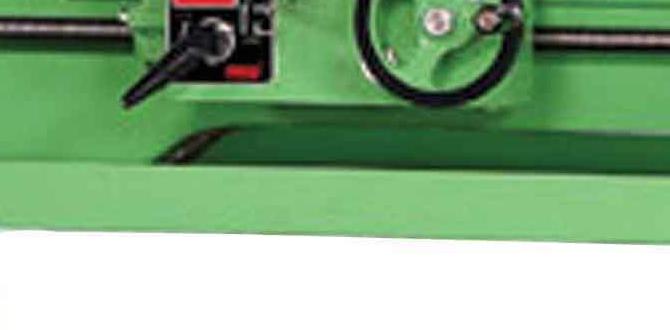

Have you ever watched someone use a lathe? It’s fascinating how a simple piece of metal can turn into something amazing. A lathe tool grinds away material to shape it. But it’s not just about shaping; it’s also about precision. That’s where the metal lathe chuck key comes in.

The chuck key helps hold the workpiece tight. Without it, your project could turn into a big mess! Have you ever tried to screw in a bolt without the right tool? You might have struggled, just like when using a lathe without the proper key.

Did you know using the right lathe tool can make all the difference? It can turn a rough piece of metal into a smooth, shiny product. People often don’t realize how important these little tools are. They help ensure everything stays in place while you create something new.

Curious about how to master lathe tool grinding? Let’s explore the tricks and tips that will make you a pro!

Lathe Tool Grinding: Mastering The Metal Lathe Chuck Key

Understanding Lathe Tool Grinding and the Metal Lathe Chuck Key

Grinding lathe tools is essential for precision and efficiency in metalworking. A well-ground tool cuts smoothly and lasts longer. Did you know that proper grinding improves the quality of your projects? The metal lathe chuck key is crucial for securing tools in place. Without it, projects may go awry. Learning about tool grinding and how to use the chuck key can elevate your skills. Embrace these techniques, and watch your work transform!Essential Tools and Equipment for Grinding Lathe Tools

Description of necessary grinding machines and accessories. Safety equipment and precautions during grinding.Grinding lathe tools requires some key equipment to get the job done right. First, you need a good grinding machine. This device helps sharpen your tools quickly and efficiently. You also need accessories like a tool holder and a proper grinding wheel for the best results. Safety is important too; always wear goggles and gloves. Grinding can send sparks flying—better safe than singed! Here’s a quick reference table for essential tools:

| Tool | Description |

|---|---|

| Grinding Machine | Sharpening tools effectively |

| Tool Holder | Keeps your tools steady |

| Grinding Wheel | Essential for smooth grinding |

Types of Lathe Tools and Their Specific Grinding Needs

Highspeed steel (HSS) vs. carbide tools. Profiles and shapes of common lathe tools.Many lathe tools come in two popular types: high-speed steel (HSS) and carbide. HSS tools are like the trusty old friend who’s always up for some work. They’re easy to sharpen and great for general tasks. On the other hand, carbide tools are like superheroes; they can handle tough jobs but are a bit tricky to grind. Common shapes include turning tools, parting tools, and boring bars. Each has a unique role, like characters in a play!

| Tool Type | Material | Grinding Need |

|---|---|---|

| Turning Tool | HSS | Regular sharpening |

| Parting Tool | Carbide | Precision grinding |

| Boring Bar | HSS/Carbide | Careful upkeep |

So, whether you’re wielding a turning tool or a boring bar, remember that some tools need a little more TLC. Happy grinding!

Steps for Proper Lathe Tool Grinding

Detailed grinding procedures for various tool types. Tips for achieving the right angles and finishes.Grinding lathe tools can seem tricky, but it’s really just about practice and precision. Start by choosing the right tool type. Each tool has its grinding needs. A sharp angle means a sharper cut! Use a handy wheel to get those angles perfect. For finishing, remember: smooth is the name of the game. A smooth finish makes everything look snazzy!

| Tool Type | Recommended Angle | Finishing Tips |

|---|---|---|

| High-Speed Steel | 30-35 degrees | Use finer grits for a polished look |

| Cobalt | 45 degrees | Sparkling finish? Compound is your buddy! |

| Carbide | 15-20 degrees | Keep it cool to avoid burning! |

With these handy tips, you’ll be the superhero of lathe tool grinding! Remember, a happy lathe means happy metal!

