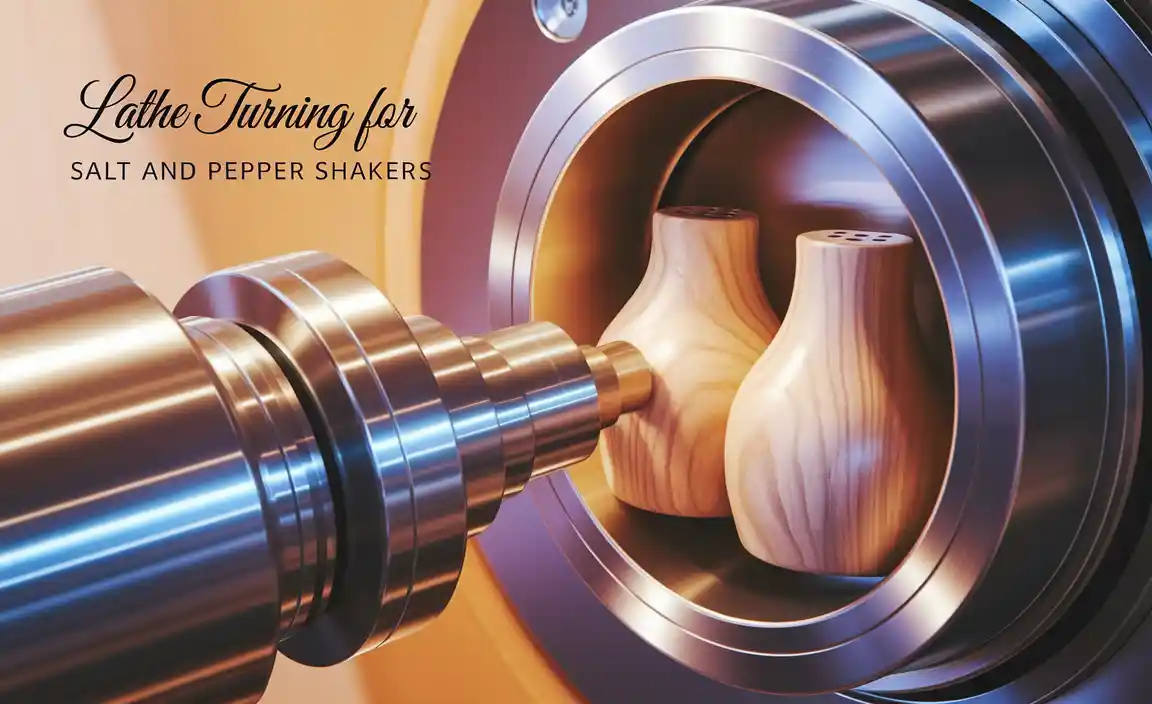

Have you ever wondered how metal parts are shaped perfectly? A metal lathe plays a key role in that magic. This powerful machine uses tools to cut, shape, and form metal. One important process it performs is lathe threading. It allows smooth and precise screws or bolts. But how does it all work together?

Imagine you want to make a cool toy car that needs wheels. To attach the wheels, you need screws. A metal lathe can create the threads on those screws, ensuring they fit perfectly. When we talk about lathe threading, torque becomes a crucial word. Torque is the twisting power that helps the lathe spin metal pieces. How much torque you need can change the outcome of your work.

In this article, we will dive deeper into lathe threading and explore how torque influences the quality of metal parts. You’ll learn tips and tricks to master using a metal lathe. Get ready to discover the wonders of this essential tool!

Lathe Threading: Mastering Metal Lathe Torque Techniques

Types of Threading Techniques in Metal Lathes

Explanation of various threading methods (e.g., singlepoint threading, tapping). Comparison of threading techniques and their specific uses.Many ways exist for threading in a metal lathe. Each method has its special uses. Single-point threading works well for creating threads on a workpiece. It uses one tool to cut the thread. Tapping is another method. It makes internal threads by twisting a tool into the material. Here’s a quick comparison:

- Single-point threading: Great for different thread types and sizes.

