Have you ever watched a lathe in action? It’s fascinating how a simple block of metal transforms into a detailed piece. But did you know that safety features, like the metal lathe foot brake, are just as important as the machine itself?

Imagine you’re working on a project. Suddenly, something goes wrong. That’s where the foot brake comes in handy. It helps stop the tool quickly, keeping you safe.

In this article, we will explore how lathe threading works. You’ll discover the role of the metal lathe foot brake and why it’s essential for smooth and safe operation.

Get ready to dive into the world of lathes and learn some surprising facts along the way!

Lathe Threading: Metal Lathe Foot Brake Advantages Explained

Lathe Threading: Understanding the Metal Lathe Foot Brake

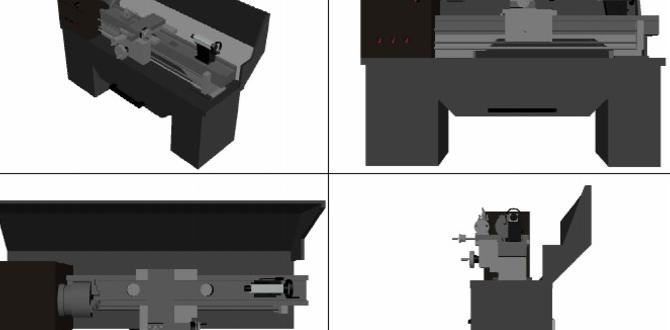

When using a metal lathe, the foot brake is crucial for safety. This simple tool helps stop the machine quickly. Have you ever wondered how it keeps users safe while threading? Properly using the foot brake prevents accidents and injuries. Learning this adds to your skills when working with lathes. A fun fact: many seasoned machinists attribute their safe practices to the proper use of foot brakes! This shows the importance of understanding every part of your machine.What is a Lathe Threading?

Definition and importance of threading in metalworking. Common applications and benefits of lathe threading.A lathe is a tool that helps shape metal. One important function is threading. Threading creates spirals on metal. These spirals allow parts to fit together perfectly. They are vital for screws, bolts, and pipes. The benefits of lathe threading include:

- Precision in fitting parts

- Strength in metal joints

- Improved functionality of tools

This skill helps many industries, from construction to automotive, making it essential for workers. Without threading, many products wouldn’t work as well.

What is the purpose of threading in metalworking?

The purpose of threading in metalworking is to create strong and precise fittings. Threading ensures that parts connect securely and function smoothly. This makes machines and tools more reliable and safer to use.

Understanding the Metal Lathe Foot Brake

Definition and purpose of a foot brake in lathe operation. Safety benefits associated with using a foot brake.A foot brake is a tool on a metal lathe. It helps stop the machine quickly and safely. This is important during lathe operation. With a foot brake, you can stop the lathe with your foot. This lets your hands stay free to handle the workpiece. Safety is a big benefit of using a foot brake. It reduces the chance of accidents while you work.

What are the safety benefits of using a foot brake?

Using a foot brake can prevent serious injuries. It allows you to quickly stop the lathe when needed. This keeps you safe from spinning parts and flying debris. Always remember: safety first!

- Fast stopping: Reduce risk of accidents.

- Hands-free operation: Keep hands on your workpiece.

- Improved control: Make confident adjustments.

How to Adjust the Lathe Foot Brake

Stepbystep guide for adjusting the foot brake for optimal performance. Common issues and troubleshooting tips.Adjusting the foot brake on a lathe is a simple task that can make a big difference. Follow these steps to get it right. First, check the brake’s tightness; it shouldn’t be too loose or too tight. Next, look for any wear on the brake pads. Replace them if needed. If you feel like you’re wrestling a bear, you might need some adjustment! Lastly, always test the brake after adjustments. If it squeaks like a mouse, it’s time for more TLC.

| Issue | Solution |

|---|---|

| Brake feels too loose | Adjust the tension using the knob. |

| Squeaking sound | Lubricate or replace brake pads. |

| Brake doesn’t hold | Check for wear and adjust balance. |

Remember, a well-adjusted brake keeps things safe and helps your lathe perform better. If problems persist, don’t hesitate to ask for help or consult the manual. After all, even machines have their bad days!

