Have you ever wondered how skilled craftsmen create smooth surfaces on metal parts? A lathe is one of the coolest tools that helps with this. It spins the metal while special tools shape it. This process is called turning. With a lathe surface finish, the final product looks shiny and feels great to the touch.

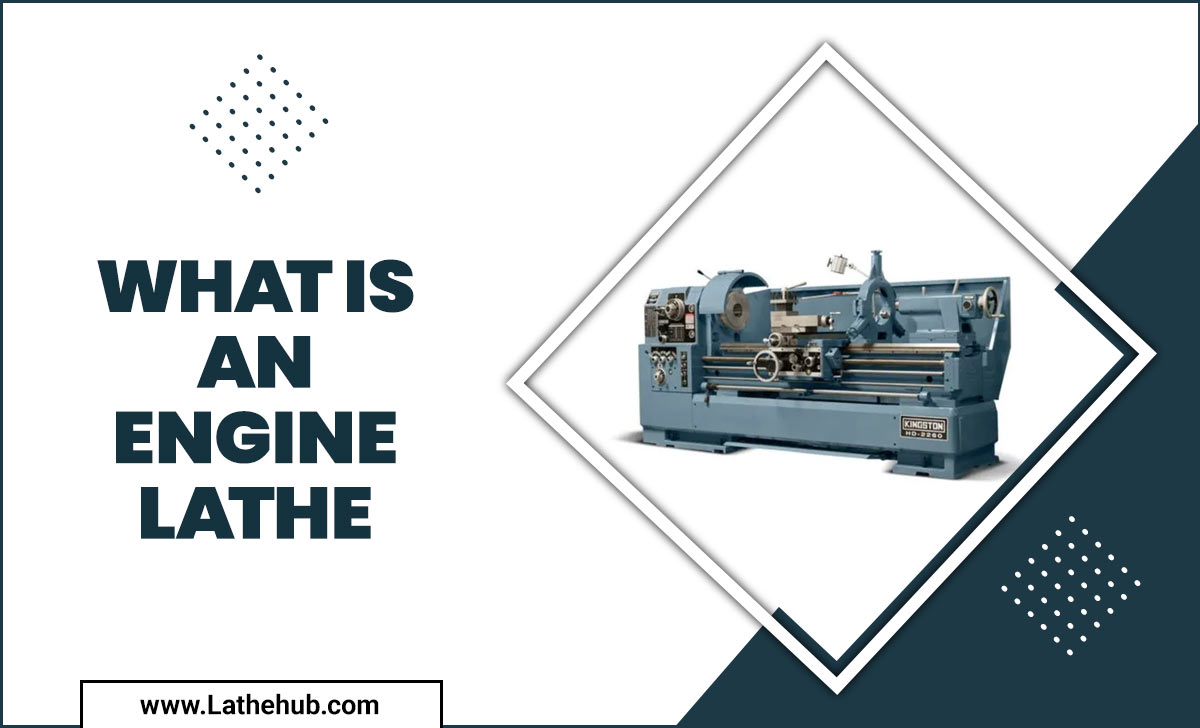

Mini metal lathes are perfect for hobbyists and beginners. They are small, easy to use, and still very powerful. Imagine making your own metal parts for toys or even small machines! Wouldn’t that be exciting?

Here’s a fun fact: A good surface finish can make a huge difference. It helps parts fit better and work smoothly. So, getting the right lathe surface finish with a mini metal lathe is key to creating amazing projects!

In this article, we will explore how to achieve that perfect finish. Whether you’re a beginner or looking to improve your skills, there’s something for everyone. Get ready to dive in!

Achieving A Quality Lathe Surface Finish With Mini Metal Lathe

Understanding Lathe Surface Finish in Mini Metal Lathes

Want to achieve a smooth finish on your mini metal lathe projects? Lathe surface finish greatly affects how a piece looks and feels. Choosing the right cutting tool and feed rate can make a big difference. A finer finish often requires slower speeds and careful adjustments. Did you know that a well-finished surface can help parts fit better? Learning these tips will enhance your metalworking skills and make your projects shine!Understanding Lathe Surface Finish

Definition of surface finish in machining. Importance of surface finish for performance and aesthetics.Surface finish in machining refers to how smooth or rough a material’s surface is after it is worked on a machine. It is important for both performance and looks. A smoother surface can help parts work better and last longer. It also makes products more attractive. Here are a few key reasons why surface finish matters:

- Improved performance: Smooth surfaces reduce friction.

- Better aesthetics: A polished look attracts customers.

- Increased durability: A fine finish can prevent wear and tear.

Factors Influencing Lathe Surface Finish

Material selection and its impact. Tool geometry and cutting edge considerations.Choosing the right materials is key for good surface finish. Different metals behave differently when cut. Some allow for smoother finishes, while others may not. Tool design also plays a big role. The shape and sharpness of the cutting edge affect the final result. A sharper tool cuts better and leaves a neater surface. Here are some important points to consider:

- Material type: Soft metals produce cleaner finishes.

- Tool angle: The right angle helps prevent roughness.

