Have you ever watched a metal lathe in action? It’s like magic! You start with a big piece of metal and end up with something smooth and shiny. But what makes this process so precise? The answer often lies in the lathe threading metal lathe controller board.

This little device is the brain of the operation. It controls everything, from the speed to the depth of each cut. Without it, threading metal would be much harder and less accurate. Imagine trying to carve a pumpkin without a knife. It’s just not the same!

Do you know why the controller board is so important? It allows you to make the tiniest adjustments. This means that engineers can ensure every part fits perfectly. It’s this attention to detail that makes metalwork truly impressive.

Join us as we dive deeper into the world of lathe threading. You’ll discover how this amazing controller board works and why it’s essential for anyone working with metal. Trust us, you won’t want to miss it!

Lathe Threading: Optimize Your Metal Lathe Controller Board

Lathe Threading Metal Lathe Controller Board

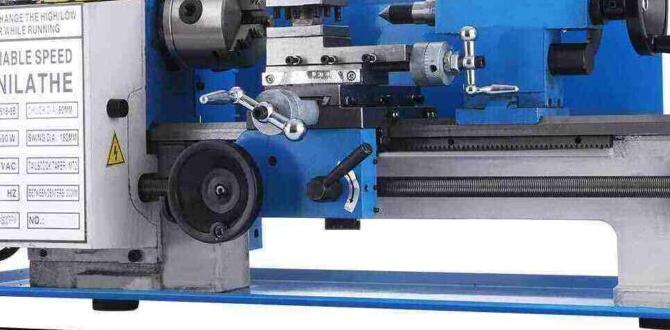

Using a lathe for threading can seem tough, but the right controller board makes it easy. A lathe threading metal lathe controller board lets you make precise threads on metal pieces. Imagine building a beautiful, detailed part for a project you love. These boards can control speed and movement, helping you create perfect threads every time. Surprisingly, they often come with added features like digital displays, making it simple to monitor your work. Wouldn’t it be great to master this skill?Understanding Lathe Threading

Definition and importance of lathe threading in machining. Types of threads commonly produced with a lathe.Lathe threading is a fun and essential part of machining. It involves cutting helical grooves on a workpiece to create threads. Think of it like making a spiral candy cane—yummy! These threads help parts fit together, allowing them to screw into one another. Common types include metric, inch, and pipe threads. Each type serves a unique purpose, making lathe threading a superstar in the machining world.

| Type of Thread | Common Use |

|---|---|

| Metric | International standards |

| Inch | Used mainly in the U.S. |

| Pipe | For plumbing and piping |

Types of Metal Lathe Controller Boards

Comparison of different controller board types (e.g., CNC, manual). Key features and specifications to consider.There are two main types of metal lathe controller boards: CNC and manual. CNC stands for Computer Numerical Control, while manual means you have to use your hands. CNC boards let you program shapes and sizes. Manual boards are simpler but require more skill. Key features to look for include motor control and ease of use. Want to spin metal like a pro? Choose wisely, because choosing the wrong board could leave your projects looking like a toddler’s art class!

| Type | Features | Best For |

|---|---|---|

| CNC | High precision, programmable | Complex designs |

| Manual | Simple controls, hands-on | Beginners and hobbyists |

Benefits of Upgrading Your Controller Board

Enhanced precision and accuracy in threading operations. Increased efficiency and productivity in machining processes.Upgrading your controller board brings exciting changes, especially for threading metal. With a new board, you get improved precision. Imagine your lathe cutting like a hot knife through butter! This means better results and fewer mistakes. Efficiency? Absolutely! You can finish tasks faster, making your machine a productivity superhero. Less time messing around means more time for snacks. Plus, a happier lathe equals happier users!

| Benefit | Description |

|---|---|

| Precision | Enhanced accuracy in threading operations. |

| Efficiency | Increased productivity in machining processes. |

Installation and Setup of Controller Boards

Stepbystep guide to installing a lathe controller board. Tips for configuring the board for optimal performance.Installing a lathe controller board can seem tough, but it’s manageable if you follow these simple steps. First, gather all tools needed, like a screwdriver and wires. Next, carefully open the lathe and locate the old board. Then, remove it and replace it with the new one. Make sure to connect the wires correctly.

For the best performance, adjust settings based on your specific lathe type. Check the manual for suggestions. Keep the board clean and protected from dust for longer life.

- Gather tools: screwdriver, wires

- Remove old board

- Install new board

- Connect wires correctly

- Adjust settings per manual

What do I need for installation?

You’ll need basic tools like a screwdriver and the right wires for your lathe. Always check the manual for extra parts.

How can I ensure optimal performance?

