Have you ever watched a lathe spin and wondered how it works? A lathe is a powerful machine that shapes metal. But what makes it even more special is the lathe tool grinding process. This process sharpens tools for better cutting. Imagine trying to carve wood with a dull knife. It’s frustrating, right? Now, picture how important it is for metalworking.

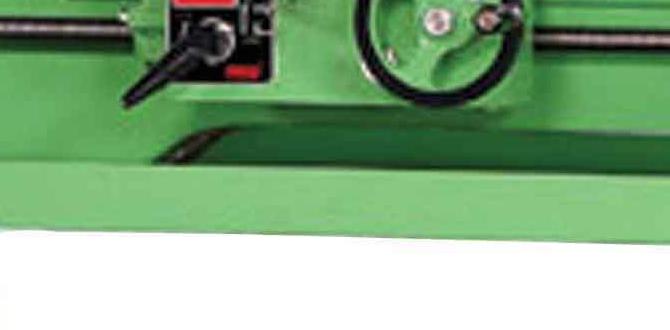

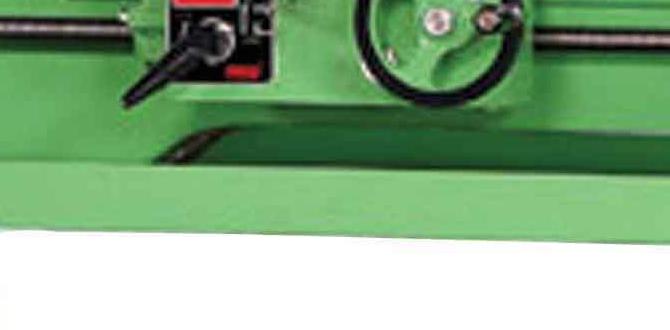

The control panel of a metal lathe is where the magic happens. It allows you to adjust settings and control speeds. Do you want smoother cuts? The control panel helps you do that. With the right tools and knowledge, you can create amazing projects.

Did you know that even a small mistake in tool grinding can change everything? It can ruin your work or even cause accidents. But don’t worry! Learning about this can be fun and rewarding.

Ready to dive into the world of lathe tool grinding? Let’s explore the secrets behind the control panel and how it can change your metalworking experience!

Lathe Tool Grinding: Mastering The Metal Lathe Control Panel

Understanding Lathe Tool Grinding and the Control Panel

Lathe tool grinding is crucial for shaping metal accurately. It helps maintain sharp edges on cutting tools. The control panel on a metal lathe allows users to adjust speed and settings easily. Have you ever wondered how precision is achieved in metalworking? Proper tool grinding is key! With the right setup, metalworkers can create intricate designs and smooth finishes. This process enhances both efficiency and safety in various projects. Explore the power of lathe tools for your next crafting adventure!Components of a Metal Lathe Control Panel

Description of key components found in a metal lathe control panel.. Functions and significance of each component in the grinding process..A metal lathe control panel has key parts that make it work. Each part helps in shaping metal safely and accurately. Common components include:

- Speed Control Knob: Adjusts the turning speed of the lathe.

- Power Switch: Turns the machine on and off.

- Emergency Stop Button: Stops the machine quickly in case of danger.

- Feed Rate Control: Sets how fast the material moves against the tool.

These pieces are important for safe operation and smooth grinding. They help users get the best results.

What are the main parts of a metal lathe control panel?

The key parts include the speed control knob, power switch, emergency stop button, and feed rate control. Each one plays an essential role in controlling the lathe during metal grinding.

Types of Grinding Techniques for Lathe Tools

Explanation of various grinding techniques applicable to lathe tools.. Advantages and disadvantages of each technique..Grinding techniques vary for lathe tools, each with unique features. Here are some popular methods:

- Wheel Grinding: This uses rotating wheels. It’s fast but can cause heat damage.

- Diamond Grinding: This method is precise and gives a smooth finish. However, it’s quite costly.

- Surface Grinding: Great for flat surfaces. It’s efficient but not suited for complex shapes.

- Cylindrical Grinding: Perfect for round objects. It takes longer but offers accuracy.

Each technique has its pros and cons. Knowing these helps you choose the best grinding method for your lathe tools.

