Imagine you’re working on a metal lathe, feeling the excitement of crafting something new. Everything seems to be going well, but suddenly, the surface finish is not what you expected. Have you ever faced a rough finish that makes you question your skills?

Lathe surface finish is crucial for any metal project. It can be the difference between a piece that shines and one that looks rough. You might wonder, what caused this issue? Was it the tool, the speed, or perhaps something else?

Troubleshooting problems with your metal lathe can seem tricky. But don’t worry! Many people have faced the same challenges you are. Learning how to fix these issues can be fun and rewarding.

In this article, we will explore common problems and solutions. You’ll discover tips to achieve a perfect surface. So, let’s dive in and turn those rough edges into smooth finishes!

Lathe Surface Finish: Metal Lathe Troubleshooting Guide

Lathe Surface Finish Metal Lathe Troubleshooting

Lathe surface finish is crucial for quality metalwork. Understanding how to troubleshoot issues can save time and materials. Common problems include rough surfaces, chatter, and tool wear. Did you know that using the right feed rate and cutting speed can improve your results significantly? Proper tool maintenance also plays a big role. By learning these tips, you can produce smoother finishes and become more efficient in your work. Curious to know more about perfecting your lathe techniques?Understanding Lathe Surface Finish

Definition of surface finish in metalworking. Importance of surface finish in machining applications.Surface finish is how smooth or rough a metal part’s surface is. It affects how it looks and works. A good surface finish can help parts fit together well and last longer.

- Improves appearance: A smooth finish looks better.

- Enhances performance: It helps reduce friction and wear.

- Reduces defects: Good finishing reduces problems during assembly.

Why is surface finish vital in machining?

Surface finish greatly affects how well a machine part functions. A good finish improves strength and reduces wear. In fact, studies indicate that a 10% better finish can lead to a 30% increase in durability.

Common Causes of Poor Surface Finish

Tool wear and its effects on finish quality. Material properties influencing surface finish.Poor surface finish can happen for a few reasons. One of the main causes is tool wear. When tools get dull, they do not cut as smoothly. This can leave rough spots on the metal. Another factor is material properties. Different metals behave differently when cut. Softer metals might finish easier than harder ones. Always check both the tool and material to ensure a smooth surface.

What is tool wear and how does it affect surface finish?

Tool wear refers to the gradual loss of material from the cutting tool. When a tool wears down, its cutting edge becomes dull, leading to a rougher finish on the metal. Regular maintenance of tools helps achieve better results.

What material properties influence surface finish?

- Hardness: Harder materials are tougher to cut.

- Ductility: Ductile materials can stretch, affecting cutting smoothness.

- Grain Structure: Different grain structures can lead to varied finishes.

Lathe Setup and Its Impact on Surface Finish

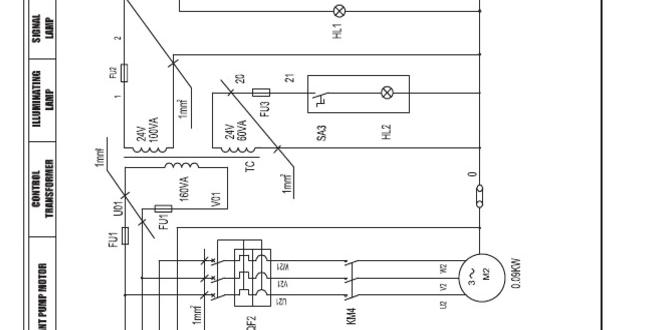

Importance of proper alignment and calibration. Role of cutting speeds and feeds on finish quality.Setting up a lathe correctly is crucial for a smooth metal surface. Proper alignment and calibration help ensure that every cut is clean. If the lathe is off, it can create rough edges. Selecting the right cutting speeds and feeds also affects the finish. A fast speed can lead to a poor surface, while slower speeds often give better results. Take the time to adjust these settings for the best quality possible.

Why is proper alignment so important?

Proper alignment ensures smoother cuts. If the machine isn’t aligned, it can create a rough surface or even damage the piece you are working on.

Factors for Better Surface Finish:

- Alignment: Keeps the cutting tool in the right position.

- Calibration: Ensures accurate measurements.

- Cutting Speeds: Slower speeds improve the quality.

- Feeds: Minding the feed rate can reduce chatter.

Tool Selection for Optimal Surface Finish

Types of cutting tools and their attributes. Coatings and materials that enhance surface finish.Choosing the right cutting tool can feel like picking snacks at the candy store. Each tool has its own superpowers! For example, high-speed steel (HSS) tools are great for general tasks, while carbide tools shine when you need a sharp edge all day long. Coatings like titanium nitride give tools a shiny armor to resist wear. These coatings improve surface finish and tool life, making machining feel like magic. Check out the table below for a quick comparison:

| Tool Type | Best Use | Key Benefit |

|---|---|---|

| High-Speed Steel (HSS) | General machining | Sharpness and durability |

| Carbide | Hard materials | Long-lasting sharpness |

| Coated Tools | Precision work | Enhanced surface finish |

So, remember, the right tool makes a world of difference. Happy machining!

