Have you ever wondered how to create precise and beautiful designs with wood or metal? The lathe tailstock offset boring technique might just be the answer. This approach allows you to drill holes at precise angles and offsets, making your projects stand out.

Imagine crafting a perfect wooden toy or a unique piece of art. With the right lathe techniques, you can turn simple materials into masterpieces. The tailstock plays a crucial role in how you shape and bore those pieces. It helps you keep everything steady while you work!

Did you know that even a small adjustment to the tailstock can change the outcome? This method might sound complicated at first, but it opens a world of possibilities. You’ll discover skills that will impress your friends and family.

Ready to dive in and learn more about lathe tailstock offset boring? Let’s explore this fascinating technique together!

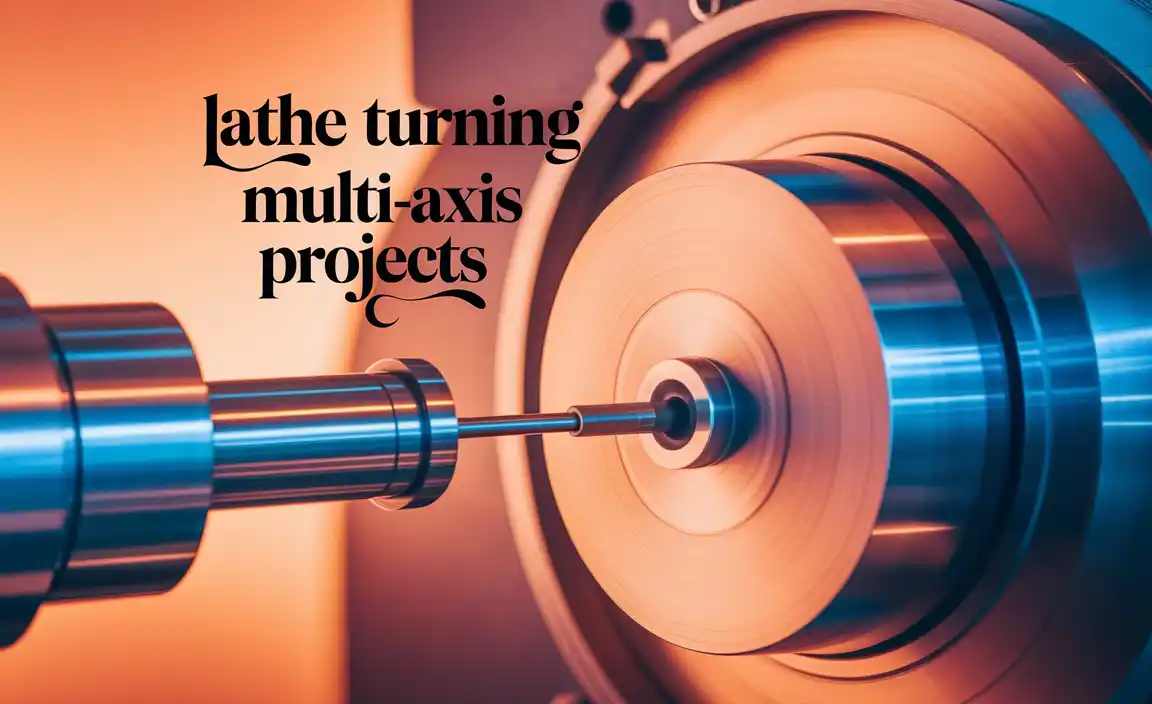

Lathe Tailstock Offset Boring Technique: A Comprehensive Guide

Lathe Tailstock Offset Boring Technique

The lathe tailstock offset boring technique is a clever method for enhancing precision in drilling. By shifting the tailstock, you can create angled holes without complex setups. This approach saves time and improves accuracy, especially for projects that require angled cuts. Imagine needing to drill a hole at a special angle; this technique makes it easy! Knowing how to use lathe tailstock offset can boost your craftsmanship and open doors to new creative challenges.Understanding Lathe Tailstock

