Have you ever wondered how a simple lathe can create smooth metal surfaces? It might sound tricky, but with the right skills, it’s easy. One key factor in making sure your lathe works well is the tailstock alignment. If it’s not aligned correctly, your metal finish can turn out uneven or rough.

Think of it like riding a bike. If your wheels aren’t lined up, you might wobble and stumble. The same goes for using a metal lathe. Proper tailstock alignment makes a huge difference. Did you know that even a tiny misalignment can mess up your project? It can cost you time and materials.

In this article, we will explore lathe surface finish, the importance of tailstock alignment, and how you can achieve the best results. Ready to get started on making your lathe work like a pro? Let’s dive in!

Lathe Surface Finish: Metal Lathe Tailstock Alignment Explained

Understanding Lathe Surface Finish and Tailstock Alignment

Proper lathe surface finish is crucial for any metalworking project. Did you know that an aligned tailstock can greatly improve accuracy? When the tailstock isn’t aligned, it can cause poor surface finish and uneven cuts. Ensuring correct tailstock alignment means smoother operations and better results. Always check your alignment before starting a project. This small step can save you time and materials, and who doesn’t want a perfect finish on their work?Understanding Lathe Surface Finish

Definition and importance of surface finish in machining. Common surface finish standards and their implications.Imagine a mirror finish on metal; that’s what surface finish is all about! It measures how smooth a material is after machining. A great surface finish is important because it affects how a part fits together and how long it lasts. Think of it as giving your metal a good spa day!

There are some common standards for surface finish. For example, Ra measures the average roughness. A lower number means a smoother surface. Here’s a quick look at common surface finish standards:

| Standard | Roughness Level (Ra) |

|---|---|

| Very Rough | 5.0 µm |

| Rough | 3.2 µm |

| Medium | 1.6 µm |

| Smooth | 0.4 µm |

| Very Smooth | 0.1 µm |

Better surface finishes lead to less wear and tear. Plus, who doesn’t love a shiny metal piece that sparkles like a diamond? So, remember, a good surface finish means better performance!

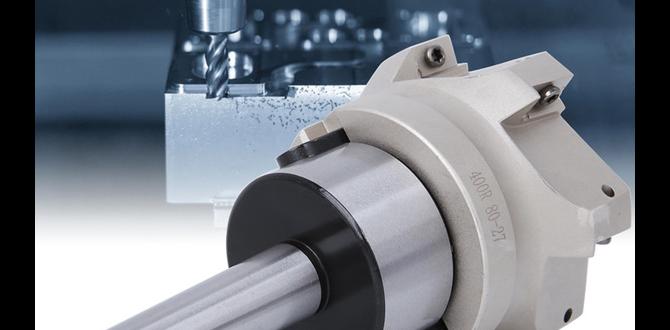

The Role of Tailstock in Metal Lathes

Explanation of the function of the tailstock in lathe operations. How tailstock alignment affects overall machining accuracy.The tailstock is like the trusty sidekick in metal lathe operations. It supports the other end of the workpiece, much like how a friend holds a heavy pizza box! If it’s not aligned properly, expect some wobble. This affects machining accuracy—nobody wants uneven donut-shaped metal parts! Good alignment ensures a smooth finish and precision cut. Remember, a well-aligned tailstock leads to happy machining!

| Key Points | Effects of Poor Alignment |

|---|---|

| Stability of workpiece | Wobbly and uneven cuts |

| Accuracy in machining | Increased errors |

| Final surface finish | Poor quality output |

Common Tailstock Alignment Issues

Identification of typical problems encountered with tailstock alignment. Effects of misalignment on surface finish quality.Many users face issues with tailstock alignment on their lathes. Some common problems include:

- Misalignment of the tailstock

- Worn-out or damaged parts

- Poor adjustment of tailstock screws

Misalignment can lead to bad surface finishes on your metal work. You might see scratches, uneven surfaces, or vibrations. These issues can ruin your project and waste materials. Proper alignment is crucial for best results.

What are the main problems of tailstock alignment?

Common problems include misalignment, worn parts, and improper adjustments. These issues can affect the quality of your work significantly.

Achieving Optimal Surface Finish Through Proper Alignment

Correlation between tailstock alignment and surface finish quality. Case studies or examples illustrating alignment effects on surface finish.Proper tailstock alignment can make a huge difference in the surface finish of your workpiece! Think of it like trying to draw a straight line; if your pencil is misaligned, the line gets wobbly. Case studies show a misaligned tailstock can lead to scratches and uneven surfaces. For instance, one shop saw a 30% improvement in surface quality after correcting alignment. Below is a quick overview:

| Alignment Status | Surface Finish Quality |

|---|---|

| Misaligned | Poor |

| Correctly Aligned | Excellent |

So, keep that tailstock in check, and you’ll be turning out shiny pieces in no time! Who knew alignment could bring out your inner machining artist?

Regular Maintenance Practices for Tailstock and Surface Finish Quality

Recommended maintenance routines for lathes and tailstocks. Signs that indicate the need for alignment checks and adjustments.Keeping your lathe and tailstock in great shape is like feeding a pet; it keeps them happy and working well! Regular maintenance should include cleaning and oiling parts. Look for signs your tailstock may need some love: loose handles or poor surface finish can be clues. A good rule is to check alignment every few months or when you notice something feels off.

| Maintenance Routine | Signs for Alignment Check |

|---|---|

| Clean and lubricate parts weekly | Wobbling in tools or materials |

| Check for wear and tear monthly | Uneven cuts or surface finish |

| Examine tailstock alignment bi-monthly | Difficulty in locking tailstock |

It’s like giving your lathe a spa day, minus the cucumber slices! When your lathe feels good, it performs like a champion.