- Edge sharpness: Sharper edges make smoother cuts.

Both material and tool design are crucial for a great lathe finish.

What are common materials for a mini metal lathe?

Common materials include aluminum, steel, and brass. These metals allow for various finishes when used properly.

Essential Tools for Improving Surface Finish

Types of cutting tools for mini lathes. Importance of tool sharpness and maintenance.To get the best surface finish on a mini lathe, having the right cutting tools is key. Carbide inserts are popular because they stay sharp longer. Don’t forget about tool sharpness—dull tools create messier cuts. Regular sharpening keeps everything looking smooth, like your favorite butter knife after it’s been cleaned! Remember, a well-maintained tool can be the difference between a shiny finish and a plank of wood. Here’s a quick look at some common tools:

| Tool Type | Best For |

|---|---|

| HSS Tools | General cutting |

| Carbide Tools | Hard materials |

| CNC Tools | Automated precision |

Choose wisely and keep those tools sharp for the best results!

Techniques for Optimal Surface Finish

Recommended machining speeds and feeds. Effective use of lubrication and cooling.To get the best surface finish using a lathe, pay attention to speed and feed rates. Choose the right speeds for the material you are working with. Too fast can ruin the finish!

Lubrication is also key. Adding oil cools the metal and helps the tool last longer. This keeps the surface smooth. A well-lubricated lathe produces great results.

- For metals, use speeds around 300-600 RPM.

- For softer materials, slower speeds work best.

- Use cutting oil for improved finishes.

What speeds and feeds should I use for better surface finish?

Using the right speeds and feeds can improve your lathe projects. 300-600 RPM is best for most metal work, while softer materials need lower speeds.

Common Surface Finishing Methods

Polishing and grinding techniques. Use of abrasive compounds and brushes.Different methods are used to make a surface smooth and shiny. Two common techniques are polishing and grinding. Polishing uses special tools to rub surfaces until they shine. Grinding uses hard materials to cut away rough parts. Abrasive compounds can help with this process. Brushes with tiny hard bristles also polish surfaces effectively. These methods help create a final finish that looks and feels great!

What is polishing and grinding?

Polishing makes surfaces shiny and smooth by rubbing them, while grinding removes rough edges to create a clean finish.

Facts about surface finishing methods

- Polishing uses soft cloths or wheels.

- Grinding uses harder substances for better cutting.

- Abrasive compounds improve the effectiveness.

Measuring Surface Finish Quality

Tools for measuring surface roughness. Interpreting surface finish measurements.To check how smooth a surface is, we need the right tools. Instruments like roughness testers help measure tiny bumps and dips on metal. They give a precise reading, helping us understand the quality of our work. Interpreting these measurements involves looking at values like Ra and Rz. Ra tells us the average roughness, while Rz shows the height of the tallest peaks. Think of it like measuring how bumpy a rollercoaster is—nobody wants to ride one that feels like a cheese grater!

| Measurement | Description |

|---|---|

| Ra | Average roughness of the surface |

| Rz | Height of the tallest peaks |

Troubleshooting Surface Finish Issues

Common problems and their causes. Solutions to improve poor surface finish.Troubleshooting surface finish issues can feel like solving a mystery. Common problems include rough surfaces or uneven finishes, often caused by improper tool selection or dull blades. Sometimes, it’s the speed or feed rate that’s off, making your project look like a cat walked across it! To improve a poor surface finish, try adjusting your lathe speed, using sharp tools, and ensuring proper lubrication. Here’s a quick table of solutions:

| Issue | Cause | Solution |

|---|---|---|

| Rough Surface | Dull tool or wrong speed | Sharpen tools & adjust speed |

| Uneven Finish | Incorrect feed rate | Check and modify feed rate |

With these tips, you’ll turn your mini metal lathe into a finish magician. Abracadabra!

Real-Life Applications of Mini Metal Lathes

Industries utilizing mini metal lathes for surface finishing. Examples of projects benefitting from superior surface finish.Many different industries use mini metal lathes for their nifty abilities. From hobbyist workshops to large factories, these machines help create smoother finishes on metal parts. For instance, a mini lathe can make tiny gears and bolts with a polished touch that makes them look like shiny little treasures. It’s like giving metals a spa day! Automotive, manufacturing, and even aerospace benefit from top-notch surface finishes to ensure everything runs smoothly and safely.

| Industry | Applications |

|---|---|

| Automotive | Making precise engine components |

| Manufacturing | Creating tools and machinery parts |

| Aerospace | Producing lightweight yet strong components |

These projects show how important a great surface finish can be. It’s the difference between “is it good enough?” and “wow, that’s shiny!”

Conclusion

In summary, achieving a great surface finish on a mini metal lathe is important for quality work. You can improve surface finish by choosing the right tools, adjusting speeds, and practicing your technique. Experiment with different materials and settings to see what works best for you. Keep learning and exploring to enhance your lathe skills further!FAQs

Sure! Here Are Five Questions Related To Lathe Surface Finish On Mini Metal Lathes:Sure! Here are five questions about the surface finish on mini metal lathes. 1. What is surface finish? Surface finish is how smooth or rough a metal piece is after using the lathe. 2. Why does surface finish matter? A good surface finish makes the metal look nice and can help it work better. 3. How can we improve surface finish? We can improve surface finish by using sharp tools and going slowly when we cut the metal. 4. What tools help with surface finish? We can use sandpaper or special polishing tools to make the surface smoother. 5. How do you know if the finish is good? You can feel the surface with your hand. A good finish feels smooth, like glass.

