Have you ever wondered how metal parts are made with such precision? One essential tool in this process is the lathe. A lathe shapes metal pieces smoothly and accurately. But what if we told you there’s a way to sharpen lathe tools that makes working with metal even easier?

Meet the lathe tool grinding. This is not just any grinding; it makes your tools last longer and work better. Imagine cutting through metal like butter! You can achieve this with the right techniques. And the heart of this process is often found in the lathe controller board.

This smart device helps you control the grinding process efficiently. Plus, it adds a level of fun to your workspace! Have you ever seen how a simple board can make complex tasks easier? It’s like magic!

Join us as we dive deeper into the fascinating world of lathe tool grinding and the powerful role of the metal lathe controller board. You’ll discover tips and tricks that can change your metalworking game forever.

Lathe Tool Grinding: Enhancing Your Metal Lathe Controller Board

Understanding Lathe Tool Grinding and Controller Boards

Lathe tool grinding ensures your metal lathe operates at its best. It sharpens tools to create precise cuts. Imagine making a wooden toy car; it needs smooth edges, right? That’s what proper grinding does for metalwork. A metal lathe controller board runs these machines effectively. It helps in controlling speed and movement, which is crucial for accuracy. By learning about these tools, you can enhance your skills and create amazing projects. Are you ready to dive into the world of metal crafting?Understanding Lathe Tool Grinding

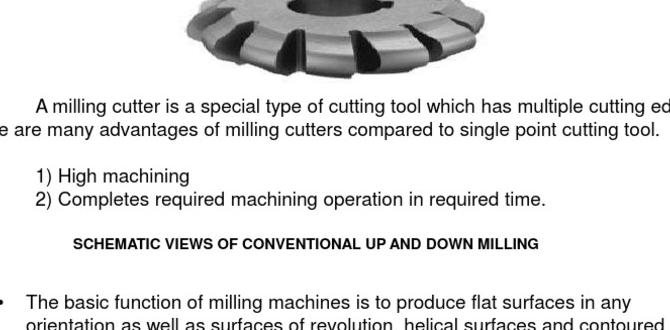

Definition and importance of lathe tool grinding. Types of lathe tools that require grinding.Lathe tool grinding is the process of sharpening and shaping lathe tools. This keeps the tools effective and helps them cut better. Proper grinding can save time and make work smoother.

There are many types of lathe tools that need grinding:

- Cutting tools

- Facing tools

- Turning tools

- Boring tools

Regular sharpening is key. It ensures safety and improves performance.

Why is tool grinding important?

Tool grinding improves cutting efficiency and extends tool life. Properly ground tools also reduce material waste, making projects more cost-effective.

Common types of lathe tools:

- High-speed steel (HSS) tools

- Cobalt tools

- Carbide tools

Step-by-Step Guide to Grinding Lathe Tools

Detailed process on how to grind specific lathe tools. Tips for achieving precision and accuracy in grinding.Grinding lathe tools can be as fun as making a sandwich, minus the crumbs! Start by choosing your tool and securing it in a vise. Set the angle correctly; it’s like finding the sweet spot for a perfect selfie! Next, move it slowly back and forth against the grinding wheel. Don’t rush—precision is key. To help, check out this handy table:

| Lathe Tool Type | Angle for Grinding |

|---|---|

| Parting Tool | 10-15° |

| Turning Tool | 20-30° |

| Facing Tool | 5-10° |

Keep an eye on the spark showers; they’re not as fun as fireworks! Always check your work with a gauge to make sure you’re spot on. Remember, slow and steady wins the grinding race!

Choosing the Right Metal Lathe Controller Board

Importance of a controller board in metal lathe operations. Factors to consider when selecting a controller board.The controller board is vital for smooth metal lathe operations. It directs the lathe and affects speed and precision. Selecting the right board ensures your projects turn out great. Here are some key factors to consider:

- Compatibility with your lathe type

- Easy-to-use interface

- Available features for various projects

- Support from the manufacturer

Choosing wisely leads to better results and less frustration.

Why is a controller board important?

The controller board plays a crucial role. It helps control speed, movement, and accuracy. A good board enhances your overall experience with metal lathes.

What factors should be considered when selecting a metal lathe controller board?

Look for these factors:

- Compatibility: Make sure it fits your lathe.

- Interface: Choose one that is user-friendly.

- Features: Consider what functions you might need.

- Support: Check if help is available if you need it.

