Have you ever wondered how a lathe works perfectly? One key part is the tailstock. But did you know that proper taper alignment can make a big difference? Many people overlook this tiny detail. Yet, it plays a huge role in how well your projects turn out.

Imagine you’re trying to carve a beautiful piece of wood. Your lathe splutters, and your design collapses. Frustrating, right? That could happen if your lathe tailstock taper isn’t aligned well. This is a common issue, but it’s easy to fix.

Getting the tailstock alignment just right helps tools move smoothly. It saves time and effort. Plus, it prevents mistakes. In this article, we’ll explore easy ways to check and adjust your lathe tailstock taper alignment. You might just be amazed at how simple it is!

Lathe Tailstock Taper Alignment: Ensuring Precision Setup

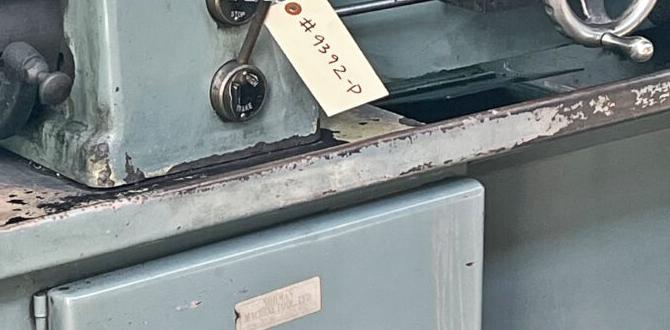

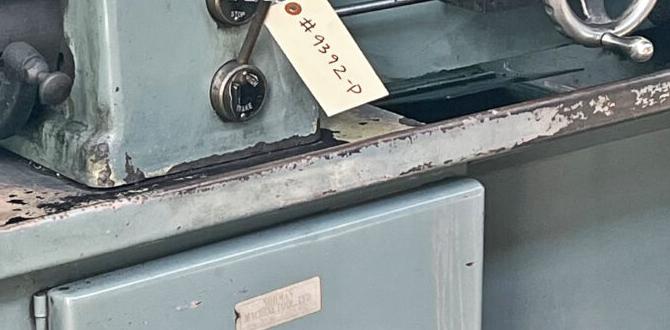

Lathe Tailstock Taper Alignment

Lathe tailstock taper alignment is crucial for precision in turning projects. Proper alignment helps ensure that the tailstock is directly aligned with the lathe’s spindle. This alignment prevents issues like inaccurate cuts and uneven surfaces. Did you know that a small misalignment can lead to major problems in your work? Regular checks and adjustments can keep your lathe functioning smoothly. Mastering this skill can boost your confidence as a woodworker or metalworker!Understanding Lathe Tailstock Functionality

Explanation of tailstock role in lathe operations. Importance of accurate alignment for precision machining.The tailstock plays an important role in lathe machines. It holds tools and supports the workpiece during turning operations. A well-aligned tailstock helps create smooth and accurate parts. Here’s why proper alignment matters:

- Ensures precise measurements

- Reduces tool wear

- Improves overall product quality

Accurate alignment affects every step of machining. A small mistake can lead to big issues later. Remember, in precision work, every detail counts!

Why is alignment so crucial?

Alignment is crucial for precision machining. It ensures pieces fit together perfectly and function well.

Methods for Aligning Lathe Tailstock Taper

Stepbystep guide to aligning the tailstock taper manually. Tools needed for effective alignment processes.Aligning your lathe tailstock taper doesn’t have to be a hair-pulling experience. Start by gathering some simple tools: a dial indicator, a wrench, and a bit of patience. First, set your dial indicator on the tailstock and move it along the taper. Watch those numbers like a hawk! If they wobble like jelly, it’s time for some adjustments.

Next, gently loosen the tailstock bolts. This gives you room to play. Fine-tune the tailstock’s position until the indicator shows a nice, steady reading. Tighten it up, and voilà! You’re aligned. For a handy reference, check the table below:

| Tools Needed | Description |

|---|---|

| Dial Indicator | Measures alignment accuracy |

| Wrench | Tightens or loosens bolts |

| Patience | Essential for perfecting alignment |

Remember, a little tweaking can save you a lot of headaches later. Happy aligning!

Advanced Techniques for Precision Alignment

Using alignment bars for improved accuracy. Implementing digital tools and gauges for precision.Alignment bars can help make your lathe’s tailstock more precise. These bars often fit snugly into the tailstock and work like a guide. This leads to better cuts and smoother operations. Digital tools and gauges are also fantastic for precision. They provide exact readings, which helps you adjust correctly. With these tools, you can ensure everything lines up just right.

How can I improve tailstock alignment?

