Have you ever wondered how a metal lathe can create such smooth surfaces? The secret lies in the lathe surface finish and the magic of torque. Imagine spinning a piece of metal fast while shaping it perfectly. This process helps create the smooth, shiny finishes we often admire.

Many people don’t know that the quality of a lathe surface finish can affect a project’s success. It’s like building a sandcastle; if the sand is wet and packed right, it holds perfectly. But if it’s dry and crumbly, the castle crumbles.

Did you know that torque plays a huge role in how well the lathe works? Higher torque allows the lathe to cut through tough materials easily. This is essential for making precise parts in machines and tools.

In this article, we will explore how the lathe surface finish, metal lathe, and torque come together. We’ll share tips and tricks to help you achieve top-notch results in your projects. Get ready to dive into the fascinating world of metal lathing!

Lathe Surface Finish: Maximizing Metal Lathe Torque Efficiency

Lathe Surface Finish and Torque

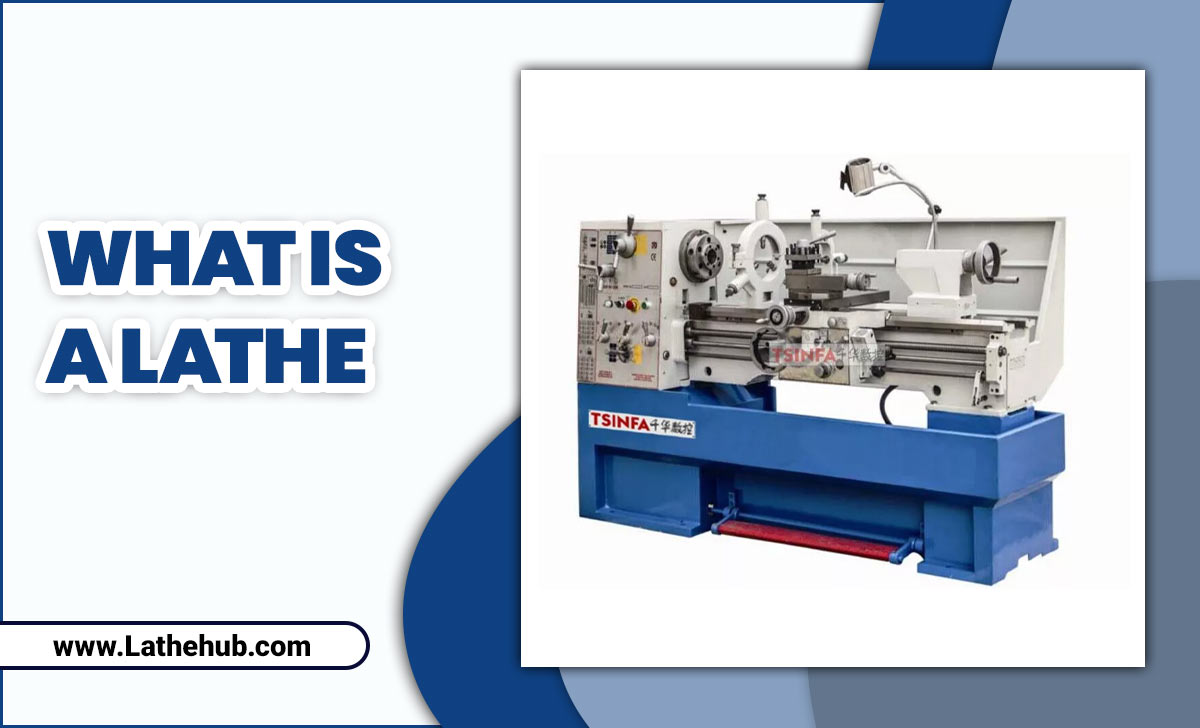

Using a metal lathe can transform rough materials into smooth and precise shapes. Understanding lathe surface finish is crucial. It determines how polished and clean the final product looks. The finish depends on factors like the type of tooling and settings. Ever wondered how torque influences this process? Higher torque can improve cutting power, making it easier to achieve that perfect surface. With the right technique, you can create works that not only function well but look great too!Understanding Lathe Surface Finish

Definition and significance in machining. Factors affecting surface finish quality.Lathe surface finish is very important in machining. It refers to how smooth or rough a surface is after cutting. A good finish helps parts work better and last longer. Factors that affect the quality of the surface finish include:

- Tool sharpness

- Cutting speed

- Feed rate

- Material type

Understanding these factors helps create better-made machines. Remember, smooth surfaces help machines run nicely!

Why is surface finish important?

Surface finish affects how well parts fit together and how long they last. A rough surface can cause friction and wear. On the other hand, a smooth surface reduces wear and improves performance. This is why it matters so much in machining.