Expert Tips for Advanced Machinists

Professional insights and best practices for enhancing lathe operations. Recommended adjustments and setups for different machining scenarios.Improving lathe operations can boost your productivity. Here are some expert tips:

- Check the tailstock alignment regularly. Misalignment can lead to poor finishes.

- Adjust the speed for different materials. Softer metals need slower speeds.

- Use quality tools for better surface finishes.

- Maintain consistent pressure while machining to reduce chatter.

Follow these practices, and you’ll see great results!

How can I improve lathe surface finish?

Use sharp tools and clean the workspace. Adjust the speed based on the material for smoother cuts.Recommended adjustments:

- Lower speed for soft materials.

- Increase speed for harder materials.

- Use lubricant for better cut quality.

Conclusion

In conclusion, proper tailstock alignment on a metal lathe is crucial for a smooth surface finish. It helps prevent defects and improve accuracy. Remember to check your alignment regularly and adjust if needed. Practice these tips to enhance your skills. For more details, consider reading guides or watching videos on lathe setup and maintenance. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And Tailstock Alignment:Sure! Lathe surface finish means how smooth the metal looks after using the lathe machine. A good surface finish feels nice and looks shiny. Tailstock alignment is how straight the tailstock is with the rest of the lathe. If the tailstock is not aligned, it can make rough surfaces. We want everything to be straight, so our work is neat and tidy!

Sure! Please provide the question you would like me to answer.

What Are The Key Factors That Affect The Surface Finish Of A Workpiece When Using A Metal Lathe?The surface finish of a workpiece on a metal lathe depends on a few things. First, the cutting speed matters. If you spin the workpiece faster, it can look smoother. Second, the type of cutting tool you use is important. A sharp tool makes a better finish than a dull one. Finally, the amount of pressure you use while cutting can change the finish too. Light pressure usually gives a nicer surface!

How Can You Determine If The Tailstock Of A Lathe Is Properly Aligned With The Spindle?To check if the tailstock of a lathe is aligned with the spindle, we can use a test rod. First, put a rod in the spindle and tighten it. Then, place the same rod in the tailstock and adjust it until it touches the rod in the spindle. If both ends of the rod touch, the tailstock is aligned. If not, we need to adjust the tailstock until they do touch.

What Are The Common Symptoms Of A Misaligned Tailstock, And How Do They Impact Surface Finish?If the tailstock is misaligned, you might see a few problems. Your workpiece could wobble or shake while you cut it. This can cause uneven cuts, making the surface look rough or bumpy. You may also notice more marks or scratches on the surface. Fixing the alignment helps make everything smooth and nice!

What Techniques Or Tools Can Be Used To Adjust The Alignment Of The Tailstock On A Metal Lathe?To adjust the tailstock on a metal lathe, you can use a few simple tools. First, use a tailstock alignment bar to see if it’s straight. You can also use a level to make sure it’s even. Finally, you can loosen screws on the tailstock and move it until it lines up with the main part of the lathe. Always check your work to make sure it’s right!

How Does The Alignment Of The Tailstock Influence The Accuracy Of Taper Turning Operations?The tailstock is part of a machine that helps hold material while you work on it. If the tailstock is aligned correctly, it helps keep everything straight. When we make a taper, which is a shape that gets smaller at one end, good alignment ensures it turns out well. If it’s off, the taper can look crooked or uneven. So, keeping the tailstock straight helps make a better taper!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathe surface finish means how smooth the metal looks after using the lathe machine. A good surface finish feels nice and looks shiny. Tailstock alignment is how straight the tailstock is with the rest of the lathe. If the tailstock is not aligned, it can make rough surfaces. We want everything to be straight, so our work is neat and tidy!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors That Affect The Surface Finish Of A Workpiece When Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The surface finish of a workpiece on a metal lathe depends on a few things. First, the cutting speed matters. If you spin the workpiece faster, it can look smoother. Second, the type of cutting tool you use is important. A sharp tool makes a better finish than a dull one. Finally, the amount of pressure you use while cutting can change the finish too. Light pressure usually gives a nicer surface!”}},{“@type”: “Question”,”name”: “How Can You Determine If The Tailstock Of A Lathe Is Properly Aligned With The Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if the tailstock of a lathe is aligned with the spindle, we can use a test rod. First, put a rod in the spindle and tighten it. Then, place the same rod in the tailstock and adjust it until it touches the rod in the spindle. If both ends of the rod touch, the tailstock is aligned. If not, we need to adjust the tailstock until they do touch.”}},{“@type”: “Question”,”name”: “What Are The Common Symptoms Of A Misaligned Tailstock, And How Do They Impact Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock is misaligned, you might see a few problems. Your workpiece could wobble or shake while you cut it. This can cause uneven cuts, making the surface look rough or bumpy. You may also notice more marks or scratches on the surface. Fixing the alignment helps make everything smooth and nice!”}},{“@type”: “Question”,”name”: “What Techniques Or Tools Can Be Used To Adjust The Alignment Of The Tailstock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the tailstock on a metal lathe, you can use a few simple tools. First, use a tailstock alignment bar to see if it’s straight. You can also use a level to make sure it’s even. Finally, you can loosen screws on the tailstock and move it until it lines up with the main part of the lathe. Always check your work to make sure it’s right!”}},{“@type”: “Question”,”name”: “How Does The Alignment Of The Tailstock Influence The Accuracy Of Taper Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The tailstock is part of a machine that helps hold material while you work on it. If the tailstock is aligned correctly, it helps keep everything straight. When we make a taper, which is a shape that gets smaller at one end, good alignment ensures it turns out well. If it’s off, the taper can look crooked or uneven. So, keeping the tailstock straight helps make a better taper!”}}]}