Using alignment bars and digital gauges can enhance precision significantly. These tools help you make the necessary tweaks to achieve accurate alignment.

Testing and Verifying Tailstock Alignment

Techniques for assessing the effectiveness of alignment. Recommended checks to ensure sustained accuracy.Aligning a tailstock might sound tricky, but it’s actually a fun challenge! First, use a sensitive measuring tool like a dial indicator to check the alignment. Put it on the spindle and move it to the tailstock. It should show a consistent reading. If it wiggles like a jelly on a rollercoaster, it’s time for adjustments!

Next, ensure accuracy by repeating checks after each adjustment. A great tip is to keep a checklist handy for your recommended checks. This way, you won’t miss any vital step. Remember, a precise tailstock means smoother projects and less headache!

| Check | Method | Notes |

|---|---|---|

| Indicator Setup | Attach and zero it on spindle | Consistency is key! |

| Measurement | Move to tailstock | Look for any major shifts |

| Adjustment | Tweak as needed | Recheck after each tweak! |

Keeping your tailstock aligned is like keeping your shoelaces tied; it avoids a lot of falls!

Preventative Measures for Tailstock Misalignment

Tips for regular maintenance and upkeep. Best practices to avoid common alignment pitfalls.Regular maintenance can prevent tailstock misalignment. Here are some helpful tips:

- Check the tailstock regularly for wear and tear.

- Clean the tailstock and surrounding area.

- Lubricate moving parts to keep them smooth.

- Inspect for loose screws and tighten them as needed.

- Align the tailstock often to avoid problems.

Remember, taking small steps now can save you big troubles later. Keeping your lathe in good shape helps it work better and last longer!

What are some common alignment pitfalls?

Common pitfalls include not checking the tailstock often enough and ignoring signs of wear. Addressing these issues early can prevent bigger problems.

Q&A: Troubleshooting Tailstock Alignment Issues

Frequently asked questions regarding tailstock taper alignment. Solutions to common problems faced by machinists.Dealing with pesky tailstock alignment issues can be tricky. Many machinists wonder, “Why is my tailstock off?” One common problem is that the taper isn’t aligned, making machining a challenge. To fix it, check if the tailstock is level and adjust as needed. Another question is, “How often should I check alignment?” A good rule of thumb is every time you change the taper. Remember, a little adjustment can save a lot of frustration—plus, it keeps your work from looking like a funhouse mirror! Here’s a quick table of common issues and solutions:

| Issue | Solution |

|---|---|

| Tailstock loose | Tighten the locking mechanism |

| Taper not fitting | Inspect and clean the taper |

| Repeated misalignment | Use a dial indicator for precision |

Conclusion

In conclusion, aligning your lathe tailstock taper is essential for accurate work. Regular checks prevent mistakes and improve results. You can use simple tools to measure and adjust alignment. Always remember to keep your equipment clean and well-maintained. For more tips, check out guides online or ask a friend in the workshop. Happy machining!FAQs

What Are The Common Methods Used To Check The Alignment Of A Lathe Tailstock Taper With The Spindle Taper?You can check the alignment of a lathe tailstock in a few easy ways. First, use a long rod and insert it into both the tailstock and spindle. If the rod touches both ends, they are aligned. Another way is to use a dial indicator. It shows if the tailstock is straight compared to the spindle. Finally, you can measure with calipers to check for any gaps.

How Can Misalignment Of The Tailstock Taper Affect The Accuracy And Quality Of The Workpiece?When the tailstock taper is not lined up properly, it can cause problems. The tailstock holds the workpiece in place while you work. If it’s crooked, the workpiece may wobble. This wobbling can make your cuts uneven and ruin the final product. You want everything to be straight to make good quality work!

What Tools Or Instruments Are Recommended For Adjusting The Tailstock Taper Alignment On A Lathe?To adjust the tailstock taper alignment on a lathe, you can use a few simple tools. A dial indicator helps check for any misalignment. You might also need an Allen wrench to make adjustments. A small screwdriver can help if you need to tighten anything. These tools can help you ensure your lathe works correctly!

How Often Should A Lathe’S Tailstock Taper Alignment Be Checked And Adjusted To Maintain Optimal Performance?You should check the tailstock taper alignment every few months. This helps keep your lathe working well. If you notice any problems, adjust it right away. Keeping it aligned will help you make better parts. Regular checks help prevent bigger issues later.

What Steps Should Be Taken To Realign A Tailstock Taper If Persistent Inaccuracies Are Observed During Machining?To realign a tailstock taper, first, check the machine for any loose parts. Next, use a tool to measure if it’s straight. If it’s not, make adjustments to the tailstock until it is. Tighten everything securely and test it again. This will help make your machine work better.