Choosing the Right Lathe for Threading

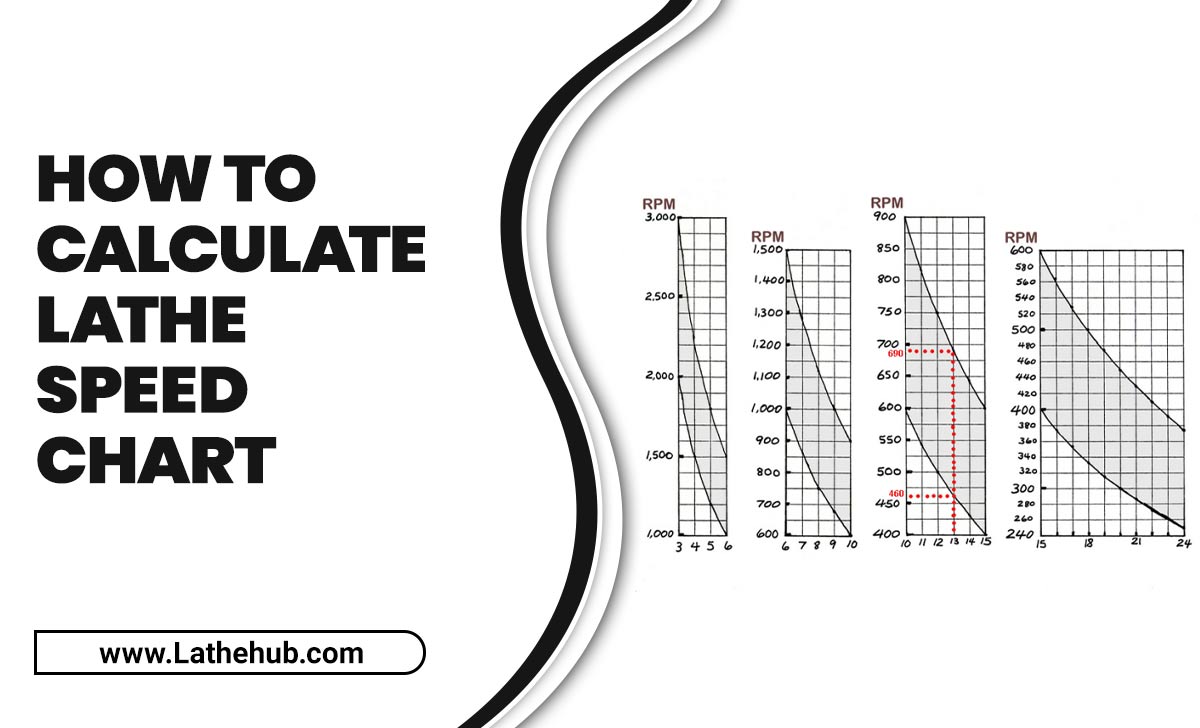

Key features to consider when selecting a metal lathe for threading. Comparison of popular lathe models and their features.Picking the right lathe for threading is important. Key features to think about include the lathe size, speed settings, and foot brake safety. Some lathes are like turtles—slow but steady, while others zip around like rabbits! Popular models like the Grizzly G0765 and Jet JWL-1442 have unique features. Grizzly is praised for its sturdiness, while Jet is known for its user-friendly design. Choosing the right one can make your metal working fun!

| Lathe Model | Key Features |

|---|---|

| Grizzly G0765 | Sturdy, high torque, precise threading |

| Jet JWL-1442 | User-friendly, variable speeds, foot brake |

Best Practices for Threading on a Metal Lathe

Essential tips for achieving precise and clean threads. Maintenance practices to ensure longevity and accuracy in threading.Threading on a metal lathe can seem tricky, but a few simple tips make it easy. First, always measure twice and cut once. This ensures your threads are precise and neat. Regularly maintain your lathe with oil and cleaning to keep it in top shape. It’s like giving your machine a spa day! Clean tools create clean threads. Remember, a little care can go a long way. Happy turning!

