Have you ever wondered how metal parts are made with precision? The answer often lies in a machine called a lathe. A lathe is a powerful tool that shapes various materials into amazing products. But to use it effectively, you first need proper training.

A lathe training course can help you learn all about using a metal lathe. One important aspect you will discover is the gear train. This system of gears controls the speed and motion of the lathe. Understanding how a gear train works is crucial for achieving the best results.

Imagine you’re in a workshop. You see a shiny metal piece transforming under the spinning lathe. Each turn brings it closer to perfection. But without the right knowledge about the lathe and its gear train, that shiny result may never happen.

Curious what else you can learn in a lathe training course? You’ll dive into exciting projects and develop skills that last a lifetime. This training can open doors to many career paths. So, get ready to explore the world of metalworking!

Comprehensive Lathe Training Course: Master Metal Lathe Gear Train

Lathe Training Course: Metal Lathe Gear Train

Lathe training courses teach you how to use metal lathes safely and effectively. A key part is understanding the gear train, which helps turn raw materials into precise shapes. Have you ever wondered how machines create smooth parts? A gear train does this by transferring power. Through hands-on lessons, learners discover how each gear affects speed and torque. This knowledge is vital for anyone interested in metalworking. Dive into this exciting world of machining!Understanding Metal Lathes

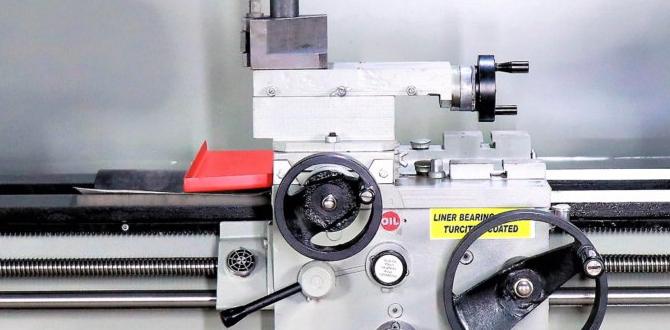

Definition and types of metal lathes. Key components and their functions.Metal lathes are machines that shape metal into useful objects. There are different types, like engine lathes and bench lathes. Engine lathes are popular for big jobs, while bench lathes are great for smaller tasks. Key parts include the headstock, which holds the spindle, and the tailstock, used for supporting long pieces. Let’s look at these parts in the table below:

| Component | Function |

|---|---|

| Headstock | Holds the spindle and motor |

| Tailstock | Supports workpieces |

| Carriage | Guides tools for cutting |

Understanding these parts helps you become a lathe master. Remember, even the best lathes can’t shape clay into a vase, so stick with metal!

Components of a Gear Train in Metal Lathes

Types of gears used in metal lathes. Understanding gear ratios and their significance.A metal lathe gear train has different types of gears. These gears work together like a team of superheroes, each with its role. Common types include spur gears, bevel gears, and worm gears. They help control speed and torque. Understanding gear ratios is vital too. A high ratio means more torque, while a lower ratio gives more speed. It’s like choosing between running fast or lifting heavy! Check out how they stack up:

| Type of Gear | Function |

|---|---|

| Spur Gear | Transmits power in parallel |

| Bevel Gear | Changes the axis of rotation |

| Worm Gear | Provides high torque with low speed |

Remember, picking the right gears can turn a metal lathe into a crafting wizard!

Setting Up a Gear Train

Stepbystep guide to assembling a gear train. Common pitfalls to avoid during setup.Assembling a gear train can be quite the adventure! First, gather all your parts and lay them out like a treasure map. Assemble the gears carefully, making sure they fit snugly. Remember, no one likes a wobbling gear! Avoid common pitfalls like mismatched gear sizes or forgetting to use lubricant—yikes! Here’s a quick checklist:

| Step | Tip |

|---|---|

| 1 | Gather all parts |

| 2 | Align gears correctly |

| 3 | Add lubricant |

| 4 | Test functionality |

Keep this checklist handy, and you’ll be zipping along with your gear train in no time. Remember, a smooth gear train is a happy gear train!

Adjustments and Maintenance of Gear Trains

Routine maintenance tips for longevity. Troubleshooting common gear train issues.Want your gear train to run like a happy robot? Regular maintenance is key! Clean those gears and keep them well-oiled. A little grease goes a long way, like butter on toast. If something’s not working, check for loose screws or missing parts. They can be sneakier than a cat in a box! Here are some tips for keeping your gear train in tip-top shape:

| Maintenance Tips | Common Issues | Troubleshooting Steps |

|---|---|---|

| Clean regularly | Strange noises | Check for debris |

| Lubricate often | Stiff movement | Apply more oil |

| Inspect for wear | Slipping gears | Tighten or replace |

Remember, a well-maintained gear train is your best friend in metalwork! Keep an eye out, and you won’t get stuck in a jam. Happy lathing!

Applications of Gear Trains in Lathe Operations

Different machining processes where gear trains are crucial. Realworld examples of gear train application.Gear trains play a vital role in many lathe operations. They allow for precise speed changes and torque adjustments, making tasks smoother. For instance, when creating threads in metal, gear trains help achieve the right pitch. Imagine trying to bake a cake without measuring—chaos! In machining, gear trains are the secret recipe.

| Machining Process | Use of Gear Train |

|---|---|

| Turning | Controls spindle speed |

| Threading | Achieves precise pitch |

| Milling | Enhances feed rates |

So next time you see a lathe, remember: gear trains are like the friendly little elves, making everything work just right!

Safety Practices in Lathe Operations

Essential safety gear and precautions. Common hazards and how to avoid them.Using a lathe can be safe if you follow important rules. First, wear essential safety gear. Always use safety glasses and gloves. These protect you from flying debris. Next, be aware of common hazards. Watch out for loose clothing or long hair, as they can get caught in the machine. To avoid accidents:

- Keep your work area clean.

