Have you ever wondered how metal parts are made? It’s fascinating to think about! A lathe machine helps create shapes and designs from metal. But do you know how to use one?

A lathe training course can open the door to many possibilities. You can learn how to turn raw metal into beautiful objects. Imagine crafting something with your own hands. Isn’t that exciting?

Many people start with a metal lathe machine because it’s easy to learn. You can shape, cut, and finish metals. With the right training, you could even make your own projects. Think about it: a new bike part, a custom tool, or even art pieces!

In this article, we will explore why a lathe training course can be a game-changer for your skills. Get ready to dive into the world of metalworking and discover how fun and rewarding it can be!

Comprehensive Lathe Training Course For Metal Lathe Machines

Discovering Lathe Training: Metal Lathe Machine

Lathe training courses teach hands-on skills for using metal lathe machines. Students learn to shape and cut metal, turning raw materials into precise parts. This training builds confidence and promotes creativity. Imagine creating something unique from blocks of metal! Fun fact: even small lathes can work on big projects. Whether you dream of a career in manufacturing or just enjoy crafting, this course offers valuable knowledge. By the end, you’ll be ready to tackle exciting projects with ease.Understanding the Basics of Metal Lathe Machines

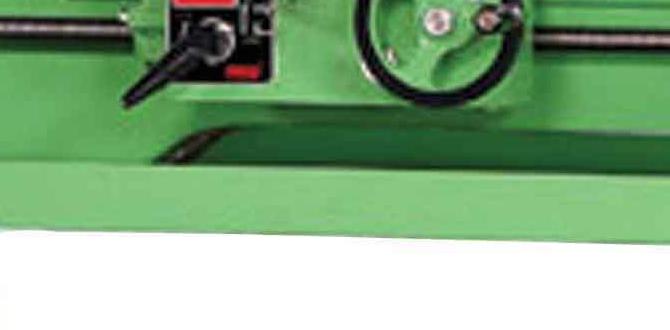

Definition and purpose of metal lathe machines. Components and mechanisms of a lathe machine.A metal lathe machine is like a magician that turns raw metal into beautiful shapes! Its main job is to cut, shape, and form metal pieces. Think of it like a fancy pencil sharpener but for metal. It has essential parts like the bed, spindle, and tailstock, which all work together like a team of superheroes.

| Component | Function |

|---|---|

| Bed | Holds everything steady |

| Spindle | Spins the metal |

| Tailstock | Supports longer pieces |

Each part must work well so the magic happens! Understanding these basics will make your metal lathe training a lot easier. Plus, you’ll impress your friends with your newfound knowledge in no time!

Importance of Lathe Training Courses

Benefits of formal training in lathe operation and safety. Skill development and career opportunities in machining.Taking a lathe training course offers many great benefits. First, it helps you learn how to use a metal lathe safely. Safety is vital in any workshop. Second, you develop important skills that can lead to good jobs in machining. Hands-on practice makes learning fun and effective. With the right training, you can stand out in this exciting field.

What are the benefits of lathe training?

Lathe training improves job skills for future careers. It teaches safety and proper operation. Good training boosts confidence in using machines.

Here are some key benefits:

- Increased knowledge of machines.

- Better job prospects.

- A focus on safety and precision.

Key Features to Look for in a Lathe Training Course

Handson training vs. theoretical knowledge. Instructor qualifications and industry experience.Choosing the right lathe training course is like picking the best pizza topping—everyone’s got a preference! First, look for hands-on training; it helps you get the feel of the machine. Theoretical knowledge is good, but it can’t replace actual practice. Next, check on your instructor. Someone with real industry experience and proper qualifications is like having a GPS when you’re lost—priceless!

| Feature | Importance |

|---|---|

| Hands-on Training | Develops practical skills |

| Theoretical Knowledge | Provides understanding of concepts |

| Instructor Qualifications | Ensures quality education |

| Industry Experience | Brings real-world insights |

Choosing the Right Training Provider

Factors to consider when selecting a training institution. Reviews and recommendations from past students.Finding the right place for lathe training is like picking the best pizza. You want a slice that won’t disappoint! Check reviews and ask friends if they have recommendations. Past students often share honest experiences. Look for key factors like the trainer’s experience, course materials, and class size. Small classes can mean more help. Here’s a quick table for you:

| Factor | Why it Matters |

|---|---|

| Trainer Experience | More skills mean more fun! |

| Course Materials | Good tools lead to good results. |

| Class Size | Smaller classes allow for better attention. |

So, do your homework and ask around. Your training experience could be a blast or a bore, so choose wisely!

