Have you ever watched a skilled craftsman at work? It’s mesmerizing to see how they turn raw metal into beautiful shapes. One vital part of this process is using a lathe tool. But did you know that to make a lathe tool work perfectly, it needs to be ground correctly? Lathe tool grinding is essential for getting a precise cut.

Let’s focus on the metal lathe quill. It’s the part that holds the tool in place. If it’s not set up right, your work can go wrong quickly. Imagine trying to carve a perfect circle, but your tool isn’t sharp enough. The result might be a messy, uneven shape.

In this article, we’ll explore how to grind lathe tools to keep that metal lathe quill performing at its best. You’ll learn tips, tricks, and even some secrets that can make a big difference in your projects. Ready to become a master in lathe tool grinding?

Lathe Tool Grinding: Mastering Metal Lathe Quill Techniques

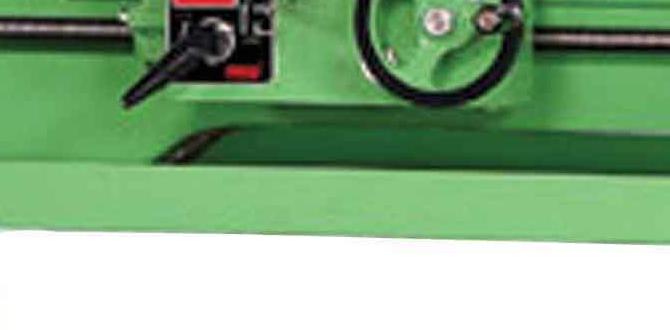

Understanding Lathe Tool Grinding and the Metal Lathe Quill

Lathe tool grinding shapes tools for precision tasks, ensuring they cut smoothly. A key part is the quill, which holds the tool in place. Did you know that a well-ground tool can make a huge difference? Inefficient tools can ruin your project. By learning proper grinding techniques, you ensure tools remain sharp and effective. This skill not only saves time but enhances the quality of your work. Discover how mastering these tools can sharpen your craft!Understanding the Metal Lathe Quill

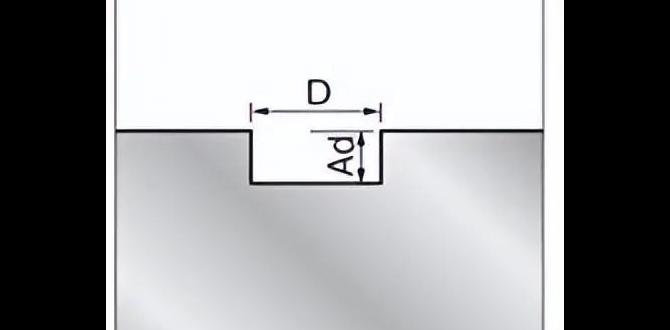

Definition and functionality of the lathe quill. Importance of the quill in precision machining.A metal lathe quill is a vital part of a metal lathe. It holds and moves tools like cutting bits. This tool holder helps shape and cut metal precisely. Without it, machining would be inaccurate and messy.

- It ensures stable tool support.

- It allows for quick adjustments.

- It helps produce high-quality work.

What does the lathe quill do?

The lathe quill holds tools securely and allows for movement. This lets the worker control the cutting process and produce precise designs.

Key Functions of the Quill

- Stability: Keeps tools steady while working.

- Adjustability: Can quickly change depth and angle.

- Efficiency: Works faster, saving time.

Essential Tools for Lathe Tool Grinding

List of necessary tools and equipment. Recommendations for quality tool brands.To grind lathe tools, you need some essential equipment. Think of it as assembling your superhero toolkit! First, you’ll want a good grinding wheel. This is where the magic happens. Next, grab a tool rest to keep everything steady. Don’t forget a coolant system to prevent overheating. For quality, brands like Norton and Baldor are reliable choices. Look at this handy table for a quick overview:

| Tool | Recommended Brands |

|---|---|

| Grinding Wheel | Norton, Baldor |

| Tool Rest | Grizzly, Jet |

| Coolant System | Milwaukee, Tormek |

With these tools in hand, you’ll be well on your way to becoming a lathe grinding master! And who knows, maybe you’ll impress your mom by making her the best paper towel holder ever!

Preparing for Tool Grinding

Steps to prepare your lathe tool for grinding. Safety measures to follow during preparation.Before starting to grind your lathe tool, make sure you have everything ready! First, always wear safety glasses to protect your eyes. Check that your work area is clean. You wouldn’t want to trip over stray tools—that’s a trip to the emergency room you don’t need. Make sure the lathe is turned off and unplugged before you touch anything. This is important!

| Steps to Prepare | Safety Measures |

|---|---|

| 1. Clean the tool. | Always wear goggles. |

| 2. Inspect for damage. | Secure loose clothing. |

| 3. Set grinding angles. | Use ear protection if needed. |

These simple steps can keep you safe. Remember, safety first means less adventure in the hospital!

