Have you ever wondered how metal parts are shaped and designed? A lathe training course can take you into the exciting world of metalworking. Imagine learning to use a CNC lathe, which is a powerful machine that transforms raw metal into precise parts.

Many people don’t know that they can easily learn this skill. With a lathe training course, you can start turning metal into something amazing. Whether you’re a hobbyist or looking to jumpstart a career, this training can open doors.

What if I told you that retrofitting a CNC machine can make a huge difference in how you create? This fun fact highlights just how much technology has grown. By taking a lathe training course, you can be part of that growth!

Let’s dive into how these courses work and why they are valuable. You might just find your next passion in metalworking!

Comprehensive Lathe Training Course: Metal Lathe Cnc Retrofit

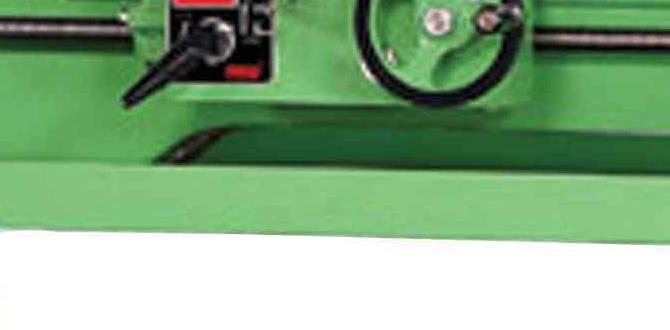

Lathe Training Course: Metal Lathe CNC Retrofit

Looking to master metalworking? A lathe training course can kickstart your journey. You’ll learn how to use a metal lathe effectively and efficiently. Imagine creating precise parts for machines or custom projects! These courses often include hands-on training, making learning fun and practical. Did you know that retrofitting CNC features can bring old lathes back to life? It’s an exciting way to blend traditional skills with modern technology. Start your adventure in metalworking today!Understanding Lathe Training Courses

Definition and purpose of lathe training courses. Importance of skill development in machining industry.Lathe training courses teach people how to use lathes, which are machines that shape metal and wood. The main goal is to help learners become skilled in machining. In the machining industry, skill development is very important. It ensures workers can make precise parts and keep machines running well. A good lathe course prepares students for exciting careers. It is a stepping stone to being successful in this field.

Why Are Lathe Training Courses Important?

They are key to gaining skills needed in modern manufacturing.

Benefits of Lathe Training:

- Hands-on experience with machines.

- Improves job opportunities in the industry.

- Boosts confidence and competence.

Key Components of a Lathe Training Course

Curriculum breakdown: essential skills and knowledge. Handson training vs. theoretical learning.A lathe training course covers important skills and knowledge. Students learn about machine parts, safety, and how to operate lathes effectively. The course mixes hands-on training with classroom lessons. This way, learners can practice and apply their knowledge. Here are the key components:

- Curriculum Breakdown: Focused lessons on using a lathe.

- Hands-On Training: Real-world practice on machines.

- Theoretical Learning: Understanding concepts before using tools.

What do you learn in a lathe training course?

Students learn how to operate lathes, understand safety rules, and practice techniques for metalworking. This helps them build skills for future jobs in manufacturing and repair.

Benefits of CNC Retrofit Training

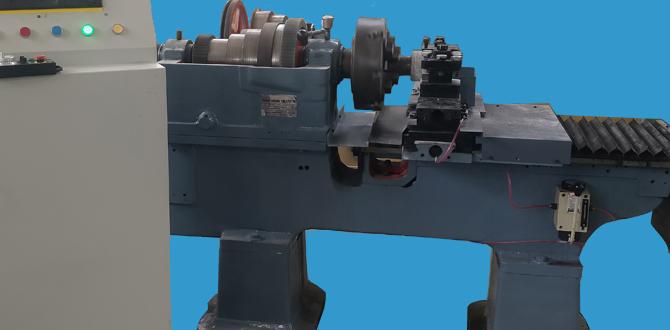

Advantages of retrofitting older lathes for modern production. Costeffectiveness of CNC retrofitting for businesses.CNC retrofit training provides big perks for older lathes. It helps turn ancient machines into modern production powerhouses. Imagine your old lathe getting a high-tech makeover! Retrofits boost efficiency and save time. Plus, they cost less than buying new machines. Imagine splurging on a fancy coffee, then finding a deal on your favorite mug instead—just like that!

| Advantage | Benefit |

|---|---|

| Increased Efficiency | Modern controls improve speed and precision. |

| Cost-Effectiveness | Lower cost than new machines, making your wallet happy! |

| Longevity | Retrofitting extends the life of your old lathe. |

In short, upgrading with CNC training is a smart move. It’s like giving your lathe a brand new lease on life while saving money! Who wouldn’t want that?

