Have you ever wondered how a simple chunk of metal can turn into a shiny new part? It all starts with a metal lathe. Imagine working with your hands to create something useful. A lathe training course can teach you this exciting skill.

Many people enjoy making things from metal. From toys to tools, there’s no limit to what you can create. But how do you get started? Joining a lathe training course can help. You’ll learn how to use a metal lathe safely and effectively. Plus, you’ll discover the magic behind gears and other parts.

Did you know that the metal lathe has been around for centuries? It changed the way we make things. By learning about this machine, you can be part of a long tradition. Imagine telling your friends that you can turn raw metal into impressive shapes!

Learning about a metal lathe and its gear can open doors to new hobbies and careers. Are you ready to explore this fascinating world? Dive into the adventure of lathe training today!

Comprehensive Lathe Training Course: Mastering Metal Lathe Gear

Lathe Training Course: Metal Lathe Gear

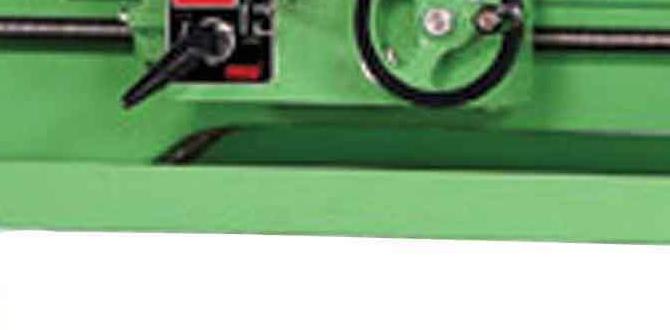

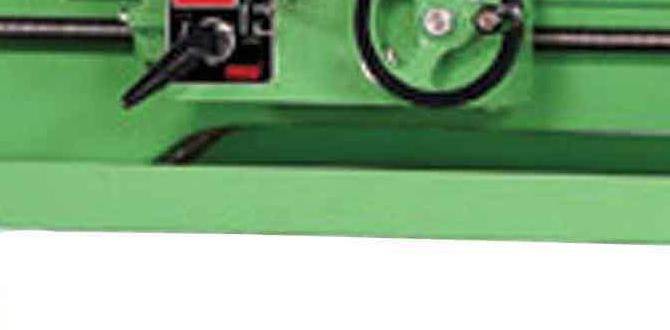

Discover the exciting world of metal lathes in a specialized lathe training course. Enthusiasts can learn how to operate and maintain these machines effectively. Participants gain hands-on experience, which builds confidence. Did you know that mastering lathe techniques can unlock many creative projects? Imagine crafting custom parts or unique designs. This course offers essential skills, making it perfect for beginners or those wanting to advance in machining. Ready to turn your ideas into reality?Importance of Lathe Training

Benefits of formal training for metal lathe operation. How training enhances safety and efficiency.Learning to use a metal lathe is very important. With formal training, users can understand how to operate the machine safely. This can prevent accidents and injuries. Training also improves skill. It allows operators to work faster and make better products. Here are some benefits:

- Enhanced Safety: Knowledge of how to use the equipment reduces the risk of accidents.

- Increased Efficiency: Trained operators can complete tasks quicker and more accurately.

- Better Quality: Formal training helps in producing high-quality work consistently.

What are the benefits of a lathe training course?

A lathe training course teaches safety, efficiency, and skill improvement. This skill can lead to better job opportunities in metalworking.Course Structure for Lathe Training

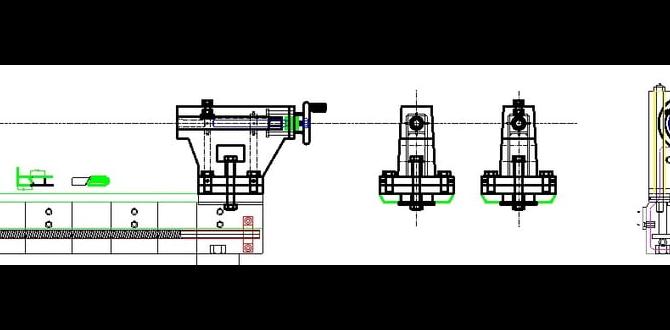

Typical modules included in a metal lathe training program. Handson versus theoretical training components.In a metal lathe training program, students explore various modules to master the craft. They learn about machine setup, tool selection, and safety procedures that are as important as pizza toppings! Training blends hands-on practice with theoretical lessons. Students turn raw metal into treasures, while also soaking in knowledge from textbooks. The balance of doing and learning keeps things fun and engaging. Below is an overview of typical course modules:

| Module | Description |

|---|---|

| Machine Basics | Understanding parts and functions of metal lathes. |

| Safety Training | Learning safe practices while operating machines. |

| Tool Use | How to choose and apply the right tools. |

| Hands-On Projects | Creating simple projects to practice skills. |

| Theory Lessons | Studying concepts behind lathe operation. |

This mix of practical and theoretical lessons ensures that budding machinists are ready for the workshop and the world!

