Have you ever wondered how metal objects get their smooth finishes? A lathe is the secret tool behind this magic. It shapes, cuts, and finishes metal with incredible precision.

Imagine watching a piece of rough metal transform into something shiny and smooth. That’s the power of a lathe! The surface finish it provides is vital in many industries, from aerospace to automobiles.

One key feature of a lathe is the threading dial. It helps machinists cut threads accurately. Without this tool, achieving perfect threads would be much harder.

Did you know that achieving a good surface finish can also affect how long the metal lasts? It’s true! A well-finished surface can resist wear and tear better. This is why knowing about lathe techniques is so important.

Join us as we explore how lathe surface finish impacts metalwork and transforms everyday items. Your curiosity might just lead to a new hobby!

Lathe Surface Finish: Mastering Metal Lathe Threading Dial

Lathe Surface Finish and Metal Lathe Threading Dial

A metal lathe makes smooth surfaces and threads on metal. The finish of that surface is important for both looks and function. Using a threading dial helps make perfect threads every time. Are you curious how it works? The threading dial lets you track your cuts accurately. Did you know that a good surface finish can reduce friction? This means your projects can work better and last longer. Learning about these tools helps in creating better metal products.Understanding Lathe Surface Finish

Definition and importance of surface finish in machining. Factors that affect surface finish quality.Surface finish is how smooth or rough a metal piece is after it’s shaped. It matters because a good finish protects the piece and makes it work better. A shiny, smooth surface can help parts fit together perfectly.

Several factors affect surface finish quality:

- The speed of the lathe.

- The type of cutting tool used.

- The material of the metal piece.

- The feed rate of the tool.

All these elements work together to create the final look of the metal part. Knowing them helps make better, high-quality pieces!

What is the importance of surface finish in machining?

A good surface finish helps parts fit and function better. It can reduce wear and tear, leading to longer-lasting products.

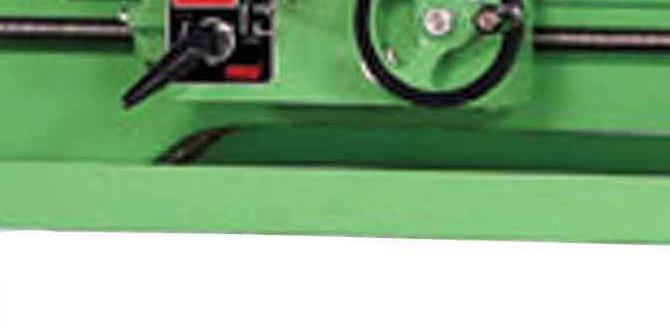

The Role of a Metal Lathe in Achieving Surface Finish

Explanation of a metal lathe and its components. How lathes achieve different surface finishes.A metal lathe is a machine tool that spins materials to shape them. It has several important parts, such as the spindle, tool rest, and tailstock. Each part works together to create different shapes and finishes. Lathes can achieve various surface finishes by changing the speed and type of tools used. A smooth finish needs sharp tools and slow speed, while rough finishes can use faster speeds with different tools.

What are the components of a metal lathe?

- Spindle: Holds and spins the workpiece.

- Tool Rest: Supports the cutting tools.

- Tailstock: Holds tools for drilling or supporting long pieces.

These parts work together to create different finishing styles on metal surfaces.

How do metal lathes create surface finishes?

Metal lathes create surface finishes by adjusting speed and tools. For a finer finish, they use slower speeds and sharper tools. For a rougher finish, they can speed it up and use coarser tools. This versatility makes lathes very useful in metalworking.

Remember, the right combination leads to the best results!

Techniques for Optimizing Surface Finish on a Metal Lathe

Recommended tools and materials for surface finishing. Stepbystep techniques for improving surface finish.To make your metal lathe projects shine, a few key tools can help. Always have sandpaper, files, and a polishing compound on hand. Start with a rough cut, then slowly work to finer grades. Use the threading dial wisely; this keeps everything aligned. Remember, patience is key! Finish off with a good polish. Your metal will be so shiny, you might just see your reflection and wonder, “Who’s that handsome machinist?”

| Tool/Material | Purpose |

|---|---|

| Sandpaper | Smooths surfaces. |

| Files | Shapes edges finely. |

| Polishing Compound | Gives that shiny finish. |

Common Problems and Solutions in Surface Finishing

Identification of typical issues affecting surface quality. Effective solutions and preventative measures.Surface finishing can have common issues that affect quality. Common problems include rough spots, scratches, and uneven surfaces. To solve these issues, check the tool condition and material. Proper speed and feed rates can also help improve finishing. Regular cleaning is important too. Here are some effective methods:

- Inspect tools and replace if worn.

