Have you ever watched a craftsman shape metal into something amazing? It’s fascinating, isn’t it? One essential part of this process is the lathe tool. Using a metal lathe can transform ideas into real objects. But what happens when a tool needs sharpening? That’s where lathe tool grinding comes in.

Many people overlook the importance of this step. However, a well-ground tool makes a big difference in how smooth and accurate cutting will be. You might wonder how to set up everything correctly. A clear wiring diagram for your metal lathe can help you understand the setup better.

Did you know that a simple adjustment can save you tons of time? A good understanding of both grinding and wiring can turn any project from “just okay” to amazing. Join us as we explore the ins and outs of lathe tool grinding and the wiring diagrams that make your metal lathe work like a charm!

Lathe Tool Grinding: Metal Lathe Wiring Diagram Explained

Lathe Tool Grinding and Metal Lathe Wiring Diagram

Lathe tool grinding is essential for creating sharp, precise tools for machining. Understanding how to grind these tools can improve your projects significantly. Did you know that the right angle on a cutting tool affects its performance? Additionally, the wiring diagram for a metal lathe helps you connect components correctly. Knowing the connections ensures your lathe runs smoothly. With this knowledge, you can enhance your skills and achieve better results in your metalworking tasks.Understanding Lathe Tool Grinding

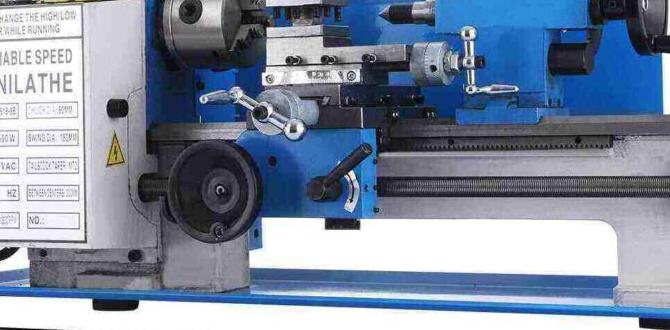

Definition and importance of lathe tool grinding. Types of lathe tools and their grinding requirements.Lathe tool grinding is the process of sharpening and shaping tools used in a lathe machine. It makes tools work better and last longer. Without proper grinding, tools can become dull and messy, leading to bad results. Different lathe tools need different grinding methods. For example, turning tools require specific angles, while bore tools need a different shape. Understanding these needs helps ensure quality work.

What is the importance of lathe tool grinding?

It keeps tools sharp for better performance and smoother cuts.

Common types of lathe tools and their grinding needs:

- Turning Tools – Need pointed tips and clean edges.

- Boring Tools – Require flat surfaces for precise drilling.

- Parting Tools – Must be sharp on the sides to cut cleanly.

Benefits of Proper Lathe Tool Grinding

Enhanced tool performance and lifespan. Improved precision in metalworking tasks.Grinding lathe tools properly can work wonders for your projects. First, it boosts *tool performance* and extends their *lifespan*. Imagine a superhero tool that doesn’t wear out after a few uses! Yikes! Improved precision is another great benefit. With sharp tools, you get cleaner cuts and more accurate shapes. Your metalworking tasks will be easier, making you look like a genius. Remember, a happy lathe tool means happy metal!

| Benefit | Description |

|---|---|

| Enhanced Performance | Sharp tools cut better, making your work smoother. |

| Longer Lifespan | Well-ground tools last longer, saving you time and money. |

| Improved Precision | Accurate tools lead to cleaner cuts and better projects. |

Step-by-Step Procedure for Grinding Lathe Tools

Preparing the lathe tools for grinding. Detailed grinding process for various tool shapes.First, prepare the lathe tools. Make sure they are clean and free from rust. Use a soft cloth to wipe them down. Then, gather your grinding equipment. It’s important to have a sturdy grinding wheel that fits your tool shape.

Next, follow these steps for grinding:

- Set the tool in the grinding position.

- Turn on the grinding wheel.

- Carefully apply the tool’s edge to the wheel.

- Keep the tool moving to avoid overheating.

- Check the angle for different shapes like flat, round, or pointed.

Grinding tools takes practice, but it’s rewarding. A sharp tool cuts better. Always wear safety gear!

How do you know the right angle for grinding?

The right angle depends on the tool’s shape. For example, a flat tool needs a 45-degree angle, while a pointed tool works well at a 30-degree angle. Adjust the angle for best results.