Common Troubleshooting Techniques

Identifying symptoms of poor surface finish. Stepbystep troubleshooting process.Sometimes, a metal lathe can behave like a grumpy cat, giving you a poor surface finish. To tackle this, you need to first identify the symptoms. Look for scratches, rough spots, or an uneven texture. Next, follow this step-by-step process for troubleshooting:

| Step | Action |

|---|---|

| 1 | Check the tool sharpness. |

| 2 | Adjust the feed rate. |

| 3 | Inspect the workpiece for damage. |

| 4 | Make sure the lathe is properly aligned. |

Follow these steps, and soon your lathe will be back to making shiny metal, not a rough patch like your friend’s hair after a windy day!

Adjusting Cutting Parameters for Better Results

Modifying feed rates and speeds. Experimenting with depth of cut.To get a better finish on your metal lathe projects, it’s important to adjust your settings. First, try changing the feed rates and speeds. Slower speeds can give a smoother finish. Next, play around with the depth of cut. A lighter cut can improve surface quality. Remember, small changes can make a big difference!

How can I improve my lathe surface finish?

Improving your lathe surface finish is simple. Adjusting feed rates and experimenting with the depth of cut are effective methods. Keeping these changes small lets you see what works best.

Quick Tips:

- Set slower feed rates for a finer finish.

- Test different depths of cut for best results.

- Always check your tools for sharpness and alignment.

Maintenance Practices to Improve Surface Finish

Regular maintenance of tools and lathe equipment. Importance of lubrication and cleanliness.Taking care of your lathe is like feeding a pet—treat it well, and it works better! Regular maintenance helps keep your lathe squeaky clean and running smoothly. Remember to check your tools often; a dull tool is like trying to cut butter with a spoon. Lubrication is essential too! It’s the lathe’s way of staying slick and happy. A well-lubricated machine produces a smooth surface finish like butter on hot toast. Cleanliness matters, or else chips and grime may ruin your work. Follow these tips for better results!

| Maintenance Tip | Benefit |

|---|---|

| Regular Tool Check | Ensures sharp cuts |

| Frequent Lubrication | Reduces friction |

| Keep It Clean | Improves surface quality |

Real-World Case Studies and Solutions

Analyzing specific troubleshooting scenarios. Successful implementation of corrective actions.When metal lathe troubles arise, real-world case studies often hold the key. For example, if a lathe is producing a rough surface finish, it might be due to dull tools or incorrect speeds. It’s like trying to slice bread with a butter knife—no good can come from that! In such cases, simply changing the tool can make a world of difference.

| Issue | Solution |

|---|---|

| Rough Surface | Use sharper tools and adjust speeds |

| Strange Noise | Check for loose parts |

| Inconsistent Dimensions | Calibrate your equipment regularly |

By implementing these simple fixes, operators can enjoy a smoother experience with their lathes. After all, who doesn’t want their metal to shine like a new penny?

Future Trends in Lathe Technology and Surface Finish

Advancements in CNC lathe technologies. Emerging materials and coatings affecting surface finish.As technology moves forward, lathe machines are getting smarter. CNC (Computer Numerical Control) lathes now offer pinpoint accuracy and speed. Imagine a robot that cuts metal – that’s how precise they are! New materials, like diamond-coated tools, make surfaces shiny and smooth. These tools can conquer wear and tear better than your favorite superhero. Even cool combinations of metals are hitting the scene, improving how finished products look and feel. Who knew metal could be so stylish?

| Technology | Benefits |

|---|---|

| CNC Lathes | High accuracy and efficiency |

| Diamond Coatings | Smoother surfaces and longer tool life |

| New Metal Alloys | Better durability and aesthetics |

Conclusion

In summary, achieving a good lathe surface finish involves attention to detail. If you encounter problems, check your tools and settings first. Don’t hesitate to experiment and learn from mistakes. You can improve your skills with practice. For more tips, consider reading additional guides or watching videos on metal lathe troubleshooting. Let’s keep making great things together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And Troubleshooting:Sure! When using a lathe, you want a smooth surface on the metal you’re working with. If it feels rough, we can check a few things. First, make sure the tools are sharp. Dull tools can make rough surfaces. We also need to adjust the speed of the lathe. If it’s too fast or too slow, it can affect the finish too.

Sure! I can help with that. Just let me know the question you want me to answer, and I’ll keep it simple and easy to understand.

What Are The Common Causes Of Poor Surface Finish On Machined Components Using A Metal Lathe?Poor surface finish on machined parts can happen for a few reasons. First, if the cutting tool is dull, it won’t cut smoothly. Second, if the machine is moving too fast or too slow, it can leave rough spots. Third, using the wrong type of tool or material can also make surfaces look bad. Lastly, not keeping the machine clean can cause extra bumps and scratches.