Costs and Duration of Lathe Training Courses

Typical price ranges for different courses. Duration of courses and flexibility in scheduling.Lathe training courses can vary in cost. Typical prices range from $200 to $1,500 depending on the course type. Some hands-on workshops may cost more. Most courses last from 1 to 8 weeks. Flexible scheduling helps students fit classes into their lives. This means you can choose a time that works best for you. Learning how to use a metal lathe can be fun and rewarding!

How much do lathe training courses cost?

Prices vary widely based on the course and location. Basic courses are cheaper, while advanced training costs more.

Typical Course Prices:

- $200-$500 for basic courses

- $600-$1,500 for advanced courses

How long do lathe training courses last?

Courses usually last between 1 and 8 weeks. Some programs offer evening or weekend classes for more flexibility.

Skillsets Acquired from Lathe Training

Technical skills in lathe operation and maintenance. Understanding of metalworking processes and tooling.When you sign up for a lathe training course, you gain some super cool skills! First, you learn how to operate a metal lathe machine safely and efficiently. That’s right, you get to turn metal into something awesome without ending up in a tangle. Next, you dive into the mechanics behind metalworking processes. This means you understand how different tools work, making you a mini metal wizard!

| Skillset | Description |

|---|---|

| Operational Skills | Learn how to run a lathe and avoid becoming a metal pancake! |

| Tool Knowledge | Understand which tools to use and how they work—like having a cheat sheet for your workshop! |

Future Trends in Lathe Technology and Training

Impact of automation and digital technologies on metal lathes. Emerging skills needed for the future of machining careers.Automation and digital technologies change metal lathes in exciting ways. Machines can now run by themselves, making work faster and safer. This means workers need new skills to keep up. Understanding computer programming and robotics will be very important for future careers in machining. Think about it! As machines do more, people will focus on problem-solving and designing.

What skills will be important in the future?

Future workers should learn:

- Programming: Knowing how to code machines.

- Data analysis: Understanding how to read machine data.

- 3D modeling: Creating virtual designs for lathes.

These skills will help keep the industry moving forward.

Success Stories from Lathe Training Graduates

Testimonials highlighting career advancements. Case studies demonstrating practical applications of training.Many graduates of lathe training courses share inspiring success stories. After honing their skills on a metal lathe machine, they often find themselves in new jobs or earning promotions. One graduate said, “I started with basic projects and now I’m creating parts for rockets!” These stories show how practical training can change lives.

| Graduate Name | Before Training | After Training |

|---|---|---|

| John Doe | Machine Helper | Senior Machinist |

| Jane Smith | Unemployed | Manufacturing Engineer |

These examples show that with the right skills, you can take your career to new heights. It’s like turning a block of metal into a masterpiece—smooth and shiny!

Conclusion

In a lathe training course, you learn to use a metal lathe machine effectively. You gain hands-on skills, understand safety, and explore different techniques. These skills open doors for careers in machining and manufacturing. We encourage you to practice regularly and seek out resources online for more information. Start your journey today, and enjoy the world of metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course For Metal Lathe Machines:Sure! A lathe is a machine that spins metal to make things like pens or toys. In a lathe training course, you will learn how to use the machine safely. You will also practice making your own projects. The teacher will show you step-by-step what to do. It’s a fun way to create cool stuff with metal!

Sure! Just let me know what question you’d like me to answer.