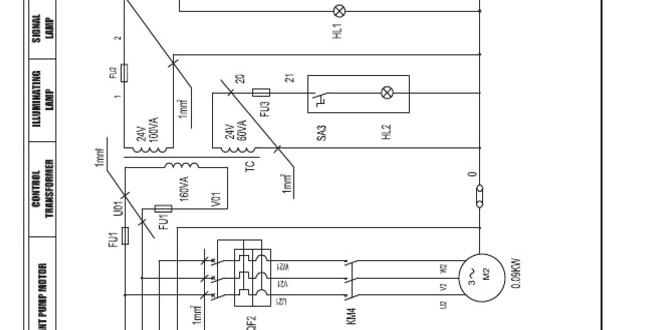

Understanding Metal Lathe Wiring Diagrams

Explanation of wiring diagrams and their purpose. Key components in a metal lathe’s wiring system.Wiring diagrams show how to connect parts of a metal lathe. They act like a treasure map, revealing where each wire goes. Understanding these diagrams is key to keeping your lathe running smoothly. Key components include the motor, control panel, and power supply. Each part plays a role in making your lathe work. Without the right connections, your lathe could throw a tantrum. Here’s a quick look at some essential parts:

| Component | Function |

|---|---|

| Motor | Powers the lathe |

| Control Panel | Manages settings |

| Power Supply | Provides electricity |

With a clear diagram, anyone can wire a lathe without risking a hair dryer explosion. So grab your tools and let’s get wiring!

Interpreting Electrical Schematics for Metal Lathes

Breakdown of common symbols and terminology found in diagrams. Stepbystep guide to reading a metal lathe wiring diagram.Reading electrical schematics can be like cracking a secret code. Most diagrams use symbols to show connections and parts. For example, a circle often means a wire connection, while a line can indicate power flow. Here’s a simple guide to get started:

| Symbol | Meaning |

|---|---|

| ⚫ | Connection Point |

| ➡️ | Power Flow |

| 🔋 | Battery |

First, look for the power source at the top. Next, follow the lines like a treasure map, making sure to note any switches or devices along the way. It’s like playing hide-and-seek, only with wires instead of friends!

Common Wiring Problems in Metal Lathes and Solutions

Identification of typical electrical issues. Troubleshooting techniques and repair tips.Metal lathes can have electrical hiccups like a cat stuck in a tree. Common problems include blown fuses, faulty switches, and tangled wires. To troubleshoot, check the power supply first—sometimes it’s as simple as flipping a circuit breaker. Tighten loose connections, too; they can cause sparks that rival a Fourth of July show! If issues persist, consult your wiring diagram for precise solutions. Remember, even machines need a bit of TLC.

| Problem | Solution |

|---|---|

| Blown Fuse | Check the circuit breaker |

| Faulty Switch | Replace the switch |

| Tangled Wires | Organize and secure wiring |

Maintenance Tips for Lathe Tools and Wiring Systems

Best practices for tool maintenance and care. Electrical maintenance to prevent wiring failures.Keeping your lathe tools and wiring systems in good shape is important for smooth work. Regular cleaning helps avoid dirt buildup. Always check tools for wear. Sharpen them regularly to maintain cutting quality. For electrical maintenance, inspect wires often. Look for any signs of wear or damage.

- Use proper lubrication for tools.

- Avoid overloading electrical circuits.

- Keep wiring connected securely.

- Replace damaged cords immediately.

How can I maintain my lathe tools effectively?

To maintain your lathe tools effectively, regularly clean and sharpen them. This boosts performance and increases their lifespan. Check them for damage and replace if needed. Proper care prevents costly repairs.

Resources for Further Learning on Lathe Tool Grinding and Wiring

Recommended books and online courses. Relevant forums and communities for hobbyists and professionals.If you’re eager to learn more about lathe tool grinding, check out these helpful resources. They can boost your skills and knowledge.

- Books: Look for titles like “Metalworking: A Guide to Tools,” which can teach you the basics.

- Online Courses: Websites like Udemy or Coursera often have classes on lathe tool techniques.

- Forums: Visit communities like Reddit’s r/metalworking for tips and support from others.

- Professional Groups: Join organizations such as the American Society of Machinists for expert advice.

What are good resources for learning about lathe tool grinding?

Many options help you learn better. Books and online courses are great starts. You can also join forums or professional groups to connect with others.