Essential Skills Gained from Lathe Training

Key technical skills acquired during the course. Problemsolving and critical thinking applications in lathe work.Taking a lathe training course opens a world of exciting skills! You’ll master techniques for using a metal lathe, making precise parts that fit just right. But wait, there’s more! You’ll learn how to solve problems. Imagine figuring out why a screw won’t fit. That’s critical thinking in action! In the end, it’s not just about spinning metal; it’s about becoming a tool-wielding superhero!

| Skills Learned | How It Helps |

|---|---|

| Precision Measurement | Makes parts fit perfectly. |

| Problem-Solving | Fixes issues without breaking a sweat. |

| Critical Thinking | Helps make smart choices quickly. |

Tools and Equipment Used in Metal Lathe Training

Common tools utilized in the training process. Importance of understanding gear mechanisms in metal lathes.Learning metal lathes use important tools. Some common tools include:

- Measuring tools

- Cutting tools

- Chucks

- Collets

- Tool holders

Understanding gear mechanisms in metal lathes is key. Gears help control speed and movement. This means you can create precise parts. Knowing gears makes you a better machinist. Remember, every tool has a purpose in this training. They work together like a team!

What tools are essential for metal lathe training?

Essential tools greatly affect learning in lathe training. The most important ones include cutting tools, measuring devices, and gear systems. These tools help you understand how to shape and cut metal accurately.

Finding the Right Lathe Training Course

Criteria for selecting a quality training program. Recommendations for reputable institutions or online courses.Choosing the right training program can be fun and rewarding! First, look for courses with certified instructors who know their stuff. Check reviews from other students—if they’re smiling, you might be too! Online classes offer flexibility, while in-person sessions can provide hands-on experience, which is super important. Don’t skip out on checking for equipment availability during training. Below is a quick list to help you find reputable options:

| Institution/Platform | Type | Rating |

|---|---|---|

| ABC Metalworking Academy | In-Person | ⭐⭐⭐⭐⭐ |

| Lathe Wizard Online | Online | ⭐⭐⭐⭐ |

| Hands-On Training Center | In-Person | ⭐⭐⭐⭐⭐ |

These options strike a balance between knowledge and fun! Learning with tools can make anyone feel like a wizard.

Cost Considerations for Lathe Training Courses

Average costs associated with different types of courses. Factors influencing the price of lathe training programs.Lathe training courses vary in cost. Basic courses might start around $200. Advanced programs can reach $1,000 or more. What causes these price differences? Here are some key factors:

- Course Duration: Longer courses usually cost more.

- Instructor Experience: Well-known teachers may charge higher fees.

- Materials Provided: Courses that include tools or textbooks can be pricier.

- Location: Prices can differ based on where you take the class.

It’s wise to compare options before enrolling. Assess what each course offers to find the best value.

What is the average price for lathe training courses?

The average price for lathe training is between $200 to $1,000, depending on the course level.

Real-World Applications of Metal Lathe Training

Industries that employ skills learned in lathe training. Case studies showcasing successful applications of metal lathe skills.Metal lathe training opens doors to many exciting industries. From automotive to manufacturing, companies use these skills to create parts and machines. For instance, a small auto shop can turn old car parts into shiny new ones. A case study showed how a local business lowered costs by 30% after training workers on the lathe. That’s like finding money in your couch cushions! Below is a quick look at some industries that benefit from these skills:

| Industry | Application |

|---|---|

| Automotive | Creating engine parts |

| Aerospace | Manufacturing aircraft components |

| Machine Shops | Custom tool creation |

| Medical Devices | Producing surgical instruments |

With lathe skills, workers not only find jobs but also get the chance to make cool things!

Continuing Education and Advanced Training Options

Opportunities for advanced courses after initial training. Importance of staying updated with industry standards and technologies.After completing your first training, more opportunities await! Advanced courses in lathe training can sharpen your skills and keep you ahead. Staying updated with new industry standards is as important as having your morning coffee. It helps you stay competitive and efficient. Plus, who wouldn’t want to impress others with the latest tricks of the trade? Here’s a quick look at some options:

| Course Name | Duration | Focus Area |

|---|---|---|

| Precision Machining | 6 Months | Advanced Techniques |

| CAD for Machinists | 3 Months | Design Skills |

| Industry Standards Update | 2 Weeks | Latest Regulations |

Remember, continuing education is not just a requirement; it’s your chance to be the best in the game. So gear up and let’s get learning!