Common Mistakes in Lathe Tool Grinding

Identifying and avoiding frequent grinding errors. Consequences of improper grinding on tool performance.Grinders can create problems if not used carefully. One common mistake is not holding the tool steady. This can lead to uneven edges and a sad tool. Another issue is ignoring the right angle during grinding. A slight tilt can make your tool lose its sharpness faster. The consequences? Poor performance and wasted time! Remember, a well-ground tool saves both effort and metal. Here’s a quick look at the key mistakes:

| Error | Consequence |

|---|---|

| Unsteady grip | Uneven edges |

| Wrong angle | Quick dulling |

Grinding tools right ensures they stay sharp longer. It’s like taking care of your favorite toy; less time fixing equals more fun using it!

Maintaining and Sharpening Your Lathe Tool Chuck Key

Techniques for keeping chuck key in prime condition. Importance of regular maintenance for longlasting performance.To keep your lathe tool chuck key in great shape, regular care is crucial. Here are some simple techniques:

- **Clean it often.** Remove dust and debris after each use.

- **Check for damage.** Look for cracks or wear on the key.

- **Sharpen as needed.** A sharp key makes tasks easier and safer.

By performing regular maintenance, you can enjoy a longer-lasting, more effective chuck key. Remember, a little care goes a long way in keeping your tools sharp and ready!

How often should you sharpen your lathe tool chuck key?

It’s best to sharpen your lathe tool chuck key every few months, depending on how much you use it. This keeps it effective and safe. Regular checks can help you notice when it needs sharpening sooner.

Enhancing Lathe Tool Performance Through Grinding

How precision grinding improves machining outcomes. Case studies demonstrating successful tool grinding results.Grinding tools helps them work better. Precision grinding makes cuts smoother and faster. This means machines work well and make fewer mistakes. Case studies show that companies saw up to 30% improvement in their outcomes after grinding tools. When tools are sharp, they last longer and save money.

- Tools work faster

- Less wear and tear

- Higher quality finishes

How does precision grinding improve machining outcomes?

Precision grinding makes tools sharper and more accurate. Sharp tools cut better, which means cleaner shapes and better designs. This helps makers create exactly what they want in less time.

What are the benefits of successful tool grinding?

- Saves time and money

- Reduces errors in cutting

- Increases tool lifespan

Resources and Further Learning for Lathe Tool Grinding

Recommended books, courses, and online resources. Communities and forums for lathe tool enthusiasts and professionals.Learning about lathe tool grinding can be exciting! Here are some great resources to help you out:

- Books: Look for titles like “The Machinist’s Handbook” or “Metalworking: Tools, Techniques, and Tips.”

- Courses: Visit platforms like Udemy or Coursera for online classes focused on machining.

- Online Resources: Check out YouTube channels dedicated to machining, like “This Old Tony.”

- Communities: Join forums like the Machinist’s Forum or Reddit’s r/Machinists. They offer tips and support.

These resources will boost your skills and connect you with fellow enthusiasts!

What are some great books for lathe tool grinding?

Some recommended books include “How to Run a Lathe” by James A. McGeough and “Machine Shop Trade Secrets” by James A. Harvey. These cover techniques and tips for better grinding!

Conclusion

In summary, understanding lathe tool grinding and using a metal lathe chuck key is crucial for beginners. Properly sharpening tools improves their performance and durability. Always handle your chuck key with care to ensure your safety. We encourage you to practice these skills and explore more resources to enhance your lathe work knowledge. Happy crafting!FAQs

What Are The Essential Steps For Properly Grinding Lathe Tools To Ensure Optimal Performance And Durability?To grind lathe tools properly, first choose the right tool and grinding wheel. Next, hold the tool at the right angle while grinding. Move the tool back and forth for even sharpening. Check the edge often to make sure it’s sharp and shaped correctly. Finally, clean the tool to remove any dust or debris before using it.

