Have you ever wondered how metal parts are made? It’s fascinating to think about how craftsmen shape metal into useful items. One important tool in this process is the lathe. A lathe can create everything from toys to car parts.

Many people enjoy working with metal. They love crafting and building things. A lathe training course can help you learn this skill. You can explore how to operate a metal lathe bed efficiently.

Imagine taking a block of metal and turning it into something amazing. You can learn how to do that! With the right training, you can master the art of using a lathe. It’s like learning to ride a bike. At first, it seems tricky, but practice makes it easier.

Did you know that lathes have been used for thousands of years? They played a big role in the Industrial Revolution. Today, they are still essential in many shops and factories. Your journey into metalworking could start with lathe training. Ready to turn your ideas into reality?

Lathe Training Course: Mastering Metal Lathe Bed Skills

Metal lathe beds are essential for any lathe training course. They provide the support needed for smooth and precise machining. Participants learn how to operate the lathe effectively and safely. Did you know that the right technique can make a huge difference in your projects? Imagine creating perfectly shaped parts just by mastering the lathe! With hands-on training, you’ll discover tips and tricks to enhance your skills and build confidence in metalworking.

What is a Metal Lathe Bed?

Definition and importance in metalworking. Components of a metal lathe bed and their functions.

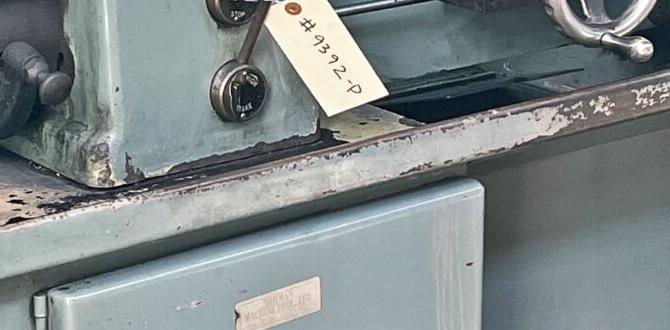

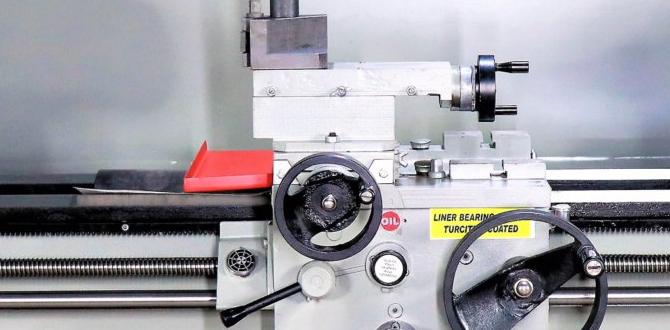

A metal lathe bed is the sturdy foundation where all the magic happens. It holds and supports the machine’s main parts. Think of it as the bed your teddy bear sleeps on, but much, much heavier! The bed plays a vital role by ensuring precision while cutting and shaping metal. Without it, you’d have more “oops!” moments than successful projects. Here are some key parts of a metal lathe bed and their functions:

| Component | Function |

|---|---|

| Base | Supports the entire lathe and keeps it steady. |

| Ways | Guides the movement of the carriage and tailstock. |

| Spindle | Holds and rotates the workpiece for shaping. |

The bed’s design ensures smooth movements. So, if your project turns out awesome, you can thank the bed’s hard work. Without it, you’d have chaos, like a cat in a room full of laser pointers!

Benefits of Enrolling in a Lathe Training Course

Skill development for beginners and advanced users. Industry demand for trained lathe operators.

Joining a lathe training course can be a real game-changer. For beginners, it builds essential skills, making complex tasks feel like a breeze. Even advanced users can refine their techniques, becoming true masters of their craft. There’s a big demand for skilled lathe operators in various industries. Companies want workers who know what they’re doing, and a training course can be your ticket to success. Remember, practice makes perfect—and maybe even gives you an unrestricted VIP pass to the machining world!

| Benefits | Beginners | Advanced Users |

|---|---|---|

| Skill Development | Essential Techniques | Refine Methods |

| Industry Demand | Job Opportunities | Increased Salary |

Essential Topics Covered in Lathe Training Courses

Safety protocols and best practices. Operation and maintenance of the metal lathe bed.

Lathe training courses teach important skills. Students learn about safety protocols and best practices to protect themselves and others. They discover how to use protective gear like goggles and gloves. Courses also cover the operation and maintenance of the metal lathe bed. This includes how to run the machine properly and keep it clean. Keeping the lathe in good shape helps ensure safe and smooth work.

What safety tips are taught in lathe training?

