Have you ever watched a craftsman work wonders on a metal lathe? It’s fascinating! These powerful tools help shape metal into amazing things. But what happens when the tools get dull? This is where the art of lathe tool grinding comes in.

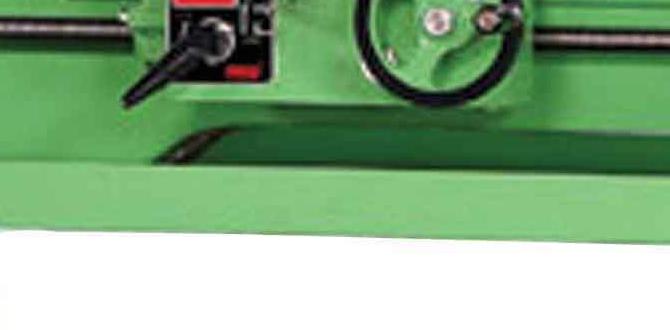

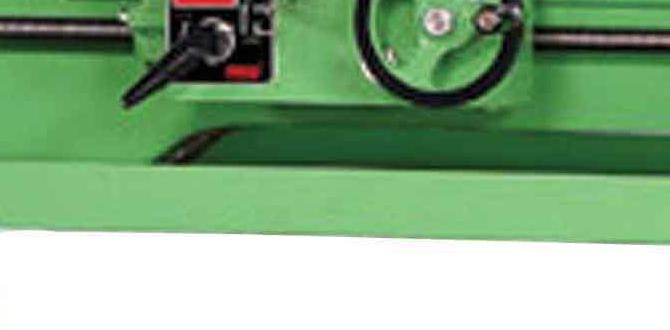

Grinding lathe tools is essential for skilled workers. It ensures that every cut is clean and precise. But there’s more to it than just sharpening. The compound rest on a lathe plays a key role in this process. This part helps position the tool perfectly for every job.

Imagine trying to cut a perfect circle with a dull knife. It just won’t work, right? The same goes for metal lathes. A well-ground tool means a smoother, more enjoyable work process. Learning how to grind these tools properly can make all the difference!

Ready to dive deeper into the world of lathe tool grinding? You’ll discover tips, tricks, and techniques that can elevate your skills. Get ready to transform dull tools into sharp, efficient machines!

Lathe Tool Grinding: Optimizing Your Metal Lathe Compound Rest

Lathe Tool Grinding for Metal Lathes

Lathe tool grinding is essential for metal lathe precision. The compound rest allows for easy adjustments while shaping metal. Do you know how important sharp tools are for smooth cuts? When tools are sharp, they create cleaner edges. A fun fact: a well-ground tool can last longer and save you money! This process involves correctly positioning the tool at different angles. Proper grinding improves accuracy and efficiency. Understanding tool grinding can make your projects easier and more enjoyable!What is a Lathe Tool Grinder?

Definition and purpose. Importance in metalworking processes.A lathe tool grinder is a machine that shapes and sharpens tools used on lathes. It helps create precise tools for cutting metal. The grinding process is vital for ensuring tools are effective. With a sharp tool, metalworkers can achieve clean cuts and better finishes. This leads to higher-quality projects.

- Definition: A machine that sharpens lathe tools.

- Purpose: Improves tool effectiveness in metalworking.

- Importance: Essential for quality and precision in metal projects.

What does a lathe tool grinder do?

It sharpens and shapes tools to cut metal better. This helps metalworking become more accurate and efficient.

Understanding the Compound Rest

Explanation of the compound rest function. How it affects accuracy and efficiency in grinding.The compound rest is a key part of a lathe. It helps position the cutting tool accurately. This placement increases precision during grinding. A well-adjusted compound rest ensures smooth operation. This makes work faster and more efficient.

- Improves accuracy: A precise tool position leads to better results.

- Increases efficiency: Less time is wasted on adjustments.

- Enhances safety: A stable setup reduces the risk of accidents.

How does the compound rest affect grinding?

The compound rest improves accuracy and efficiency in grinding. It allows for better tool control, resulting in cleaner cuts and reduced waste.Types of Lathe Tools and Their Uses

Common lathe tools and their specifications. Best practices for selecting the right tool for grinding.Lathe tools come in many types. Each tool has a special job. Here are some common ones:

- Cutting Tool: Shapes materials with sharp edges.

- Drill Tool: Creates holes in the material.

- Parting Tool: Cuts off pieces from the main part.

Choosing the right tool is important for grinding. Think about:

- Material type: Use the right tool for the material.

- Tool sharpness: A sharp tool works better.

- Project needs: Match the tool to what you are making.

What are the best practices for selecting a lathe tool?

Choose tools based on your project and material to ensure the best results. Always keep your tools sharp and well-maintained for safety and efficiency.

Step-by-Step Guide to Lathe Tool Grinding

Preparation before grinding. Detailed grinding techniques for different lathe tools.Before you start grinding, make sure everything is set. First, gather the right tools and materials. Clean your workspace for safety. Check the lathe tool for any damage. A good setup ensures a smooth process. Proper preparation saves time and effort later.

Next, each lathe tool needs a specific technique for grinding. Here’s a quick guide:

- For roughing tools, use an aggressive angle to remove metal fast.

- Finishing tools require a finer grind. This gives a smooth finish.

- Drill bits need a pointed grind to create holes easily.

How can I prepare for lathe tool grinding?

Preparation involves having the right tools, checking the lathe, and cleaning your workspace. Follow these steps, and you’ll be ready to grind effectively and safely!

