Have you ever wondered how metal is shaped into tools and machines? It all starts with a metal lathe. But to make the best tools, you need special techniques, like lathe tool grinding. Many people in workshops don’t realize how important a lathe foot brake is. This simple feature can make your work safer and more efficient.

Imagine trying to cut metal without stopping safely. That would be a real challenge! With a foot brake, you can control the lathe quickly. This means fewer mistakes and more amazing projects. Did you know that using the right grinding techniques can extend your tool’s life? Your tools are like superheroes for your projects, and they need care to stay strong.

In this article, we will explore how to properly grind lathe tools. We will also discover the role of the lathe foot brake. Get ready to dive into the world of metalworking, where every detail matters!

Lathe Tool Grinding: Metal Lathe Foot Brake Techniques

Lathe Tool Grinding Metal Lathe Foot Brake

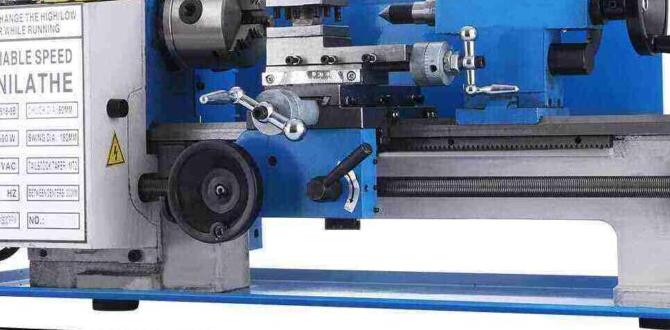

A lathe tool grinding metal lathe foot brake is essential for safe operation. It allows quick stopping when working on a lathe, preventing accidents. Did you know that having a foot brake can be the difference between minor mishaps and serious injuries? Properly grinding lathe tools enhances their cutting ability, leading to smoother finishes. Learning to combine these skills can boost your confidence in metalworking. So, why not explore the power of a lathe and the safety it brings?Understanding Lathe Tool Grinding

Definition and importance of lathe tool grinding in machining. Types of lathe tools and their specific grinding requirements.Lathe tool grinding shapes the tools used in machining. It is important because it helps tools cut metal smoothly. Well-ground tools last longer and work better. There are many types of lathe tools, like turning tools and boring bars. Each tool needs special grinding to be effective. This ensures they perform their best during work.

- Turning tools: Need a sharp point for smooth cuts.

- Boring bars: Should have a specific angle for accuracy.

What are the key benefits of lathe tool grinding?

Lathe tool grinding improves tool performance and prolongs tool life. It also helps in achieving better precision and quality in machining tasks. Properly ground tools save time and material by reducing waste.

Step-by-Step Lathe Tool Grinding Process

Detailed procedure for grinding highspeed steel (HSS) and carbide tools. Illustrations or diagrams for better understanding.Grinding tools takes skill and care. Follow these steps to grind high-speed steel (HSS) and carbide tools effectively:

- Start by cleaning the tool. Ensure it’s free of rust and dirt.

- Set up the grinding machine. Adjust the speed to match the material.

- Hold the tool at the right angle. Aim for about 20 to 30 degrees.

- Slowly move the tool across the grinder. Keep steady pressure.

- Check your progress regularly. Look for a shiny edge as a sign of a good grind.

Using illustrations helps visualize these steps. Diagrams can show proper angles and tool positions. Practice makes perfect!

How do you grind HSS and carbide tools?

To grind HSS tools, use a rough wheel first and then a fine one. For carbide, use a diamond wheel. Always wear safety gear while grinding.

Setting Up a Foot Brake for Metal Lathes

Importance of foot brakes in lathe operation. Guide to selecting and installing an effective foot brake.Foot brakes in metal lathe operation are more than just fancy gadgets. They are crucial for safety and precision. Imagine trying to stop a runaway lathe without one! That would be as fun as a cat in a bathtub. When choosing a foot brake, consider its responsiveness and durability. Look for a model that fits your lathe and your feet! Here’s a quick guide:

| Feature | Description |

|---|---|

| Responsiveness | Quick to stop your lathe when needed. |

| Durability | Long-lasting materials that withstand wear. |

| Compatibility | Fits your specific lathe model perfectly. |

Installing the right foot brake can save you from accidents and help you work better. So, don’t skip this step; it’s the “foot”note to success!

Best Practices for Maintenance and Safety

Recommended maintenance for lathe tools and grinding equipment. Safety measures to implement during grinding operations.Taking care of lathe tools is key to safe and effective work. Regular maintenance helps them last longer and work better. Here are some best practices:

- Keep tools clean and dry.

- Check for wear and tear often.

- Sharpen or replace dull blades.

- Oil moving parts to prevent rust.

Safety is important during grinding:

- Always wear safety goggles.

- Secure workpieces tightly.

- Never reach into moving parts.

- Keep bystanders away from the area.

Being careful can prevent accidents and keep everyone safe!

What are the safety tips while using a lathe?

Wear protective gear and maintain a clean workspace. Always check equipment before use. Be aware of your surroundings to avoid accidents.