Definition and purpose of the tailstock in a lathe.. Types of tailstocks and their features..The tailstock is a part of a lathe that helps support the workpiece while it spins. Think of it as a buddy that keeps everything steady so you can work on your projects without them wobbling around like a dancing jelly! There are various types of tailstocks like manual and automatic, each with cool features. Some allow for easy adjustments, while others offer quick-release options. This makes it easier to switch tasks without breaking a sweat. Below is a simple table showing different types:

| Type of Tailstock | Features |

|---|---|

| Manual Tailstock | Easy adjustments with a handwheel |

| Automatic Tailstock | Quick-release capabilities for fast work |

| Sliding Tailstock | Can move back and forth for different sizes |

Each type has its perks, helping you to get the best results! So, remember, a good tailstock is like a good friend—it makes your work easier and a lot more fun!

Importance of Tailstock Offset Boring

Benefits of using offset boring for precision.. Applications where tailstock offset boring is essential..Using the tailstock offset boring technique brings great benefits for precision. It allows for small adjustments that help align the workpiece correctly. This makes sure the holes are just right, not too big or too small. Imagine trying to fit a square peg in a round hole—yikes! It’s crucial for parts in machines, cars, and even toys. Without it, you might end up with some very wobbly wheels!

| Applications | Importance |

|---|---|

| Automotive parts | High precision needed for safety. |

| Industrial machinery | Avoids costly errors and downtime. |

| Medical devices | Ensures functionality and safety. |

So, remember, tailstock offset boring isn’t just a fancy term. It’s a game-changer for making sure everything fits together nicely!

Equipment Required for Tailstock Offset Boring

Essential tools and accessories for the technique.. Safety gear and considerations..To start mastering the tailstock offset boring technique, you’ll need some essential tools. First, grab a reliable lathe machine; it’s your trusty sidekick in this adventure. Don’t forget about a quality boring bar and some sharp bits to make your holes nice and smooth. Safety gear is a must—think goggles and gloves. We all want to keep our fingers and eyes intact! Here’s a quick look at what you need:

| Equipment | Purpose |

|---|---|

| Lathe Machine | Your main tool for the job |

| Boring Bar | To drill those clean holes |

| Safety Goggles | To protect your peepers |

| Gloves | To keep your hands safe |

So, gear up and bore away! Just remember, safety first—no one wants to explain a missing thumb to their friends!

Preparing the Lathe for Offset Boring

Steps for setting up the lathe and tailstock.. Checking alignment and calibration before boring..To prepare your lathe for offset boring, start by carefully setting it up. First, ensure that your lathe is stable on a flat surface. Secure the tailstock and make sure it lines up with the spindle. Then, check the alignment. Adjust it if needed so the tool and workpiece meet perfectly. You wouldn’t want them doing any awkward dance moves! Finally, calibrate everything to avoid mischief during boring.

| Steps | Description |

|---|---|

| 1. Set Up | Ensure lathe is on a flat surface. |

| 2. Secure Tailstock | Align it with the spindle. |

| 3. Check Alignment | Adjust for a perfect fit. |

| 4. Calibration | Make sure everything is set correctly. |

Step-by-Step Guide to Tailstock Offset Boring

Detailed instructions on the boring process.. Common techniques for achieving the best results..To achieve success with tailstock offset boring, follow these steps:

- First, adjust the tailstock position. This helps create the offset needed for boring.

- Next, set the drill bit securely. A stable bit leads to better accuracy.

- Then, start the lathe slowly. Gradually increase speed for consistent results.

- Finally, check the depth often. This ensures you reach the desired measurement.

Using these techniques will help you create precise holes every time.

What is the tailstock offset boring technique?

Tailstock offset boring is a method to drill holes at an angle. This technique helps create unique shapes in your project. It’s useful for designs needing angled holes.

Key techniques for best results:

- Measure carefully before starting.

- Keep tools clean for smooth operation.

- Practice on scrap wood first.

Troubleshooting Common Issues

Identifying problems during the offset boring process.. Solutions to enhance accuracy and finish quality..During the offset boring process, you might spot a few issues. Common problems include misalignment and inconsistent finishes. These can make your work less precise. Here are some tips to solve them:

- Check the tailstock alignment. Proper alignment is key.