- Tapping: Best for holes needing threaded inserts.

What are the main threading techniques used in metal lathes?

Metal lathes use techniques like single-point threading and tapping to create threads. Each method is important for different tasks. This helps in making strong and precise parts.

The Importance of Torque in Lathe Operations

Definition of torque and its relevance in lathe threading. How torque affects threading quality and efficiency.Torque is the twisty force that helps machines, like lathes, do their magical work. Think of it as the muscle behind **lathe threading**. Without enough torque, threading quality can drop faster than a cat off a roof! Low torque can lead to messy threads and longer machining time, which nobody wants. It’s like trying to butter bread with a frozen knife—just doesn’t work well! The right torque means smooth, efficient threads, making your projects look neat and tidy.

| Torque Level | Threading Quality | Efficiency |

|---|---|---|

| Low Torque | Messy Threads | Slow Machining |

| Optimal Torque | Smooth Threads | Fast Machining |

Selecting the Right Metal Lathe for Threading

Factors to consider when choosing a metal lathe for threading tasks. Recommended features that enhance torque performance in lathes.Choosing a metal lathe for threading is no small task! First, consider the size and speed. The right size means less wobble, and who likes wobbly threads? Next, focus on torque. A lathe with strong torque will help you cut through metal easily, like a hot knife through butter. Look for features like variable speed controls and a sturdy base. Remember, a good lathe can turn you into a threading wizard!

| Feature | Benefit |

|---|---|

| High Torque | Makes threading smoother and faster. |

| Variable Speed Control | Gives you more control over the threading process. |

| Sturdy Construction | Reduces vibration and increases accuracy. |

Measuring Torque in Lathe Threading

Tools and techniques for measuring torque accurately. Understanding torque settings based on material type and threading requirements.To measure torque in lathe threading, use precise tools. A torque wrench or a digital torque meter provides accurate readings. Choose tools based on the material you are working with. Softer metals need less torque than harder ones. Understanding these differences is key for a smooth process.

- Use a torque wrench for accuracy.

- Digital torque meters give precise results.

- Match torque levels to material types.

- Follow threading requirements closely.

How can I ensure accurate torque measurement?

Select the right tool for your project. For example, use a digital torque meter for easy reading. Always check torque settings based on your material’s hardness to avoid damage.

Best Practices for Threading with a Metal Lathe

Safety precautions to take when threading on a lathe. Tips for achieving precision and consistency in threaded projects.Threading on a metal lathe can be fun but requires safety and careful practices. Always wear goggles to protect your eyes. Keep your hair tied back and wear tight clothing to avoid accidents. To achieve precision, start with a clean workspace and properly set the tool. Measure twice before starting. Use a steady hand and adjust the speed slowly. This way, you’ll make clean, consistent threads.

What are key safety steps for using a lathe?

Wear protective gear, keep the area clean, and ensure no loose clothing is near moving parts.

- Use the correct tool for threading.

- Adjust the torque to match the material.

- Regularly check your measurements.

Common Issues and Troubleshooting in Lathe Threading

Identifying frequent problems encountered during lathe threading. Effective solutions to improve threading outcomes.Lathe threading can be tricky. Common issues include poor thread quality and uneven cuts. These happen if the lathe torque is incorrect. Imagine trying to cut a cake with a wobbly knife. Yikes! A simple solution is to check the tool’s alignment and ensure everything is tightened properly. Keeping your lathe clean can also help. A clean workspace is like a happy place, right?

| Problem | Solution |

|---|---|

| Poor thread quality | Adjust tool height and check torque |

| Uneven cuts | Ensure steady speed and proper feeding |

By knowing these common issues and their fixes, you’ll keep your lathe threading smooth and consistent. Happy threading!

Advanced Techniques for Experienced Machinists

Exploration of complex threading techniques and their applications. How to optimize lathe settings for enhanced performance and torque management.For skilled machinists, mastering complex threading techniques is key. These methods can create strong and precise threads. It’s essential to know how to adjust lathe settings for better performance. Managing torque can significantly enhance your work. Here are some tips:

- Use the right tool for each thread type.

