Have you ever wondered how to achieve the perfect threads on a metal lathe? Proper lathe threading can make all the difference in your projects. However, did you know that tailstock alignment is key to this process?

Imagine working hard on a metal piece, only to find it doesn’t fit right. Frustrating, right? Many people overlook tailstock alignment when using a lathe, thinking it’s not important. But this small step can save a lot of headaches later.

In this article, we will explore why tailstock alignment matters. We will also share simple tips to help you perfect your lathe threading skills. By the end, you’ll understand how to get better results every time you use a metal lathe.

So, are you ready to take your lathe work to the next level? Let’s dive in!

Lathe Threading: Metal Lathe Tailstock Alignment Techniques

Lathe Threading: Mastering Tailstock Alignment

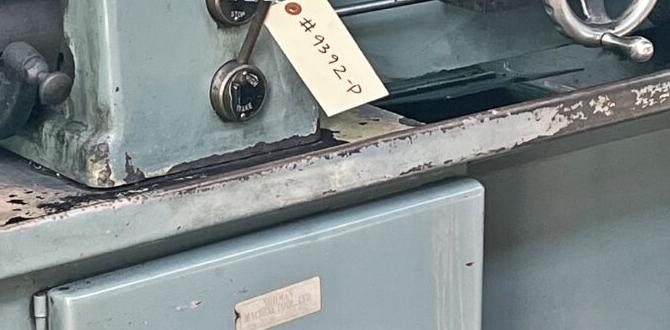

Proper alignment of the tailstock on a metal lathe is crucial for accurate threading. Misalignment can lead to uneven threads and wasted materials. How can you ensure it’s right? First, check the tailstock with a dial indicator. This will help you see any shifts. Did you know that even tiny misalignments can ruin your project? For best results, adjust until you get precision. Perfect alignment makes threading easier and gives you a professional finish.The Role of Tailstock in Lathe Operations

Explanation of tailstock functions in lathe machinery. Importance of tailstock alignment in achieving accurate threading.The tailstock is an important part of a lathe machine. It helps support long pieces of metal as they spin. This support is crucial for cutting smooth and even threads. If the tailstock is not aligned correctly, it can make the threads uneven. This can cause problems in your projects. Good alignment helps achieve precision and accuracy. Remember, aligning the tailstock is key to getting the best results with threading.

What does the tailstock do in lathe operations?

The tailstock serves several vital functions:

- It provides extra support for the material being worked on.

- It helps in drilling and inserting tool bits.

- It allows for easy adjustments during the operation.

Why is tailstock alignment important for threading?

Proper tailstock alignment ensures that the threads are straight and accurate. An unaligned tailstock can lead to wasted materials and time.

Essential Tools for Tailstock Alignment

List of tools required for precise alignment. Tips on selecting the right tools for different lathe models.For proper tailstock alignment, specific tools are crucial. These tools ensure your lathe works well and produces accurate results. Here’s a list of essential tools:

- Laser alignment tool

- Tapered test bar

- Dial indicator

- Feeler gauge

Choosing the right tools depends on your lathe model. Always check your lathe’s manual. Some tools may suit certain models better than others. Selecting wisely can save you time and effort.

What tools do I need for tailstock alignment?

You will need a laser alignment tool, a tapered test bar, a dial indicator, and a feeler gauge to achieve accurate tailstock alignment.

Steps for Proper Tailstock Alignment

Detailed process for aligning the tailstock. Common mistakes to avoid during alignment.Aligning the tailstock on your metal lathe is essential for accuracy. Follow these steps for proper alignment:

- First, check the center height of the tailstock. It should match the spindle height.

- Next, loosen the tailstock locking screws.

- Adjust the tailstock until it lines up with the spindle.

- Tighten the screws securely.

Common mistakes include:

- Not checking the height before adjusting.

- Forgetting to tighten screws after alignment.

A little care here goes a long way in your lathe projects!

What is the importance of tailstock alignment?

The tailstock helps support the workpiece. Good alignment improves accuracy and helps prevent damage. It makes your work neat and precise.