Fun Fact

Amazingly, a very smooth surface can reduce friction by up to 50%! This makes machines more efficient.

The Role of Torque in Metal Lathing

Explanation of torque in the context of lathe operations. Impact of torque on cutting performance and surface finish.Torque is the twist that makes a lathe work. It helps turn the metal smoothly and with power. If there isn’t enough torque, the machine may struggle, leading to poor cuts. A high torque can make clean and sharp finishes. Here are a few points about torque in metal lathe operations:

- More torque means smoother cuts.

- Lower torque can cause rough surfaces.

- Proper torque improves cutting speed.

In summary, torque plays a big role in how well a lathe works and the quality of the surface finish.

What is torque in lathe operations?

Torque is the force that spins the lathe, helping it cut metal effectively. It affects how smooth the final product will be.

How does torque affect cutting performance?

- High torque provides better control for cleaner cuts.

- Low torque may lead to slower cutting speed.

Measuring Lathe Surface Finish

Tools and techniques for assessing surface quality. Importance of precision in measurement.To measure lathe surface finish, tools like surface roughness testers are key. These handy gadgets help check how smooth or rough a metal part is. Precision matters! Why? Because even a tiny error can change how parts fit together. Remember, a smoother finish means better performance. A good rule is: the smoother, the better! Here’s a quick look at measuring tools:

| Tool | Purpose |

|---|---|

| Surface Roughness Tester | Measures roughness |

| Micrometer | Checks thickness |

| Caliper | Measures dimensions |

Using the right tools keeps your lathe work top-notch! Remember, a smooth finish is like a good haircut—no one wants a lumpy bob!

Optimizing Torque Settings for Better Finishes

Recommended torque settings for different materials. How to adjust torque for optimal surface finishes.To get the best finish on metal, knowing the right torque is key. Different materials need different torque settings. For instance, use low torque for soft metals like aluminum and higher torque for harder metals like steel. Adjusting your torque helps create smoother surfaces.

- Soft metals: **20-30 Nm**

- Steel: **40-60 Nm**

- Hard metals: **70-90 Nm**

By fine-tuning the torque, you can improve the surface finish and achieve better results with your lathe. Keeping track of the torque on your machine can make a big difference!

What are optimal torque settings for different materials?

Optimal torque settings vary by material type. Adjust torque according to metal hardness for the best surface finish.

Common Problems Affecting Surface Finish

Identification of issues leading to poor finishes. Solutions and preventive measures.Let’s face it, nobody wants a surface that feels like a cat’s tongue. Common problems that ruin a shiny finish include dull tools and wrong speeds. Bad setups can lead to scratches, too. To solve these issues, first, check your tools. Are they sharp? If not, get them sharpened or replaced! Use the right speed and feed rates; it’s like finding the perfect dance rhythm!

| Problem | Solution |

|---|---|

| Dull tools | Sharpen or replace |

| Wrong speed | Adjust speed and feed rate |

| Poor setup | Double-check your setup |

Remember, practice makes perfect! Regular maintenance can keep your lathe happy, and a happy lathe means a smooth finish. You’ll be the proud owner of the shiniest metal in town!

Best Practices for Achieving Ideal Surface Finish

Recommended speeds and feeds during operation. Importance of tool maintenance and selection.To achieve the best surface finish, start with the right speeds and feeds. Use fast speeds with light cuts for smooth surfaces. Keep your tools sharp and clean. A dull tool can ruin your work. Choose the right tool for the job. Different materials need different tools. Remember to check your tools regularly to keep them working well.

What are the best speeds and feeds for a lathe?

Use high speeds for soft metals and lower speeds for hard metals. Light feeds help make a smoother finish.

- Fast Speeds: Soft Metals (e.g., aluminum)

- Slow Speeds: Hard Metals (e.g., steel)

- Light Feeds: Smooth Finish

Cleaning and maintaining your lathe tools is very important. This will help you get the perfect finish every time. Keep these tips in mind for great results!

Future Trends in Lathe Technology

Innovations in lathe design affecting surface finish. The evolution of torque measurement technology in machining.New lathe designs are changing how we work with metal. These innovations improve surface finish. Machines now use smart features for better cuts. They help shape metal precisely. On another note, torque measurement technology is getting smarter, too. New tools measure force with great accuracy. They ensure safety and quality. This change in measurement affects production speed. Both advancements help factories operate better.

How do new lathe designs improve metal work?

New lathe designs improve metal work by providing clearer readings, better control, and high-quality finishes.