- Adjust the RPM for different materials.

- Pay attention to tool wear and replace as needed.

- Ensure proper lubrication for smoother operation.

By optimizing these techniques, you can achieve greater efficiency and accuracy in your projects.

What are complex threading techniques?

Complex threading techniques include various patterns like trapezoidal and acme threads. They are used in niche applications like lead screws and gears, where strength and precision are crucial

How can I optimize lathe settings?

To optimize lathe settings, adjust the speed, feed rate, and depth of cut. This helps manage torque, ensuring the machine works smoothly and extends tool life.

Case Studies and Practical Examples of Lathe Threading

Realworld applications showcasing successful lathe threading projects. Lessons learned and best practices derived from case studies.Many shops are finding great success with lathe threading projects. For example, one company needed precise threads for custom parts. They used lathe threading and saved both time and money. After a few hiccups, like needing the right torque settings, they learned best practices. Key lessons include checking tools often and always measuring twice before cutting. These tips help avoid mistakes and make threading smooth as butter!

| Project | Lesson Learned |

|---|---|

| Custom Parts | Check torque settings! |

| Production Run | Measure twice, cut once. |

| Prototyping | Use sharp tools for smooth threads. |

Future Trends in Lathe Technology and Threading Innovations

Emerging technologies that influence lathe threading practices. Predictions for the future of metal lathe torque and threading advancements.New technologies are changing the way we use lathes and thread metal. Smart sensors can now track torque in real-time. This makes threading more precise and safer. Automation is also on the rise, cutting down time and labor costs. Many believe that more advances in machine learning could improve designs. Imagine machines that adapt while working! This could lead to even better metal lathe torque and threading innovations in the future.

What are future trends in lathe technology?

Future trends include automation, smart sensors, and machine learning. These advancements will increase precision and efficiency in lathe threading.

| Trend | Description |

|---|---|

| Smart Sensors | Track torque and performance in real-time. |

| Automation | Reduces labor costs and speeds up production. |

| Machine Learning | Improves designs and adapts to different tasks. |

Conclusion

In conclusion, understanding lathe threading on a metal lathe is crucial for your projects. You need to control torque carefully to ensure accurate cuts. Don’t rush; take your time to practice these skills. You can improve your results and enjoy the process. For more tips and techniques, consider reading more about metalworking and lathes to enhance your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Threading And Metal Lathe Torque:Sure! Here are some simple answers about lathe threading and metal lathe torque: 1. **What is lathe threading?** Lathe threading helps us make grooves on a metal piece. These grooves let two pieces screw together. 2. **Why do we use a lathe?** We use a lathe because it shapes metal and makes it smooth. It helps us create different shapes easily. 3. **What is torque in metal lathes?** Torque is the turning force of the lathe. It helps move the tool and shape the metal. 4. **How do we control the speed of a lathe?** You can control the speed by changing the settings. Faster speeds cut metal quickly, while slower speeds offer better control. 5. **Can anyone use a lathe?** Yes! But it’s important to learn how to use it safely first. Always follow the instructions and wear safety gear.

Sure! Please provide the question you want me to answer.

What Is The Role Of Torque In The Threading Process On A Metal Lathe, And How Does It Affect The Quality Of The Threads Produced?Torque helps the machine turn the tool that cuts the threads in metal. When you have the right amount of torque, the threads come out smooth and even. If the torque is too low, the tool might get stuck or make rough threads. If it’s too high, it can break the tool or mess up the threads. Good torque is important for making strong and neat threads on the metal.

How Can A Metal Lathe’S Torque Settings Be Adjusted For Different Types Of Materials When Threading?To adjust a metal lathe’s torque settings, you can change the settings on the machine. Different materials need different amounts of strength. For softer materials, like aluminum, use lower torque. For harder materials, like steel, use higher torque. Always check the instructions for your lathe to find the best settings.