Choosing the Right Lathe Training Course

Factors to consider: course length, certification, and instructors. Recommendations for reputable training providers.Choosing a lathe training course is important. Consider the course length first. Some courses may last a few days, while others take weeks. Next, think about the certification you will receive. A good course offers a recognized certificate after completion. Lastly, check the instructors. They should have real-world experience. Look for reputable training providers like local community colleges or specialized trade schools.

- Course Length: Days or Weeks

- Certification: Recognized Programs

- Instructors: Experienced Professionals

What should I look for in a lathe training course?

Look for experienced instructors, a solid certificate, and how long the course lasts. This helps you learn better.

Real-World Applications and Case Studies

Examples of successful lathe training implementation. Industry demand for skilled lathe operatives.Many businesses now rely on well-trained lathe operators. For example, a local manufacturing company boosted production after offering a lathe training program. This led to better quality products and shorter work times. Companies need skilled operatives more than ever. Demand is high in various sectors like automotive and construction.

- Improved product quality.

- Shorter production time.

- Higher job satisfaction for employees.

This shows why lathe training courses, like those for CNC retrofits, are essential for keeping industries strong and efficient.

How do lathe training programs help companies?

Lathe training programs help companies by improving skills, boosting productivity, and meeting industry demands.

Key Benefits of Training:

- Safety in the workplace.

- Increased job opportunities for workers.

- Adaptability to new technologies.

Common Challenges in Lathe Training

Identifying obstacles learners face in training. Strategies to overcome these challenges.Learning to use a lathe can be tough. Students often face problems like tool setup, making mistakes, or feeling lost with technology. These challenges can make training feel overwhelming. To help, here are some useful strategies:

- Practice regularly to build confidence.

- Ask questions when unsure about something.

- Break tasks into smaller steps for easier understanding.

Remember, everyone makes mistakes. They are part of learning! With patience and effort, learners can overcome these hurdles in lathe training.

What are the common problems in lathe training?

Many students struggle with setup, understanding commands, and executing precise cuts. Practicing these skills in a supportive environment can help boost their confidence.

Future Trends in Lathe Technology and Training

Upcoming advancements in lathe machinery and CNC technology. The evolving landscape of lathe training programs and industry needs.Technology is always changing, especially in lathe machines and CNC tools. New features make these machines faster and easier to use. Automatic controls and smart software are on the rise. This means better training programs are needed. As industry needs grow, schools must adapt. More focus will be on teaching both traditional skills and new techniques. This helps students stay ready for future jobs.

What are the future advancements in lathe technology?

New machines will be more efficient and precise. They might use artificial intelligence to improve performance. This makes work faster and safer.

Key advancements include:

- Smart sensors for accuracy

- Remote operation capabilities

- Eco-friendly designs

How are lathe training programs evolving?

Training is becoming more focused on hands-on experience with modern machines. Schools are adding lessons about CNC technology as it is becoming essential in the industry.

Examples of training evolution:

- Online courses for flexible learning

- Workshops with new equipment

- Certifications for diverse skills

Conclusion

In summary, a lathe training course teaches you how to use both manual and CNC lathes effectively. You’ll learn valuable skills for crafting metal parts. Retrofits can enhance older machines, making them competitive again. If you’re interested, consider signing up for a course or researching CNC technology further. Your journey in machining can start now!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Training Courses And Cnc Retrofitting For Metal Lathes:Sure! Learning about lathes can help you work with metal. A lathe is a machine that shapes pieces of metal by spinning them. Training courses teach you how to use lathes safely and correctly. CNC stands for Computer Numerical Control. It helps automate lathes, making work faster and easier. Retrofitting means adding new parts to old machines to upgrade them.

