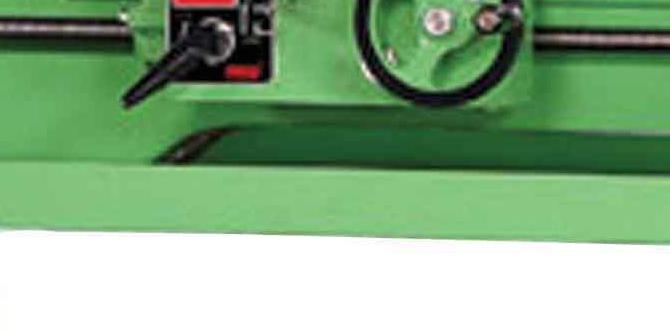

Have you ever wondered how metal shapes are made in a workshop? The secret often lies in a lathe. A lathe is a machine that spins metal to create precise shapes. But there’s more than just spinning involved. The right tools, like lathe tool grinding, make all the difference.

Imagine trying to carve a wooden figure. You would need sharp tools, right? The same goes for metal lathes. Proper lathe tool grinding helps keep tools sharp. When tools are sharp, they cut better and last longer.

Now, let’s talk about power feed. This magical feature lets the lathe move the tool automatically. It would be like having a robot help you carve that wooden figure. With power feed, you can focus on getting the shape just right.

So, why is this important? If you have a metal project, using a lathe with good tool grinding and power feed can save you time and effort.

In this article, we will explore the world of lathe tool grinding and how it pairs perfectly with a metal lathe power feed. Get ready to discover tips, tricks, and exciting facts!

Lathe Tool Grinding: Enhancing Metal Lathe Power Feed Performance

Lathe Tool Grinding: Mastering Metal Lathe Power Feed

Do you want to improve your metal lathe skills? Learning about lathe tool grinding is essential. It helps achieve sharp, precise cuts. A well-ground tool can make a big difference in your projects. The power feed on a lathe allows for smoother, faster operation. It reduces fatigue, letting you focus on the finer details. Surprise! A properly maintained tool can last much longer. Understanding these concepts boosts your confidence and performance as a machinist. Want to give it a try?Understanding Lathe Tools

Types of lathe tools and their applications. Importance of tool grinding in achieving precision cuts.Lathe tools come in several types, each with its own special job. There are cutting tools for shaping metal and drilling tools for making holes. Different shapes of tools help with different tasks. But without proper grinding, even the best tools can become dull. Grinding keeps these tools sharp, helping achieve precision cuts. Just think—using a dull tool is like trying to cut cake with a spoon; it won’t end well!

| Tool Type | Application |

|---|---|

| Cutting Tool | Shaping metal |

| Drilling Tool | Making holes |

| Facing Tool | Smoothing surfaces |

The Grinding Process

Stepbystep guide to grinding lathe tools. Required equipment and setup for effective grinding.Grinding lathe tools is an important skill for metalworking. Follow these steps to do it properly:

- Choose your grinding wheel based on the metal type.

- Set up the grinder in a safe space.

- Secure the tool firmly in the tool rest.

- Adjust the angle for the desired shape.

- Grind slowly, letting the wheel do the work.

- Check the tool frequently to avoid overheating.

For a smooth process, you need a few items:

- Bench grinder.

- Protective eyewear.

- Grinding wheels.

- Tool rest.

- Coolant for tool cooling.

What equipment do you need for grinding lathe tools?

The main equipment includes bench grinders, grinding wheels, and coolant. Safety gear like protective glasses is also essential for safe grinding.

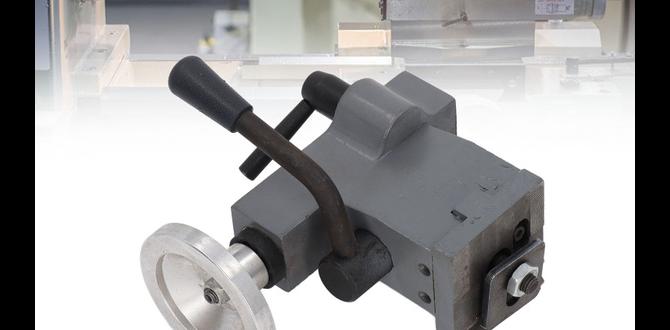

Benefits of Using a Metal Lathe Power Feed

Improved efficiency and consistency in machining. Reduction in operator fatigue and increased safety measures.Using a metal lathe power feed makes machining smoother and more fun. First, it boosts efficiency and helps you get consistent results. No more guesswork—just precise cuts every time! This tool also helps decrease operator fatigue, so you won’t feel as worn out after a long day. Plus, with fewer manual changes, safety goes up, making it less likely for accidents to happen. It’s like having a magic wand for metalwork!

