look nice and work better. You need to keep the saddle clean to get good results. Checking the saddle often helps improve the finish of your pieces.

Sure! Please give me the question you would like me to answer.

What Factors Influence The Surface Finish Quality Of Components Machined On A Metal Lathe Saddle?The surface finish quality of parts made on a metal lathe saddle depends on a few things. First, the sharpness of the cutting tools matters. When they are sharp, they cut smoothly. Second, the speed of the lathe affects how the metal is shaped. If it’s too fast or too slow, it can create rough surfaces. Lastly, the type of metal being used also changes the finish. Softer metals can look smoother than harder ones.

How Can The Cutting Tool Geometry Affect The Surface Finish When Using A Metal Lathe Saddle?The shape of the cutting tool can change how smooth the metal feels. If the tool is sharp and set at the right angle, it cuts better. This means you get fewer bumps and scratches on the surface. If it’s too dull or at the wrong angle, the finish can be rough and uneven. So, we need to choose the right tool shape for a nice finish.

What Are The Best Practices For Maintaining The Surface Finish On A Metal Lathe Saddle During Machining Operations?To keep the surface finish on a metal lathe saddle looking good, you should clean it regularly. Use a soft cloth to wipe off dust and chips from machining. Make sure to oil the saddle to keep it running smoothly. You should also check that the cutting tools are sharp. Sharp tools help make a better finish!

How Does The Choice Of Machining Parameters, Such As Feed Rate And Spindle Speed, Impact The Surface Finish Achieved On A Lathe Saddle?When we use a lathe, we can change the feed rate and spindle speed. The feed rate controls how fast the tool moves. A slower feed rate usually gives a smoother surface. Higher spindle speed can also help make the surface nice and shiny. So, choosing the right settings makes our work look better!

What Are Common Methods For Measuring And Assessing Surface Finish Quality On Parts Produced By A Metal Lathe Saddle?You can check the surface finish of parts made by a metal lathe using simple tools. One method is using a ruler to measure how smooth it feels. You can also use a device called a surface roughness tester. This device can tell you how rough or smooth the surface is with numbers. Lastly, you can look at the part under a light to see how shiny or dull it is.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Specifically Focusing On The Metal Lathe Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! The lathe saddle is an important part of a metal lathe. It holds the cutting tool in place. A smooth surface finish makes the final product look nice and work better. You need to keep the saddle clean to get good results. Checking the saddle often helps improve the finish of your pieces.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Quality Of Components Machined On A Metal Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The surface finish quality of parts made on a metal lathe saddle depends on a few things. First, the sharpness of the cutting tools matters. When they are sharp, they cut smoothly. Second, the speed of the lathe affects how the metal is shaped. If it’s too fast or too slow, it can create rough surfaces. Lastly, the type of metal being used also changes the finish. Softer metals can look smoother than harder ones.”}},{“@type”: “Question”,”name”: “How Can The Cutting Tool Geometry Affect The Surface Finish When Using A Metal Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The shape of the cutting tool can change how smooth the metal feels. If the tool is sharp and set at the right angle, it cuts better. This means you get fewer bumps and scratches on the surface. If it’s too dull or at the wrong angle, the finish can be rough and uneven. So, we need to choose the right tool shape for a nice finish.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining The Surface Finish On A Metal Lathe Saddle During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the surface finish on a metal lathe saddle looking good, you should clean it regularly. Use a soft cloth to wipe off dust and chips from machining. Make sure to oil the saddle to keep it running smoothly. You should also check that the cutting tools are sharp. Sharp tools help make a better finish!”}},{“@type”: “Question”,”name”: “How Does The Choice Of Machining Parameters, Such As Feed Rate And Spindle Speed, Impact The Surface Finish Achieved On A Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use a lathe, we can change the feed rate and spindle speed. The feed rate controls how fast the tool moves. A slower feed rate usually gives a smoother surface. Higher spindle speed can also help make the surface nice and shiny. So, choosing the right settings makes our work look better!”}},{“@type”: “Question”,”name”: “What Are Common Methods For Measuring And Assessing Surface Finish Quality On Parts Produced By A Metal Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can check the surface finish of parts made by a metal lathe using simple tools. One method is using a ruler to measure how smooth it feels. You can also use a device called a surface roughness tester. This device can tell you how rough or smooth the surface is with numbers. Lastly, you can look at the part under a light to see how shiny or dull it is.”}}]}