Have you ever wondered how metal objects are shaped? It’s all about using machines like a lathe. A lathe spins metal to help cut and shape it. With a good lathe training course, you can learn how to use this amazing tool.

Imagine being able to create your own metal projects. You could make anything from simple tools to beautiful art pieces. But how do you get started? That’s where the lathe training course comes in. It teaches you everything you need to know.

One of the key parts of a lathe is the belt. The belt drives the machine, making it work smoothly. If you know how to use it correctly, you’ll be ahead of the game. Many beginners get stuck, but with practice, anyone can learn.

Wouldn’t it be exciting to turn a block of metal into something useful? With the right training, that dream can come true!

Lathe Training Course: Mastering Metal Lathe Belt Techniques

Lathe Training Course Metal Lathe Belt

Are you curious about how metal parts are made? A lathe training course can show you. You’ll learn how to operate a metal lathe properly, ensuring safety and precision. Did you know that the right belt can make a huge difference in a lathe’s performance? By understanding the equipment, you can create incredible projects. Whether you’re a beginner or looking to sharpen your skills, this course offers hands-on experience and valuable tips for success. Discover the world of metalworking today!Understanding the Basics of Metal Lathes

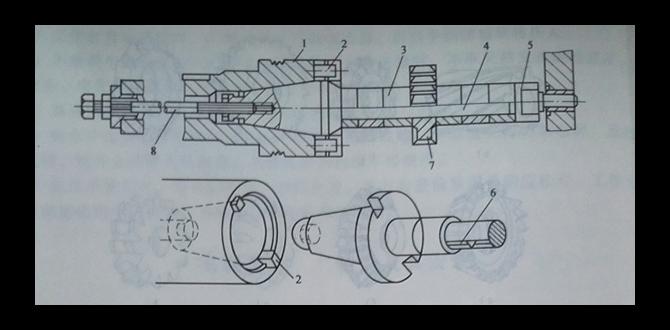

Definition and purpose of a metal lathe. Key components and how they function.A metal lathe is a tool that helps shape metal into various objects. Think of it as a fancy magic wand for metal! It spins the metal while you shave it down to the desired shape. Key components include the headstock, which holds the spinning piece, and the tailstock, where you can add supports or tools. Want to know how fast it spins? It can go faster than your favorite video game character!

| Component | Function |

|---|---|

| Headstock | Holds and spins the metal |

| Tailstock | Supports tools and adds stability |

| Tool Rest | Holds cutting tools steady |

Components of a Lathe Training Course

Curriculum outline and key topics covered. Instruction methods: handson training vs. theoretical learning.A lathe training course covers essential topics like machine parts, operations, and safety measures. Students learn through a mix of hands-on training and theoretical lessons. Hands-on training lets you spin and shape metal, while theory gives you the “why” behind it. Don’t worry; you won’t just be stuck in a classroom counting sheep! Expect to see things like this:

| Key Topics | Instruction Method |

|---|---|

| Machine Setup | Hands-on |

| Tool Selection | Theoretical |

| Safety Procedures | Hands-on |

| Basic Operations | Combines Both |

This approach helps you master the lathe while keeping it fun. Like they say, “Learning should be a joyride!”

Choosing the Right Lathe Training Course

Factors to consider when selecting a course. Comparing online vs. inperson training options.Picking the right lathe training course is important. First, think about your learning style. Do you like to learn at home in pajamas or in a classroom with friends? Online courses are great for busy bees, while in-person classes let you ask questions face-to-face. Check out this handy table to see some factors:

| Factor | Online Training | In-Person Training |

|---|---|---|

| Flexibility | 👍 Anytime, anywhere! | 👨🏫 Set schedule |

| Cost | 💰 Often cheaper | 💵 Usually pricier |

| Hands-On Learning | 🖥️ Limited | 🔧 Lots of practice! |

Whichever option you choose, make sure it fits your needs. Remember, learning to use a metal lathe could make you the next tool wizard!

The Role of the Metal Lathe Belt

Explanation of the metal lathe belt’s function. Types of lathe belts and their applications.The metal lathe belt is a key player in the lathe machine’s game. It transfers power from the motor to the spindle. This allows the lathe to spin, shaping metal like a magician shaping clay. There are different types of belts, like the flat belt and V-belt, each with its own special job. Some are perfect for heavy work, while others shine in lighter tasks. Today, let’s break it down with some simple examples.

| Type of Belt | Application |

|---|---|

| Flat Belt | Best for high-speed operations |

| V-Belt | Excellent for heavy-duty tasks |

In short, the right belt can make your lathe run smoother than a cat on a hot tin roof!

Common Challenges Faced During Lathe Training

Typical mistakes beginners make with metal lathes. Strategies for overcoming common difficulties.Learning how to use a metal lathe can be tricky for beginners. One common mistake is not measuring correctly, which can lead to tiny but serious disasters. Remember, measuring twice is a lot easier than fixing a crooked piece! Another pitfall is not understanding the speed settings; going too fast can be as dangerous as spinning in circles on a merry-go-round. To overcome these bumps, take your time and practice regularly. And, of course, don’t forget to wear your safety goggles—nobody likes flying metal shards in their eyes!

| Challenge | Solution |

|---|---|

| Poor Measurements | Measure twice, cut once! |

| Incorrect Speed Settings | Start slow and increase gradually. |

| Ignoring Safety | Always wear safety gear! |

Real-world Applications of Lathe Skills

Industries that rely on metal lathe training. Case studies of successful lathe operators and projects.Many industries depend on lathe skills. For example, automotive companies use lathes to create precise parts for engines. Construction also needs lathe workers for tooling and equipment. Imagine a lathe operator shaping metal like a sculptor! One case study shows a lathe operator who built custom bike frames. His creations even won races! Here’s a simple table that highlights key fields where lathe skills shine:

| Industry | Application |

|---|---|

| Automotive | Engine parts |

| Aerospace | Aircraft components |

| Construction | Tooling |

| Arts | Custom designs |

With these skills, workers can make unique items and even chase their dreams. Talk about a win-win!

