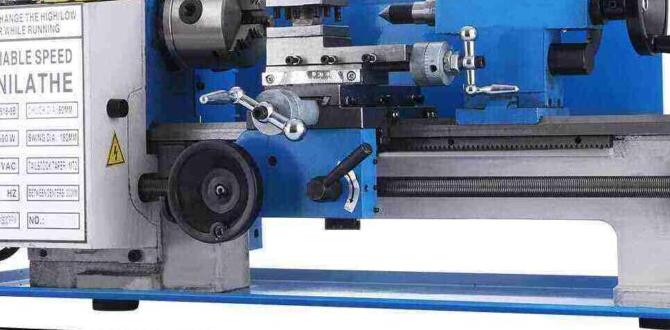

Have you ever watched a metal lathe in action? It’s a fascinating machine! A metal lathe can shape and craft materials into beautiful pieces. But to master this tool, you need proper training. That’s where a lathe training course comes in.

Imagine yourself confidently creating projects from metal. From small gadgets to complex parts, the possibilities are endless. With the right lathe training course, you’ll learn the skills needed to use a metal lathe effectively.

Did you know that some metal lathes now come with DRO, or Digital Readouts? This technology makes it easier to measure and cut accurately. Taking a lathe training course that includes DRO instruction can give you a real edge.

So, are you ready to dive into the world of metalworking? Let’s explore how a lathe training course can set you on the right path. Your journey toward mastering the metal lathe starts here!

Comprehensive Lathe Training Course: Master Metal Lathe Dro

Lathe Training Course Metal Lathe DRO

A lathe training course on metal lathe with Digital Readouts (DRO) offers hands-on experience for beginners and experts alike. Students learn to operate lathes effectively, enhancing their metalworking skills. Did you know that using DRO can improve precision by up to 10 times? This course covers safety practices, setup procedures, and essential techniques. So, have you ever thought about how accuracy in machining can change project outcomes? Dive into the world of lathes and discover the excitement of creating precise metal parts!Understanding the Basics of Metal Lathes

Definition and purpose of metal lathes. Types of metal lathes and their applications.Metal lathes are machines that shape metal into different parts. Think of them as giant pencils, but instead of drawing, they spin metal. The main goal? To create round objects like shafts or cylinders efficiently. There are various types of metal lathes, each with special uses. For example, engine lathes are great for small parts, while CNC lathes can make complex shapes with a push of a button—talk about a metal magician!

| Type of Metal Lathe | Application |

|---|---|

| Engine Lathe | Used for turning small parts. |

| CNC Lathe | Creates complex shapes automatically. |

| Turret Lathe | Great for production runs of similar parts. |

Overall, understanding metal lathes helps in many fields. From crafting engines to making art, these tools are handy!

What is a DRO (Digital Readout) System?

Explanation of DRO and its components. Benefits of using DRO in lathe operations.A digital readout (DRO) system shows exact measurements on machines like lathes. It has a computer and sensors to track where the tool is. With a DRO, you get better accuracy and quick readings. This makes jobs easier and helps avoid mistakes. Here are some key benefits:

- Precise cuts resulting in high-quality work.

- Less time spent measuring.

- Ease of use for beginners and experts.

Using a DRO means fewer problems and more fun in metalworking!

What advantages does a DRO provide in lathe operations?

DROs provide greater accuracy, faster measurements, and reduce errors in lathe operations.

Essential Safety Protocols in Lathe Operations

Personal protective equipment (PPE) needed. Common safety practices when using lathes.Using a lathe can be fun, but safety comes first! Always wear personal protective equipment (PPE) like goggles and gloves. Have a buddy nearby; it’s like having a superhero on standby. Before starting, check the machine for loose parts. Keep your hair tied back—no one wants to see a “hair-raising” experience! Here’s a quick table to remember those safety musts:

| Safety Practice | Description |

|---|---|

| PPE | Wear goggles, gloves, and ear protection. |

| Check Equipment | Inspect for loose parts before use. |

| Stay Alert | Focus on the task; no daydreaming! |

| Clean Up | Keep the area tidy to avoid accidents. |

Remember, safety isn’t just a rule—it’s a game plan!

Learning Outcomes: What to Expect from the Course

Proficiency in metal lathe operations. Mastery of DRO functionalities in machining.By the end of this course, you’ll be a wizard with the metal lathe! Expect to learn how to operate a lathe like a pro and impress your friends with your fancy skills. You’ll also discover the magic of Digital Readouts (DRO)—like having a robot sidekick while machining. Ready for some fun? Here’s a glimpse of what you’ll master:

| Skill | Description |

|---|---|

| Lathe Operations | Learn precise turning, shaping, and finishing of materials. |

| DRO Functionality | Master measurements and calculations with high-tech ease. |

Get ready to unleash your creativity and have a few laughs along the way. Who knew making metal things could be this much fun?

Hands-On Training: Importance of Practical Experience

Role of handson practice in skill development. Realworld projects and applications for students.Hands-on practice is key to learning. It helps you make sense of what you learn in class. When students work on real projects, they understand the tools better. They gain confidence by using metal lathes in actual tasks. This experience helps build valuable skills. Practical training bridges the gap between theory and practice. Students enjoy learning more when they can touch and create. It’s exciting to see ideas come to life!

Why is hands-on training important?

Hands-on training helps students learn faster and remember more. It lets them solve real-world problems, preparing them for jobs.

Benefits of Hands-on Practice:

- Improves understanding.

- Builds confidence.

- Encourages creativity.

- Prepares for real-world challenges.

