Have you ever wondered how metal objects get smooth, detailed threads? The answer lies in a process called lathe threading. This technique uses a special tool mounted on a machine known as a metal lathe. But what makes a metal lathe tick? It all comes down to its drive system.

The drive system is the heart of the lathe. It powers the motion needed for threading. Imagine trying to ride a bicycle without pedals. It just wouldn’t work! Likewise, without a reliable drive system, a lathe cannot function properly.

Fun fact: The concept of a lathe goes back thousands of years! Ancient artisans used one to make wooden bowls and pots. Today, we have advanced metal lathes that perform complex tasks with ease.

In this article, we’ll explore how the lathe threading process works and the crucial role of the drive system. You’ll discover why understanding these parts is essential for anyone interested in crafting metal objects. Ready to dive in?

Lathe Threading: Understanding Metal Lathe Drive System

Understanding Lathe Threading and Drive Systems

Lathe threading is essential for creating precise screw threads on metal parts. A metal lathe drive system powers the machine and controls its rotation. Do you know why this matters? Without a good drive system, your threads might end up uneven! Many lathes come with different types of drive systems, like belt or gear-driven options, which can affect their performance. Understanding these systems can help you choose the right machine for your projects. It’s like choosing the right tool for a job!What is a Lathe Threading System?

Definition and purpose of lathe threading systems.. Different types of threading operations typically performed on a lathe..A lathe threading system is a magical tool! It helps create threads on metal pieces, like the spiral grooves on a screw. This process gives parts the ability to fit together snugly, just like your favorite puzzle pieces. The main job of this system is to ensure that everything screws together correctly so nobody ends up with a wobbly chair.

| Threading Operation | Description |

|---|---|

| External Threading | Making threads on the outside of a cylinder. |

| Internal Threading | Creating threads on the inside of a hole. |

| Acme Threading | A special, wider thread for better strength. |

| Square Threading | Threads shaped like squares for unique applications. |

Different types of threading operations are done using lathes, including both external and internal threading. Think of them as the superheroes of metalwork, making sure everything fits just right. Why did the screw go to school? It wanted to get a little more *threaded*! With the lathe threading system, creating precise threads has never been easier or more fun!

The Components of a Lathe Drive System

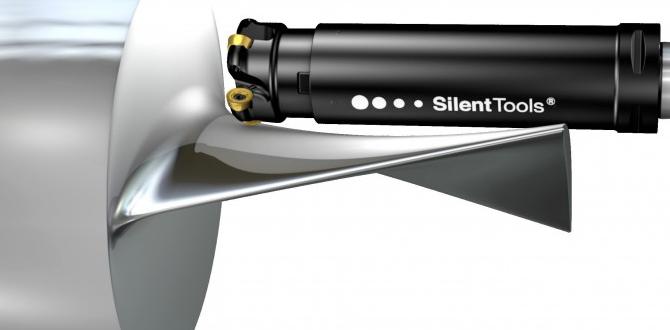

Detailed breakdown of key components (motor, gearbox, belt system).. Explanation of how each component contributes to threading efficiency..The heart of a lathe drive system includes several key parts that work together like a team of superheroes. First, the motor powers the whole system. It gives energy to the machine. Next, we have the gearbox, which helps change the speed. It makes sure the lathe can cut metal at just the right pace. Finally, the belt system connects everything, transferring power smoothly. If one part is weak, the whole team struggles!

| Component | Role |

|---|---|

| Motor | Powers the entire system. |

| Gearbox | Adjusts speed for efficient cutting. |

| Belt System | Links parts for smooth operation. |

When these components work together, threading becomes much easier and faster. Imagine trying to bake cake without an oven—challenge accepted! The right drive system keeps everything running just right.

Threading Methods in Lathe Operations

Description of different threading techniques (single point, chase threading).. Comparison of methods based on precision and application..Lathe operations use different techniques for threading. Single point threading uses one tool to cut a thread. It’s great for custom threads and gives good precision. In contrast, chase threading uses two tools that work together. This method is faster for large numbers of parts. Here’s a quick comparison:

- Single Point: High precision, customizable.

- Chase Threading: Faster for mass production.

Each method has its own benefits based on the project needs. Choose wisely for the best results!

What is threading in a lathe?

Threading in a lathe is the process of creating helical grooves on a workpiece. This helps in making screws and bolts.

Setting Up the Lathe for Threading

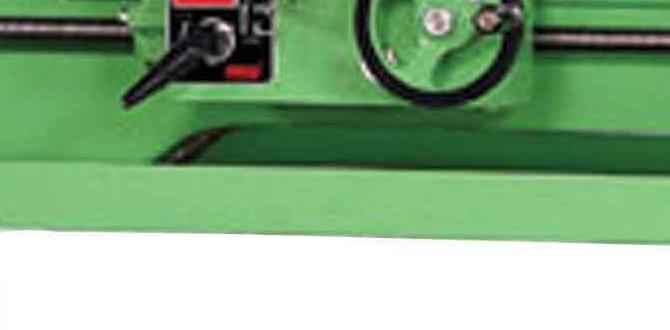

Stepbystep guide on preparing the lathe for threading operations.. Importance of proper setup to ensure accuracy and safety..Before starting, check your lathe settings. Proper setup is key for accuracy and safety. Follow these steps to get ready:

- Clean the machine: Remove dust and chips from previous work.

