Have you ever watched a metal lathe in action? It’s fascinating how such a machine can shape metal with ease! If you’re curious about how to use one, a lathe training course may be just what you need.

Learning about metal lathes is not just for experts. Even beginners can master these machines. Have you ever imagined creating something unique from metal? With the right training, you can do just that.

One exciting feature of many metal lathes is the power feed. It allows for smooth and steady cuts. This makes your work much easier. Do you want to learn how to control it effectively? A lathe training course can teach you everything you need to know.

Join a community of makers and creators. You might meet others who share your interests. Together, you’ll explore the endless possibilities of what you can create with metal lathes!

Essential Lathe Training Course: Master Metal Lathe Power Feed

Lathe Training Course: Metal Lathe Power Feed

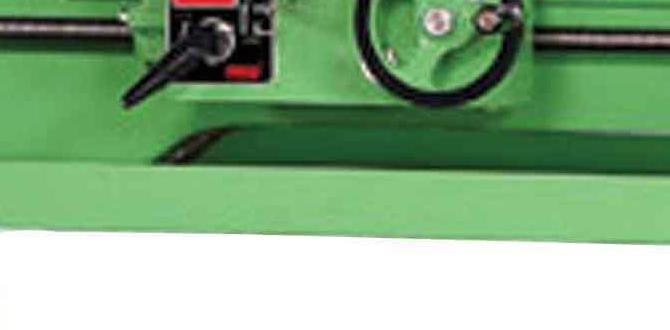

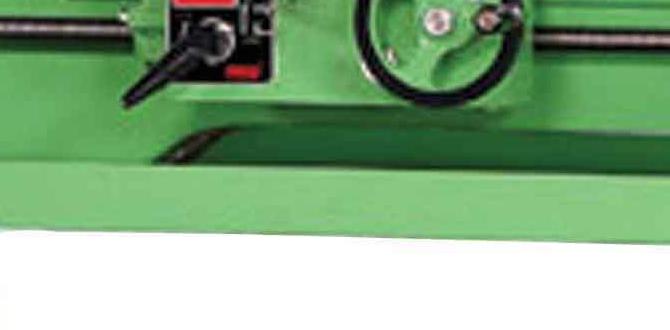

A lathe training course teaches you all about using a metal lathe with power feed. You’ll discover how this handy tool can make tasks easier and faster. Imagine not having to turn the handle manually! In the course, you learn basic settings and advanced techniques to improve your skills. Did you know that many industries rely on lathes for precision work? Mastering this tool can open doors to exciting job opportunities. Why not explore how a lathe can enhance your projects?Components of a Metal Lathe

Detailed breakdown of lathe parts and their functions. Importance of each component in the power feed mechanism.A metal lathe is made up of several key parts, each with a special job. These parts work together to shape metal into precise tools. Here are some important components:

- Headstock: Holds the motor and controls.

- Tailstock: Supports the other end of the material.

- Bed: The base that keeps the lathe steady.

- Carriage: Moves the tool and holds it in place.

- Power Feed: Automatically moves the tool for even cuts.

Each part plays a vital role in the power feed mechanism. For example, the power feed makes cutting easier and quicker. This means you get better shapes in less time!

What is the function of the power feed in a metal lathe?

The power feed is important because it helps move the tool across the metal automatically. This saves time and energy, making the work smooth and accurate.

Selecting the Right Lathe Training Course

Key factors to consider when choosing a training program. Importance of handson experience and theoretical knowledge.Choosing the right training program needs careful thought. Here are some key factors:

- Hands-on Experience: Practical work helps you learn skills better than books alone.

- Theoretical Knowledge: Understanding the theory supports your hands-on tasks.

- Course Content: Ensure the program covers metal lathe skills and power feed techniques.

- Instructor Expertise: Teachers should be experienced and knowledgeable.

By balancing these points, you will find a course that meets your learning needs.

Why is hands-on training important?

Hands-on training is essential because it builds confidence and improves skills through practice. Doing tasks helps everyone remember lessons better than just listening or reading about them.