Sure! Please share the question you need answered, and I’ll help you with that.

What Are The Key Components Of A Cnc Retrofit For A Traditional Metal Lathe?To retrofit a traditional metal lathe with CNC (Computer Numerical Control), you need a few key parts. First, you need stepper motors or servos to move the lathe automatically. Then, you need a controller to tell these motors what to do. You also need a computer or software to create the designs and instructions. Finally, don’t forget to add sensors to help with accuracy and safety.

How Can A Lathe Training Course Prepare Participants For Operating Both Manual And Cnc Lathes?A lathe training course teaches you how to use both manual and CNC (Computer Numerical Control) lathes. You will learn to set up the machines, which is like getting them ready to work. We will practice measuring and cutting materials safely. This way, you get the skills to make shapes and parts properly. You’ll feel confident using both types of lathes by the end of the course!

What Are The Benefits Of Retrofitting A Conventional Metal Lathe With Cnc Technology?Retrofitting a regular metal lathe with CNC (Computer Numerical Control) technology makes it better and easier to use. You can create more precise shapes, which means your work will be more accurate. It also saves time because the machine can run automatically. Plus, you can make more complex designs that would be hard to do by hand. Overall, it helps you work faster and smarter!

What Safety Protocols Should Be Emphasized In A Lathe Training Course That Includes Cnc Operations?In a lathe training course for CNC (Computer Numerical Control) operations, we should focus on a few important safety rules. First, always wear safety goggles to protect your eyes. Next, keep loose clothing and long hair away from the machine. Make sure your work area is clean and free of clutter. Finally, know how to use the emergency stop button in case something goes wrong.

How Long Does A Typical Lathe Training Course Take, And What Practical Skills Can Participants Expect To Gain?A typical lathe training course takes about one to two weeks. During this time, you will learn how to use a lathe safely. You’ll also practice making different shapes from wood or metal. By the end, you can turn simple projects into real objects. It’s a fun way to get hands-on experience!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Training Courses And Cnc Retrofitting For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Learning about lathes can help you work with metal. A lathe is a machine that shapes pieces of metal by spinning them. Training courses teach you how to use lathes safely and correctly. CNC stands for Computer Numerical Control. It helps automate lathes, making work faster and easier. Retrofitting means adding new parts to old machines to upgrade them.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you need answered, and I’ll help you with that.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Cnc Retrofit For A Traditional Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To retrofit a traditional metal lathe with CNC (Computer Numerical Control), you need a few key parts. First, you need stepper motors or servos to move the lathe automatically. Then, you need a controller to tell these motors what to do. You also need a computer or software to create the designs and instructions. Finally, don’t forget to add sensors to help with accuracy and safety.”}},{“@type”: “Question”,”name”: “How Can A Lathe Training Course Prepare Participants For Operating Both Manual And Cnc Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe training course teaches you how to use both manual and CNC (Computer Numerical Control) lathes. You will learn to set up the machines, which is like getting them ready to work. We will practice measuring and cutting materials safely. This way, you get the skills to make shapes and parts properly. You’ll feel confident using both types of lathes by the end of the course!”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Retrofitting A Conventional Metal Lathe With Cnc Technology?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Retrofitting a regular metal lathe with CNC (Computer Numerical Control) technology makes it better and easier to use. You can create more precise shapes, which means your work will be more accurate. It also saves time because the machine can run automatically. Plus, you can make more complex designs that would be hard to do by hand. Overall, it helps you work faster and smarter!”}},{“@type”: “Question”,”name”: “What Safety Protocols Should Be Emphasized In A Lathe Training Course That Includes Cnc Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a lathe training course for CNC (Computer Numerical Control) operations, we should focus on a few important safety rules. First, always wear safety goggles to protect your eyes. Next, keep loose clothing and long hair away from the machine. Make sure your work area is clean and free of clutter. Finally, know how to use the emergency stop button in case something goes wrong.”}},{“@type”: “Question”,”name”: “How Long Does A Typical Lathe Training Course Take, And What Practical Skills Can Participants Expect To Gain?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A typical lathe training course takes about one to two weeks. During this time, you will learn how to use a lathe safely. You’ll also practice making different shapes from wood or metal. By the end, you can turn simple projects into real objects. It’s a fun way to get hands-on experience!”}}]}