Have you ever wondered how metal objects get their perfect threads? It’s all thanks to a machine called a lathe. Using a metal lathe is like magic for makers, but it takes something special to make it work well. That special part is the gear train.

The gear train in a lathe helps control how fast and accurately the lathe spins the metal. It acts like the engine of a car, giving it the right power. Imagine trying to drive a car without a good engine; it would be tough, right? The same goes for threading metal.

Here’s a fun fact: the first lathes were used thousands of years ago! They played a big role in shaping tools and parts. Today, we still use lathes, but they have better technology like gear trains. This means we can make strong, precise threads in metal.

Want to learn more? Let’s dive into the world of lathe threading and discover the amazing gear train that makes it all possible!

Lathe Threading: Understanding Metal Lathe Gear Train Mechanics

Lathe Threading Metal Lathe Gear Train

Lathe threading requires a proper gear train for efficient operation. Understanding the gear train helps you create precise threads on metal components. Did you know that a simple mistake in setup can lead to uneven threads? By mastering lathe gear arrangements, you can produce perfect threads. This knowledge is vital for anyone interested in metalworking. Besides, it makes your projects look professional and clean. Gears may seem complex, but once you grasp their role, threading becomes so much easier!What is Lathe Threading?

Definition of lathe threading and its importance in metalworking.. Common applications of lathe threading in various industries..Lathe threading is a process in metalworking that creates grooves on a metal piece. These grooves help in making screws and bolts. Threading is important because it allows parts to fit together tightly. This makes machines work better and last longer. Common uses of lathe threading include:

- Automotive parts

- Construction tools

- Manufacturing equipment

Overall, lathe threading is essential in many industries. It helps build strong and reliable machines.

What industries use lathe threading?

Many industries, such as automotive, aerospace, and construction, use lathe threading. These industries rely on threaded parts for machinery and tools.

Types of Threads Created on a Lathe

Detailed description of different thread types (UNC, UNF, Metric, etc.).. Discussion on how thread type affects the design of the gear train..There are different types of threads you can create on a lathe. Let’s take a peek! First, we have UNC (Unified National Coarse) threads. They are strong and great for heavy loads. Then comes UNF (Unified National Fine) threads, which are fab for tighter spaces. Ever heard of Metric threads? They are measured in millimeters and are common worldwide. Each thread type changes how the gear train is designed. You need the right combination for smooth turning! Here’s a quick look:

| Thread Type | Common Use | Preferred For |

|---|---|---|

| UNC | Heavy Loads | Durability |

| UNF | Tight Spaces | Precision |

| Metric | Worldwide Use | Standardization |

In short, picking the right thread can make or break your project. Choose wisely, or your gears will be spinning in circles!

The Gear Train Setup for Threading

Stepbystep guide on setting up the gear train for threading operations.. Common mistakes to avoid when configuring the gear train..Setting up a gear train for threading is like assembling a puzzle. Follow these steps: first, choose the correct gears. Next, align them properly on the lathe. Then, secure everything tightly. Now, watch out for common mistakes! Avoid mismatched gears like you’d avoid mismatched socks. Double-check your settings before starting, or you might end up with more spaghetti than thread!

| Step | Action |

|---|---|

| 1 | Choose the right gears |

| 2 | Align gears on the lathe |

| 3 | Secure the setup |

Always remember, the right gear setup makes all the difference! Happy threading!

Best Practices for Effective Lathe Threading

Tips for achieving precision and consistency in threading.. Importance of tool selection and maintenance for quality threads..To create precise and consistent threads, pay attention to your tool choices. Always use sharp tools for clean cuts. Regularly check and maintain your tools; dull ones can ruin your work. It’s also vital to set your lathe correctly. A well-calibrated machine leads to better results. Remember these tips for perfect threading:

- Use the right tool for the job.

- Keep tools clean and sharpened.

- Adjust the lathe settings carefully.

What tools are best for lathe threading?

High-speed steel (HSS) or carbide tools work best for lathe threading. They ensure durability and precision, leading to high-quality threads.

Moreover, always clean your workspace. A tidy area helps avoid mistakes. Fun fact: Did you know? Proper tool care can extend their life by 100%!

Troubleshooting Common Lathe Threading Issues

Identification of typical problems encountered during threading.. Solutions and adjustments for common threading issues..Threading on a lathe can lead to some common problems. Identifying these issues is the first step to fixing them. Problems often include uneven threads, backlash, and chattering. To troubleshoot effectively, check the following:

- Ensure the tool is sharp.

- Adjust the feed rate correctly.

- Inspect for proper alignment.

These quick checks can save you time and frustration. Remember, small adjustments can make a big difference in your results.

What causes uneven threads in lathe threading?