Grinding Techniques for Lathe Tools

Detailed grinding methods for various tool shapes. Tips for achieving optimal sharpness and durability.To grind tools well, there are different methods for each shape. Round tools need a smooth curve on the edge. Flat tools require an even surface and sharp angles. For optimal sharpness, remember to:

- Choose the right wheel grit.

- Keep a steady hand while grinding.

- Check your angle often.

- Test tool sharpness with a soft material.

These tips help your tools last longer and work better.

What are the best tips for sharpening lathe tools?

Use a fine-grit wheel for a smooth edge. Keep the tool cool to avoid damage. Check the sharpness using soft wood. Regular grinding keeps tools effective and safe.

Common Mistakes in Tool Grinding

Identification of frequent errors and how to avoid them. Impact of poor grinding on tool performance.Tool grinding can seem easy, but many make mistakes. Common errors include:

- Not using the right angle.

- Grinding too fast or too slow.

- Skipping checks on tool sharpness.

Poor grinding harms tools. A dull tool does not cut well and can even break. This can lead to wasted time and materials. To avoid mistakes, always check your work. Take your time and ensure every cut is clean.

What are the common mistakes in tool grinding?

People often misuse angles and grind too quickly. These errors reduce tool sharpness and effectiveness. It leads to more frustration and less productivity.

How can I improve my tool grinding?

- Practice regularly.

- Follow proper guidelines.

- Always check your settings.

Maintenance of Lathe Tools

Best practices for maintaining sharpened tools. Signs that indicate tool sharpness needs evaluation.Keeping lathe tools sharp is key for good work. Here are some best practices for maintenance:

- Regularly clean tools after use.

- Store tools in a dry place to avoid rust.

- Inspect tools for chips or cracks.

Signs that your tool may need sharpening include:

- Difficulty cutting through materials.

- Rough edges on finished pieces.

- Increased noise during use.

Stay sharp for better results!

How can you tell if your lathe tool is dull?

You can tell if your lathe tool is dull by noticing trouble during cutting, a rough finish on materials, or if it makes unusual sounds.Advanced Grinding Strategies

Techniques for specialized tool grinding. Adaptive grinding methods for diverse materials.Grabbing the right grinding technique makes a world of difference. For specialized tool grinding, using precision methods can boost accuracy. Think of it like shaving a tiny amount off your sandwich, just enough for a perfect fit! Adaptive grinding methods work well on various materials too. Whether you’re tackling metal or plastic, adjusting the grind speed is key. It’s like dancing with your materials—twist and turn to get the best out of every cut!

| Material Type | Recommended Grinding Speed |

|---|---|

| Metal | Medium speed |

| Plastic | Low speed |

| Wood | High speed |

Troubleshooting Grinding Issues

Common grinding problems and their solutions. How to effectively diagnose grinding challenges.Grinding issues can be frustrating. Let’s look at common problems and how to solve them. Some issues include uneven finishes, excessive noise, and overheating. Diagnosing these is key for success. Check the grinding wheel. Make sure it’s clean and suitable for the metal. Pay attention to the speed settings. Here’s a quick guide:

- Uneven Finish: Replace the grinding wheel.

- Excess Noise: Check for a secure wheel fixture.

- Overheating: Reduce speed and apply coolant.

Actively observe the grinding process. This helps you catch problems early and keep everything running smoothly.

What are common grinding problems?

Common issues are uneven finishes, loud noises, and overheating. Each problem has a specific solution. You can improve your grinding by quickly fixing these problems.

Future Trends in Lathe Tool Grinding

Innovations in grinding technology. How modern advancements can enhance grinding efficiency.Many exciting innovations are coming to lathe tool grinding. New machines use advanced technology to make grinding faster and easier. These modern tools can enhance grinding efficiency significantly. Some advancements include:

- Smart sensors that notify operators of problems.

- Software that helps plan the grinding process better.

- Faster grinding wheels that save time.

All these upgrades make grinding tools better and help finish projects quickly. With the right tech, even beginners can achieve professional results.

What innovations are changing lathe tool grinding?

Innovation in lathe tool grinding includes smart technology, faster machines, and improved design. These changes work to save time and improve quality.