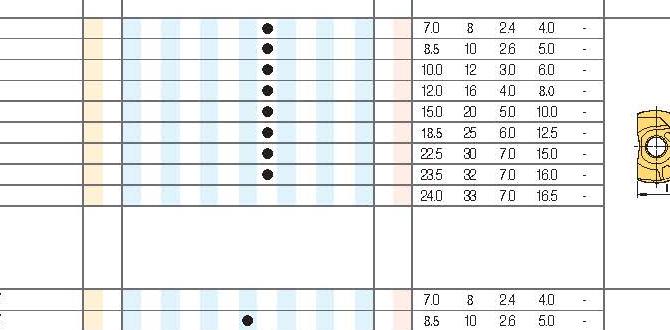

Testing Alignment Accuracy

Methods to check tailstock alignment after adjustments. Recommended practices for verifying threading precision.Checking if your tailstock is aligned is like ensuring your ice cream cone is perfectly balanced. You don’t want it to topple! One simple way to test alignment is to use a dial indicator. It shows whether your tailstock is in line or not. Another method is the “pen test.” Just slide a marker into the tailstock; it should spin smoothly without wobbling. For threading precision, try cutting a test thread on scrap metal. This will give you a clear idea of how well everything lines up.

| Method | Description |

|---|---|

| Dial Indicator | Measures alignment; look for consistent readings. |

| Pen Test | Insert a marker; it should not wobble. |

| Test Thread | Cut on scrap to check threading accuracy. |

Maintenance Tips for Lathe and Tailstock

Routine maintenance practices to ensure alignment stability. Signs that indicate the need for realignment or maintenance.Regular care for your lathe and tailstock keeps them working well. Check for loose parts and make sure everything lines up right. Signs of trouble include uneven cuts and vibration during use. To keep your tools in top shape, follow these simple steps:

- Inspect for wear and tear.

- Clean regularly to avoid debris buildup.

- Lubricate moving parts often.

- Check alignment frequently.

These practices help your lathe run smoothly and prevent costly repairs.

What signs mean it’s time to realign or maintain?

Look for uneven cuts, noise, and vibrations while the lathe is running. These indicate it needs attention. Regular checks help you catch issues early.

Advanced Techniques for Experienced Machinists

Techniques to enhance threading precision beyond basic alignment. Innovative methods and technologies in tailstock alignment.Many skilled machinists look for ways to improve their work. Advanced techniques can help increase threading precision. Here are some methods to consider:

- Use a laser alignment tool for accurate placement.

- Check your tailstock regularly for wear and tear.

- Consider using electronic measuring tools for better results.

- Try different setups to find your most effective threading technique.

Each of these methods can lead to tighter and more precise threads. Using technology can make your work easier and better.

What is the best way to align a lathe tailstock?

The best way to align a lathe tailstock is to use a dial indicator. This tool helps check if the tailstock is correctly aligned with the spindle.

Resources and Further Reading

Suggested books, articles, and online resources on lathe threading and alignment. Links to instructional videos and forums for community support.Ready to become a lathe pro? Check out these fantastic resources! For book lovers, “Lathe Work: A Complete Guide” is a treasure trove of tips. Don’t miss the online forums; they’re like your favorite pizza place—everyone shares advice, and friendships are made over metal shavings!

| Resource Type | Title/Link |

|---|---|

| Book | Lathe Work: A Complete Guide |

| Article | The Art of Lathe Threading |

| Video Tutorial | Lathe Tips on YouTube |

Watch videos for quick tips, or join discussions to learn from others. Remember, everyone starts somewhere. So dive in, and don’t be shy—everyone loves a good pun about threads!

Conclusion

In summary, proper tailstock alignment is crucial for accurate lathe threading. It helps prevent defects and ensures smooth cuts. You should always check your tailstock before starting a project. This simple step can improve your work significantly. For better results, practice aligning your lathe and explore more resources on metalworking techniques. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Threading And Tailstock Alignment:Sure! When using a lathe for threading, it’s important to make sure the tailstock is aligned correctly. This helps the machine cut straight and even threads. You can check the alignment by measuring the distance between the tailstock and the spindle. If it’s not right, you might need to adjust it. Keeping things aligned helps your work turn out better!

Sure! Just ask your question, and I’ll be happy to help you with a short answer.