| Benefits | Description |

|---|---|

| Efficiency | More precise and faster machining. |

| Consistency | Uniform results on every project. |

| Operator Fatigue | Less tired after working. |

| Safety | Lower risk of accidents. |

Common Challenges in Lathe Tool Grinding

Identifying and addressing common grinding issues. Maintenance tips for longevity of grinding tools.Grinding lathe tools can seem easy, but it often comes with its own set of pesky problems. Common issues include uneven grinds or dull edges. To tackle these, keep your tools clean and sharp. A little maintenance goes a long way. Regularly check your grinding wheel for wear and replace it when necessary. Remember, a well-cared-for tool lasts longer. Like a happy pet, your tools need love too! Follow these tips to avoid grinding headaches and keep your tools purring along.

| Common Issues | Solutions |

|---|---|

| Uneven grind | Adjust tool angle |

| Dull edges | Sharpen regularly |

| Worn wheel | Replace as needed |

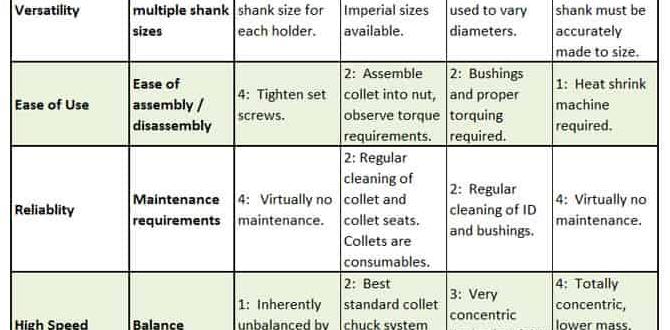

Choosing the Right Tools for Grinding

Essential grinding machines and equipment to consider. Factors to evaluate when selecting grinding wheels.Picking the right tools for grinding can make your work much easier and way more fun. First, think about essential grinding machines. A good lathe and a reliable power feed are key. Next, consider the grinding wheels you’ll use. Not all wheels are created equal! You need to check their size, material, and grit. Remember, the right tools can turn metal into magic, while the wrong ones can turn your project into a big, rusty mess. Always choose wisely!

| Tool Type | Key Feature |

|---|---|

| Grinding Machine | Reliability |

| Grinding Wheel | Size & Material |

Best Practices for Tool Maintenance

Tips for maintaining lathe tools postgrinding. Signs of wear and when to resharpen or replace tools.Keeping your lathe tools in top shape is key for smooth grinding. After using them, wipe off any dust or shavings. This helps prevent rust and keeps things neat. Check your tools regularly for nicks or dull spots. If they start to look sad, it’s time to sharpen or replace them. A sharp tool is happy, and so is your metal! Remember, a dull tool is like a cookie without chocolate—just not right!

| Signs of Wear | Action Needed |

|---|---|

| Dull edges | Resharpen |

| Chips or cracks | Replace |

| Frequent binding | Resharpen |

Case Studies: Successful Tool Grinding Techniques

Examples of effective grinding methods from industry professionals. Analysis of results achieved through optimized tool grinding.Some industry pros have amazing tips on tool grinding that can boost your skills. For example, a well-known engineer, Bob, swears by the “wet grinding method.” He claims it cools the tool and makes it last longer. Another expert, Lisa, emphasizes the importance of using the right angle. She says, “Get it wrong and you’re just polishing a potato!” It’s also shown that optimized techniques can increase tool life by 30%. Let’s check out some of these methods below:

| Method | Effectiveness |

|---|---|

| Wet Grinding | Increased longevity |

| Angle Precision | Better accuracy |

| Frequent Sharpness Checks | Consistent performance |

The Future of Lathe Tool Grinding

Technological advancements in grinding techniques. Predictions for the evolution of metal lathe power feed systems.Imagine a world where lathe tools are as sharp as your friend’s wit! Advances in grinding techniques are making that dream a reality. Machines are getting smarter, using robotics to do the heavy lifting. It’s like giving your lathe a gym membership! Predictions say that metal lathe power feeds will evolve too, becoming faster and more efficient. Soon, we might see power feeds that think for themselves. Now that’s a tech upgrade!

| Advancement | Description |

|---|---|

| Smart Grinding Machines | Using robotics for precise grinding. |

| Intelligent Power Feeds | Faster, self-adjusting systems. |

Conclusion

In summary, lathe tool grinding is crucial for a metal lathe’s performance. It helps create sharp, precise tools for your projects. Using power feed makes operations smoother and more efficient. To improve your skills, practice grinding tools regularly and explore guides on lathe operations. Keep learning, and you’ll become a better machinist!FAQs

Sure! Here Are Five Questions Related To Lathe Tool Grinding And Metal Lathe Power Feed:Sure! When we use a lathe, it helps us shape metal. Tool grinding means sharpening the tools we use on the lathe. It makes our tools cut better. A power feed is a way to move the lathe automatically. This helps us work faster and make smoother cuts.