Resources for Further Learning and Practice

Recommended books, online platforms, and tools for continued education. Communities and forums for network and knowledge sharing.Learning doesn’t stop after a lathe training course metal lathe belt. Many resources can help you keep growing. Here are some recommendations:

- **Books:** Look for titles like “Machining Fundamentals” and “The Complete Guide to Metal Lathe Projects.” These can guide your practice.

- **Online Platforms:** Websites like Coursera and Udemy offer great courses to expand your skills.

- **Tools:** Explore software like Fusion 360 for design and simulation.

- **Communities:** Join forums such as Reddit’s r/Machining to share knowledge and ask questions.

These resources can help you improve and connect with others, making learning fun and easier!

What are the best books for learning metal lathing?

Look for books like “Machining Fundamentals” and “Lathe Work”. They teach all about lathes and techniques.

Conclusion

In conclusion, a lathe training course on metal lathes teaches you essential skills for machining. You learn how to use the equipment safely and efficiently. With practice, you can create precise parts for projects. Don’t hesitate to sign up for a course or find more resources. Let’s take your skills to the next level together!FAQs

What Are The Key Skills And Techniques Covered In A Metal Lathe Training Course With A Focus On Belt-Driven Lathes?In a metal lathe training course, we learn important skills for using a belt-driven lathe. You will discover how to safely set up the machine. We practice measuring materials and cutting them accurately. You will also learn to adjust the speed of the belt to match the job. Finally, we focus on cleaning and maintaining the lathe to keep it in good shape.

How Does The Maintenance Of A Belt-Driven Lathe Differ From That Of Other Types Of Lathes In A Training Course?Maintaining a belt-driven lathe is a bit different from other lathes. You need to check the belt often. If the belt gets loose, it can slip and not work well. Other lathes might not have belts, so they need different care. Always make sure everything is clean and tight, so you can work safely and easily!

What Safety Precautions Should Be Emphasized In A Metal Lathe Training Course When Working With Belt-Driven Machinery?When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and remove loose clothing that could get caught. Keep your hands away from the moving parts and use tools to reach small areas. Make sure everyone knows the emergency stop button. Lastly, never run the machine when no one else is around to help.

What Common Projects Or Exercises Can Participants Expect To Complete During A Metal Lathe Belt Training Course?In a metal lathe training course, you can expect to do fun projects. You might make simple shapes like cylinders and cones. We will learn how to cut and smooth metal pieces. You will also practice measuring parts correctly. By the end, you can create cool metal items!

How Can Understanding Belt Selection And Tensioning Improve The Performance Of A Metal Lathe In Practical Applications?Choosing the right belt for a metal lathe helps it work better. If the belt is too loose, it can slip and not grip well. A tight and strong belt makes sure the lathe spins smoothly and cuts properly. This means your projects will turn out better and faster. So, understanding belts and how tight they should be is really important!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Skills And Techniques Covered In A Metal Lathe Training Course With A Focus On Belt-Driven Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe training course, we learn important skills for using a belt-driven lathe. You will discover how to safely set up the machine. We practice measuring materials and cutting them accurately. You will also learn to adjust the speed of the belt to match the job. Finally, we focus on cleaning and maintaining the lathe to keep it in good shape.”}},{“@type”: “Question”,”name”: “How Does The Maintenance Of A Belt-Driven Lathe Differ From That Of Other Types Of Lathes In A Training Course?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Maintaining a belt-driven lathe is a bit different from other lathes. You need to check the belt often. If the belt gets loose, it can slip and not work well. Other lathes might not have belts, so they need different care. Always make sure everything is clean and tight, so you can work safely and easily!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Emphasized In A Metal Lathe Training Course When Working With Belt-Driven Machinery?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and remove loose clothing that could get caught. Keep your hands away from the moving parts and use tools to reach small areas. Make sure everyone knows the emergency stop button. Lastly, never run the machine when no one else is around to help.”}},{“@type”: “Question”,”name”: “What Common Projects Or Exercises Can Participants Expect To Complete During A Metal Lathe Belt Training Course?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe training course, you can expect to do fun projects. You might make simple shapes like cylinders and cones. We will learn how to cut and smooth metal pieces. You will also practice measuring parts correctly. By the end, you can create cool metal items!”}},{“@type”: “Question”,”name”: “How Can Understanding Belt Selection And Tensioning Improve The Performance Of A Metal Lathe In Practical Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right belt for a metal lathe helps it work better. If the belt is too loose, it can slip and not grip well. A tight and strong belt makes sure the lathe spins smoothly and cuts properly. This means your projects will turn out better and faster. So, understanding belts and how tight they should be is really important!”}}]}