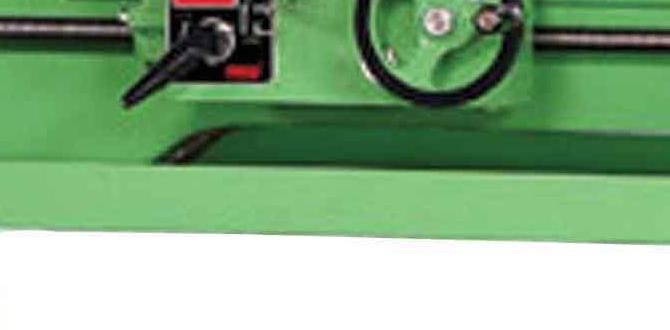

Have you ever wondered how intricate parts are made from solid metal? One of the most important tools for this job is the lathe. A lathe allows craftsmen to shape and cut metal into precise forms. It’s truly fascinating how it works!

One key feature of the lathe is the threading system. Threading helps create the grooves on a screw or bolt. But did you know that the compound rest plays a big role in this process? This part helps you adjust the cutting tool’s angle, making threading metal a lot easier.

Imagine you are building a robot and need to create a special bolt. With a metal lathe and its compound rest, you can make it to fit perfectly! Knowing how to use these tools can open up a world of creativity. Are you ready to learn more about lathe threading and how the compound rest works?

Lathe Threading: Understanding Metal Lathe Compound Rest

Understanding Lathe Threading with the Metal Lathe Compound Rest

Lathe threading is an essential skill for metalworkers. The compound rest on a metal lathe helps control the cutting tool’s angle. This setup enables precise threads on various materials. Did you know that even small adjustments can change the thread’s appearance drastically? Proper use of the compound rest leads to smoother threads and better fit. Mastering this technique opens new possibilities in metalworking projects. Have you tried it yet?The Anatomy of a Metal Lathe

Key components of a metal lathe and their functions.. Detailed explanation of the compound rest and its significance in threading..A metal lathe has several important parts. Each part helps shape metal. Here are some key components:

- Headstock: Holds the main motor and spindle.

- Tailstock: Supports the other end of the workpiece.

- Bed: Holds everything in place.

- Cutter: Does the actual cutting of the metal.

- Compound Rest: Allows precise adjustments while threading.

The compound rest is very important for threading. It helps set the angle of the cutter accurately. This makes clean and perfect threads possible. Strong threads can hold parts together better. Without this tool, threading would be much harder. Accuracy in threading is key for good fitting and stronger connectors.

What is the purpose of the compound rest in lathe threading?

The compound rest helps to adjust the tool’s position for threading. It lets you change the angle and depth easily. This leads to precise cuts and perfect threads. Good threading means stronger connections in metal parts.

Proper Setup for Lathe Threading

Stepbystep guide to preparing the lathe for threading.. Importance of tool selection and adjustment for optimal results..Getting your lathe ready for threading doesn’t have to be a headache! First, check your tool selection. A sharp, appropriate tool makes threading easier—like eating spaghetti with a fork instead of a spoon! Next, adjust the compound rest carefully; this helps ensure precision. Remember to lock everything in place so your tool doesn’t decide to dance while you work. Lastly, set the feed rate, and you’re good to go. Let’s get threading!

| Step | Description |

|---|---|

| 1 | Choose the right tool. |

| 2 | Adjust the compound rest. |

| 3 | Lock everything in place. |

| 4 | Set the feed rate. |

Using the Compound Rest Effectively

Techniques for adjusting the compound rest for different thread pitches.. Tips for maintaining accuracy and consistency throughout the threading process..Adjust the compound rest carefully for different thread pitches. Move the handle smoothly. This helps make clean threads. To keep everything straight, follow these tips:

- Check the angle before cutting.

- Use a gauge to measure thread pitch.

- Keep the tool sharp for better results.

Accuracy matters. This keeps your threaded pieces fitting just right. Consistency is key, so repeat your adjustments as needed. With practice, threading will become easier, and you will see excellent results!

How do I maintain accuracy while threading?

To maintain accuracy, always check your measurements and ensure the lathe is well-calibrated. Regularly inspect your tools for wear or damage, as this can affect performance.

Troubleshooting Lathe Threading Issues

Common problems encountered during lathe threading and solutions.. Preventive maintenance tips to avoid recurring issues..Lathe threading can be tricky. Many people face problems like uneven threads or poor finish. Here are some common issues and solutions:

- Inconsistent thread depth: Check the tool height and adjust it as needed.

- Chatter: Ensure the machine is secure and avoid high speeds.

- Dirty threads: Keep the lathe clean and lubricated for smooth operations.

To prevent these issues, follow these tips:

- Regularly inspect the lathe.

- Keep tools sharp and well-maintained.

- Use appropriate speeds and feeds for materials.

With care, you can enjoy smooth threading on your lathe!