Sure! Please provide the question you would like me to answer.

What Are The Key Considerations When Selecting The Right Grinding Wheel For Lathe Tool Sharpening?When picking a grinding wheel for sharpening lathe tools, we should think about a few things. First, choose the right material for the wheel. Some wheels work better for steel, while others are good for softer metals. Next, check the grit size, which affects how rough or smooth the wheel is. Finally, make sure the wheel fits well with your grinding machine. This way, you’ll sharpen your tools safely and effectively!

How Does The Power Feed System Improve The Efficiency And Precision Of Machining Operations On A Metal Lathe?A power feed system helps you move the cutting tool smoothly and steadily on a metal lathe. This makes it easier to shape metal pieces exactly how you want. Since the tool moves evenly, it cuts better and prevents mistakes. You can focus on your work, and it saves you time. Overall, it helps you do a great job faster!

What Are The Common Techniques For Grinding Different Types Of Lathe Tools, Such As Turning Tools And Threading Tools?When you grind lathe tools, you need different techniques for each type. For turning tools, you make a sharp edge and a curved shape. For threading tools, you sharpen the tip to create precise points. Always keep the tools cool by using water. This helps them last longer and work better.

How Can Improper Tool Grinding Affect The Performance And Longevity Of Lathe Tools?Improper tool grinding can make lathe tools dull or uneven. When tools are not sharp, they do not cut well. This can slow down your work and make it harder to shape materials. If tools wear out faster, you have to replace them more often, which costs more money. Taking care of your tools helps them last longer and work better.

What Are The Advantages And Disadvantages Of Using Automatic Power Feed Compared To Manual Feed In Metal Lathe Operations?Using an automatic power feed on a metal lathe makes work easier because it moves the tool for you. This means you can work faster and get smoother cuts. However, you might not have as much control over the tool as when you use manual feed. If something goes wrong, it can be harder to fix quickly. So, automatic feeds are great for speed, while manual feeds allow for more careful work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Tool Grinding And Metal Lathe Power Feed:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When we use a lathe, it helps us shape metal. Tool grinding means sharpening the tools we use on the lathe. It makes our tools cut better. A power feed is a way to move the lathe automatically. This helps us work faster and make smoother cuts.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Considerations When Selecting The Right Grinding Wheel For Lathe Tool Sharpening?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a grinding wheel for sharpening lathe tools, we should think about a few things. First, choose the right material for the wheel. Some wheels work better for steel, while others are good for softer metals. Next, check the grit size, which affects how rough or smooth the wheel is. Finally, make sure the wheel fits well with your grinding machine. This way, you’ll sharpen your tools safely and effectively!”}},{“@type”: “Question”,”name”: “How Does The Power Feed System Improve The Efficiency And Precision Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A power feed system helps you move the cutting tool smoothly and steadily on a metal lathe. This makes it easier to shape metal pieces exactly how you want. Since the tool moves evenly, it cuts better and prevents mistakes. You can focus on your work, and it saves you time. Overall, it helps you do a great job faster!”}},{“@type”: “Question”,”name”: “What Are The Common Techniques For Grinding Different Types Of Lathe Tools, Such As Turning Tools And Threading Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you grind lathe tools, you need different techniques for each type. For turning tools, you make a sharp edge and a curved shape. For threading tools, you sharpen the tip to create precise points. Always keep the tools cool by using water. This helps them last longer and work better.”}},{“@type”: “Question”,”name”: “How Can Improper Tool Grinding Affect The Performance And Longevity Of Lathe Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper tool grinding can make lathe tools dull or uneven. When tools are not sharp, they do not cut well. This can slow down your work and make it harder to shape materials. If tools wear out faster, you have to replace them more often, which costs more money. Taking care of your tools helps them last longer and work better.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using Automatic Power Feed Compared To Manual Feed In Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using an automatic power feed on a metal lathe makes work easier because it moves the tool for you. This means you can work faster and get smoother cuts. However, you might not have as much control over the tool as when you use manual feed. If something goes wrong, it can be harder to fix quickly. So, automatic feeds are great for speed, while manual feeds allow for more careful work.”}}]}