Sure! Please provide the question, and I’ll give you a clear and simple answer.

What Are The Key Factors That Influence Surface Finish Quality When Using A Mini Metal Lathe?To get a good surface finish when using a mini metal lathe, you need to focus on a few important things. First, use the right speed for the lathe. Too fast or too slow can make it rough. Second, choose a sharp tool. A dull tool can cause bumps and scratches. Finally, keep the tool steady and move smoothly. This helps make the surface nice and smooth.

How Do Different Cutting Speeds And Feed Rates Affect The Surface Finish Of Machined Components?Cutting speed and feed rate are important for making smooth machine parts. If you cut too fast or use a high feed rate, the surface can be rough. Slower speeds and lower feed rates usually make a smoother finish. This is because the tool has more time to touch the material gently. For a nice, clean look, we should find the right balance between speed and feed rate.

What Types Of Tooling And Cutting Inserts Are Best Suited For Achieving A Smooth Surface Finish On A Mini Lathe?To get a smooth surface on a mini lathe, we should use high-speed steel (HSS) tools. They are good for many materials and last a long time. Carbide inserts are also great because they stay sharp and help make a nice finish. Always choose sharp tools and keep them clean for the best results!

How Can You Minimize Vibration And Chatter During Machining To Improve The Surface Finish?To reduce vibration and chatter while machining, you can do a few things. First, use sharp tools. Sharp tools cut better and help avoid bumps. Next, hold your workpiece tightly so it doesn’t move. You can also change the speed of the machine. Sometimes a slower speed helps make a smoother finish. Finally, make sure everything is clean and well-oiled. This helps the machine run smoothly.

What Post-Machining Processes Can Enhance The Surface Finish Of Machined Parts Produced On A Mini Metal Lathe?To make your metal parts smoother after using a mini metal lathe, you can try some easy steps. You can sand the surface to remove rough spots. Polishing makes the metal shiny and smooth. Then, you can clean the part to get rid of any leftover dust. Finally, using a coating can protect and make the surface feel even nicer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Surface Finish On Mini Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about the surface finish on mini metal lathes. 1. What is surface finish? Surface finish is how smooth or rough a metal piece is after using the lathe. 2. Why does surface finish matter? A good surface finish makes the metal look nice and can help it work better. 3. How can we improve surface finish? We can improve surface finish by using sharp tools and going slowly when we cut the metal. 4. What tools help with surface finish? We can use sandpaper or special polishing tools to make the surface smoother. 5. How do you know if the finish is good? You can feel the surface with your hand. A good finish feels smooth, like glass.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question, and I’ll give you a clear and simple answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors That Influence Surface Finish Quality When Using A Mini Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a good surface finish when using a mini metal lathe, you need to focus on a few important things. First, use the right speed for the lathe. Too fast or too slow can make it rough. Second, choose a sharp tool. A dull tool can cause bumps and scratches. Finally, keep the tool steady and move smoothly. This helps make the surface nice and smooth.”}},{“@type”: “Question”,”name”: “How Do Different Cutting Speeds And Feed Rates Affect The Surface Finish Of Machined Components?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Cutting speed and feed rate are important for making smooth machine parts. If you cut too fast or use a high feed rate, the surface can be rough. Slower speeds and lower feed rates usually make a smoother finish. This is because the tool has more time to touch the material gently. For a nice, clean look, we should find the right balance between speed and feed rate.”}},{“@type”: “Question”,”name”: “What Types Of Tooling And Cutting Inserts Are Best Suited For Achieving A Smooth Surface Finish On A Mini Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a smooth surface on a mini lathe, we should use high-speed steel (HSS) tools. They are good for many materials and last a long time. Carbide inserts are also great because they stay sharp and help make a nice finish. Always choose sharp tools and keep them clean for the best results!”}},{“@type”: “Question”,”name”: “How Can You Minimize Vibration And Chatter During Machining To Improve The Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibration and chatter while machining, you can do a few things. First, use sharp tools. Sharp tools cut better and help avoid bumps. Next, hold your workpiece tightly so it doesn’t move. You can also change the speed of the machine. Sometimes a slower speed helps make a smoother finish. Finally, make sure everything is clean and well-oiled. This helps the machine run smoothly.”}},{“@type”: “Question”,”name”: “What Post-Machining Processes Can Enhance The Surface Finish Of Machined Parts Produced On A Mini Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your metal parts smoother after using a mini metal lathe, you can try some easy steps. You can sand the surface to remove rough spots. Polishing makes the metal shiny and smooth. Then, you can clean the part to get rid of any leftover dust. Finally, using a coating can protect and make the surface feel even nicer.”}}]}