Key Innovations:

- Smart technology for precise cutting

- Better torque measurements for safety

- Enhanced materials for durability

Conclusion

In conclusion, achieving a good surface finish on metal lathes requires understanding torque and tool settings. You should focus on the right speed and feed rate. Remember, practice improves your skills and results. Explore tutorials or guides to deepen your knowledge. With time and patience, you’ll master lathe techniques and produce excellent finishes. Keep learning and experimenting!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathes, And Torque:Sure! A lathe is a machine that helps us shape metal. Surface finish is how smooth or rough the metal feels after using the lathe. If we want a shiny look, we may use special tools or techniques. Torque means how strong the machine turns. It helps us cut the metal properly!

Sure! Please share the question you want me to answer.

What Are The Key Factors That Influence Surface Finish Quality When Machining Metals On A Lathe?To make a metal surface smooth on a lathe, we need to think about a few important things. First, the speed of the lathe is key; if it spins too fast or too slow, the surface might not be smooth. Second, using the right type of cutting tool helps; sharp tools work better than dull ones. Third, we should consider how much pressure we use when cutting. Lastly, keeping everything clean and well-lubricated helps avoid scratches and marks.

How Does The Torque Exerted By A Metal Lathe Affect The Cutting Performance And Surface Finish Of The Workpiece?The torque from a metal lathe helps cut the metal smoothly. When the torque is just right, it makes sure the tool cuts through easily. This means you get a nice, smooth surface on the workpiece. If the torque is too low, the cut may be rough. If it’s too high, the metal might break or chip.

What Types Of Cutting Tools And Parameters (E.G., Feed Rate, Depth Of Cut) Can Be Optimized To Achieve Better Surface Finishes On A Lathe?To get a better finish on a lathe, you can choose different cutting tools. Use sharper tools for smoother cuts. You can also change the feed rate, which is how fast the tool moves. A slower feed rate often gives a better surface. Lastly, adjusting the depth of cut, or how deep the tool goes, can help too.

How Can Vibrations And Chatter During Metal Lathe Operations Impact Both Torque And Surface Finish?When we use a metal lathe, vibrations and chatter can cause problems. They make it harder to control the machine, which can change the torque, or turning force. If the machine shakes too much, it can also create a rough surface on the metal. This means we don’t get a smooth and clean finish. So, less vibration results in better control and nicer-looking parts.

What Methods Or Techniques Can Be Employed To Measure And Assess The Surface Finish Achieved On Components Machined Using A Lathe?To check how smooth a lathe-made piece is, we can use a few simple tools. One tool is a ruler or caliper to measure tiny bumps and dips. Another is a special light that shows shiny spots. We can also feel the surface with our fingers to see if it feels rough or smooth. These methods help us understand how well we did our work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Surface Finish, Metal Lathes, And Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal. Surface finish is how smooth or rough the metal feels after using the lathe. If we want a shiny look, we may use special tools or techniques. Torque means how strong the machine turns. It helps us cut the metal properly!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors That Influence Surface Finish Quality When Machining Metals On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal surface smooth on a lathe, we need to think about a few important things. First, the speed of the lathe is key; if it spins too fast or too slow, the surface might not be smooth. Second, using the right type of cutting tool helps; sharp tools work better than dull ones. Third, we should consider how much pressure we use when cutting. Lastly, keeping everything clean and well-lubricated helps avoid scratches and marks.”}},{“@type”: “Question”,”name”: “How Does The Torque Exerted By A Metal Lathe Affect The Cutting Performance And Surface Finish Of The Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The torque from a metal lathe helps cut the metal smoothly. When the torque is just right, it makes sure the tool cuts through easily. This means you get a nice, smooth surface on the workpiece. If the torque is too low, the cut may be rough. If it’s too high, the metal might break or chip.”}},{“@type”: “Question”,”name”: “What Types Of Cutting Tools And Parameters (E.G., Feed Rate, Depth Of Cut) Can Be Optimized To Achieve Better Surface Finishes On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a better finish on a lathe, you can choose different cutting tools. Use sharper tools for smoother cuts. You can also change the feed rate, which is how fast the tool moves. A slower feed rate often gives a better surface. Lastly, adjusting the depth of cut, or how deep the tool goes, can help too.”}},{“@type”: “Question”,”name”: “How Can Vibrations And Chatter During Metal Lathe Operations Impact Both Torque And Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use a metal lathe, vibrations and chatter can cause problems. They make it harder to control the machine, which can change the torque, or turning force. If the machine shakes too much, it can also create a rough surface on the metal. This means we don’t get a smooth and clean finish. So, less vibration results in better control and nicer-looking parts.”}},{“@type”: “Question”,”name”: “What Methods Or Techniques Can Be Employed To Measure And Assess The Surface Finish Achieved On Components Machined Using A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check how smooth a lathe-made piece is, we can use a few simple tools. One tool is a ruler or caliper to measure tiny bumps and dips. Another is a special light that shows shiny spots. We can also feel the surface with our fingers to see if it feels rough or smooth. These methods help us understand how well we did our work.”}}]}