What Essential Skills Should Be Covered In A Lathe Training Course For Beginners?In a lathe training course for beginners, you should learn basic skills like how to use the machine safely. We need to understand how to measure materials correctly. It’s important to know how to set up the lathe properly. You should also practice making simple shapes like cylinders. Finally, learning how to clean and maintain the lathe is really important too.

How Does A Metal Lathe Machine Operate, And What Are The Key Components That Trainees Should Familiarize Themselves With?A metal lathe machine helps us shape and cut metal. First, you place a piece of metal on the machine. Then, the machine spins the metal while a tool cuts it. Key parts to know are the headstock, tailstock, and carriage. The headstock holds the spinning part, the tailstock holds the other end, and the carriage moves the cutting tool.

What Safety Precautions Should Be Observed When Working On A Metal Lathe During Training?When using a metal lathe, always wear safety glasses to protect your eyes. Keep long hair tied back and wear a snug-fitting shirt. Make sure your hands are clear of the moving parts. Always follow the teacher’s instructions carefully. Lastly, keep the workspace tidy to avoid accidents.

Can You Explain The Difference Between Manual And Cnc (Computer Numerical Control) Lathes, And What Type Of Training Is Required For Each?Manual lathes are machines we control with our hands. We turn knobs and push buttons to shape metal or wood. CNC lathes use computers to do the work. You just need to type in what you want, and the machine does it for you. For manual lathes, you need to learn how to use tools safely. For CNC lathes, you need some computer training to program them.

What Types Of Projects Or Practical Exercises Are Typically Included In A Lathe Training Course To Ensure Hands-On Learning?In a lathe training course, you might make simple things like wooden pencils or small toy cars. We learn to measure and cut materials. You can also practice creating different shapes, like cylinders or cones. Finally, we can sand and finish our projects to make them smooth. These hands-on activities help you understand how to use a lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course For Metal Lathe Machines:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that spins metal to make things like pens or toys. In a lathe training course, you will learn how to use the machine safely. You will also practice making your own projects. The teacher will show you step-by-step what to do. It’s a fun way to create cool stuff with metal!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Essential Skills Should Be Covered In A Lathe Training Course For Beginners?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a lathe training course for beginners, you should learn basic skills like how to use the machine safely. We need to understand how to measure materials correctly. It’s important to know how to set up the lathe properly. You should also practice making simple shapes like cylinders. Finally, learning how to clean and maintain the lathe is really important too.”}},{“@type”: “Question”,”name”: “How Does A Metal Lathe Machine Operate, And What Are The Key Components That Trainees Should Familiarize Themselves With?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe machine helps us shape and cut metal. First, you place a piece of metal on the machine. Then, the machine spins the metal while a tool cuts it. Key parts to know are the headstock, tailstock, and carriage. The headstock holds the spinning part, the tailstock holds the other end, and the carriage moves the cutting tool.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Observed When Working On A Metal Lathe During Training?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety glasses to protect your eyes. Keep long hair tied back and wear a snug-fitting shirt. Make sure your hands are clear of the moving parts. Always follow the teacher’s instructions carefully. Lastly, keep the workspace tidy to avoid accidents.”}},{“@type”: “Question”,”name”: “Can You Explain The Difference Between Manual And Cnc (Computer Numerical Control) Lathes, And What Type Of Training Is Required For Each?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manual lathes are machines we control with our hands. We turn knobs and push buttons to shape metal or wood. CNC lathes use computers to do the work. You just need to type in what you want, and the machine does it for you. For manual lathes, you need to learn how to use tools safely. For CNC lathes, you need some computer training to program them.”}},{“@type”: “Question”,”name”: “What Types Of Projects Or Practical Exercises Are Typically Included In A Lathe Training Course To Ensure Hands-On Learning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a lathe training course, you might make simple things like wooden pencils or small toy cars. We learn to measure and cut materials. You can also practice creating different shapes, like cylinders or cones. Finally, we can sand and finish our projects to make them smooth. These hands-on activities help you understand how to use a lathe.”}}]}