Students learn to wear safety gear, keep the workspace tidy, and understand machine parts.

In lathe training, students also cover:

- How to check tools for damage

- Where to place hands while working

- What to do in case of accidents

Popular Lathe Training Course Formats

Online vs. inperson training options. Duration, costs, and certifications available.

Different lathe training courses offer unique experiences. You can choose between online and in-person formats. Online courses are often more flexible. They allow you to learn at your own pace. In-person classes can provide hands-on learning, which is very useful.

Course duration and costs can vary. Typically, online courses last from a few weeks to several months. In-person courses usually range from a few days to several weeks. Costs also differ. Online courses may start as low as $100, while in-person could be $500 or more.

Some courses offer certifications. These prove you have the skills needed. Having a certification can help you in job searches.

- Online Training: Flexible and often cheaper.

- In-Person Training: Hands-on experience but usually more costly.

- Duration: Varies from weeks to months.

- Costs: Ranges from $100 to $500+.

- Certifications: Available in both formats.

What are the benefits of online lathe training?

Online lathe training allows flexible learning, often at a lower cost. This format also helps learners balance education with other responsibilities.

Choosing the Right Lathe Training Course

Evaluating course content and instructor qualifications. Reviews and testimonials from past students.

Finding the best lathe training course is essential. Look closely at what the course offers. Check if they teach you about the metal lathe bed and more. A good instructor makes learning fun, so review their background too. Did they create masterpieces or just make noise? Don’t forget to look at what other students say. Their reviews can reveal a lot! A course with happy students is usually a winner.

| Course Aspect | Importance |

|---|---|

| Course Content | Offers hands-on training with real lathe machines |

| Instructor Experience | Experienced instructors can make tough topics fun! |

| Student Reviews | Positive feedback can be your golden ticket! |

Tips for Maximizing Your Lathe Training Experience

Practice projects to complement learning. Networking opportunities within the metalworking community.

Getting the most out of your lathe training can be fun and rewarding! Start with some practice projects to sharpen your skills. Simple items like coasters or keychains can boost your confidence and creativity. Plus, they won’t judge you if you mess up!

Don’t forget to mingle with fellow metalworkers. Joining workshops and community events can unlock new friendships and ideas. You might meet someone who can give you tips on avoiding that pesky “oops” moment!

| Practice Project Ideas | Networking Opportunities |

|---|---|

| Coasters | Local workshops |

| Keychains | Online forums |

| Candle holders | Meetup groups |

Conclusion

In summary, a lathe training course teaches you how to use a metal lathe bed effectively. You learn important skills for shaping metal. This training boosts your confidence and opens new career opportunities. To get started, consider enrolling in a local class. You can also explore online resources to deepen your knowledge. Let’s turn your interest into practical skills!

FAQs

What Are The Key Features And Components Of A Metal Lathe Bed That Trainees Should Be Familiar With?

A metal lathe bed is the long, flat part that holds everything together. It keeps the machine stable while it works. You should know about the tailstock, which helps support the other end of the piece you’re working on. The carriage moves side to side and brings the tools closer to the piece. Lastly, there are railings that guide the moving parts smoothly.

How Do The Precision And Stability Of A Lathe Bed Affect The Overall Machining Process And Finished Product?

The precision and stability of a lathe bed are very important. If the bed is stable, it helps keep the tool steady while it works. This means your finished product will be smoother and more accurate. If the bed is not precise, the tool can slip or shake, making mistakes. So, a good lathe bed helps you create better pieces!

What Are The Common Types Of Metal Lathe Beds, And How Do Their Designs Impact Their Performance?

There are three common types of metal lathe beds: flat, slant, and box. Flat beds are strong and easy to use, making them good for most tasks. Slant beds help with cutting by keeping the tools at a better angle. Box beds are sturdy and help make precise shapes. Each design affects how well the lathe works and how accurate your projects can be.

What Safety Precautions Should Be Taken When Working With A Metal Lathe Bed During Training?

When using a metal lathe bed, we should always wear safety goggles to protect our eyes. You should keep your hair tied back and wear snug clothing to avoid getting caught in the machine. Always check that the area around the lathe is clean and free from tools or debris. It’s smart to ask for help if you’re unsure about something. Lastly, focus on what you’re doing and never rush. Safety first!

How Can Proper Maintenance Of The Lathe Bed Enhance The Longevity And Accuracy Of The Metal Lathe?

Taking care of the lathe bed helps it last longer and work better. You should keep it clean and free from dirt. This way, the machine stays smooth and shapes metal accurately. Regular check-ups can spot problems early, so you can fix them. By maintaining the lathe bed, you help your machine stay strong and precise!