Common Mistakes in Lathe Tool Grinding

Identifying frequent pitfalls. How to avoid errors for better results.Many people make simple mistakes while grinding lathe tools. One common error is not aligning the tool properly. This can lead to uneven edges. Another pitfall is using the wrong angle—think of it like trying to cut a pizza with a spoon! To improve, double-check your setup and take your time. Remember, patience pays off. The table below lists some common mistakes and tips to avoid them:

| Error | How to Avoid |

|---|---|

| Poor alignment | Always check your tool position before grinding. |

| Wrong angle | Use guides and measure angles carefully. |

| Rushing the process | Take breaks and review your work regularly. |

By steering clear of these errors, your results will shine brighter than a new penny!

Safety Precautions When Grinding Lathe Tools

Key safety measures to follow. Importance of protective gear and workspace organization.Grinding lathe tools can be exciting but also risky. Safety must come first. Wear protective gear like goggles and gloves. This helps protect you from sparks and sharp tools. Keep your workspace tidy. Remove clutter to avoid accidents. Follow these key measures:

- Always wear a face shield.

- Use dust masks to avoid breathing in particles.

- Check tools for damage before use.

- Secure workpieces strongly on the lathe.

These steps can keep you safe and make grinding easier.

Why is protective gear important?

Wearing protective gear is crucial. It protects you from injuries. A small spark can cause burns. A flying chip can hurt your eyes. Safety first helps you enjoy your work!

Maintaining Your Lathe and Grinding Equipment

Routine maintenance practices for longevity. Tips for troubleshooting and resolving common issues.Keeping your lathe and grinding tools in tip-top shape is easier than you think! Regular checks—like cleaning and oiling parts—can make them last longer. Need to fix a problem? Check for loose screws or worn-out belts first. Don’t worry, nobody’s perfect! Even the best tools get a little cranky sometimes. Here’s a handy table with quick maintenance tips:

| Task | Frequency |

|---|---|

| Clean surfaces | After each use |

| Lubricate moving parts | Weekly |

| Check for damage | Monthly |

| Sharpen blades | After every few uses |

These simple steps keep everything running smoothly. Remember, a happy lathe means happy projects!

Conclusion

In conclusion, understanding lathe tool grinding and using the compound rest is essential for metalworking. You can improve your projects with sharp tools and proper setups. Remember to practice your grinding techniques for better results. We encourage you to explore more resources on lathe operations to enhance your skills. Happy machining!FAQs

What Are The Essential Angles To Consider When Grinding Lathe Tools For Optimal Cutting Performance?When grinding lathe tools, you need to think about a few important angles. First, the cutting angle helps the tool slice through material easily. Next, the clearance angle makes sure the tool doesn’t rub against the workpiece. Lastly, the nose radius changes how smooth the final shape will be. Getting these angles right helps your tools work better and last longer!

How Does The Design Of The Compound Rest On A Metal Lathe Influence The Accuracy Of Tool Grinding?The compound rest on a metal lathe helps hold the tool steady. When it’s designed well, it lets you make precise movements. This way, you can grind the tool more accurately. If the rest is not strong or wobbly, the tool can end up uneven. Good design means better tool grinding!

What Safety Precautions Should Be Taken While Grinding Lathe Tools Using A Bench Grinder?When you use a bench grinder, always wear safety goggles to protect your eyes. Make sure your hair and clothes are secure and away from the machine. Use both hands to hold the tool you’re grinding. Keep your face away from the grinder while it’s running. Always let the machine stop completely before touching it.

How Do Different Types Of Cutting Materials (E.G., High-Speed Steel Vs. Carbide) Affect The Grinding Process Of Lathe Tools?Different cutting materials change how we grind lathe tools. High-speed steel is easier to shape and sharpen. It’s good for softer metals. Carbide is much harder and lasts longer, but it’s tricky to grind. So, you need special tools for carbide. Each type behaves differently when you grind them!

What Are Common Techniques To Set Up The Compound Rest For Precision Grinding Operations On A Metal Lathe?To set up the compound rest on a metal lathe for grinding, first, make sure it’s clean and free of debris. Then, adjust the angle using the dial so it points correctly. You can lock it in place once it’s set. Finally, check that the tool is sharp and secure before you start grinding. This helps you make precise cuts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Angles To Consider When Grinding Lathe Tools For Optimal Cutting Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When grinding lathe tools, you need to think about a few important angles. First, the cutting angle helps the tool slice through material easily. Next, the clearance angle makes sure the tool doesn’t rub against the workpiece. Lastly, the nose radius changes how smooth the final shape will be. Getting these angles right helps your tools work better and last longer!”}},{“@type”: “Question”,”name”: “How Does The Design Of The Compound Rest On A Metal Lathe Influence The Accuracy Of Tool Grinding? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest on a metal lathe helps hold the tool steady. When it’s designed well, it lets you make precise movements. This way, you can grind the tool more accurately. If the rest is not strong or wobbly, the tool can end up uneven. Good design means better tool grinding!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken While Grinding Lathe Tools Using A Bench Grinder? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a bench grinder, always wear safety goggles to protect your eyes. Make sure your hair and clothes are secure and away from the machine. Use both hands to hold the tool you’re grinding. Keep your face away from the grinder while it’s running. Always let the machine stop completely before touching it.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Cutting Materials (E.G., High-Speed Steel Vs. Carbide) Affect The Grinding Process Of Lathe Tools? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting materials change how we grind lathe tools. High-speed steel is easier to shape and sharpen. It’s good for softer metals. Carbide is much harder and lasts longer, but it’s tricky to grind. So, you need special tools for carbide. Each type behaves differently when you grind them!”}},{“@type”: “Question”,”name”: “What Are Common Techniques To Set Up The Compound Rest For Precision Grinding Operations On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the compound rest on a metal lathe for grinding, first, make sure it’s clean and free of debris. Then, adjust the angle using the dial so it points correctly. You can lock it in place once it’s set. Finally, check that the tool is sharp and secure before you start grinding. This helps you make precise cuts.”}}]}