What Are The Common Indicators That The Tailstock Of A Metal Lathe May Be Misaligned?You can tell if the tailstock of a metal lathe is misaligned if you see uneven cuts on your metal piece. If the tool is wearing out too quickly, that’s another sign. You might also notice that the pieces are not fitting together right. Lastly, if you’re having trouble getting a straight finish, the tailstock could be off.

How Do You Accurately Measure And Adjust The Alignment Of The Tailstock On A Metal Lathe?To measure the tailstock alignment on a metal lathe, you can use a tool called a dial indicator. First, place the dial indicator on the lathe bed and set it to zero. Next, move the tailstock and check the reading. If it’s not zero, you need to adjust it. Loosen the screws on the tailstock and move it until the dial shows zero again. Then, tighten the screws back up. This way, you’re making sure the tailstock is straight and where it should be!

What Tools Or Fixtures Are Typically Used To Ensure Precise Tailstock Alignment During The Threading Process?To make sure the tailstock is straight during threading, we can use a few simple tools. One tool is an alignment bar, which helps check if everything is lined up. Another tool is a dial indicator, which shows tiny movements. We can also use a gauge to measure the distance easily. These tools help us do good and accurate work!

How Does Tailstock Alignment Impact The Quality And Accuracy Of Threads Produced On A Metal Lathe?If the tailstock on a metal lathe is not lined up right, the threads we make can come out crooked. This happens because the tool may not cut evenly. If we want straight and even threads, we need to check the tailstock often. Good alignment means better quality and accuracy in our work. It helps us create parts that fit together properly.

What Steps Should Be Taken To Verify Tailstock Alignment Before Starting A Threading Operation?To check if the tailstock is lined up correctly, first, you need to make sure the lathe (a tool that spins metal) is turned off. Then, use a test piece, like a long rod, and put it in the tailstock. Make sure the rod is straight by watching it spin. If it wobbles, the tailstock isn’t aligned. You can adjust it to make it straight before you start threading.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Threading And Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When using a lathe for threading, it’s important to make sure the tailstock is aligned correctly. This helps the machine cut straight and even threads. You can check the alignment by measuring the distance between the tailstock and the spindle. If it’s not right, you might need to adjust it. Keeping things aligned helps your work turn out better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Common Indicators That The Tailstock Of A Metal Lathe May Be Misaligned?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell if the tailstock of a metal lathe is misaligned if you see uneven cuts on your metal piece. If the tool is wearing out too quickly, that’s another sign. You might also notice that the pieces are not fitting together right. Lastly, if you’re having trouble getting a straight finish, the tailstock could be off.”}},{“@type”: “Question”,”name”: “How Do You Accurately Measure And Adjust The Alignment Of The Tailstock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure the tailstock alignment on a metal lathe, you can use a tool called a dial indicator. First, place the dial indicator on the lathe bed and set it to zero. Next, move the tailstock and check the reading. If it’s not zero, you need to adjust it. Loosen the screws on the tailstock and move it until the dial shows zero again. Then, tighten the screws back up. This way, you’re making sure the tailstock is straight and where it should be!”}},{“@type”: “Question”,”name”: “What Tools Or Fixtures Are Typically Used To Ensure Precise Tailstock Alignment During The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure the tailstock is straight during threading, we can use a few simple tools. One tool is an alignment bar, which helps check if everything is lined up. Another tool is a dial indicator, which shows tiny movements. We can also use a gauge to measure the distance easily. These tools help us do good and accurate work!”}},{“@type”: “Question”,”name”: “How Does Tailstock Alignment Impact The Quality And Accuracy Of Threads Produced On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock on a metal lathe is not lined up right, the threads we make can come out crooked. This happens because the tool may not cut evenly. If we want straight and even threads, we need to check the tailstock often. Good alignment means better quality and accuracy in our work. It helps us create parts that fit together properly.”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Verify Tailstock Alignment Before Starting A Threading Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if the tailstock is lined up correctly, first, you need to make sure the lathe (a tool that spins metal) is turned off. Then, use a test piece, like a long rod, and put it in the tailstock. Make sure the rod is straight by watching it spin. If it wobbles, the tailstock isn’t aligned. You can adjust it to make it straight before you start threading.”}}]}