Have you ever wondered how metal parts are shaped and refined? One crucial process involves lathe tool grinding. This technique helps create sharp and precise tools for cutting metal. But what if you want to thread metal? That’s where the metal lathe threading dial comes into play.

Imagine you have a piece of metal. You want it to fit perfectly with another piece. Using a lathe, you can achieve that neat, threaded design. With the threading dial, you can make sure every groove is just right. It’s like drawing a straight line, but with tools that can slice through metal!

Here’s an interesting fact: Did you know that skilled machinists can create intricate designs? They use lathe tool grinding to keep their tools sharp. A sharp tool makes all the difference. It cuts cleaner and faster, saving time and effort.

So, whether you’re a beginner or just curious, understanding these tools can open up a new world. Ready to dive into the fascinating process of lathe tool grinding and threading? Let’s explore together!

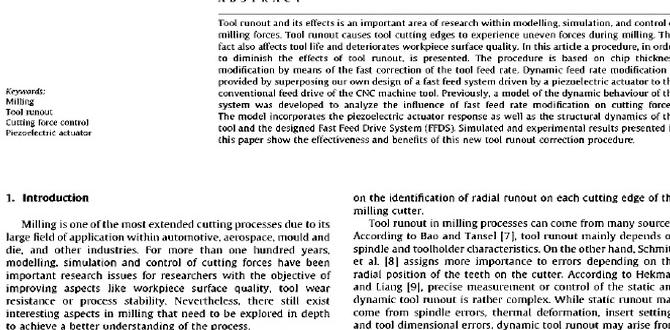

Lathe Tool Grinding: Mastering Metal Lathe Threading Dial Techniques

Lathe Tool Grinding: Mastering Metal Lathe Threading Dial

Discover how lathe tool grinding transforms metalworking. It sharpens tools, ensuring clean cuts during threading. Using a threading dial helps create precise threads on metals. Imagine spinning a piece of wood, seeing it transform into something beautiful! Did you know having a sharp tool can make your project easier and faster? Proper technique not only enhances accuracy but improves safety, too. Mastering these skills opens the door to endless creative possibilities in crafting.Understanding Lathe Tools

Types of lathe tools and their applications. Importance of tool grinding in metalworking.Lathe tools come in various types, each designed for special tasks. Turning tools help shape the metal, while facing tools cut flat surfaces. There are also bore tools for making holes and parting tools for cutting shapes off. Proper tool grinding is key in metalworking. Sharp tools make cleaner cuts and last longer. Just like a chef needs sharp knives, a machinist needs sharp lathe tools to create magic in metal!

| Type of Tool | Application |

|---|---|

| Turning Tool | Shaping metal |

| Facing Tool | Creating flat surfaces |

| Bore Tool | Drilling holes |

| Parting Tool | Cuts off shapes |

Basics of Lathe Tool Grinding

Essential grinding techniques for smooth operation. Equipment and materials needed for grinding.Grinding tools is key for smooth and safe lathe operation. Start with a steady hand and sharp eyes. Here are some essential techniques:

- Use the right angle for grinding.

- Keep the tool cool to prevent damage.

- Check for a smooth finish often.

For grinding, you will need:

- A quality grinder.

- Grinding wheels.

- Safety goggles.

- Proper clamps.

These items help you get the job done right, ensuring your lathe tools work well and last longer.

What are the best practices for lathe tool grinding?

Best practices include using a consistent angle, keeping tools cool, and checking the finish frequently.

How can I improve my grinding skills?

Practice regularly and observe other skilled workers. Watching online tutorials can also help enhance your technique.

Step-by-Step Guide to Grinding Lathe Tools

Preparing the lathe tool for grinding. Detailed grinding process with tips for accuracy.Start by getting your lathe tool ready for grinding. Clean it to remove dirt and rust. Check for any damage that may affect the grinding. Secure the tool tightly in a holder. This keeps it stable during the process.

For an accurate grind, follow these steps:

- Adjust the grindstone angle carefully.

- Use light pressure while grinding.

- Move the tool steadily across the stone.

- Take breaks to cool the tool.

These tips will help you create sharp and effective tools!

How do you grind a lathe tool properly?

To grind a lathe tool properly, clean it well and check for damage. Adjust the grindstone angle, apply light pressure while moving the tool steadily. This ensures a sharp and effective tool.