| Tip | Details |

|---|---|

| Measure Twice | Get accurate measurements before starting. |

| Regular Maintenance | Oil and clean your lathe for best results. |

| Use Sharp Tools | Sharp tools produce cleaner threads! |

Maintenance of Lathe Equipment for Threading

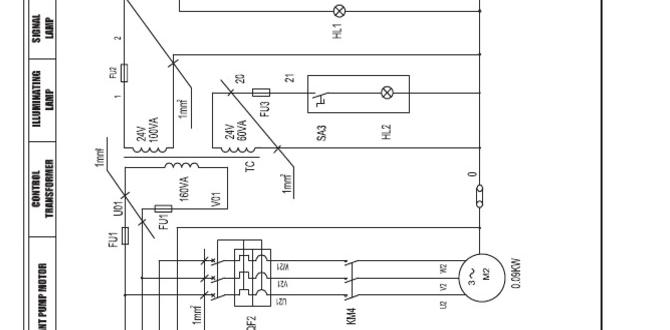

Importance of regular maintenance for threading efficiency. Checklist for maintaining a metal lathe and its components.Regular maintenance keeps your lathe running smoothly. It helps with threading efficiency and extends the machine’s life. Check your machine often to catch problems early. This simple routine can save you time and money.

- Clean the lathe regularly.

- Check the oil levels to ensure smooth operation.

- Inspect the foot brake for proper function.

- Tighten any loose parts.

- Keep all controls free of debris.

Why maintain lathe equipment?

Regular maintenance boosts threading efficiency and prevents serious issues. A well-maintained lathe means fewer repairs and longer lifespan.

Future Trends in Lathe Technology

Innovations in lathe technology that impact threading capabilities. The role of automation and computerization in modern lathe threading.As we move forward, lathe technology is evolving faster than a cat chasing a laser pointer. Innovations are changing how we thread materials. Automated systems are now part of the game, helping make precise cuts that would impress even the toughest teachers. With computerization, lathes can remember settings, so you don’t have to! Imagine setting it up while sipping your favorite drink and leaving the hard work to your trusty machine.

| Trend | Description |

|---|---|

| Automation | Machines do the work, making threading easier and faster. |

| Computerization | Lathes save settings to improve precision and repeatability. |

Conclusion

In summary, a lathe threading metal lathe foot brake enhances safety and control when working. It helps you stop quickly while threading. Remember, always follow safety guidelines and check your tools regularly. You can improve your skills with practice. Keep exploring more about threading techniques and lathe functionalities to become a better machinist!FAQs

What Is The Purpose Of A Foot Brake On A Metal Lathe, And How Does It Enhance Safety During Threading Operations?A foot brake on a metal lathe helps you stop the machine quickly. When you’re threading, it’s important to stop fast to avoid accidents. If something goes wrong, you can use your foot to hit the brake. This makes it safer for you while working. Overall, the foot brake helps keep everyone safe in the workshop.

How Do You Properly Adjust And Maintain The Foot Brake System On A Metal Lathe To Ensure Optimal Performance?To adjust the foot brake on a metal lathe, start by checking the brake pedal for looseness. Please tighten any screws or bolts you find. Next, test the brake to see if it stops the lathe quickly. If it doesn’t, you might need to replace parts. Finally, keep the brake clean by wiping it down regularly to help it work well.

What Are The Key Differences Between Manual And Automatic Foot Brake Systems In Metal Lathes When Threading?Manual foot brakes let you control the lathe by pressing down with your foot. You can stop the machine whenever you want. Automatic foot brakes work on their own—they stop the lathe when you let go of the foot pedal. This makes it easier to focus on your work. Overall, manual brakes give you more control, while automatic ones are smoother and quicker.

How Can Improper Use Of The Foot Brake On A Metal Lathe Lead To Threading Inaccuracies Or Damage To The Workpiece?Using the foot brake wrong on a metal lathe can cause big problems. If you stop the machine too quickly, it can make the tool move unevenly. This can lead to mistakes in threading, making the piece not fit right. You might also scratch or break the workpiece if you aren’t gentle. Always use the brake carefully to make sure everything stays safe and accurate.

What Steps Should Be Taken To Troubleshoot Common Issues With The Foot Brake Mechanism On A Metal Lathe During Threading Tasks?To fix problems with the foot brake on a metal lathe, start by checking the brake pedal. Make sure it moves freely and is not stuck. Next, look for any loose or broken parts. If you find something, tighten it or replace it. Finally, test the brake to see if it works properly.