- Adjust speeds and feeds as needed.

- Keep work areas clean and free of debris.

- Develop a routine for maintenance.

What are typical surface finish problems?

Typical problems include uneven surfaces, scratches, and fine lines. These can occur due to tool wear, incorrect speeds, or dirty work areas. Addressing these issues early can prevent costly mistakes and improve overall quality.

Best Practices for Maintenance of Metal Lathes and Threading Dials

Routine maintenance tips for metal lathes. Importance of keeping threading dials calibrated.Keeping metal lathes and threading dials in good shape is very important. Regular care helps them last longer. Here are some easy tips:

- Check oil levels and add oil regularly.

- Clean any dust or metal shavings after every use.

- Inspect the threading dial to ensure it isn’t stuck.

- Calibrate the threading dial often for accuracy.

- Look for any wear and tear and fix it quickly.

A well-maintained machine can make precise cuts. A good practice is to keep the threading dial calibrated. This ensures that your measurements are correct!

Why is it important to calibrate threading dials?

Calibrated threading dials help you get accurate measurements. This leads to better quality work and fewer mistakes.Case Studies: Successful Projects Utilizing Lathe Surface Finish Techniques

Examples of industrial applications. Lessons learned and best practices from realworld scenarios.Many industries have turned to lathe surface finish techniques for their amazing projects. For example, the auto industry uses these methods to make shiny car parts. They learned that a smooth finish can help parts last longer. A project with a shaky lathe may cause parts to wobble like jelly. Yikes! Best practices show that checking settings often leads to better results. The table below summarizes some successful applications.

| Industry | Application | Lesson Learned |

|---|---|---|

| Automotive | Engine Components | Precision is key for durability. |

| Aerospace | Airfoil Design | Focus on a mirror-like finish. |

| Manufacturing | Production Tools | Regular checks save time and materials. |

Future Trends in Lathe Technology and Surface Finishing

Innovations in lathe surface finish techniques. The impact of automation and CNC machining on traditional methods.Exciting changes are on the horizon for lathe technology! New techniques for surface finishing are becoming smoother than a butter slide. Innovations like advanced coatings and new tool designs give metals a shiny makeover. Automation and CNC machining? Oh boy, they’re like the superheroes of the workshop. They zoom past traditional methods, making work faster and more precise. Think of it as upgrading from a rotary phone to a smartphone—goodbye old school, hello new cool!

| Innovation | Description |

|---|---|

| Advanced Coatings | Provide superior surface finishes and protect against wear. |

| CNC Machining | Automates processes for better speed and accuracy. |

| Smart Tools | Ensure consistent results every time. |

With these changes, the future looks shiny and bright! The world of lathes is transforming, promising smoother surfaces and easier operations. So, buckle up and get ready for a ride full of innovation!

Conclusion

In summary, a lathe surface finish is important for smooth, precise work. Using the metal lathe threading dial helps ensure accurate threads. You can achieve better results by practicing and paying attention to details. To learn more, explore online guides or videos on lathe techniques. With time, you’ll become skilled in creating quality finishes in your projects!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathe Threading, And The Threading Dial:Sure! When we use a lathe, it helps us shape metal into smooth parts. Metal lathe threading means making spiral grooves on the metal to connect pieces. A threading dial helps you line up the lathe to cut these grooves correctly. This way, everything fits together nicely. Good finishes make our parts look better and work better!

Sure! Please provide the question you would like me to answer.

What Is The Importance Of Surface Finish In Metal Lathe Operations, And How Does It Affect The Final Product?Surface finish is really important when we use a metal lathe. A smooth finish makes the final product look nice and feel good. It helps parts fit together better, which can make them last longer. If the surface is rough, it might cause problems later. So, a good surface finish means a better end result!