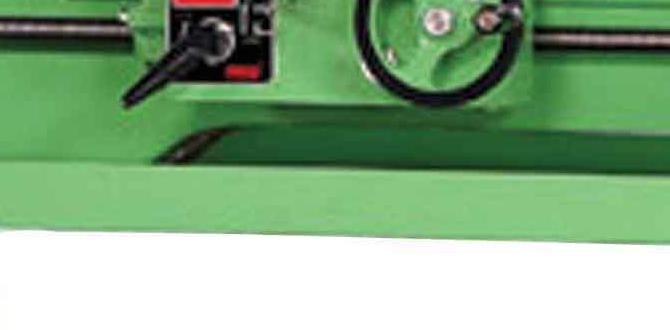

Adjusting the Lathe Threading Dial

Importance of proper dial adjustment for precision threading. Stepbystep instructions for dial calibration.Getting your threading dial set right is like putting on your favorite sneakers. It makes everything smoother! Proper adjustments ensure every thread is spot-on, leading to better fits. Follow these easy steps to calibrate your dial:

| Step | Action |

|---|---|

| 1 | Loosen the lock screw on the dial. |

| 2 | Turn the dial until it reads zero. |

| 3 | Secure the lock screw back. |

Remember, a tiny adjustment can make a big difference. It’s not rocket science, but it helps if you pay attention. Happy threading!

Common Mistakes in Lathe Tool Grinding

Recurring errors to avoid during the grinding process. How to troubleshoot grinding problems.Many people make mistakes while grinding lathe tools. Common errors could ruin your work. Not checking the tool’s angle is a big one. If you’ve set the angle wrong, cutting will be hard. Poor sharpening can lead to dull tools, which cause rough cut edges. Always inspect your tool before use.

If you run into issues, here are some quick fixes:

- Check the angle and realign if needed.

- Sharpen tools correctly to prevent dullness.

- Use a consistent speed while grinding.

Taking time to avoid these errors will improve your results. Remember, practice makes perfect!

What are some common issues in lathe tool grinding?

Common issues include dull tools, incorrect angles, and inconsistent speeds during the grinding process.

How can I solve grinding problems?

- Always check your tool angles.

- Keep your tools sharp.

- Maintain steady speed while grinding.

Maintenance Tips for Metal Lathe Tools

Routine maintenance practices to extend tool life. Signs that indicate when to sharpen or replace tools.Taking care of your metal lathe tools is like giving them a spa day. Regular maintenance helps them last longer and work better. Check your tools for dull edges. If they look like they’ve been through a cheese grater, it’s time to sharpen or replace them. Keeping your lathe clean is essential too; dirt won’t help it shine! Here are some tips.

| Maintenance Practice | How Often | Signs to Replace |

|---|---|---|

| Clean the lathe | After each use | Rough finish on workpiece |

| Inspect tools | Weekly | Visible damage or chips |

| Sharpen cutting edges | Monthly | Working harder than usual |

Remember, a well-cared lathe is a happy lathe—one that won’t leave you hanging during your metal projects. Keep an eye out for those signs, and your tools will thank you!

Advanced Techniques for Professional Results

Techniques for enhancing cutting edge geometry. Utilizing specialized grinding machines for efficiency.Mastering the art of metal turning requires advanced techniques. Enhancing cutting edge geometry can lead to sharper tools. A sharp tool cuts better and lasts longer. Use specialized grinding machines for more efficiency. These machines ensure precise angles, resulting in cleaner cuts. Here are some essential tips:

- Adjust the angle of the grind for better cutting.

- Use coolant to keep the tool cool while grinding.

- Regularly check the tool for wear and tear.

With practice, these techniques can elevate your work to a professional level.

How do you enhance cutting edge geometry?

To enhance cutting edge geometry, adjust the grinding angle, keep tools sharp, and regularly inspect for wear.

What grinding machines help with efficiency?

Specialized grinding machines include surface grinders and tool grinders that ensure precise cuts and angles.

Resources and Tools for Further Learning

Recommended books, websites, and tutorials. Community forums and expert groups for metal lathe enthusiasts.Learning more about metal lathes can be fun! You can check out cool books like “Lathe Work for Beginners” or “The Metalworker’s Bible” for some great tips. Websites like YouTube offer many tutorials that help you grind tools and use the threading dial effectively. Don’t forget to join community forums like “Lathe Lovers” or “Metalworking Maniacs.” Here, you can ask questions and share your funny lathe mishaps!

| Resource Type | Recommended Resources |

|---|---|

| Books | “Lathe Work for Beginners”, “The Metalworker’s Bible” |

| Websites | YouTube Tutorials |

| Forums | “Lathe Lovers”, “Metalworking Maniacs” |

Conclusion

In summary, understanding lathe tool grinding and metal lathe threading is crucial for successful projects. You can improve your skills with practice and the right tools. Remember to use the threading dial for precise results. If you want to learn more, check out videos or guides about lathe techniques. Start experimenting, and take your machining skills to the next level!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Threading Dials:Sure! Here are some answers about lathe tool grinding and threading dials. 1. **What is lathe tool grinding?** Lathe tool grinding is sharpening tools used on a machine called a lathe. This helps the tools cut better. 2. **Why do we grind lathe tools?** We grind lathe tools to make them sharp. Sharper tools cut metal more easily and smoothly. 3. **How often should you grind your tools?** You should grind your tools whenever they become dull. This keeps your work nice and neat. 4. **What is a threading dial?** A threading dial helps you make threads on metal. It tells you when to start and stop cutting threads. 5. **How do you use a threading dial?** To use a threading dial, you line it up with a mark. Then, you turn the lathe to create threads.