- Do not distract others when they are working.

- Always check that tools are in good condition.

Staying safe is key to enjoying your lathe work!

What safety gear do you need for lathe work?

You need to have proper safety gear. This includes safety glasses, gloves, and ear protection. These items help prevent injuries.

Future Trends in Lathe Technology

Innovations in gear train design and functionality. The evolution of metal lathe training courses.New inventions in gear train design are making metal lathes smarter and faster. Imagine running a race where your lathe wins by a mile! With less energy used, those gears do a happy dance while they work. Meanwhile, metal lathe training courses are also changing. They now include hands-on tech and virtual lessons, turning old-school learning into a cool tech adventure. So grab your safety goggles and get ready to spin some metal!

| Innovation | Effect |

|---|---|

| Smart Sensors | Monitor and adjust machine performance |

| Eco-friendly Materials | Reduce waste, save the planet! |

| 3D Printing Integration | Create custom parts quickly |

The future looks bright for lathe technology. With these advancements, metal lathes and their training will keep evolving, making machining as exciting as a roller coaster ride!

Conclusion

In conclusion, a lathe training course teaches you essential skills for working with metal lathes and gear trains. You learn how to create precise parts and understand machinery better. These skills are valuable in many jobs. Consider enrolling in a course or finding more resources online. Start your journey in metalworking today!FAQs

Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathe Gear Trains:Sure! A lathe is a machine that shapes metal into different forms. Gear trains help the lathe turn at different speeds. In our training course, you will learn how to set up and use these gears. You’ll also practice making parts with the lathe. This way, you can create cool metal projects!

Sure! Please share the question you want me to answer.

What Are The Fundamental Components Of A Metal Lathe Gear Train, And How Do They Interact To Transmit Power And Motion?A metal lathe gear train has a few main parts: gears, a motor, and a spindle. The motor makes the gears turn. When one gear turns, it moves the next gear. This motion travels through the gears to the spindle, which helps shape the metal. Together, they work to change speed and direction, making the lathe useful for cutting.

How Does The Selection And Arrangement Of Gears In A Gear Train Affect The Speed And Torque Output Of A Metal Lathe?The gears in a gear train help control how fast and strong a metal lathe can work. When you choose larger gears, they can make the lathe move slower but stronger. Smaller gears speed things up but make them weaker. By arranging the gears differently, we can change both the speed and the strength of the lathe to match what we need.

What Are The Common Types Of Gear Configurations Used In Metal Lathes, And What Advantages Do They Offer In Terms Of Machining Operations?Metal lathes often use different gear setups, like spur gears and bevel gears. Spur gears help with simple, straight cutting. They are easy to use and change speeds quickly. Bevel gears help when you need to change directions while working. These setups help you cut metals more accurately and efficiently.

How Can Understanding Gear Ratios Contribute To More Precise Cutting Operations And Tool Life When Using A Metal Lathe?Understanding gear ratios on a metal lathe helps us cut metal more accurately. When we know the ratio, we can control the speed better. This means the cutting tool can work smoothly and last longer. If we use the right gear ratio, we avoid damaging the tool and get neat cuts. So, knowing this helps us do a great job!

What Safety Considerations Should Be Taken Into Account When Working With Gear Trains On A Metal Lathe During A Training Course?When working with gear trains on a metal lathe, keep a few safety rules in mind. Always wear safety glasses to protect your eyes. Keep long hair tied back to avoid getting caught in the machine. Make sure your hands are clear of moving parts to prevent injuries. Lastly, always follow instructions carefully and ask for help if unsure.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathe Gear Trains:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal into different forms. Gear trains help the lathe turn at different speeds. In our training course, you will learn how to set up and use these gears. You’ll also practice making parts with the lathe. This way, you can create cool metal projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Fundamental Components Of A Metal Lathe Gear Train, And How Do They Interact To Transmit Power And Motion?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe gear train has a few main parts: gears, a motor, and a spindle. The motor makes the gears turn. When one gear turns, it moves the next gear. This motion travels through the gears to the spindle, which helps shape the metal. Together, they work to change speed and direction, making the lathe useful for cutting.”}},{“@type”: “Question”,”name”: “How Does The Selection And Arrangement Of Gears In A Gear Train Affect The Speed And Torque Output Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gears in a gear train help control how fast and strong a metal lathe can work. When you choose larger gears, they can make the lathe move slower but stronger. Smaller gears speed things up but make them weaker. By arranging the gears differently, we can change both the speed and the strength of the lathe to match what we need.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Gear Configurations Used In Metal Lathes, And What Advantages Do They Offer In Terms Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes often use different gear setups, like spur gears and bevel gears. Spur gears help with simple, straight cutting. They are easy to use and change speeds quickly. Bevel gears help when you need to change directions while working. These setups help you cut metals more accurately and efficiently.”}},{“@type”: “Question”,”name”: “How Can Understanding Gear Ratios Contribute To More Precise Cutting Operations And Tool Life When Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Understanding gear ratios on a metal lathe helps us cut metal more accurately. When we know the ratio, we can control the speed better. This means the cutting tool can work smoothly and last longer. If we use the right gear ratio, we avoid damaging the tool and get neat cuts. So, knowing this helps us do a great job!”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account When Working With Gear Trains On A Metal Lathe During A Training Course?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working with gear trains on a metal lathe, keep a few safety rules in mind. Always wear safety glasses to protect your eyes. Keep long hair tied back to avoid getting caught in the machine. Make sure your hands are clear of moving parts to prevent injuries. Lastly, always follow instructions carefully and ask for help if unsure.”}}]}