- Use a steady hand while boring. This helps keep things straight.

- Adjust the speed of the lathe. Sometimes, a slower speed gives better results.

- Inspect your tools. Dull tools can lead to poor finishing.

These steps can improve both your accuracy and the quality of your finish.

What are common issues in offset boring?

Common issues include misalignment and tool wear, which affect the accuracy of the boring process.

Advanced Tailstock Offset Techniques

Exploring additional methods for complex projects.. Integrating other lathe functions for enhanced productivity..Creating complex projects can be tricky, but some advanced techniques can make your life easier. Think of tailstock offset as a secret weapon for precision boring. Combine this with other lathe functions, and you can boost productivity like a rocket! Want to bore a hole that’s just right? Offset techniques let you adjust and fine-tune your work. Just remember, good things come to those who offset. Well, that and a stable lathe!

| Technique | Benefit |

|---|---|

| Tailstock Offset | Increases accuracy |

| Integrating Multi-Tool Use | Enhances efficiency |

| Quick Adjustments | Saves time |

Comparative Analysis: Tailstock Offset vs. Traditional Boring

Pros and cons of both methods.. Situations where each technique is most effective..Each boring technique has its strengths and weaknesses. The lathe tailstock offset boring technique allows for better precision in deep holes. It’s great for long pieces and thicker materials. However, it requires careful setup and can be complex. Traditional boring is easier for beginners. It’s quick and works well for shallow holes, but can lack precision.

When should you use each method?

- Use tailstock offset for: Long, deep holes needing precise finishing.

- Use traditional boring for: Quick jobs on standard materials.

Choosing the right boring technique can improve your work quality. Always consider the project needs before starting.

What are the key differences between tailstock offset and traditional boring?

Tailstock offset gives better accuracy for deep work, while traditional boring is simpler for fast results. Tailstock is great for detail, traditional is faster.

Conclusion

In conclusion, the lathe tailstock offset boring technique helps you create precise holes. This method allows for better alignment and accuracy in your projects. Now that you understand the basics, try it out on your next woodworking task. Keep experimenting and learning more about lathe techniques to enhance your skills. Happy turning!FAQs

What Is The Purpose Of Using A Tailstock Offset In Lathe Operations, And How Does It Affect The Boring Process?Using a tailstock offset in lathe operations helps create holes that are not exactly in the center. This is important when we want to make a special shape or design. When we drill or bore, the tailstock offset makes sure the tool cuts where we want. This can help us make things that fit together better or look nicer.

What Are The Steps Involved In Setting Up A Lathe For Tailstock Offset Boring?First, you need to turn on the lathe and set it to a slow speed. Next, slide the tailstock to where you want to drill. Then, use the handle to move the tailstock slightly to the side for the offset. After that, secure the workpiece and check everything is tight. Finally, start the lathe and carefully begin boring.

How Do You Calculate The Optimal Amount Of Offset Needed For A Specific Boring Operation?To find the best offset for boring, you first need to know the size of the hole you want to make. Then, look at the tool you’re using. Measure how much extra space you need for it to work well. Finally, you can add that extra space to the size of the hole to find the offset. This helps your boring tool work better and make clean holes.

What Types Of Materials Can Be Effectively Bored Using Tailstock Offset Techniques, And Are There Any Limitations?You can use tailstock offset techniques to bore into soft materials like wood and some metals, such as aluminum. These techniques can help you create holes that are not perfectly straight. But, it can be tricky with very hard materials like steel or stone, which may not work well. You might also have trouble if the piece is very small or thin, as it can break easily.

What Are The Common Challenges And Troubleshooting Tips Associated With Tailstock Offset Boring On A Lathe?When you use a lathe with tailstock offset boring, you might face some problems. First, make sure the tailstock is lined up right. If it’s not, your hole might be crooked. If you notice a rough hole, try adjusting the speed or checking the tool sharpness. You can also support longer pieces with a steady rest to keep everything stable.