Installation and Setup of Metal Lathe Controller Boards

Stepbystep installation guide. Common challenges and solutions during setup.Getting your metal lathe controller board up and running is easier than you might think! Here’s a simple step-by-step guide:

| Step | Action |

|---|---|

| 1 | Connect the board to power and all necessary wires. |

| 2 | Install the software on your computer. |

| 3 | Configure settings according to your lathe. |

| 4 | Test the setup with a simple project. |

While setting up, you might face a few hiccups. One common challenge is confusing wires. If you feel like a spaghetti chef, don’t worry! Just double-check your manual. Another issue is software bugs—kind of like pesky flies at a picnic. Simply reboot your system for a fix!

Follow these tips, and you’ll have your lathe spinning like a well-oiled machine in no time!

Maintenance Tips for Lathe Tools and Controller Boards

Best practices for maintaining lathe tools. How to ensure longevity and efficiency of controller boards.Keeping lathe tools and controller boards in good shape is like feeding your pet—if you neglect them, they’ll turn cranky. Regular cleaning helps remove debris and oils that can cause wear. Always inspect your cutter edges. A dull tool might as well be a butter knife! For controller boards, clear dirt from connections and avoid moisture. It’s like keeping your electronics dry while swimming—definitely not a good idea!

| Maintenance Tips | Best Practices |

|---|---|

| Cleaning | Regularly wipe tools to remove debris. |

| Inspection | Check cutter edges to ensure they are sharp. |

| Drying | Keep controller boards away from moisture. |

By following these tips, you can keep your lathe tools sharp and your controller boards efficient. Who wouldn’t want a smooth ride in their metalworking? Remember, a well-maintained lathe tool is a happy lathe tool!

Common Problems in Lathe Tool Grinding and Troubleshooting

Typical challenges faced during grinding processes. Troubleshooting techniques to overcome issues.When using a lathe for grinding, some problems might pop up. You might notice rough finishes or overheating parts. These issues can be annoying, but fixing them is possible. Here are some tips to help:

- Check the tool speed. Too fast can cause rough edges.

- Keep the grinding wheel clean. Dust can lead to poor performance.

- Make sure the workpiece is stable. Any movement can ruin your work.

- Change worn tools. Dull tools won’t cut well.

If problems continue, reviewing your lathe tool setup may reveal hidden issues. With these tips, you can make your grinding process smoother.

What are common problems in lathe tool grinding?

Common problems include rough finishes, tool wear, and overheating. These can happen during extended use or improper settings.

How can you troubleshoot lathe grinding issues?

- Check for stability in the setup.

- Ensure the grinding wheel is clean.

- Adjust the speed settings.

- Examine the tools for wear.

Comparative Analysis of Different Lathe Controller Boards

Review of popular controller boards on the market. Pros and cons of each option based on user needs.There are many lathe controller boards available, each with its own features. Here’s a quick comparison to help you decide which one fits your needs.

| Controller Board | Pros | Cons |

|---|---|---|

| Board A | Easy setup, reliable performance | May be too basic for advanced users |

| Board B | Great customization options | Complex settings |

| Board C | Affordable, good for beginners | Limited durability |

Choosing a controller board is like picking a pizza topping. Everyone has their favorite, but it’s all about your taste! Each board has its perks and quirks. Consider what you need. Happy lathe-ing!

Advanced Techniques in Lathe Tool Grinding

Techniques for specialized grinding applications. Innovations and emerging trends in grinding technology.Mastering lathe tool grinding isn’t just about spinning metal. It’s also about mastering advanced techniques! Specialized grinding applications use cool new methods. For instance, CNC controls allow for precise shaping, making tools sharper than a cat’s claws. Innovations like diamond wheels are popular. They grind faster and last longer, making them a favorite among experts. Check out this table for some trending techniques:

| Technique | Description |

|---|---|

| CNC Grinding | Uses computerized controls for accuracy. |

| Diamond Wheels | Faster grinding with long-lasting edges. |

| Wet Grinding | Keeps tools cool and cuts smoother. |

And remember, the right technique can make your lathe work wonders! Why settle for dull tools when you can shine bright like a diamond?

Resources for Further Learning

Recommended books, courses, and online tutorials. Communities and forums for lathe tool enthusiasts.Learning more about lathe tools can be exciting! Here are some great resources to help you dive deeper:

- Books: Check out “The Fundamental Principles of Tool Grinding” for solid basics.