How Can Tool Geometry And Cutting Tool Material Affect The Surface Finish Achieved On A Lathe?The shape of the cutting tool and the material it’s made from can really change how smooth a surface gets on a lathe. If the tool is sharp and has the right shape, it cuts better and can make a nicer finish. Also, strong materials help the tool last longer, keeping it sharp. If you use a dull tool, it can make the surface rough. So, using the right tool helps us make smooth and shiny surfaces!

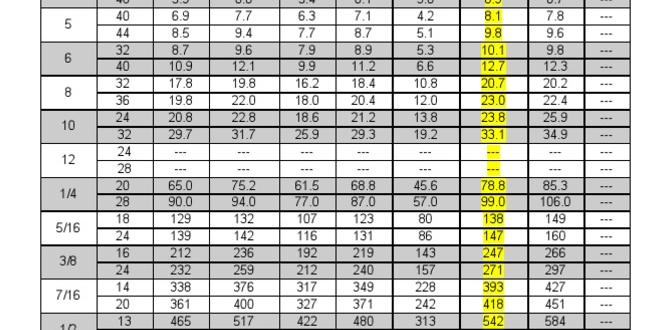

What Role Does Cutting Speed, Feed Rate, And Depth Of Cut Play In Determining The Surface Finish Quality?Cutting speed, feed rate, and depth of cut all affect how smooth a surface is when we cut something. Cutting speed is how fast the tool spins; faster speeds usually make a smoother finish. The feed rate is how quickly the tool moves across the material; if it moves too quickly, the surface may be rough. Depth of cut is how deep the tool goes into the material; cutting too deep can also make the surface bumpy. To get the best finish, we need to find the right balance between these factors.

How Can Vibrations And Chatter During Machining Impact The Surface Finish, And What Are The Methods To Minimize Them?Vibrations and chatter can make the metal surface rough and bumpy. This happens when the tools shake while cutting. To fix this, we can use better tools, slow down the machine, or change how we cut. We can also make sure everything is tight and well-balanced. All these steps help us get a smoother finish.

What Troubleshooting Steps Can Be Taken When A Lathe Produces Inconsistent Surface Finishes Across Multiple Workpieces?If your lathe makes rough spots on different pieces, you can check a few things. First, look at the cutting tool. Is it sharp and not broken? Next, make sure the pieces are held tight and not moving. You should also check the speed of the lathe. If it’s too fast or too slow, it can cause problems. Finally, clean your lathe to remove any dirt or old oil that might affect how it works.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Surface Finish And Troubleshooting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When using a lathe, you want a smooth surface on the metal you’re working with. If it feels rough, we can check a few things. First, make sure the tools are sharp. Dull tools can make rough surfaces. We also need to adjust the speed of the lathe. If it’s too fast or too slow, it can affect the finish too.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can help with that. Just let me know the question you want me to answer, and I’ll keep it simple and easy to understand.”}},{“@type”: “Question”,”name”: “What Are The Common Causes Of Poor Surface Finish On Machined Components Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Poor surface finish on machined parts can happen for a few reasons. First, if the cutting tool is dull, it won’t cut smoothly. Second, if the machine is moving too fast or too slow, it can leave rough spots. Third, using the wrong type of tool or material can also make surfaces look bad. Lastly, not keeping the machine clean can cause extra bumps and scratches.”}},{“@type”: “Question”,”name”: “How Can Tool Geometry And Cutting Tool Material Affect The Surface Finish Achieved On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The shape of the cutting tool and the material it’s made from can really change how smooth a surface gets on a lathe. If the tool is sharp and has the right shape, it cuts better and can make a nicer finish. Also, strong materials help the tool last longer, keeping it sharp. If you use a dull tool, it can make the surface rough. So, using the right tool helps us make smooth and shiny surfaces!”}},{“@type”: “Question”,”name”: “What Role Does Cutting Speed, Feed Rate, And Depth Of Cut Play In Determining The Surface Finish Quality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Cutting speed, feed rate, and depth of cut all affect how smooth a surface is when we cut something. Cutting speed is how fast the tool spins; faster speeds usually make a smoother finish. The feed rate is how quickly the tool moves across the material; if it moves too quickly, the surface may be rough. Depth of cut is how deep the tool goes into the material; cutting too deep can also make the surface bumpy. To get the best finish, we need to find the right balance between these factors.”}},{“@type”: “Question”,”name”: “How Can Vibrations And Chatter During Machining Impact The Surface Finish, And What Are The Methods To Minimize Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Vibrations and chatter can make the metal surface rough and bumpy. This happens when the tools shake while cutting. To fix this, we can use better tools, slow down the machine, or change how we cut. We can also make sure everything is tight and well-balanced. All these steps help us get a smoother finish.”}},{“@type”: “Question”,”name”: “What Troubleshooting Steps Can Be Taken When A Lathe Produces Inconsistent Surface Finishes Across Multiple Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your lathe makes rough spots on different pieces, you can check a few things. First, look at the cutting tool. Is it sharp and not broken? Next, make sure the pieces are held tight and not moving. You should also check the speed of the lathe. If it’s too fast or too slow, it can cause problems. Finally, clean your lathe to remove any dirt or old oil that might affect how it works.”}}]}