What are the benefits of lathe tool grinding?

Lathe tool grinding improves tool life and performance. It ensures sharp edges and increases efficiency, saving time and reducing waste.

Setting Up Your Metal Lathe Control Panel

Stepbystep guide on configuring a control panel for optimum performance.. Common mistakes to avoid while setting up the control panel..To set up your metal lathe control panel, follow these steps. First, ensure all tools are clean and nearby. Install the control panel securely. Next, connect the power source and check all wires. Adjust settings for speed and feed rates. Test the panel to confirm operation.

Common mistakes include:

- Not securing connections properly.

- Ignoring manufacturer guidelines.

- Skipping pre-use checks.

Remember, a well-configured control panel improves performance. Stay focused and double-check each step!

What should I avoid when setting up my control panel?

Avoid mistakes like loose connections and skipping instructions. Always refer to the user manual for guidance.

Troubleshooting Common Lathe Tool Grinding Issues

Identifying common problems encountered during the grinding process.. Solutions and tips for effective troubleshooting..Grinding tools on a lathe can be tricky. Some common problems arise in this process. Here are a few:

- Worn Abrasive Surface: This can lead to uneven grinding.

- Incorrect Speed: Too fast or slow can affect the finish.

- Improper Tool Position: Misalignment can cause damage.

To solve these issues, consider the following tips:

- Check and change the grinding wheel regularly.

- Adjust the speed according to the material.

- Ensure proper alignment before starting.

These steps can help you grind metal tools better and avoid common mistakes.

What should I check first when facing lathe tool grinding problems?

Check the abrasive wheel for wear and make sure it’s aligned correctly. This can prevent many issues right from the start.

Maintenance Tips for Longevity of Lathe Tools and Control Panels

Best practices for maintaining lathe tools postgrinding.. Routine maintenance checklists for control panels to ensure durability..Keeping your lathe tools and control panels in tip-top shape is important! After grinding, always clean your tools. Dust is their nemesis! Regularly check for any wear and tear. It’s like taking your tools to the dentist; they need a little love too. For control panels, make a checklist. Include checks for loose wires and signs of damage. A small problem can become a big issue if ignored. Remember, happy tools lead to happy projects!

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean tools after use | Every time | Dust can dull sharp edges. |

| Inspect for wear | Weekly | Catch small problems before they grow. |

| Check control panel | Monthly | Loose wires can cause big headaches! |

Advancements in Lathe Tool Grinding Technology

Exploration of innovative technologies in lathe tool grinding.. Future trends and how they impact metal lathe operations..Metal lathes are getting smarter and faster! With new grinding tech, they can shape metal pieces with pinpoint precision. Imagine a robot whispering sweet nothings to your lathe as it grinds away. Future trends include touchscreen controls and real-time data analysis, making operations smoother than a buttered banister. These advancements not only improve efficiency but also cut costs. So, let’s keep our eyes peeled for what’s next in the metal world!

| Technology | Impact |

|---|---|

| Touchscreen Controls | Easy operation, less chance of operator error |

| Real-Time Data | Better monitoring and quicker adjustments |

| Automation and AI | Increased precision and efficiency |

With these changes, you’ll find metal lathes not just useful, but *fun!* Who knew grinding tools could bring such joy? Keep grinding away, and let’s see what cool tech comes next!

Expert Recommendations and Best Practices

Advice from industry experts on efficient grinding practices.. Essential resources for continuous learning and improvement..Grinding metal can seem tricky, but expert tips make it easier! First, always keep your cutting tools sharp. This saves time and effort. Remember, dull tools are like trying to cut a steak with a spoon—it’s just messy! Get familiar with your lathe tool grinding setup. A well-organized control panel helps you avoid hiccups. Consider joining forums or watching videos for tips. Lastly, practice makes perfect. You’ll turn into a grinding ninja before you know it!

| Best Practices | Tips |

|---|---|

| Keep tools sharp | Use a honing guide |

| Understand your control panel | Read the manual! |

| Continuous learning | Watch tutorials |

Conclusion

In summary, a lathe tool grinding metal lathe control panel helps you shape and refine materials. Understanding its parts can improve your skills. Always check your settings for best results. Practice regularly to boost your confidence. If you want to learn more, consider reading guides or watching videos on lathe operations. Happy grinding!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Control Panels:Sure! Lathe tool grinding helps make tools sharp for cutting metal. We use different angles to make good shapes. A metal lathe control panel shows buttons to help us use the machine. You can change speeds and settings easily. It makes working with metal much safer and better!