Common Mistakes in Lathe Tool Grinding and How to Avoid Them

Identification of frequent errors in grinding processes. Tips for ensuring accuracy and efficiency during grinding.Grinding lathe tools can be tricky. One common mistake is not keeping the tool cool. If it overheats, it can lose its shape. Another error is using the wrong angle, which can lead to dull tools. To avoid these blunders, check your setup often, and take breaks to cool down the tool. Remember, “Hot tools don’t make sharp cuts!” Keep your workspace clean and organized for smooth sailing.

| Common Mistake | Tip to Avoid |

|---|---|

| Overheating | Use coolant and take breaks |

| Incorrect angle | Double-check angles before grinding |

Frequently Asked Questions on Lathe Tool Grinding

Answers to common queries about lathe tool grinding techniques. Expert tips for improving grinding results.Many people wonder about the best ways to grind lathe tools. One common question is, “How do I get a sharp edge?” The answer is simple: **Use a good grinding wheel and keep it cool!** Overheating can ruin your tool. Another question is, “What angle should I grind?” A general rule is to stick to **25 to 30 degrees** for most tools.

To improve your grinding experience, always clean your tool holder. It’s like cleaning your room; it makes everything better! And remember, **practice makes perfect**—so don’t be afraid to try!

| Question | Answer |

|---|---|

| What wheel should I use? | A high-quality grinding wheel! |

| How can I prevent overheating? | Use water for cooling! |

| What angle is best for grinding? | 25 to 30 degrees! |

Conclusion

In summary, lathe tool grinding is essential for shaping metal accurately. The foot brake on a lathe keeps you safe while working. Remember to maintain your tools for the best results. You can practice grinding at home to improve your skills. For more tips, check out guides online or ask a local expert. Happy crafting!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And The Metal Lathe Foot Brake:Sure! When you grind a lathe tool, you’re making it sharp so it can cut metal better. It’s like sharpening a pencil to write smoothly. The foot brake on a metal lathe helps you stop the machine quickly and safely. You press it with your foot, which makes it easy to use your hands for other things. Always be careful when using machines like this!

Sure! Please provide the section or question you’d like me to answer.

What Are The Best Practices For Sharpening Lathe Tools Using A Grinding Wheel?To sharpen lathe tools with a grinding wheel, start by wearing safety goggles. Secure the tool in a comfortable position. Hold the tool at a steady angle against the wheel. Move the tool back and forth gently to evenly sharpen it. Check the edge often to make sure it stays sharp and is not too hot.

How Does The Design Of A Metal Lathe Foot Brake Enhance Operator Safety During Machining Operations?The foot brake on a metal lathe helps keep you safe while working. When you step on the brake, it quickly stops the lathe from spinning. This prevents accidents and protects your fingers. The design is simple so you can use it easily, even when your hands are busy. With this feature, you can focus better on your work.

What Factors Should Be Considered When Selecting Grinding Wheels For Lathe Tool Sharpening?When picking grinding wheels for sharpening lathe tools, you should think about the material of the wheel. Some wheels work better on different metals. You also need to choose the right grit size; finer grit makes a smooth edge while coarser grit removes more material. The wheel’s bond type is important too; it holds the grit together. Finally, make sure the wheel fits your grinder properly.

How Can Improper Tool Grinding Affect The Performance And Lifespan Of Lathe Tools?Improper tool grinding can really hurt lathe tools. If the tool is not shaped right, it won’t cut well. This can make your work messy and hard to do. Also, a badly ground tool breaks faster, so you have to replace it often. In the end, this costs more time and money for you.

What Maintenance Techniques Can Be Employed To Ensure The Foot Brake On A Metal Lathe Functions Correctly And Safely?To keep the foot brake on a metal lathe working well, you should check it regularly. Make sure there are no dirt or dust on the brake parts. You can also oil the moving parts gently to help them work smoothly. If something seems broken, ask an adult to fix it right away. Always test the brake before you start using the lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And The Metal Lathe Foot Brake:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you grind a lathe tool, you’re making it sharp so it can cut metal better. It’s like sharpening a pencil to write smoothly. The foot brake on a metal lathe helps you stop the machine quickly and safely. You press it with your foot, which makes it easy to use your hands for other things. Always be careful when using machines like this!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the section or question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Sharpening Lathe Tools Using A Grinding Wheel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To sharpen lathe tools with a grinding wheel, start by wearing safety goggles. Secure the tool in a comfortable position. Hold the tool at a steady angle against the wheel. Move the tool back and forth gently to evenly sharpen it. Check the edge often to make sure it stays sharp and is not too hot.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Metal Lathe Foot Brake Enhance Operator Safety During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The foot brake on a metal lathe helps keep you safe while working. When you step on the brake, it quickly stops the lathe from spinning. This prevents accidents and protects your fingers. The design is simple so you can use it easily, even when your hands are busy. With this feature, you can focus better on your work.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting Grinding Wheels For Lathe Tool Sharpening?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking grinding wheels for sharpening lathe tools, you should think about the material of the wheel. Some wheels work better on different metals. You also need to choose the right grit size; finer grit makes a smooth edge while coarser grit removes more material. The wheel’s bond type is important too; it holds the grit together. Finally, make sure the wheel fits your grinder properly.”}},{“@type”: “Question”,”name”: “How Can Improper Tool Grinding Affect The Performance And Lifespan Of Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper tool grinding can really hurt lathe tools. If the tool is not shaped right, it won’t cut well. This can make your work messy and hard to do. Also, a badly ground tool breaks faster, so you have to replace it often. In the end, this costs more time and money for you.”}},{“@type”: “Question”,”name”: “What Maintenance Techniques Can Be Employed To Ensure The Foot Brake On A Metal Lathe Functions Correctly And Safely?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the foot brake on a metal lathe working well, you should check it regularly. Make sure there are no dirt or dust on the brake parts. You can also oil the moving parts gently to help them work smoothly. If something seems broken, ask an adult to fix it right away. Always test the brake before you start using the lathe.”}}]}