Essential Skills Covered in Lathe Training

Basic operation and safety protocols. Advanced techniques: turning, facing, and boring.Learning to use a lathe is a fun journey. In a lathe training course, you gain essential skills. First, you learn basic operations and important safety rules. Safety is key; always wear gear like goggles. Next, advanced techniques like turning, facing, and boring help you create precise parts.

- Turning: Shaping materials into cylinders.

- Facing: Smoothing the ends of materials.

- Boring: Making holes larger for fittings.

Mastering these skills boosts your confidence and creativity!

What is taught in a lathe training course?

In a lathe training course, participants learn both basic operations and advanced techniques. This includes learning safety protocols and hands-on practices, ensuring students become skilled operators.

Practical Applications of Power Feed in Metal Lathes

Examples of projects where power feed enhances efficiency. Comparison of time and quality with vs. without power feed.Power feed on metal lathes can boost how quickly and well you work. It helps you with smooth and steady movements, making tasks easier. For example, when making parts like gears or shafts, power feed saves time and creates better quality pieces. Using power feed can cut down project time by up to 50% compared to doing it manually!

- Projects: Gears, shafts, or custom parts

- Time saved: Manual vs. power feed

- Quality: Smooth finishes with power feed

Why is power feed useful in projects?

Power feed enhances control and accuracy. This leads to cleaner cuts and less waste. Imagine finishing a project faster and with shiny results!

Common Challenges in Learning Metal Lathe Operations

Identifying frequent mistakes made by beginners. Tips for overcoming these challenges in training.Learning to operate a metal lathe can be quite a ride! Beginners often face a few bumps along the way. Common mistakes include not properly securing the workpiece, which can lead to flying objects—yikes! Also, forgetting to adjust feed rates can make their projects turn into a game of ‘whoops, that’s not right!’ To overcome these hurdles, practicing regularly and asking for help from experts can be game-changers. Remember, even the best machinists started somewhere, probably with a few funny mishaps!

| Common Mistakes | Tips to Overcome |

|---|---|

| Improper Workpiece Securing | Double-check all clamps and fixtures. |

| Wrong Feed Rate | Refer to the manual for proper settings. |

| Ignoring Safety Gear | Always wear goggles and gloves! |

Evaluating the Effectiveness of a Lathe Course

Metrics to measure progress and skill acquisition. Importance of certification and instructor qualifications.Understanding how well a lathe course works is key. It’s like checking if a cake is baked—nobody wants a doughy mess! To measure progress, look at skill tests and project completion rates. These show if students are learning and improving. Certification matters too; it proves that the course meets standards. Qualified instructors, who know their stuff, make a big difference. Remember, a great teacher can turn a confusing subject into cakewalk—just hopefully, not a cake!

| Metric | Why It Matters |

|---|---|

| Skill Tests | Show real understanding. |

| Project Completion Rates | Indicate progress and commitment. |

| Certification | Ensures quality education. |

| Instructor Qualifications | A good teacher makes learning fun! |

Resources for Continuing Education in Lathe Operations

Recommended books, online courses, and workshops. Industry journals and forums for ongoing learning and support.For sharpening your lathe skills, a treasure trove of resources awaits. Dive into recommended books on lathe operations that can make you a wizard with metal. Online courses are like magic portals, offering hands-on tips from experts. Workshops give you a chance to wield tools under watchful eyes.

| Resource Type | Recommendations |

|---|---|

| Books | Lathework: A Complete Guide |

| Online Courses | Udemy Lathe Fundamentals |

| Workshops | Local Maker Spaces |

Additionally, keeping up with industry journals can be enlightening. They often share new techniques and trends you’ll want to know. Join forums for ongoing support; they are great for advice and humor. Remember, learning is much more fun when everyone shares a laugh!

Conclusion

In summary, a lathe training course teaches you important skills for using a metal lathe with power feed. You’ll learn how to operate the machine safely and efficiently. This knowledge is crucial for crafting precise metal pieces. We encourage you to explore local courses or online resources to boost your skills. Let’s get started and turn your ideas into reality!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathe Power Feed:Sure! In a lathe training course, you will learn how to use a metal lathe safely. You’ll get hands-on practice with power feed, which helps move the tool automatically. We will show you how to set up the machine and start it. You’ll also learn how to make different shapes from metal. It’s fun and helps you create cool projects!