Conclusion

In summary, a lathe training course helps you understand metal lathe gears better. You’ll learn how to operate the lathe and create amazing projects. Gaining this skill opens up job opportunities and personal hobbies. We encourage you to explore courses in your area or online for hands-on experience. Keep practicing, and you’ll master the lathe in no time!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathes And Gears:Sure! Here are the answers to the questions about a lathe training course. In this course, you will learn how to use a machine called a lathe. A lathe helps shape metal pieces into gears and other objects. You will practice safe and correct ways to use the tools. By the end, you’ll be able to create your own metal parts!

Sure! Please provide the question you want me to answer.

What Are The Key Safety Precautions That Students Should Follow When Operating A Metal Lathe During The Training Course?When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and avoid loose clothing that could get caught. Keep your hands away from moving parts to prevent injuries. Make sure to understand how the machine works and ask for help if you’re unsure. Lastly, always clean up the area after you finish to keep it safe for everyone.

What Types Of Projects Or Exercises Are Typically Included In A Lathe Training Course To Help Students Understand Gear Manufacturing?In a lathe training course, you might make small gears using a machine called a lathe. We could start with simple projects, like making a round disk. Then, we can try making gears with teeth that fit together. You will learn how to measure and cut the gears to the right size. Finally, you may even build something fun, like a small toy that uses the gears you made!

How Does The Course Curriculum Address The Different Types Of Gears (E.G., Spur, Helical, Bevel) And Their Specific Machining Requirements On A Lathe?In the course, we learn about different gears like spur, helical, and bevel. Each gear has unique shapes, so we need to use special techniques to make them. We practice these techniques on a machine called a lathe. You will see how each gear type needs different tools and settings on the lathe. This helps you understand how to create each gear correctly.

What Measurement And Alignment Techniques Are Taught In The Course To Ensure Precision When Creating Gears On A Metal Lathe?In the course, we learn to use tools like calipers and micrometers to measure carefully. We also align the metal lathe properly. This means making sure everything is straight and even. By doing this, we can create gears that fit together perfectly. Practice helps us get really good at measuring and aligning!

How Can Students Apply The Skills Learned In The Lathe Training Course To Real-World Applications Within The Manufacturing Industry?You can use the skills from the lathe training course in many ways. For example, you can make parts for cars or machines. These parts help things work better and faster. You can also create tools or equipment that other workers need. Your training helps you build things that are important for many jobs in factories.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathes And Gears:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are the answers to the questions about a lathe training course. In this course, you will learn how to use a machine called a lathe. A lathe helps shape metal pieces into gears and other objects. You will practice safe and correct ways to use the tools. By the end, you’ll be able to create your own metal parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Safety Precautions That Students Should Follow When Operating A Metal Lathe During The Training Course?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and avoid loose clothing that could get caught. Keep your hands away from moving parts to prevent injuries. Make sure to understand how the machine works and ask for help if you’re unsure. Lastly, always clean up the area after you finish to keep it safe for everyone.”}},{“@type”: “Question”,”name”: “What Types Of Projects Or Exercises Are Typically Included In A Lathe Training Course To Help Students Understand Gear Manufacturing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a lathe training course, you might make small gears using a machine called a lathe. We could start with simple projects, like making a round disk. Then, we can try making gears with teeth that fit together. You will learn how to measure and cut the gears to the right size. Finally, you may even build something fun, like a small toy that uses the gears you made!”}},{“@type”: “Question”,”name”: “How Does The Course Curriculum Address The Different Types Of Gears (E.G., Spur, Helical, Bevel) And Their Specific Machining Requirements On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In the course, we learn about different gears like spur, helical, and bevel. Each gear has unique shapes, so we need to use special techniques to make them. We practice these techniques on a machine called a lathe. You will see how each gear type needs different tools and settings on the lathe. This helps you understand how to create each gear correctly.”}},{“@type”: “Question”,”name”: “What Measurement And Alignment Techniques Are Taught In The Course To Ensure Precision When Creating Gears On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In the course, we learn to use tools like calipers and micrometers to measure carefully. We also align the metal lathe properly. This means making sure everything is straight and even. By doing this, we can create gears that fit together perfectly. Practice helps us get really good at measuring and aligning!”}},{“@type”: “Question”,”name”: “How Can Students Apply The Skills Learned In The Lathe Training Course To Real-World Applications Within The Manufacturing Industry?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use the skills from the lathe training course in many ways. For example, you can make parts for cars or machines. These parts help things work better and faster. You can also create tools or equipment that other workers need. Your training helps you build things that are important for many jobs in factories.”}}]}