How Do You Properly Use The Threading Dial On A Lathe To Ensure Accurate Thread Cutting?To use the threading dial on a lathe for cutting threads, first make sure the lathe is off. Then, you start by moving the cutting tool to the right spot and turning on the lathe. When the threading dial shows the right number, you can start cutting. Always use the same number on the dial to get even threads. Repeat this until your thread is the right depth.

What Factors Influence The Surface Finish Quality When Machining Metal On A Lathe?When you use a lathe to cut metal, several things affect how smooth the metal gets. First, the speed of the lathe matters. If it spins too slowly or too fast, the finish can look rough. Second, the type of tool you use is important. A sharp tool will cut better than a dull one. Finally, the way you move the tool affects the finish too. If you move it steadily and evenly, you get a nicer result.

Can You Explain The Difference Between The Various Threading Methods Used On A Lathe, Such As Single-Point Threading Versus Using A Die?Sure! When you use a lathe for threading, you can choose different methods. Single-point threading means you use one sharp tool to cut the thread directly on the material. It’s like carving a line into clay. On the other hand, using a die means you twist a special tool around the piece to shape the thread. This method is faster and easier for making many threads. Both ways help create threads, but they do it in different styles!

What Adjustments Can Be Made To A Lathe To Improve The Surface Finish When Machining Hard Metals?To make a lathe work better on hard metals, you can do a few things. First, use sharp cutting tools. Sharp tools cut better and make smoother surfaces. You should also lower the speed of the lathe. Moving slower helps create a nicer finish. Lastly, use cutting fluids to cool and lubricate the metal while you work. This helps reduce friction and improves the surface quality.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathe Threading, And The Threading Dial:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When we use a lathe, it helps us shape metal into smooth parts. Metal lathe threading means making spiral grooves on the metal to connect pieces. A threading dial helps you line up the lathe to cut these grooves correctly. This way, everything fits together nicely. Good finishes make our parts look better and work better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Importance Of Surface Finish In Metal Lathe Operations, And How Does It Affect The Final Product?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Surface finish is really important when we use a metal lathe. A smooth finish makes the final product look nice and feel good. It helps parts fit together better, which can make them last longer. If the surface is rough, it might cause problems later. So, a good surface finish means a better end result!”}},{“@type”: “Question”,”name”: “How Do You Properly Use The Threading Dial On A Lathe To Ensure Accurate Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use the threading dial on a lathe for cutting threads, first make sure the lathe is off. Then, you start by moving the cutting tool to the right spot and turning on the lathe. When the threading dial shows the right number, you can start cutting. Always use the same number on the dial to get even threads. Repeat this until your thread is the right depth.”}},{“@type”: “Question”,”name”: “What Factors Influence The Surface Finish Quality When Machining Metal On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a lathe to cut metal, several things affect how smooth the metal gets. First, the speed of the lathe matters. If it spins too slowly or too fast, the finish can look rough. Second, the type of tool you use is important. A sharp tool will cut better than a dull one. Finally, the way you move the tool affects the finish too. If you move it steadily and evenly, you get a nicer result.”}},{“@type”: “Question”,”name”: “Can You Explain The Difference Between The Various Threading Methods Used On A Lathe, Such As Single-Point Threading Versus Using A Die?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you use a lathe for threading, you can choose different methods. Single-point threading means you use one sharp tool to cut the thread directly on the material. It’s like carving a line into clay. On the other hand, using a die means you twist a special tool around the piece to shape the thread. This method is faster and easier for making many threads. Both ways help create threads, but they do it in different styles!”}},{“@type”: “Question”,”name”: “What Adjustments Can Be Made To A Lathe To Improve The Surface Finish When Machining Hard Metals?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a lathe work better on hard metals, you can do a few things. First, use sharp cutting tools. Sharp tools cut better and make smoother surfaces. You should also lower the speed of the lathe. Moving slower helps create a nicer finish. Lastly, use cutting fluids to cool and lubricate the metal while you work. This helps reduce friction and improves the surface quality.”}}]}