Uneven threads can occur from a dull tool, improper setup, or feed rate issues.Key adjustments:

- Change the cutting tool.

- Re-evaluate your setup.

- Adjust the feed rate for smoother cutting.

Advanced Techniques for Experienced Machinists

Exploration of complex threading techniques (e.g., tapered threads).. Discussion on the use of CNC lathes for advanced threading projects..Mastering complex threading techniques can take your machining skills to the next level. Think about tapered threads; they help create strong connections between parts. An expert machinist can craft these threads like a magician pulls rabbits from hats! CNC lathes are essential for advanced projects, allowing for precise cuts every time. Imagine guiding this machine at lightning speed while you sip your coffee—totally impressive! Below is a comparison of different techniques for threading:

| Technique | Description |

|---|---|

| Tapered Threads | Used to connect parts snugly, like a glove on a hand. |

| CNC Lathes | Automated machines that ensure precise and repeatable cuts. |

| Manual Techniques | Requires skill and patience—like solving a puzzle without the picture. |

Each method has its perks! So, gear up, have fun, and explore these advanced techniques! Who knew machining could be this exciting?

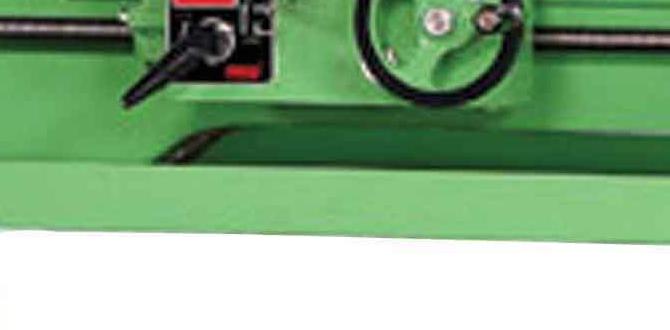

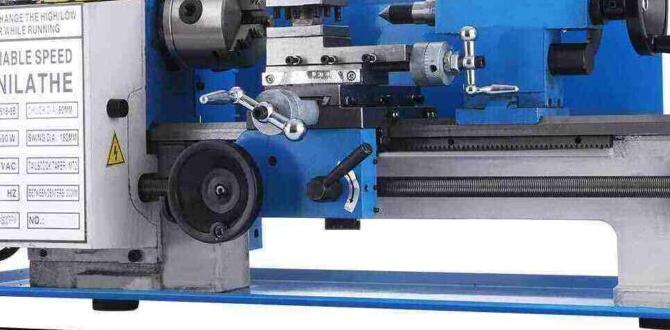

Choosing the Right Metal Lathe for Threading Applications

Criteria for selecting a metal lathe based on threading needs.. Comparison of popular metal lathe models for threading efficiency..Picking the perfect metal lathe for threading is like finding the right shoes for a dance. You want something that fits well and helps you glide through your work. First, consider size and power. A lathe with enough horsepower can make your threading smoother. Next, look at ease of use. Some machines come with handy features that make threading a breeze, while others might leave you scratching your head. Below is a quick view of popular models:

| Model | Horsepower | Ease of Use | Threading Efficiency |

|---|---|---|---|

| Lathe A | 1 HP | ⭐⭐⭐⭐⭐ | 8/10 |

| Lathe B | 2 HP | ⭐⭐⭐⭐ | 9/10 |

| Lathe C | 3 HP | ⭐⭐ | 10/10 |

Choosing wisely can save you time and prevent headaches. Remember, it’s not just about making threads; it’s about making them right!

Resources for Further Learning on Lathe Threading

List of recommended books, online courses, and video tutorials.. Information on forums and communities for networking and advice..Learning more about lathe threading can be exciting! Here are some helpful resources:

- Books: “The Complete Guide to Metal Lathe” and “Lathe Operation” are great starting points.

- Online Courses: Websites like Udemy and Coursera offer excellent classes on lathe threading.

- Video Tutorials: Check out YouTube for visual guides on using the lathe effectively.

- Forums and Communities: Join forums like The Metalworking Zone or Reddit’s r/metalworking for advice and tips.

These resources can make your learning fun and easier!

What are the best resources for learning lathe threading?

Books, online courses, video tutorials, and community forums provide excellent guidance on lathe threading. Engage with these materials to enhance your skills.

Conclusion

In summary, lathe threading on a metal lathe is essential for creating precise threads. The gear train helps control the speed and movement during this process. Understanding these parts improves your machining skills. We encourage you to explore more about lathes and gear trains. Practice threading on your own lathe to gain hands-on experience and confidence!FAQs

Sure! Here Are Five Related Questions About Lathe Threading, Particularly Focusing On The Gear Train Of A Metal Lathe:Sure! A metal lathe is a tool that helps us shape metal. The gear train is like a series of connected gears. It helps make sure the lathe spins at the right speed. This is important for cutting threads correctly. We can adjust the gears to make different thread sizes.