- Check tools: Ensure cutting tools are sharp and ready to use.

- Set speed: Choose a speed on the lathe that fits your material.

- Align materials: Make sure the metal is straight and secure.

Taking your time helps prevent mistakes. A well-set lathe works better and keeps you safe. Remember, good setups lead to great results!

Why is setup important for threading?

Proper setup ensures accuracy, safety, and high-quality threads. Skipping this step can result in poor outcomes like uneven threads.

Common Challenges in Lathe Threading

Identification of typical problems encountered during threading.. Solutions and tips for overcoming these challenges..Threading on a lathe can be tricky. Many users face common problems. One issue is inconsistent thread depth, leading to poor fit. Another challenge is tool wear, which can affect precision. To avoid these problems, try the following:

- Keep tools sharp and well-maintained.

- Adjust spindle speed to match the material.

- Use proper cutting fluids for better lubrication.

With these tips, you can improve your threading quality and make the process smoother.

What are common problems in lathe threading?

Common problems include uneven threads, excessive tool wear, and tool chatter.

How can these issues be fixed?

- Ensure tools are sharp and clean.

- Match speed with material for the best results.

- Use cutting fluids for effective thread cutting.

Maintenance of Lathe Drive Systems

Best practices for regular maintenance of drive systems.. Importance of maintenance in prolonging the lifespan of the lathe..Keeping lathe drive systems in tip-top shape is like giving your favorite toy a spa day. Regular maintenance helps keep everything running smoothly. It’s important to check parts for wear and tear, just like checking for missing socks after laundry day! Regular oiling and cleaning can greatly prolong your lathe’s lifespan. Did you know a well-maintained lathe can last up to twice as long? So, treat it well, and it’ll treat you even better!

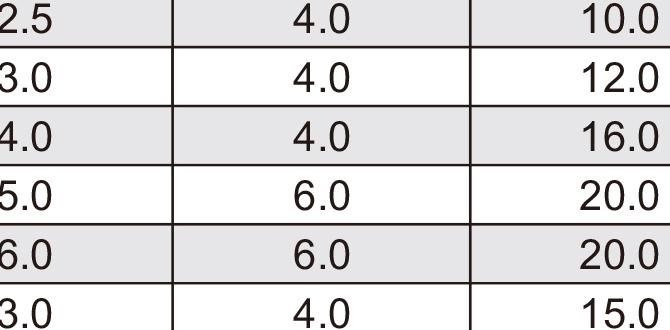

| Maintenance Tasks | Frequency |

|---|---|

| Check lubricants | Weekly |

| Inspect belts | Monthly |

| Clean drive system | Quarterly |

| Replace worn parts | As needed |

Choosing the Right Drive System for Your Needs

Factors to consider when selecting a lathe drive system.. Recommendations for specific applications and threading requirements..Choosing a drive system for your lathe can be puzzling. First, think about power. How much do you need for your projects? Then consider flexibility. Some systems are better for different types of work. If you’re threading metal, a high-torque drive is a must. For smaller tasks, a simpler option may work well. Remember, it’s like choosing between a strong coffee or a light tea—pick what fits your job best!

| Application | Recommended Drive System |

|---|---|

| Heavy Metal Turning | High Torque Drive |

| Precision Threading | Variable Speed Drive |

| Small Projects | Standard Drive |

With these factors in mind, you’ll strike the perfect balance for your lathe needs and ensure every job is a success—even if it’s only making tiny metal wool creatures!

Innovations in Lathe Technology for Threading

Recent advancements in lathe technologies and their impact on threading.. Future trends in lathe threading systems and anticipated developments..Lathe technology has taken some exciting turns! Recent advancements have made threading quicker and easier. Machines now use smart controls that adjust automatically. This means better precision and less waste. Future trends look bright too! We might see robotic arms doing the threading. Imagine a robot that’s great at threading, and it doesn’t even need a coffee break! At the same time, electric systems are getting a boost, which means less noise and more efficiency.

| Advancements | Impact on Threading |

|---|---|

| Smart Controls | Higher accuracy and less material waste |

| Robotic Assistance | Faster production with fewer human errors |

| Electric Drive Systems | Quieter operation and lower energy costs |

These innovations are shaping the future. Who knew metal lathe threading could be so thrilling?