Sure! Please provide the question you would like me to answer.

What Are The Essential Features To Consider In A Control Panel For A Metal Lathe When Setting Up A Tool Grinding Operation?When you set up a control panel for a metal lathe, you need some important features. First, you want clear buttons to turn the machine on and off easily. Next, include a speed dial to control how fast the lathe spins. You also need safety features like emergency stop buttons. Lastly, a display screen helps you see important information while you work.

How Do Different Grinding Angles On Lathe Tools Affect The Quality Of The Machined Metal Workpieces?Different grinding angles on lathe tools change how well they cut metal. If you use a sharp angle, the tool cuts cleaner and leaves a smooth surface. A wider angle can make rougher cuts, which may need more work to fix. By choosing the right angle, we can make better, nicer-looking metal pieces.

What Safety Measures Should Be Taken When Operating A Lathe Tool Grinding Machine?When using a lathe tool grinding machine, we need to be very careful. Always wear safety goggles to protect your eyes. Make sure your hair is tied back and your clothes are snug. Keep your hands away from the moving parts. Lastly, never use the machine without checking that everything is working properly first.

How Can Cnc Control Panels Enhance The Precision And Efficiency Of Lathe Tool Grinding Processes?CNC stands for Computer Numerical Control. It helps machines like lathes work better. With a CNC control panel, you can set exact measurements for tool grinding. This means your tools will be sharper and fit perfectly. It also helps you finish tasks faster, saving time and effort!

What Types Of Materials Are Typically Used For Lathe Tools, And How Do They Influence The Grinding Process And Control Settings?Lathe tools are often made from steel, carbide, or high-speed steel. These materials change how we sharpen the tools. For example, carbide is very hard, so it needs special grinding wheels. If we use high-speed steel, it can handle more heat but wears down faster. The choice of material helps us pick the right grinding speed and pressure.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Control Panels:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathe tool grinding helps make tools sharp for cutting metal. We use different angles to make good shapes. A metal lathe control panel shows buttons to help us use the machine. You can change speeds and settings easily. It makes working with metal much safer and better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Features To Consider In A Control Panel For A Metal Lathe When Setting Up A Tool Grinding Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you set up a control panel for a metal lathe, you need some important features. First, you want clear buttons to turn the machine on and off easily. Next, include a speed dial to control how fast the lathe spins. You also need safety features like emergency stop buttons. Lastly, a display screen helps you see important information while you work.”}},{“@type”: “Question”,”name”: “How Do Different Grinding Angles On Lathe Tools Affect The Quality Of The Machined Metal Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different grinding angles on lathe tools change how well they cut metal. If you use a sharp angle, the tool cuts cleaner and leaves a smooth surface. A wider angle can make rougher cuts, which may need more work to fix. By choosing the right angle, we can make better, nicer-looking metal pieces.”}},{“@type”: “Question”,”name”: “What Safety Measures Should Be Taken When Operating A Lathe Tool Grinding Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe tool grinding machine, we need to be very careful. Always wear safety goggles to protect your eyes. Make sure your hair is tied back and your clothes are snug. Keep your hands away from the moving parts. Lastly, never use the machine without checking that everything is working properly first.”}},{“@type”: “Question”,”name”: “How Can Cnc Control Panels Enhance The Precision And Efficiency Of Lathe Tool Grinding Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC stands for Computer Numerical Control. It helps machines like lathes work better. With a CNC control panel, you can set exact measurements for tool grinding. This means your tools will be sharper and fit perfectly. It also helps you finish tasks faster, saving time and effort!”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Typically Used For Lathe Tools, And How Do They Influence The Grinding Process And Control Settings?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe tools are often made from steel, carbide, or high-speed steel. These materials change how we sharpen the tools. For example, carbide is very hard, so it needs special grinding wheels. If we use high-speed steel, it can handle more heat but wears down faster. The choice of material helps us pick the right grinding speed and pressure.”}}]}