Future Trends in Metal Lathe Technology

Innovations in lathe machinery and DRO systems. Impact of technology on metalworking education.New machines and digital readout (DRO) systems are changing metal lathes. Innovations make lathes smarter and easier to use. They help workers create precise parts. Schools are also adapting. Technology in classrooms boosts understanding of metalworking. Students learn faster with hands-on experiences and simulations. Overall, the future looks bright in this industry!

What innovations are shaping metal lathes today?

Many new features are making metal lathes better. These include:

- Smart technology that can predict issues before they happen.

- Enhanced DRO systems for accurate measurements.

- More automation for faster production.

How does technology impact metalworking education?

Modern classrooms use tools like virtual reality and software to teach. This helps students understand complex concepts easily. Teachers find it engaging for students.

Resources for Continued Learning and Development

Recommended books, tutorials, and online platforms. Joining forums and communities for metalworking enthusiasts.Learning about metal lathes can be a fun journey! Start with some recommended books like “The Essential Guide to Metalworking”. Online platforms like YouTube are great too, where you can watch tutorials. Joining forums and communities, such as Metalworking Zone, can be helpful for discussing ideas and sharing laughs. It’s like a clubhouse, but with tools! Connect with other metalworking enthusiasts and make new friends while you learn.

| Resource Type | Examples |

|---|---|

| Books | “The Essential Guide to Metalworking” |

| Tutorials | YouTube Channels |

| Forums | Metalworking Zone |

Conclusion

In summary, a lathe training course focused on metal lathes and DRO can boost your skills. You learn hands-on techniques and understand equipment better. This knowledge opens doors in machining and engineering careers. We encourage you to explore local courses or online options. Gaining experience with lathes can lead to exciting projects and opportunities in the future!FAQs

What Are The Key Features And Benefits Of Using A Digital Readout (Dro) System On A Metal Lathe During Training?A digital readout (DRO) system shows you exact measurements on a screen. This makes it easier to see numbers and helps you work more accurately. You can learn how to use a lathe without guessing. A DRO also helps you save time because you don’t have to measure twice. Overall, using a DRO makes learning safer and more fun!

How Does The Integration Of A Dro Enhance Precision And Accuracy In Lathe Operations For Beginners?Using a Digital Readout (DRO) on a lathe helps you see exact measurements. This makes it easier to cut materials correctly. You can adjust the tool as needed without guessing. With a DRO, you make fewer mistakes. This helps you learn faster and become better at using the lathe.

What Safety Precautions Should Be Emphasized During Training When Operating A Metal Lathe With A Dro?When using a metal lathe with a Digital Readout (DRO), always wear safety goggles to protect your eyes. Keep your hands away from moving parts to avoid getting hurt. Tie back long hair and remove loose clothing so they don’t get caught. Make sure the area is clean and free of clutter. Lastly, listen carefully to your instructor and ask questions if you’re unsure about anything.

What Types Of Projects Are Best Suited For Beginners Learning To Use A Metal Lathe With A Dro?Beginners can start with simple projects when using a metal lathe with a Digital Readout (DRO). You can make items like spinning tops, pencil holders, or simple knobs. These projects help you learn how to measure and cut. They are fun and not too hard, making them perfect for practice. Start small, and you will get better!

How Can Participants In A Lathe Training Course Effectively Troubleshoot Common Issues Encountered With Dro Systems?To troubleshoot problems with Digital Readout (DRO) systems, start by checking the power source. Make sure everything is plugged in and working. Next, look for loose cables or connections. If the screen is blank, reset the system by turning it off and on again. Finally, read the manual or ask a teacher for help if you still have issues.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features And Benefits Of Using A Digital Readout (Dro) System On A Metal Lathe During Training? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital readout (DRO) system shows you exact measurements on a screen. This makes it easier to see numbers and helps you work more accurately. You can learn how to use a lathe without guessing. A DRO also helps you save time because you don’t have to measure twice. Overall, using a DRO makes learning safer and more fun!”}},{“@type”: “Question”,”name”: “How Does The Integration Of A Dro Enhance Precision And Accuracy In Lathe Operations For Beginners? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a Digital Readout (DRO) on a lathe helps you see exact measurements. This makes it easier to cut materials correctly. You can adjust the tool as needed without guessing. With a DRO, you make fewer mistakes. This helps you learn faster and become better at using the lathe.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Emphasized During Training When Operating A Metal Lathe With A Dro? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe with a Digital Readout (DRO), always wear safety goggles to protect your eyes. Keep your hands away from moving parts to avoid getting hurt. Tie back long hair and remove loose clothing so they don’t get caught. Make sure the area is clean and free of clutter. Lastly, listen carefully to your instructor and ask questions if you’re unsure about anything.”}},{“@type”: “Question”,”name”: “What Types Of Projects Are Best Suited For Beginners Learning To Use A Metal Lathe With A Dro? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Beginners can start with simple projects when using a metal lathe with a Digital Readout (DRO). You can make items like spinning tops, pencil holders, or simple knobs. These projects help you learn how to measure and cut. They are fun and not too hard, making them perfect for practice. Start small, and you will get better!”}},{“@type”: “Question”,”name”: “How Can Participants In A Lathe Training Course Effectively Troubleshoot Common Issues Encountered With Dro Systems? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot problems with Digital Readout (DRO) systems, start by checking the power source. Make sure everything is plugged in and working. Next, look for loose cables or connections. If the screen is blank, reset the system by turning it off and on again. Finally, read the manual or ask a teacher for help if you still have issues.”}}]}