Conclusion

In summary, a lathe threading metal lathe drive system helps you create precise threads in metal. Understanding this system is essential for accurate machining. As you explore this topic, consider hands-on practice for better skills. We encourage you to read more about lathe types and techniques. This knowledge will boost your confidence and make you a better machinist!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Threading And The Metal Lathe Drive System:Sure! A metal lathe is a machine that shapes metal into different parts. When we talk about lathe threading, it means making grooves or spirals on a piece of metal. We can use the lathe to create screws or bolts by cutting threads. The drive system helps the lathe move the metal smoothly. This makes it easier for us to create exact shapes and sizes.

Sure! Please provide the question you would like me to answer.

What Are The Essential Components Of A Metal Lathe Drive System For Effective Threading Operations?To do threading on a metal lathe, you need a few important parts. First, there’s the motor, which gives power to the lathe. Then, we have the gears, which help control the speed and direction. Lastly, you need the lead screw, which moves the cutting tool the right way. Together, these parts make sure you get a nice, even thread.

How Do Different Drive Systems (E.G., Belt Drive, Direct Drive) Impact The Threading Accuracy And Quality On A Metal Lathe?Drive systems like belt drives and direct drives help a metal lathe work better. A belt drive uses a rubber band to move parts, which can slip a bit. This can make threading less accurate. A direct drive is stronger and connects parts directly, so it usually makes a more exact thread. Better threading means your work will look nicer and fit together well.

What Are The Common Threading Techniques Used On A Metal Lathe, And How Does The Drive System Affect Their Execution?Common threading techniques on a metal lathe include single-point threading and tapping. In single-point threading, you use a special tool to cut threads along the metal as it spins. Tapping means using a tool to make threads inside a hole. The drive system, which powers the lathe, affects how fast and smoothly these techniques work. A strong drive keeps the metal moving steadily, helping us create better threads.

How Do You Properly Set Up A Metal Lathe Drive System For External Vs. Internal Threading Operations?To set up a metal lathe for threading, you first need to decide if you are making external or internal threads. For external threads, you need to secure your piece on the lathe and use the right tool on the outside. If you are making internal threads, you’ll use a special tool called a tap inside the hole of your piece. Make sure to adjust the speed of the lathe and the tool’s position for both types of threading. Always wear safety gear while working!

What Maintenance Practices Should Be Followed To Ensure The Longevity And Reliability Of The Drive System In A Metal Lathe During Threading Tasks?To keep the drive system of a metal lathe working well, you should do a few things. First, always check for loose parts before you start. Clean the lathe regularly to remove dust and chips. You should also oil the moving parts to keep them smooth. Finally, follow the user manual for any specific care tips. This helps your lathe last longer and work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Threading And The Metal Lathe Drive System:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a machine that shapes metal into different parts. When we talk about lathe threading, it means making grooves or spirals on a piece of metal. We can use the lathe to create screws or bolts by cutting threads. The drive system helps the lathe move the metal smoothly. This makes it easier for us to create exact shapes and sizes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Of A Metal Lathe Drive System For Effective Threading Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To do threading on a metal lathe, you need a few important parts. First, there’s the motor, which gives power to the lathe. Then, we have the gears, which help control the speed and direction. Lastly, you need the lead screw, which moves the cutting tool the right way. Together, these parts make sure you get a nice, even thread.”}},{“@type”: “Question”,”name”: “How Do Different Drive Systems (E.G., Belt Drive, Direct Drive) Impact The Threading Accuracy And Quality On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Drive systems like belt drives and direct drives help a metal lathe work better. A belt drive uses a rubber band to move parts, which can slip a bit. This can make threading less accurate. A direct drive is stronger and connects parts directly, so it usually makes a more exact thread. Better threading means your work will look nicer and fit together well.”}},{“@type”: “Question”,”name”: “What Are The Common Threading Techniques Used On A Metal Lathe, And How Does The Drive System Affect Their Execution?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common threading techniques on a metal lathe include single-point threading and tapping. In single-point threading, you use a special tool to cut threads along the metal as it spins. Tapping means using a tool to make threads inside a hole. The drive system, which powers the lathe, affects how fast and smoothly these techniques work. A strong drive keeps the metal moving steadily, helping us create better threads.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Metal Lathe Drive System For External Vs. Internal Threading Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for threading, you first need to decide if you are making external or internal threads. For external threads, you need to secure your piece on the lathe and use the right tool on the outside. If you are making internal threads, you’ll use a special tool called a tap inside the hole of your piece. Make sure to adjust the speed of the lathe and the tool’s position for both types of threading. Always wear safety gear while working!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Reliability Of The Drive System In A Metal Lathe During Threading Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the drive system of a metal lathe working well, you should do a few things. First, always check for loose parts before you start. Clean the lathe regularly to remove dust and chips. You should also oil the moving parts to keep them smooth. Finally, follow the user manual for any specific care tips. This helps your lathe last longer and work better!”}}]}