Sure! Please provide me with the question you’d like me to answer.

What Are The Key Factors To Consider When Grinding A Lathe Tool To Ensure Optimal Cutting Performance?When grinding a lathe tool, focus on the tool’s shape and angle. You want the right edge that can cut well. Keep the tool cool while grinding to prevent damage. Don’t forget to check for smoothness on the cutting edge. Finally, use the right grindstone for the best results.

How Does The Threading Dial On A Metal Lathe Assist In Creating Precise Threads, And How Do You Properly Use It?The threading dial on a metal lathe helps you make precise threads by showing where to start cutting. It has numbers that count the turns of the screw. When you see the right number, you can begin to cut the thread. To use it properly, turn the lathe on, watch the numbers, and line up the tool when it’s at the right spot. This way, your threads will be even and neat!

What Are The Different Types Of Lathe Tools, And How Does Each Type Affect The Tool Grinding Process?There are several types of lathe tools, like roughing tools, finishing tools, and parting tools. Roughing tools remove a lot of material quickly. Finishing tools smooth the surface for a nice finish. Parting tools help cut pieces off. Each tool shapes the edges differently, so we need to grind them in specific ways. For example, we might use a different angle when grinding a finishing tool for better results.

What Common Mistakes Should Be Avoided When Grinding Lathe Tools To Maintain Their Sharpness And Longevity?To keep your lathe tools sharp and lasting longer, avoid these mistakes. First, don’t press too hard when grinding; this can ruin the tool. Second, make sure to keep the tool cool. If it gets too hot, it can lose its edge. Finally, check the angle you are grinding; the right angle helps cut better.

How Can One Determine The Correct Angle For Grinding Different Lathe Tools For Various Materials And Applications?To find the right angle for grinding lathe tools, you can follow a few steps. First, look at the material you are using. Softer materials need a smaller angle, while harder ones need a bigger angle. Check guides or recommendations for specific tools and materials. You can also practice and adjust the angles based on how well the tool cuts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers about lathe tool grinding and threading dials. 1. **What is lathe tool grinding?** Lathe tool grinding is sharpening tools used on a machine called a lathe. This helps the tools cut better. 2. **Why do we grind lathe tools?** We grind lathe tools to make them sharp. Sharper tools cut metal more easily and smoothly. 3. **How often should you grind your tools?** You should grind your tools whenever they become dull. This keeps your work nice and neat. 4. **What is a threading dial?** A threading dial helps you make threads on metal. It tells you when to start and stop cutting threads. 5. **How do you use a threading dial?** To use a threading dial, you line it up with a mark. Then, you turn the lathe to create threads.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Grinding A Lathe Tool To Ensure Optimal Cutting Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When grinding a lathe tool, focus on the tool’s shape and angle. You want the right edge that can cut well. Keep the tool cool while grinding to prevent damage. Don’t forget to check for smoothness on the cutting edge. Finally, use the right grindstone for the best results.”}},{“@type”: “Question”,”name”: “How Does The Threading Dial On A Metal Lathe Assist In Creating Precise Threads, And How Do You Properly Use It?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial on a metal lathe helps you make precise threads by showing where to start cutting. It has numbers that count the turns of the screw. When you see the right number, you can begin to cut the thread. To use it properly, turn the lathe on, watch the numbers, and line up the tool when it’s at the right spot. This way, your threads will be even and neat!”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Lathe Tools, And How Does Each Type Affect The Tool Grinding Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are several types of lathe tools, like roughing tools, finishing tools, and parting tools. Roughing tools remove a lot of material quickly. Finishing tools smooth the surface for a nice finish. Parting tools help cut pieces off. Each tool shapes the edges differently, so we need to grind them in specific ways. For example, we might use a different angle when grinding a finishing tool for better results.”}},{“@type”: “Question”,”name”: “What Common Mistakes Should Be Avoided When Grinding Lathe Tools To Maintain Their Sharpness And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your lathe tools sharp and lasting longer, avoid these mistakes. First, don’t press too hard when grinding; this can ruin the tool. Second, make sure to keep the tool cool. If it gets too hot, it can lose its edge. Finally, check the angle you are grinding; the right angle helps cut better.”}},{“@type”: “Question”,”name”: “How Can One Determine The Correct Angle For Grinding Different Lathe Tools For Various Materials And Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right angle for grinding lathe tools, you can follow a few steps. First, look at the material you are using. Softer materials need a smaller angle, while harder ones need a bigger angle. Check guides or recommendations for specific tools and materials. You can also practice and adjust the angles based on how well the tool cuts.”}}]}