Of course! Please provide the question you would like me to answer, and I’ll be happy to help.

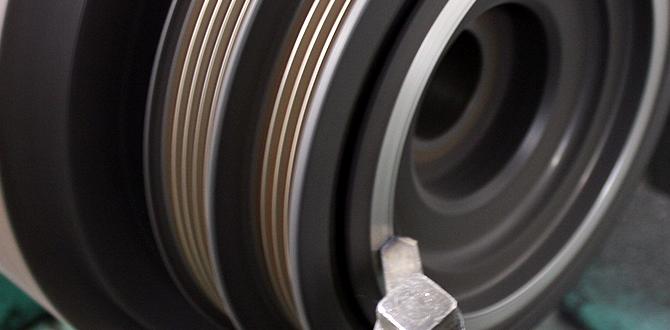

What Is The Purpose Of The Gear Train In A Metal Lathe When Performing Threading Operations?The gear train in a metal lathe helps you cut threads accurately. It connects the motor to the tool and changes the speed. This way, when you turn the handle, the tool moves at just the right speed to make threads. Without the gear train, it would be hard to create perfect threads.

How Do You Determine The Correct Gear Ratios For Achieving Different Thread Pitches On A Lathe?To find the right gear ratios for different thread pitches on a lathe, you first need to know the thread pitch you want. A thread pitch is how close the threads are together. Then, you look at the lathe’s gear system. By changing the gears, you can match the gear ratios to the thread pitch you need. This helps the lathe cut the right threads. You can check the machine’s manual for guidance on which gears to use.

What Are The Common Types Of Gear Trains Used In Metal Lathes For Threading, And How Do They Differ?Common types of gear trains in metal lathes for threading include simple gear trains and compound gear trains. A simple gear train uses just one set of gears to change speed. A compound gear train has two or more sets of gears, allowing for more options. Simple gear trains are easier to use, while compound gear trains give you more control over the thread size and shape.

How Can You Troubleshoot Common Issues Related To Gear Trains During Threading On A Metal Lathe?To troubleshoot gear train issues on a metal lathe while threading, start by checking if the gears are aligned properly. You should also make sure that all gears are clean and well-lubricated. If you hear any strange noises, it might mean a gear is damaged. Tighten any loose parts, as they can cause problems too. Finally, always double-check your settings to ensure they’re correct.

What Role Does The Lead Screw Play In Conjunction With The Gear Train When Cutting Threads On A Lathe?The lead screw helps move the cutting tool along the material. It works with the gear train to turn the tool at the right speed. This way, the tool cuts even threads. Together, they make sure the threads are smooth and straight. You can create different types of threads by changing the gears.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Lathe Threading, Particularly Focusing On The Gear Train Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a tool that helps us shape metal. The gear train is like a series of connected gears. It helps make sure the lathe spins at the right speed. This is important for cutting threads correctly. We can adjust the gears to make different thread sizes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you would like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of The Gear Train In A Metal Lathe When Performing Threading Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear train in a metal lathe helps you cut threads accurately. It connects the motor to the tool and changes the speed. This way, when you turn the handle, the tool moves at just the right speed to make threads. Without the gear train, it would be hard to create perfect threads.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Gear Ratios For Achieving Different Thread Pitches On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right gear ratios for different thread pitches on a lathe, you first need to know the thread pitch you want. A thread pitch is how close the threads are together. Then, you look at the lathe’s gear system. By changing the gears, you can match the gear ratios to the thread pitch you need. This helps the lathe cut the right threads. You can check the machine’s manual for guidance on which gears to use.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Gear Trains Used In Metal Lathes For Threading, And How Do They Differ?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common types of gear trains in metal lathes for threading include simple gear trains and compound gear trains. A simple gear train uses just one set of gears to change speed. A compound gear train has two or more sets of gears, allowing for more options. Simple gear trains are easier to use, while compound gear trains give you more control over the thread size and shape.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues Related To Gear Trains During Threading On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot gear train issues on a metal lathe while threading, start by checking if the gears are aligned properly. You should also make sure that all gears are clean and well-lubricated. If you hear any strange noises, it might mean a gear is damaged. Tighten any loose parts, as they can cause problems too. Finally, always double-check your settings to ensure they’re correct.”}},{“@type”: “Question”,”name”: “What Role Does The Lead Screw Play In Conjunction With The Gear Train When Cutting Threads On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lead screw helps move the cutting tool along the material. It works with the gear train to turn the tool at the right speed. This way, the tool cuts even threads. Together, they make sure the threads are smooth and straight. You can create different types of threads by changing the gears.”}}]}