What Are The Common Causes Of Inadequate Torque During The Threading Operation On A Lathe, And How Can They Be Mitigated?Inadequate torque during threading on a lathe can happen for a few reasons. First, the tool might be too dull or worn. We can fix this by sharpening or replacing the tool. Second, the feed rate, which is how fast you move the tool, may be too high. Slowing down can help. Lastly, the lathe’s settings might not be correct. We can check and adjust these settings to ensure proper torque.

How Does Tool Geometry Influence The Torque Required During The Threading Process On A Metal Lathe?The shape of the tool affects how easy or hard it is to turn the lathe. If the tool is sharp and pointy, it cuts the metal better. This means you need less force, or torque, to turn it. But if the tool is dull or shaped poorly, it makes cutting harder, and you need more torque. So, good tool shape helps make the job easier!

What Are The Best Practices For Measuring And Monitoring Torque While Threading With A Metal Lathe?To measure torque on a metal lathe, we can use a torque wrench. First, set the wrench to the correct amount of force needed. While threading, keep an eye on the wrench and listen for any strange sounds. If you hear clicking or feel it slipping, stop and check the thread. Always make sure the tools are tight and not loose to avoid mistakes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Threading And Metal Lathe Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some simple answers about lathe threading and metal lathe torque: 1. **What is lathe threading?** Lathe threading helps us make grooves on a metal piece. These grooves let two pieces screw together. 2. **Why do we use a lathe?** We use a lathe because it shapes metal and makes it smooth. It helps us create different shapes easily. 3. **What is torque in metal lathes?** Torque is the turning force of the lathe. It helps move the tool and shape the metal. 4. **How do we control the speed of a lathe?** You can control the speed by changing the settings. Faster speeds cut metal quickly, while slower speeds offer better control. 5. **Can anyone use a lathe?** Yes! But it’s important to learn how to use it safely first. Always follow the instructions and wear safety gear.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Is The Role Of Torque In The Threading Process On A Metal Lathe, And How Does It Affect The Quality Of The Threads Produced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Torque helps the machine turn the tool that cuts the threads in metal. When you have the right amount of torque, the threads come out smooth and even. If the torque is too low, the tool might get stuck or make rough threads. If it’s too high, it can break the tool or mess up the threads. Good torque is important for making strong and neat threads on the metal.”}},{“@type”: “Question”,”name”: “How Can A Metal Lathe’S Torque Settings Be Adjusted For Different Types Of Materials When Threading?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust a metal lathe’s torque settings, you can change the settings on the machine. Different materials need different amounts of strength. For softer materials, like aluminum, use lower torque. For harder materials, like steel, use higher torque. Always check the instructions for your lathe to find the best settings.”}},{“@type”: “Question”,”name”: “What Are The Common Causes Of Inadequate Torque During The Threading Operation On A Lathe, And How Can They Be Mitigated?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Inadequate torque during threading on a lathe can happen for a few reasons. First, the tool might be too dull or worn. We can fix this by sharpening or replacing the tool. Second, the feed rate, which is how fast you move the tool, may be too high. Slowing down can help. Lastly, the lathe’s settings might not be correct. We can check and adjust these settings to ensure proper torque.”}},{“@type”: “Question”,”name”: “How Does Tool Geometry Influence The Torque Required During The Threading Process On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The shape of the tool affects how easy or hard it is to turn the lathe. If the tool is sharp and pointy, it cuts the metal better. This means you need less force, or torque, to turn it. But if the tool is dull or shaped poorly, it makes cutting harder, and you need more torque. So, good tool shape helps make the job easier!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Measuring And Monitoring Torque While Threading With A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure torque on a metal lathe, we can use a torque wrench. First, set the wrench to the correct amount of force needed. While threading, keep an eye on the wrench and listen for any strange sounds. If you hear clicking or feel it slipping, stop and check the thread. Always make sure the tools are tight and not loose to avoid mistakes.”}}]}