Conclusion

In conclusion, grinding lathe tools for a metal lathe quill is essential for precision work. You sharpen tools to cut better and last longer. It’s a valuable skill for anyone interested in machining. We encourage you to practice this technique and explore more resources to improve your knowledge. Happy crafting, and keep honing your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Quills:Sure! A lathe tool is a tool used on a machine called a lathe to shape metal. To make a lathe tool work well, we need to grind it. Grinding means sharpening the tool to make it cut better. A metal lathe quill holds the tool in place while we work. It’s important to set it up correctly for the best results.

Sure! Please provide the question you want me to answer.

What Are The Different Types Of Lathe Tools That Can Be Ground Using A Tool Grinder, And What Specific Angles Should Be Used For Each Type?You can use a tool grinder to make different lathe tools. For a roughing tool, use a 45-degree angle. A finishing tool should have a 30-degree angle. For a cut-off tool, you need a 60-degree angle. Each angle helps the tool cut better!

How Do You Properly Set Up A Tool Grinding Machine For Sharpening Lathe Cutting Tools?To set up a tool grinding machine, first, make sure it’s clean and ready to use. Next, adjust the grinding wheel so it’s the right distance from the tool rest. Then, secure the lathe cutting tool in place, making sure it’s straight. Finally, turn on the machine and carefully grind the tool, checking often to ensure you’re sharpening it evenly. Always wear safety glasses to protect your eyes!

What Materials Are Commonly Used For Lathe Tool Bits, And How Does Their Composition Affect The Grinding Process?Lathe tool bits are often made from high-speed steel, carbide, or cobalt. High-speed steel is tough and easy to grind. Carbide is very hard and lasts longer but is harder to shape. Cobalt helps high-speed steel resist heat. Each material affects how we grind and sharpen the tools.

What Safety Precautions Should Be Taken When Grinding Lathe Tools On A Bench Grinder Or Tool Grinder?When using a bench grinder or tool grinder, always wear safety goggles to protect your eyes. Keep your hair tied back and wear a dust mask to avoid breathing in dust. Make sure your clothes are fitted and not loose to prevent them from getting caught. Stand to the side when starting the grinder, and never reach near the spinning wheel. Finally, keep your hands away from the grinding wheel to avoid getting hurt.

How Does The Design Of The Lathe Quill Influence The Performance And Precision Of Machining Operations?The lathe quill is a part that holds tools in place. Its design affects how well the tool works. A strong quill keeps the tool steady, which helps make precise cuts. If the quill is wobbly, it can create mistakes in the shape of the workpiece. So, a good quill helps you make better and more accurate pieces.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Quills:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe tool is a tool used on a machine called a lathe to shape metal. To make a lathe tool work well, we need to grind it. Grinding means sharpening the tool to make it cut better. A metal lathe quill holds the tool in place while we work. It’s important to set it up correctly for the best results.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Lathe Tools That Can Be Ground Using A Tool Grinder, And What Specific Angles Should Be Used For Each Type?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a tool grinder to make different lathe tools. For a roughing tool, use a 45-degree angle. A finishing tool should have a 30-degree angle. For a cut-off tool, you need a 60-degree angle. Each angle helps the tool cut better!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Tool Grinding Machine For Sharpening Lathe Cutting Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a tool grinding machine, first, make sure it’s clean and ready to use. Next, adjust the grinding wheel so it’s the right distance from the tool rest. Then, secure the lathe cutting tool in place, making sure it’s straight. Finally, turn on the machine and carefully grind the tool, checking often to ensure you’re sharpening it evenly. Always wear safety glasses to protect your eyes!”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Lathe Tool Bits, And How Does Their Composition Affect The Grinding Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe tool bits are often made from high-speed steel, carbide, or cobalt. High-speed steel is tough and easy to grind. Carbide is very hard and lasts longer but is harder to shape. Cobalt helps high-speed steel resist heat. Each material affects how we grind and sharpen the tools.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Grinding Lathe Tools On A Bench Grinder Or Tool Grinder?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a bench grinder or tool grinder, always wear safety goggles to protect your eyes. Keep your hair tied back and wear a dust mask to avoid breathing in dust. Make sure your clothes are fitted and not loose to prevent them from getting caught. Stand to the side when starting the grinder, and never reach near the spinning wheel. Finally, keep your hands away from the grinding wheel to avoid getting hurt.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Lathe Quill Influence The Performance And Precision Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe quill is a part that holds tools in place. Its design affects how well the tool works. A strong quill keeps the tool steady, which helps make precise cuts. If the quill is wobbly, it can create mistakes in the shape of the workpiece. So, a good quill helps you make better and more accurate pieces.”}}]}