What are some common lathe threading problems?

Common problems include uneven threads, chatter, and worn tools.

How can I prevent lathe threading issues?

- Perform regular maintenance.

- Keep your tools sharp.

- Use the right settings for your material.

Advanced Lathe Threading Tips and Tricks

Expert advice on enhancing threading precision and efficiency.. Techniques for creating complex threads and profiles..Threading on a lathe can be tricky, but some expert tips can help. First, ensure your settings are precise. Use the right feeds and speeds for clean threads. Second, don’t rush. Taking your time can enhance the quality. Third, practice special techniques for making complex threads. Here are some quick ideas:

- Adjust tool angles for better cuts.

- Use calipers to check dimensions.

- Try multiple passes for deeper grooves.

These tips will help you create strong, accurate threads with ease!

What are some tips for effective threading?

Use the right tool angles, take your time, and check dimensions carefully. These steps will improve your threading performance and increase the quality of your work.

Conclusion

In summary, the compound rest on a metal lathe is key for threading. It helps you easily adjust the tool’s position for precise cuts. Understanding how to use it improves your skills quickly. Practice using the lathe and explore more resources to enhance your knowledge. Remember, hands-on experience is the best way to learn!FAQs

What Is The Purpose Of The Compound Rest On A Metal Lathe During Threading Operations?The compound rest on a metal lathe helps you shape and cut threads on a metal piece. It can move at different angles, which lets you make perfect threads. When you thread, it gives you better control. This way, you create strong and precise threads for the job.

How Do You Set The Angle Of The Compound Rest For Different Thread Pitches On A Metal Lathe?To set the angle of the compound rest on a metal lathe, first, find out the thread pitch you need. The thread pitch is how far the screw moves with one turn. Then, you use a special chart that tells you the right angle. You turn the angle knob on the compound rest to match what the chart shows. This helps you cut the threads correctly.

What Are Some Common Issues Encountered When Threading With A Compound Rest, And How Can They Be Resolved?When using a compound rest for threading, you might face a few problems. One issue is not getting the right angle, which can make the thread look wrong. To fix this, you can double-check your setup and adjust the angles carefully. Another trouble is the tool slipping or moving. Make sure the tool is tightly secured before you start. If the thread keeps breaking, you may need to check the speed and pressure you use. Adjusting these can help make better threads.

How Does The Compound Rest Improve The Precision And Finish Of Threads Compared To Other Methods?Using a compound rest helps you make better threads because it gives you more control. You can angle the tool to cut at different positions. This makes the edges smoother and more precise. Other methods might be less accurate and take longer to finish. With the compound rest, your work looks nicer and is easier to use.

What Safety Precautions Should Be Taken When Using The Compound Rest On A Lathe While Threading?When using the compound rest on a lathe for threading, you should always wear safety goggles to protect your eyes. Keep your fingers away from the moving parts to avoid getting hurt. Make sure your hair and clothes are tied back and tidy. Always check that tools are secure before you start working. Remember to turn off the lathe when you’re finished or when you need to make adjustments.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of The Compound Rest On A Metal Lathe During Threading Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest on a metal lathe helps you shape and cut threads on a metal piece. It can move at different angles, which lets you make perfect threads. When you thread, it gives you better control. This way, you create strong and precise threads for the job.”}},{“@type”: “Question”,”name”: “How Do You Set The Angle Of The Compound Rest For Different Thread Pitches On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set the angle of the compound rest on a metal lathe, first, find out the thread pitch you need. The thread pitch is how far the screw moves with one turn. Then, you use a special chart that tells you the right angle. You turn the angle knob on the compound rest to match what the chart shows. This helps you cut the threads correctly.”}},{“@type”: “Question”,”name”: “What Are Some Common Issues Encountered When Threading With A Compound Rest, And How Can They Be Resolved? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a compound rest for threading, you might face a few problems. One issue is not getting the right angle, which can make the thread look wrong. To fix this, you can double-check your setup and adjust the angles carefully. Another trouble is the tool slipping or moving. Make sure the tool is tightly secured before you start. If the thread keeps breaking, you may need to check the speed and pressure you use. Adjusting these can help make better threads.”}},{“@type”: “Question”,”name”: “How Does The Compound Rest Improve The Precision And Finish Of Threads Compared To Other Methods? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a compound rest helps you make better threads because it gives you more control. You can angle the tool to cut at different positions. This makes the edges smoother and more precise. Other methods might be less accurate and take longer to finish. With the compound rest, your work looks nicer and is easier to use.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using The Compound Rest On A Lathe While Threading?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the compound rest on a lathe for threading, you should always wear safety goggles to protect your eyes. Keep your fingers away from the moving parts to avoid getting hurt. Make sure your hair and clothes are tied back and tidy. Always check that tools are secure before you start working. Remember to turn off the lathe when you’re finished or when you need to make adjustments.”}}]}