Adjust the settings according to the manual. Regular cleaning also helps keep your lathe in top shape.

Common Issues with Lathe Controller Boards

Troubleshooting connectivity and performance issues. Maintenance tips to prolong the lifespan of the controller board.Controller boards can be tricky little fellows. If you notice your lathe acting strange, check the connections first. Loose wires can turn a smooth day into a bumpy ride! Regular maintenance can help too. Two cleanings a year keep dirt away. Did you know that a little dust can make your controller board throw a tantrum? After all, you don’t want your lathe to take a vacation just when you need it most. Here’s a quick table of tips!

| Issue | Solution |

|---|---|

| Poor connectivity | Check for loose wires and clean connectors. |

| Performance drop | Run regular maintenance and keep it dust-free. |

| Overheating | Ensure proper ventilation around the board. |

Selecting the Right Controller Board for Your Needs

Factors to consider based on project requirements and budget. Recommendations for toprated controller boards in the market.Choosing the right controller board for your project is important. First, consider the project requirements. Think about what features you need, like speed and precision. Next, look at your budget. Some boards are more expensive but offer better quality. Check your local stores or online for reviews. Here are some recommendations:

- Arduino CNC Shield – Great for beginners.

- Grbl Controller – Simple and cost-effective.

- Mach4 Controller – Ideal for advanced users.

Select a board that matches your skills and needs. This will help ensure your work is smooth and fun!

What should I consider before buying a controller board?

Consider compatibility, features, and your budget before making a purchase.Lathe Threading Techniques and Tips

Best practices for achieving perfect threads on a lathe. Safety considerations while operating threading machines.When creating perfect threads on a lathe, it’s all about patience and precision. Start by ensuring your machine is clean and well-lubricated. This reduces friction and helps you avoid those pesky snags. Next, choose the right tool. A sharp cutter is your best buddy here! Remember, safety first: wear goggles and keep hands clear. After all, you don’t want your fingers to become part of the project. Here’s a quick tip: always measure twice! This saves time and metal. Happy threading!

| Best Practices | Safety Tips |

|---|---|

| Use sharp tools | Wear safety goggles |

| Keep the machine clean | Keep hands clear of cutting area |

| Measure twice | Secure loose clothing |

Conclusion

In conclusion, a lathe threading metal lathe controller board simplifies your metalworking projects. It gives you better control and accuracy when threading metal. If you want to improve your skills, consider learning about different controller boards available. Explore tutorials or guides online. With practice, you can create amazing projects using your lathe!FAQs

Here Are Five Related Questions On The Topic Of Lathe Threading And Metal Lathe Controller Boards:Sure! A lathe is a machine that helps us shape metal into different parts. When we use a lathe for threading, we make spiral grooves in the metal. This is important for making screws and bolts fit together. Controller boards help us control how the lathe works, like telling it how fast to spin. They make our work easier and more accurate.

Sure! Please provide me with the question you’d like me to answer.

What Are The Key Features To Look For In A Controller Board For A Metal Lathe Specifically Designed For Threading Applications?When choosing a controller board for a metal lathe, you want a few important features. First, it should let you change speeds easily for different threads. Next, it should have good programming options so you can set your lathe exactly how you want. Also, make sure it has safety features to keep you safe while working. Finally, a clear display helps you see your settings clearly.

How Do Different Types Of Controller Boards Impact The Precision And Accuracy Of Threading On A Metal Lathe?Different types of controller boards help control how a metal lathe works. Some boards are better at measuring and adjusting movements. This means they can make more accurate threads. If we use a good controller board, our threads will fit together perfectly. Choosing the right board helps us create high-quality metal pieces.

What Programming Options Are Available For Controller Boards When Setting Up Threading Operations On A Metal Lathe?When we set up threading on a metal lathe, we can use different programming options. One option is G-code, which tells the machine what to do. Another option is using software like Mach3 or CNCjs to control the lathe. You can also use special programs that help create codes for threading. Each option helps us make sure the lathe cuts threads correctly.

How Can A Metal Lathe Controller Board Be Integrated With Other Cnc Components To Enhance Threading Capabilities?You can make a metal lathe controller board work better by connecting it to other parts. First, join it with stepper motors to control movement. Next, add sensors to keep track of how deep you are cutting. Finally, use a computer program to help plan your threading more accurately. This way, you can create better threads on your projects!

What Troubleshooting Steps Can Be Taken If A Metal Lathe Controller Board Is Not Executing Threading Commands Correctly?If your metal lathe isn’t threading right, here are some steps you can try. First, check the wiring. Make sure everything is connected properly. Next, look at the settings on the controller board. Ensure they’re set for threading. Finally, restart the machine. Sometimes, a simple reset can fix the problem!