Sure! Please provide the question you would like me to answer.

What Are The Key Components Of A Metal Lathe That Are Essential For Understanding Power Feed Mechanisms?A metal lathe has some important parts you should know about for power feed mechanisms. First, it has a motor that gives the lathe power to spin. Next, there’s a gearbox that helps control the speed. We also have feed screws that move the tool forward and backward. Finally, there’s a control panel where you can set the feed speed.

How Does Power Feed Differ From Manual Feed In Metal Lathe Operations, And What Are The Advantages Of Using Power Feed?Power feed in metal lathe operations means the machine moves automatically. In manual feed, you move the tool by hand. Power feed is easier because you don’t need to keep turning the handle. It can also make smoother cuts and save time. This helps you make better products faster!

What Safety Precautions Should Be Followed When Using The Power Feed Function On A Metal Lathe During Training?When using the power feed on a metal lathe, always wear safety goggles to protect your eyes. Keep your hands away from moving parts and never reach over the machine while it’s running. Make sure your clothes are sharp and not loose to avoid getting caught. Lastly, listen carefully to your teacher and follow their instructions. Safety first!

Can You Explain The Basic Setup And Calibration Process For The Power Feed On A Typical Metal Lathe?To set up the power feed on a metal lathe, first, make sure the machine is turned off. Then, you need to find the power feed switch and turn it on. Next, adjust the feed rate, which controls how fast the machine moves. To calibrate, run the machine and measure the movement. If it’s not right, adjust the settings until it fits your needs!

What Types Of Projects Or Practical Exercises Are Typically Included In A Lathe Training Course To Enhance The Understanding Of Power Feed Operations?In a lathe training course, we might make simple shapes like cylinders or cones. You can also practice cutting different materials, like wood or metal. We will use power feed, which helps move the tool automatically. You might even create a small project, like a toy part, to see how it works. These fun exercises help us learn how to use the lathe safely and correctly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Training Course Focusing On Metal Lathe Power Feed:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! In a lathe training course, you will learn how to use a metal lathe safely. You’ll get hands-on practice with power feed, which helps move the tool automatically. We will show you how to set up the machine and start it. You’ll also learn how to make different shapes from metal. It’s fun and helps you create cool projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe That Are Essential For Understanding Power Feed Mechanisms?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has some important parts you should know about for power feed mechanisms. First, it has a motor that gives the lathe power to spin. Next, there’s a gearbox that helps control the speed. We also have feed screws that move the tool forward and backward. Finally, there’s a control panel where you can set the feed speed.”}},{“@type”: “Question”,”name”: “How Does Power Feed Differ From Manual Feed In Metal Lathe Operations, And What Are The Advantages Of Using Power Feed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Power feed in metal lathe operations means the machine moves automatically. In manual feed, you move the tool by hand. Power feed is easier because you don’t need to keep turning the handle. It can also make smoother cuts and save time. This helps you make better products faster!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Followed When Using The Power Feed Function On A Metal Lathe During Training?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the power feed on a metal lathe, always wear safety goggles to protect your eyes. Keep your hands away from moving parts and never reach over the machine while it’s running. Make sure your clothes are sharp and not loose to avoid getting caught. Lastly, listen carefully to your teacher and follow their instructions. Safety first!”}},{“@type”: “Question”,”name”: “Can You Explain The Basic Setup And Calibration Process For The Power Feed On A Typical Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the power feed on a metal lathe, first, make sure the machine is turned off. Then, you need to find the power feed switch and turn it on. Next, adjust the feed rate, which controls how fast the machine moves. To calibrate, run the machine and measure the movement. If it’s not right, adjust the settings until it fits your needs!”}},{“@type”: “Question”,”name”: “What Types Of Projects Or Practical Exercises Are Typically Included In A Lathe Training Course To Enhance The Understanding Of Power Feed Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a lathe training course, we might make simple shapes like cylinders or cones. You can also practice cutting different materials, like wood or metal. We will use power feed, which helps move the tool automatically. You might even create a small project, like a toy part, to see how it works. These fun exercises help us learn how to use the lathe safely and correctly.”}}]}