How Do You Choose The Right Material For A Lathe Tool Bit When Considering Grinding Techniques?To choose the right material for a lathe tool bit, first, think about what you will cut. Different materials work better for different jobs. For example, high-speed steel is good for many metals, while carbide is better for harder materials. You also need to think about how you will grind the tool. Some materials are easier to shape than others.

What Safety Precautions Should Be Taken When Using A Lathe Tool Grinder?When using a lathe tool grinder, you should always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight clothing. Never touch the grinder while it’s running. Make sure your hands are dry and free of oil. Lastly, pay attention and focus on your work to avoid accidents.

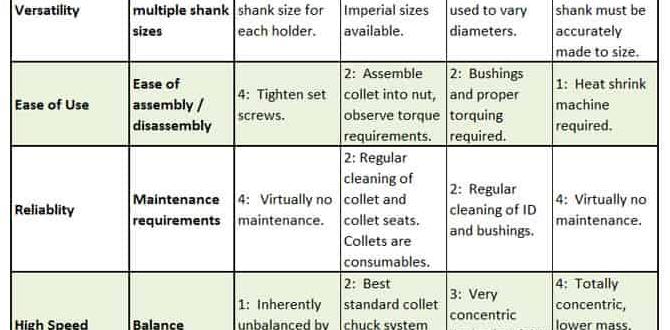

Can You Explain The Different Types Of Lathe Chucks And Their Advantages In Relation To Tool Grinding?Lathe chucks hold the tools tightly while we grind them. There are three main types: three-jaw, four-jaw, and collet chucks. The three-jaw chuck is easy to use and holds round tools well. The four-jaw chuck can hold oddly shaped tools securely. Collet chucks grip tools very tightly and are great for small sizes. Each type helps keep the tool steady while we work on it.

How Do You Properly Maintain And Store A Lathe Chuck Key To Prevent Wear And Damage?To keep your lathe chuck key safe, always store it in a designated spot. You can use a toolbox or a special holder. Make sure to clean it after each use. Wipe off any dirt or grease to prevent rust. Check it regularly for any chips or cracks.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Steps For Properly Grinding Lathe Tools To Ensure Optimal Performance And Durability? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To grind lathe tools properly, first choose the right tool and grinding wheel. Next, hold the tool at the right angle while grinding. Move the tool back and forth for even sharpening. Check the edge often to make sure it’s sharp and shaped correctly. Finally, clean the tool to remove any dust or debris before using it.”}},{“@type”: “Question”,”name”: “How Do You Choose The Right Material For A Lathe Tool Bit When Considering Grinding Techniques? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right material for a lathe tool bit, first, think about what you will cut. Different materials work better for different jobs. For example, high-speed steel is good for many metals, while carbide is better for harder materials. You also need to think about how you will grind the tool. Some materials are easier to shape than others.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Lathe Tool Grinder? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe tool grinder, you should always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight clothing. Never touch the grinder while it’s running. Make sure your hands are dry and free of oil. Lastly, pay attention and focus on your work to avoid accidents.”}},{“@type”: “Question”,”name”: “Can You Explain The Different Types Of Lathe Chucks And Their Advantages In Relation To Tool Grinding? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe chucks hold the tools tightly while we grind them. There are three main types: three-jaw, four-jaw, and collet chucks. The three-jaw chuck is easy to use and holds round tools well. The four-jaw chuck can hold oddly shaped tools securely. Collet chucks grip tools very tightly and are great for small sizes. Each type helps keep the tool steady while we work on it.”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Store A Lathe Chuck Key To Prevent Wear And Damage? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your lathe chuck key safe, always store it in a designated spot. You can use a toolbox or a special holder. Make sure to clean it after each use. Wipe off any dirt or grease to prevent rust. Check it regularly for any chips or cracks.”}}]}