Conclusion

In summary, understanding a lathe tool grinding metal lathe wiring diagram is vital for safe and effective use. You can create precise cuts and shapes when you know how the machine operates. Explore the steps for proper wiring and tool maintenance. Dive deeper into lathe fundamentals, so you feel confident in your skills and projects. Let’s get grinding!FAQs

Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Wiring Diagrams:Sure! When you grind lathe tools, you make them sharp so they can cut metal better. We use a special machine called a grinder for this. Metal lathes are machines that shape metal into different forms. They have wiring diagrams, which are like maps, showing how to connect the wires correctly. This helps the machine work safely and properly.

Sure! Please go ahead and ask your question, and I’ll be happy to answer it for you.

What Are The Fundamental Principles Of Lathe Tool Grinding, And How Do They Affect The Performance Of The Tool?Lathe tool grinding is about shaping tools to cut metal better. First, we sharpen the edges to make them pointy. Next, we create the right angles so the tool can cut smoothly. A well-ground tool lasts longer and works faster. If we don’t grind it correctly, it can break or cut poorly.

Can You Explain The Common Types Of Lathe Tools And Their Specific Grinding Angles?Sure! There are different types of lathe tools we use to shape things. For example, we have cutting tools, which help us slice wood or metal. The grinding angle for these tools is usually around 60 degrees. There are also finishing tools, with a smoother angle of about 30 degrees. Each angle helps us get the best shape for our projects!

What Should Be Included In A Wiring Diagram For A Metal Lathe To Ensure Safe And Efficient Operation?A wiring diagram for a metal lathe should show the power source and all the wires. Include labels for every part, like the motor and switches. You should mark important safety features, like circuit breakers, too. Clear colors help us see where each wire goes. This makes it safe and easy to use the lathe.

How Do You Troubleshoot Common Wiring Issues In A Metal Lathe’S Electrical System?To fix wiring issues in a metal lathe, first, make sure it is unplugged. Check the wires for any breaks or loose connections. Look for signs of burnt or damaged wires. If you find any problems, you can replace or reconnect them. Finally, plug it back in and see if it works!

What Safety Precautions Should Be Taken During The Lathe Tool Grinding Process And While Working With Lathe Wiring?When grinding tools on a lathe, wear safety goggles to protect your eyes from sparks. Keep your hair tied back and wear tight clothing to avoid getting caught in the machine. Make sure the area is clean and there are no tools or materials lying around. When working with lathe wiring, always unplug the machine before touching any wires. This helps prevent electric shocks, which can be very dangerous.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Tool Grinding And Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you grind lathe tools, you make them sharp so they can cut metal better. We use a special machine called a grinder for this. Metal lathes are machines that shape metal into different forms. They have wiring diagrams, which are like maps, showing how to connect the wires correctly. This helps the machine work safely and properly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll be happy to answer it for you.”}},{“@type”: “Question”,”name”: “What Are The Fundamental Principles Of Lathe Tool Grinding, And How Do They Affect The Performance Of The Tool?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe tool grinding is about shaping tools to cut metal better. First, we sharpen the edges to make them pointy. Next, we create the right angles so the tool can cut smoothly. A well-ground tool lasts longer and works faster. If we don’t grind it correctly, it can break or cut poorly.”}},{“@type”: “Question”,”name”: “Can You Explain The Common Types Of Lathe Tools And Their Specific Grinding Angles?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! There are different types of lathe tools we use to shape things. For example, we have cutting tools, which help us slice wood or metal. The grinding angle for these tools is usually around 60 degrees. There are also finishing tools, with a smoother angle of about 30 degrees. Each angle helps us get the best shape for our projects!”}},{“@type”: “Question”,”name”: “What Should Be Included In A Wiring Diagram For A Metal Lathe To Ensure Safe And Efficient Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A wiring diagram for a metal lathe should show the power source and all the wires. Include labels for every part, like the motor and switches. You should mark important safety features, like circuit breakers, too. Clear colors help us see where each wire goes. This makes it safe and easy to use the lathe.”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot Common Wiring Issues In A Metal Lathe’S Electrical System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix wiring issues in a metal lathe, first, make sure it is unplugged. Check the wires for any breaks or loose connections. Look for signs of burnt or damaged wires. If you find any problems, you can replace or reconnect them. Finally, plug it back in and see if it works!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken During The Lathe Tool Grinding Process And While Working With Lathe Wiring?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When grinding tools on a lathe, wear safety goggles to protect your eyes from sparks. Keep your hair tied back and wear tight clothing to avoid getting caught in the machine. Make sure the area is clean and there are no tools or materials lying around. When working with lathe wiring, always unplug the machine before touching any wires. This helps prevent electric shocks, which can be very dangerous.”}}]}