- Courses: Websites like Coursera offer courses on machining and tooling.

- Online Tutorials: YouTube has many videos that show lathe tool techniques step-by-step.

Joining communities can be helpful too. Try forums like Reddit’s r/Machinists. You’ll meet fellow enthusiasts who share tips!

What are some popular resources for lathe tool enthusiasts?

Look for online classes, books, and videos. They can improve your skills. Communities online also help you learn from others.

Conclusion

In conclusion, understanding lathe tool grinding and controller boards is vital for precision metalworking. You can create sharp tools for better results. Explore more about lathe setups and practice grinding techniques. With hands-on experience, you’ll gain confidence and skill. Don’t hesitate to dive deeper into resources or tutorials to enhance your knowledge further. Happy crafting!FAQs

What Are The Essential Features To Consider When Selecting A Controller Board For A Metal Lathe?When choosing a controller board for a metal lathe, you should think about a few important features. First, make sure it is easy to use. You want buttons and screens that are simple to understand. Next, check if it can connect to your computer or other devices. This lets you control the lathe easily. Finally, look for good safety features to keep yourself safe while working.

How Does The Precision Of Lathe Tool Grinding Affect The Overall Quality Of Machined Parts?When we grind a lathe tool precisely, we make a sharp and accurate edge. This helps the tool cut better and make smoother parts. If the tool isn’t ground well, it might create rough or uneven pieces. So, better grinding leads to higher quality parts. We want our tools to be just right for the best results.

What Types Of Grinding Wheels Are Best Suited For Sharpening Lathe Tools?The best grinding wheels for sharpening lathe tools are aluminum oxide wheels and ceramic wheels. Aluminum oxide wheels work well and last a long time. Ceramic wheels are super tough and can help you get a fine edge. Make sure the wheel is the right size for your tool and machine. These wheels will help you keep your lathe tools sharp and ready to use!

Can A Microcontroller Be Effectively Used In The Control System Of A Metal Lathe For Improved Automation?Yes, you can use a microcontroller in a metal lathe. A microcontroller is a small computer that helps control machines. It makes the lathe work automatically and do tasks better. With a microcontroller, you can create safer and faster designs for projects. Overall, it helps you in your building and crafting activities.

What Safety Precautions Should Be Taken During The Lathe Tool Grinding Process?When you use a lathe tool grinder, wear safety goggles to protect your eyes. You should also wear gloves to keep your hands safe. Make sure to tie back long hair and remove any loose clothing. Keep your workspace clean and free from clutter. Always follow the machine’s instructions to stay safe while grinding.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Features To Consider When Selecting A Controller Board For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a controller board for a metal lathe, you should think about a few important features. First, make sure it is easy to use. You want buttons and screens that are simple to understand. Next, check if it can connect to your computer or other devices. This lets you control the lathe easily. Finally, look for good safety features to keep yourself safe while working.”}},{“@type”: “Question”,”name”: “How Does The Precision Of Lathe Tool Grinding Affect The Overall Quality Of Machined Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we grind a lathe tool precisely, we make a sharp and accurate edge. This helps the tool cut better and make smoother parts. If the tool isn’t ground well, it might create rough or uneven pieces. So, better grinding leads to higher quality parts. We want our tools to be just right for the best results.”}},{“@type”: “Question”,”name”: “What Types Of Grinding Wheels Are Best Suited For Sharpening Lathe Tools? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The best grinding wheels for sharpening lathe tools are aluminum oxide wheels and ceramic wheels. Aluminum oxide wheels work well and last a long time. Ceramic wheels are super tough and can help you get a fine edge. Make sure the wheel is the right size for your tool and machine. These wheels will help you keep your lathe tools sharp and ready to use!”}},{“@type”: “Question”,”name”: “Can A Microcontroller Be Effectively Used In The Control System Of A Metal Lathe For Improved Automation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can use a microcontroller in a metal lathe. A microcontroller is a small computer that helps control machines. It makes the lathe work automatically and do tasks better. With a microcontroller, you can create safer and faster designs for projects. Overall, it helps you in your building and crafting activities.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken During The Lathe Tool Grinding Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a lathe tool grinder, wear safety goggles to protect your eyes. You should also wear gloves to keep your hands safe. Make sure to tie back long hair and remove any loose clothing. Keep your workspace clean and free from clutter. Always follow the machine’s instructions to stay safe while grinding.”}}]}